Assembled combined protective panel

A protective panel and assembled technology, which is applied to the pavement paved with prefabricated blocks, coastline protection, climate change adaptation, etc., can solve the problems of high laying requirements, long construction period, and high cost, and achieve good quality control and environmental protection The effect of protection, stability of the stress system, and reduction of project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

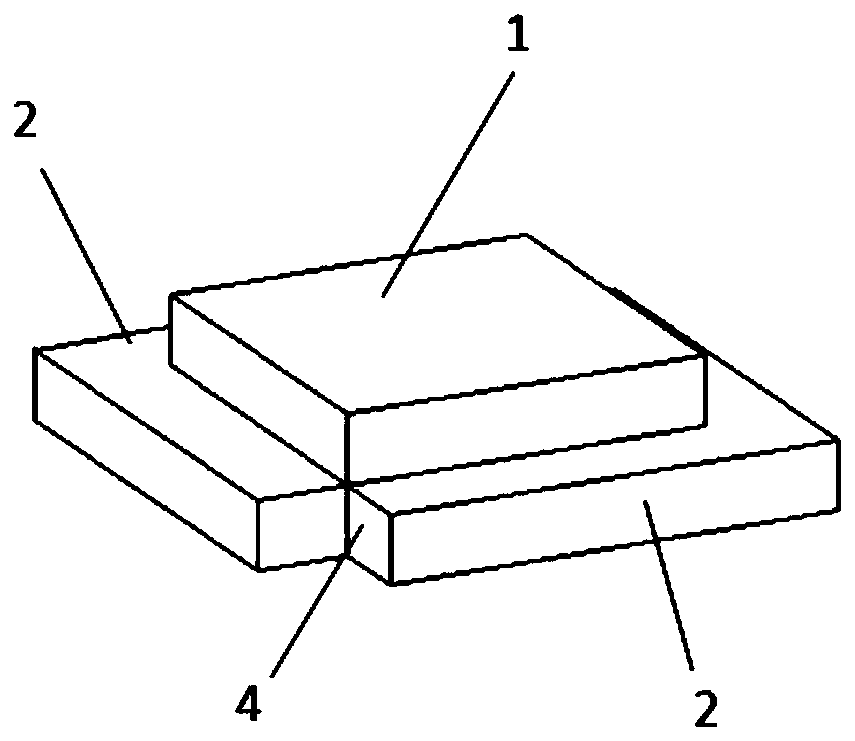

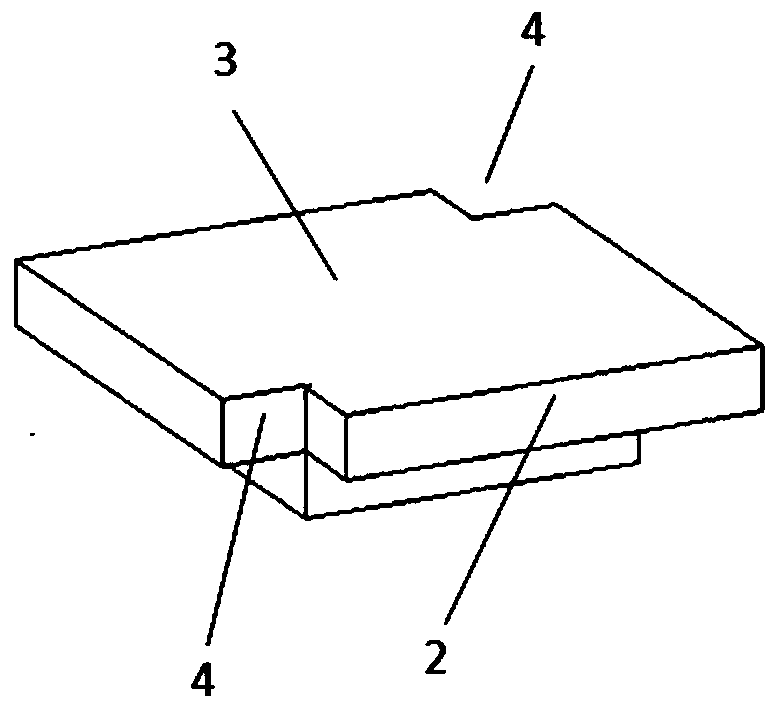

[0023] see figure 1 and figure 2 , the structural form of the assembled protective panel in the present embodiment is:

[0024] The protective panel is composed of various protective panels through assembly. Each protective panel has the same structural form. It is an overall structure formed by superimposing a rectangular front panel 1 and a rectangular back panel 3. The front panel 1 is located at the center of the back panel 3, and the periphery of the back panel 3 forms an extended bezel 2 on the periphery of the front panel 1; Rectangular notch 4; the thickness of the front panel 1 and the back panel 3 are equal.

