Device for producing nonwoven webs and method for assembling such device

A technology of non-woven fabrics and manufacturing devices, which is applied in the field of equipment for manufacturing non-woven fabric products and for assembling the equipment, which can solve the problems of maintenance cost and accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

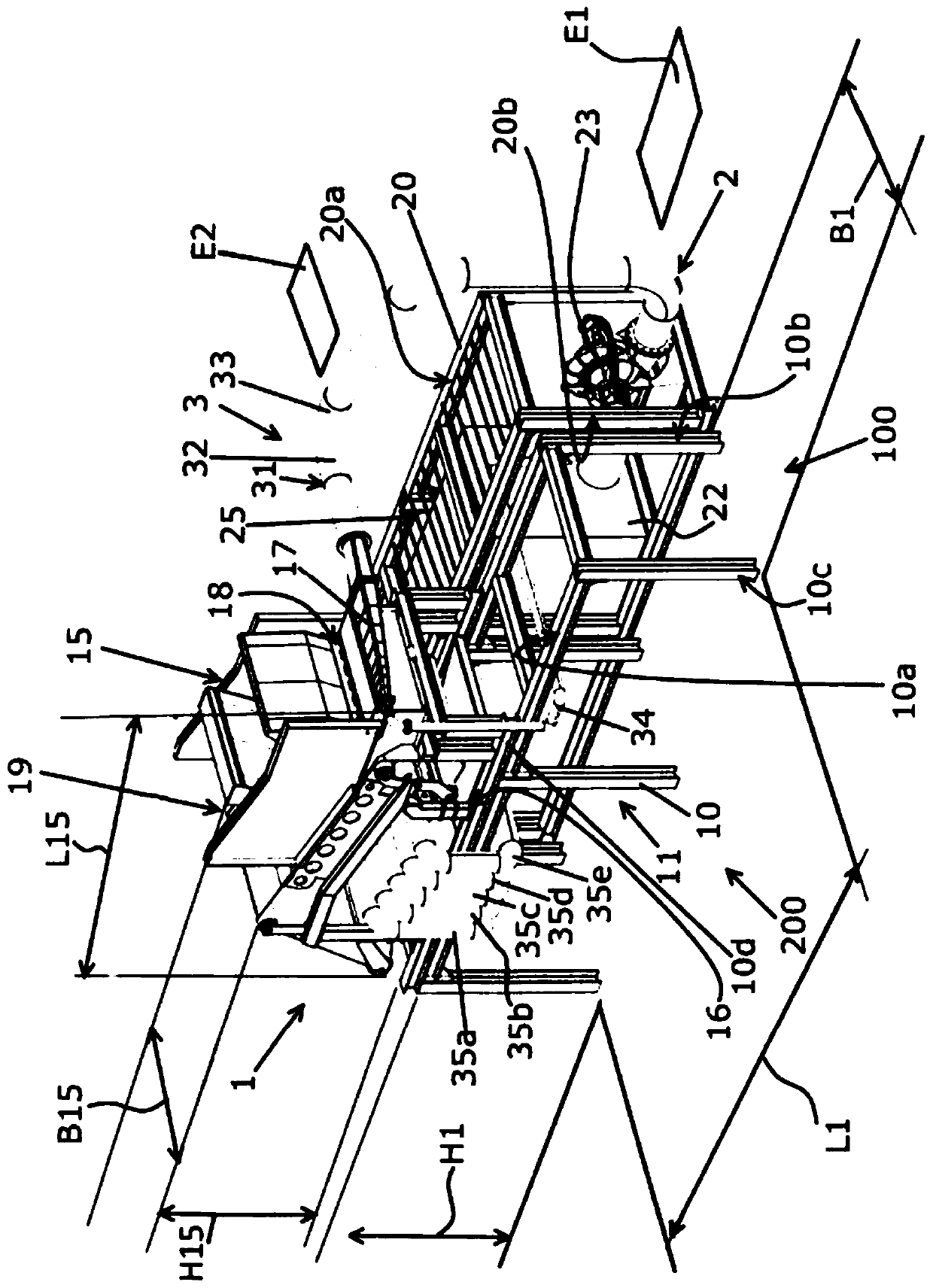

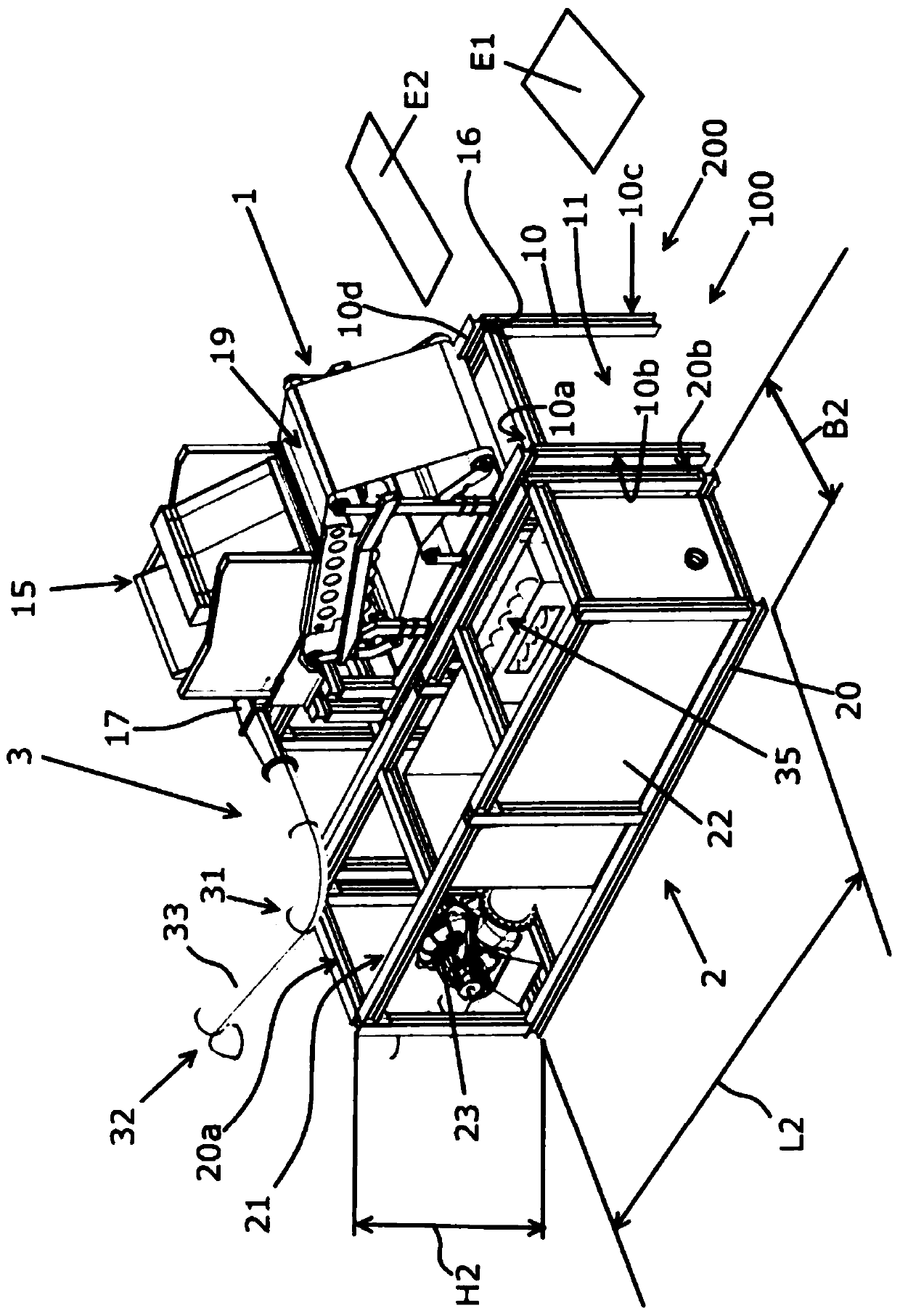

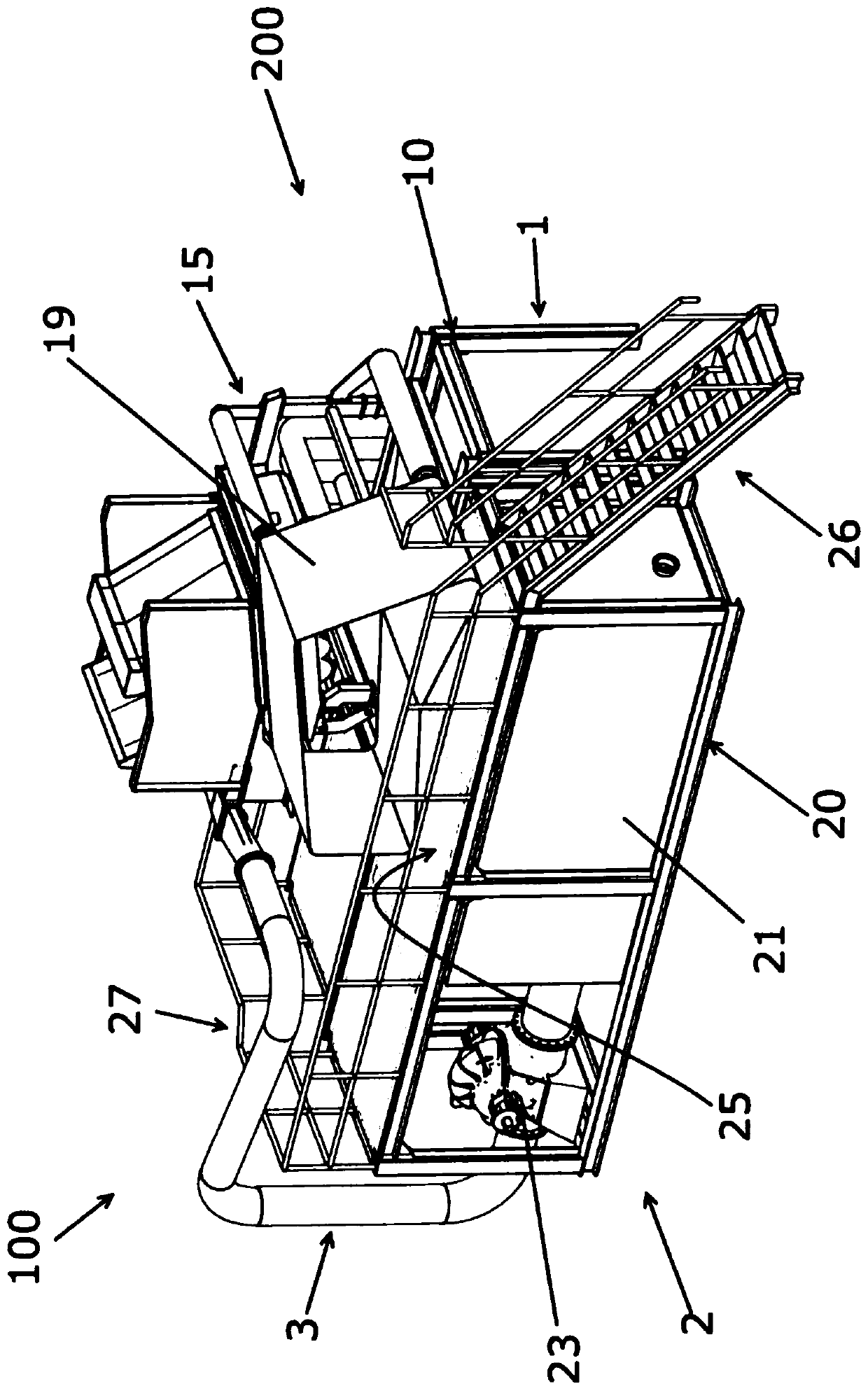

Embodiment Construction

[0038] exist Figures 1 to 3 In the figure, the device 100 for producing webs of nonwoven products is shown in two different perspective views in an assembled state 200 . The plant 100 is currently formed by a first plant module 1 (a so-called manufacturing unit) and a second plant module 2 (a so-called auxiliary unit), wherein the two plant modules 1 and 2 in the shown assembled state at least They are interconnected via a pipeline system 3 . The state of assembly is to be understood here as the state 35 which is suitable for the operation of the device 100 .

[0039] The production unit 1 comprises a nonwoven production device 15 and a carrier structure 10 on which the nonwoven production device 15 is arranged. The auxiliary unit 2 comprises a liquid tank 22 , a headbox pump 23 and a frame structure 20 surrounding these components 22 , 23 . In principle, the line system 3 connecting the nonwoven production device 15 to the liquid tank 22 can also be regarded as being assi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com