Construction method of a fabricated building mixed tower crane

A construction method and technology of a hybrid tower, which are applied in the field of construction tower cranes, can solve the problems of inability to use, increase the lifting weight, and fail to meet construction safety, and achieve the effect of avoiding hidden dangers of leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

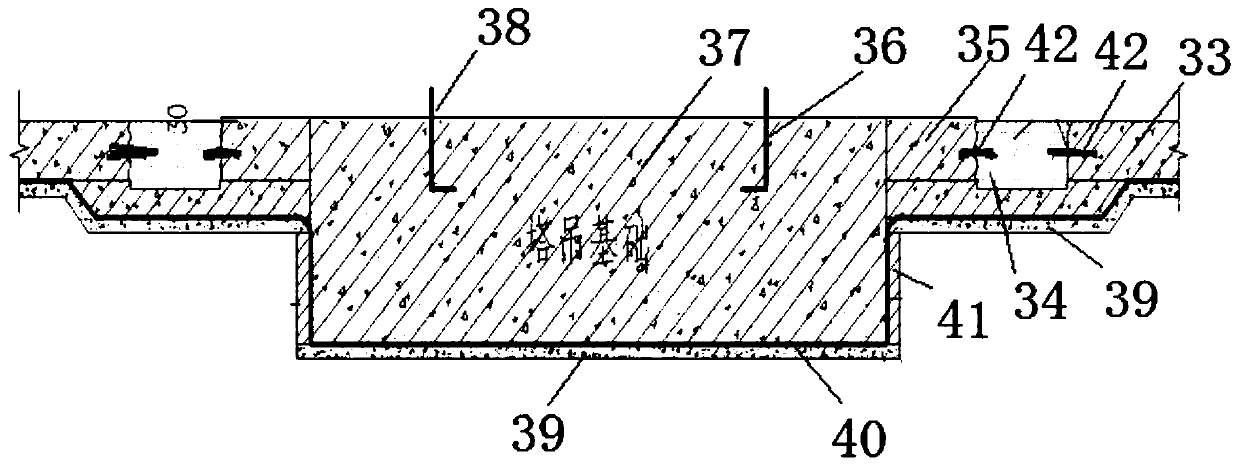

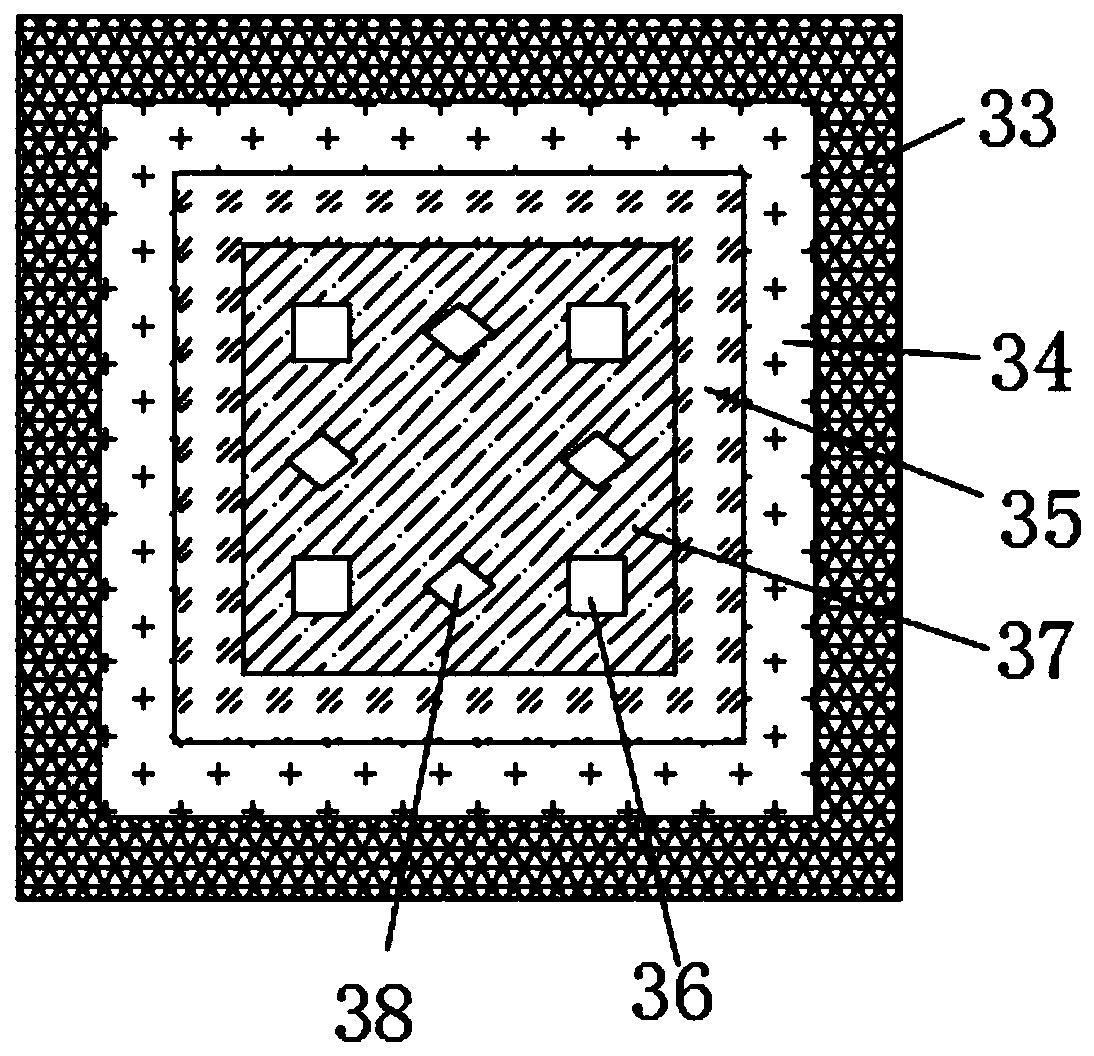

[0050] A construction method of a hybrid tower crane for a prefabricated building, including a hybrid tower crane applied to the tower crane foundation 37, and the construction method includes:

[0051] Install the large tower crane embedded part 36 and the small tower crane embedded part 38 on the tower crane foundation 37, and make the upper ends of the large tower crane embedded part 36 and the small tower crane embedded part 38 extend to the top of the tower crane foundation 37;

[0052] The outer side of the tower crane foundation 37 is provided with the outer pick plate 35 of the tower crane foundation 37 and the post-cast expansive concrete 34 in sequence;

[0053] Between the tower crane foundation 37 and the outer pick plate 35 of the tower crane foundation 37, and between the tower crane foundation 37 outer pick plate 35 and the post-cast expansive concrete 34, there are pre-embedded water-stop steel plates 42, which can avoid damage to the steel bars of the tower cra...

Embodiment 2

[0073] A construction method of a hybrid tower crane for a prefabricated building, including a hybrid tower crane applied to the tower crane foundation 37, and the construction method includes:

[0074] Install the large tower crane embedded part 36 and the small tower crane embedded part 38 on the tower crane foundation 37, and make the upper ends of the large tower crane embedded part 36 and the small tower crane embedded part 38 extend to the top of the tower crane foundation 37;

[0075] The outer side of the tower crane foundation 37 is provided with the outer pick plate 35 of the tower crane foundation 37 and the post-cast expansive concrete 34 in sequence;

[0076] Between the tower crane foundation 37 and the outer pick plate 35 of the tower crane foundation 37, and between the tower crane foundation 37 outer pick plate 35 and the post-cast expansive concrete 34, there are pre-embedded water-stop steel plates 42, which can avoid damage to the steel bars of the tower cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com