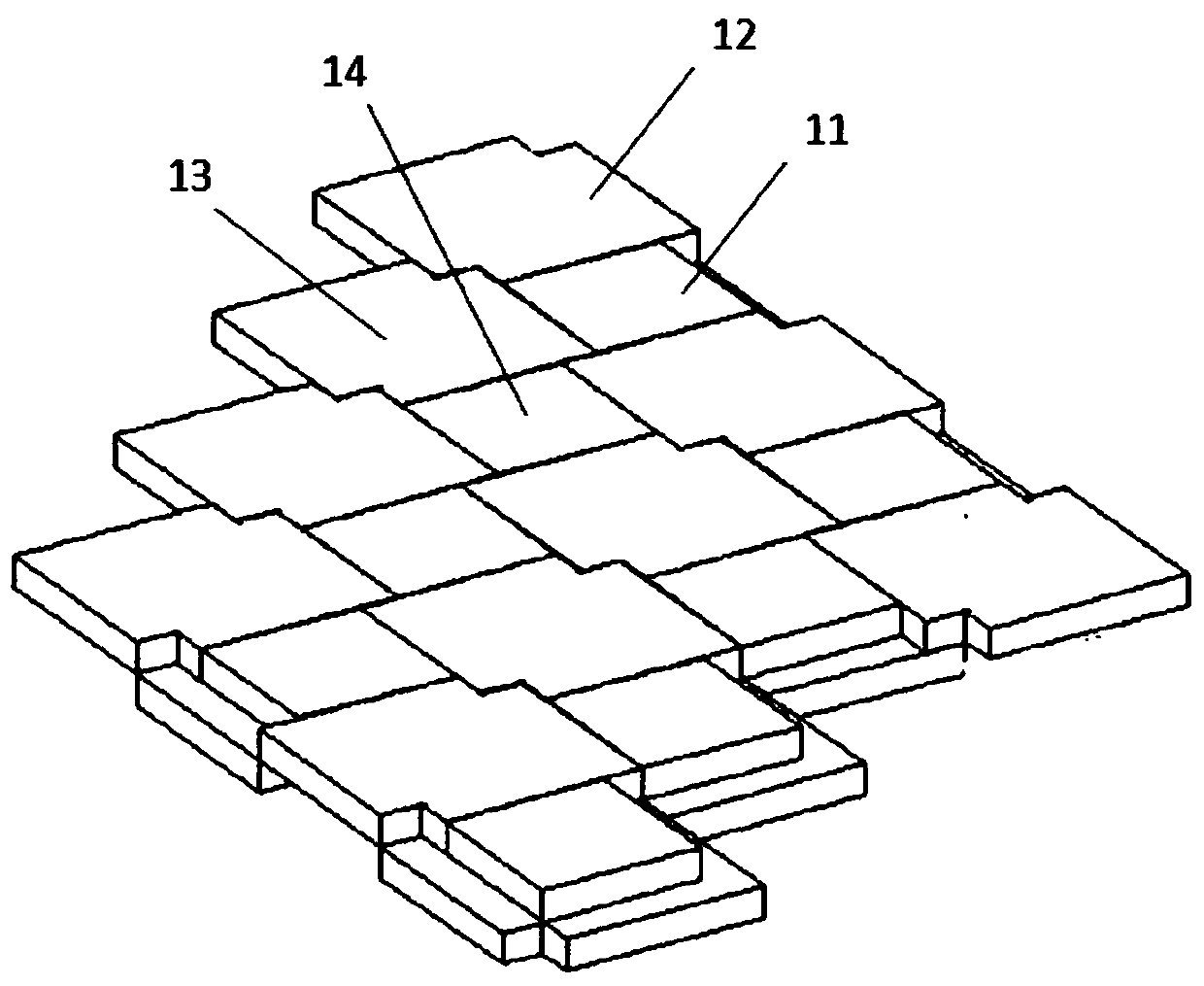

[0025] see image 3 , the assembly structure of the protective panel in this embodiment is:

[0026] Between adjacent first panel panels 11 and second panel panels 12, with the front panel of the first panel panel 11 facing up and the back panel of the second panel panel 12 facing up, the first panel panel 11 and a side of the second armor panel 12 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com