Floor drain and mounting structure and production process thereof

A technology of installation structure and production process, applied in water supply devices, drainage structures, chemical instruments and methods, etc., can solve the problems of low material cost advantage, large thickness, and many consumables, achieve material cost control, ensure installation stability, Strong installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

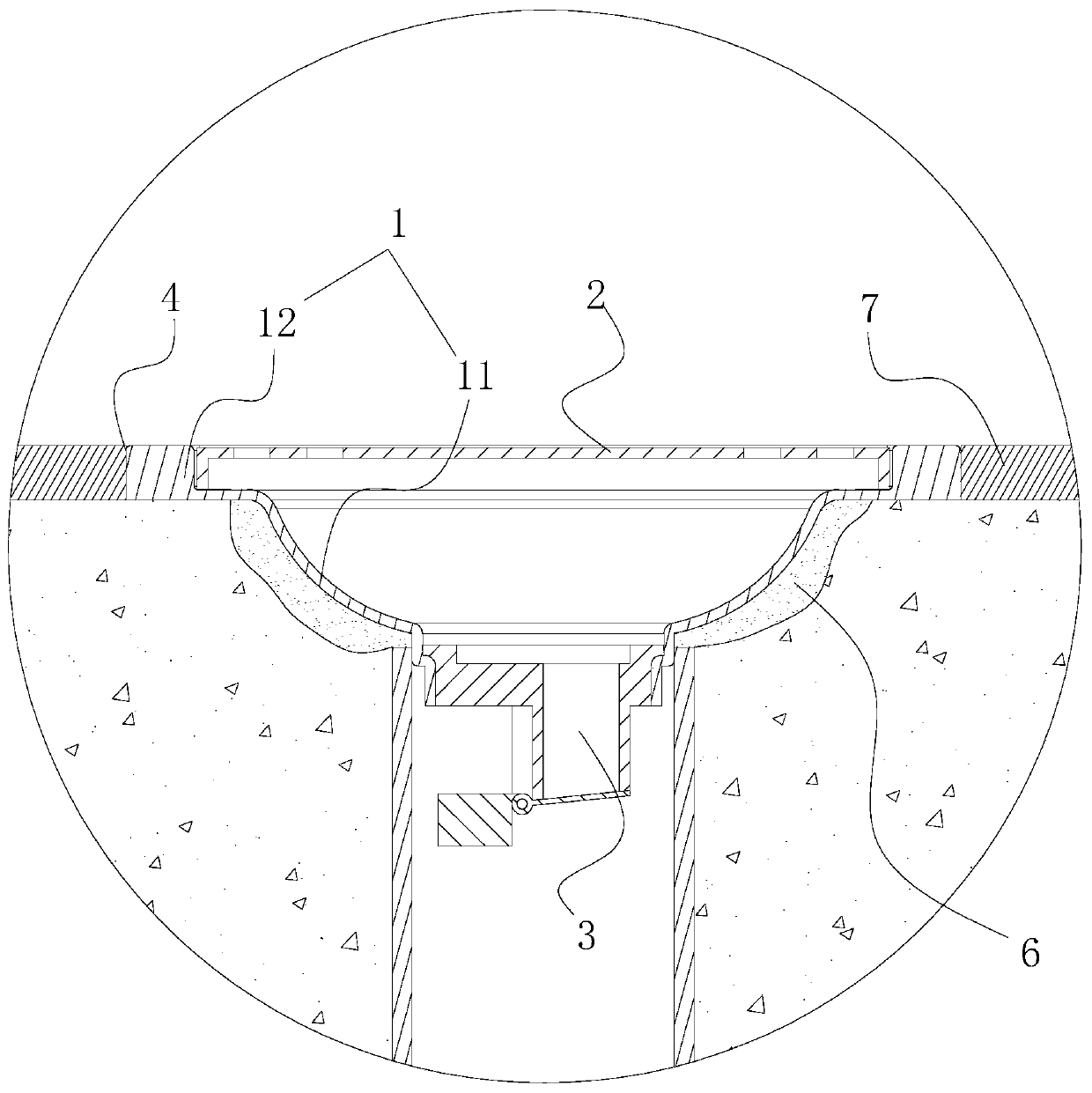

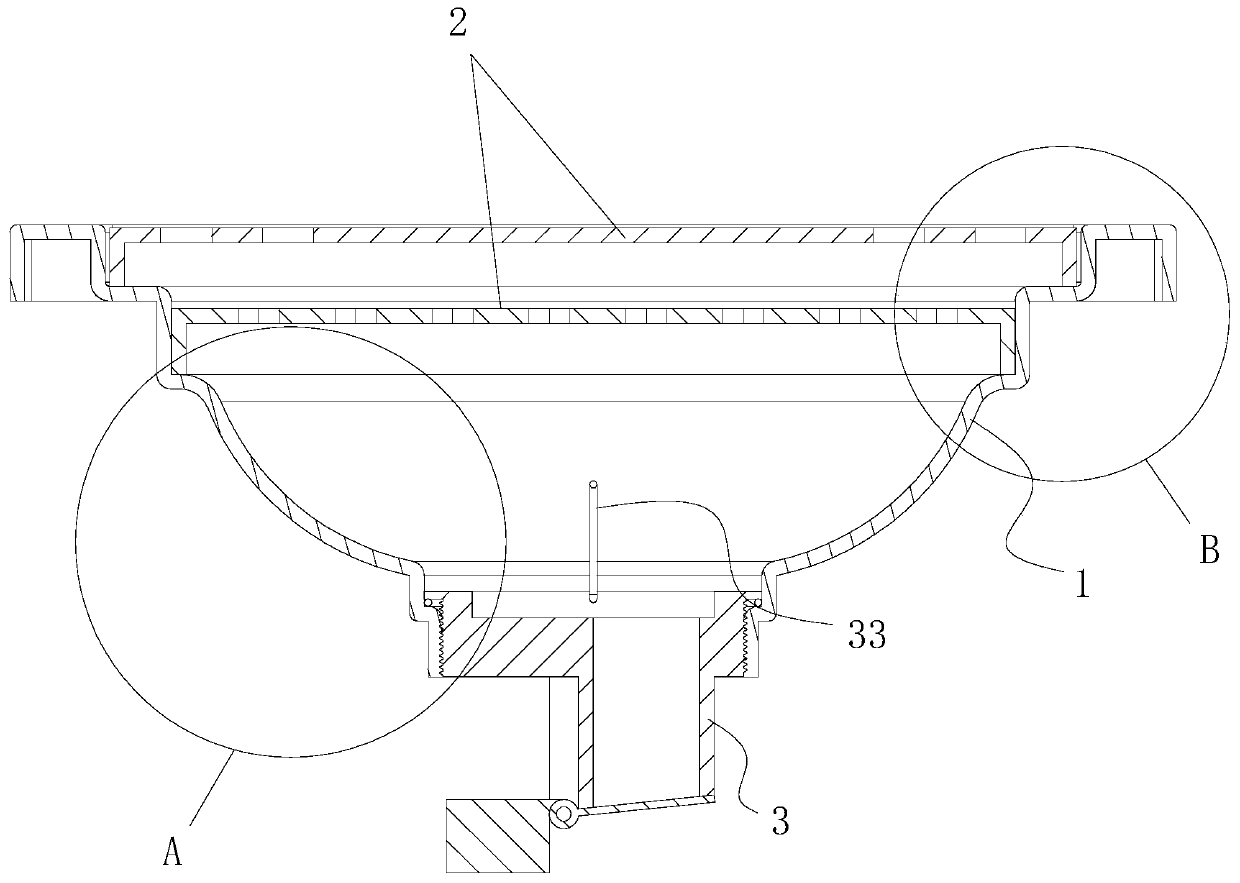

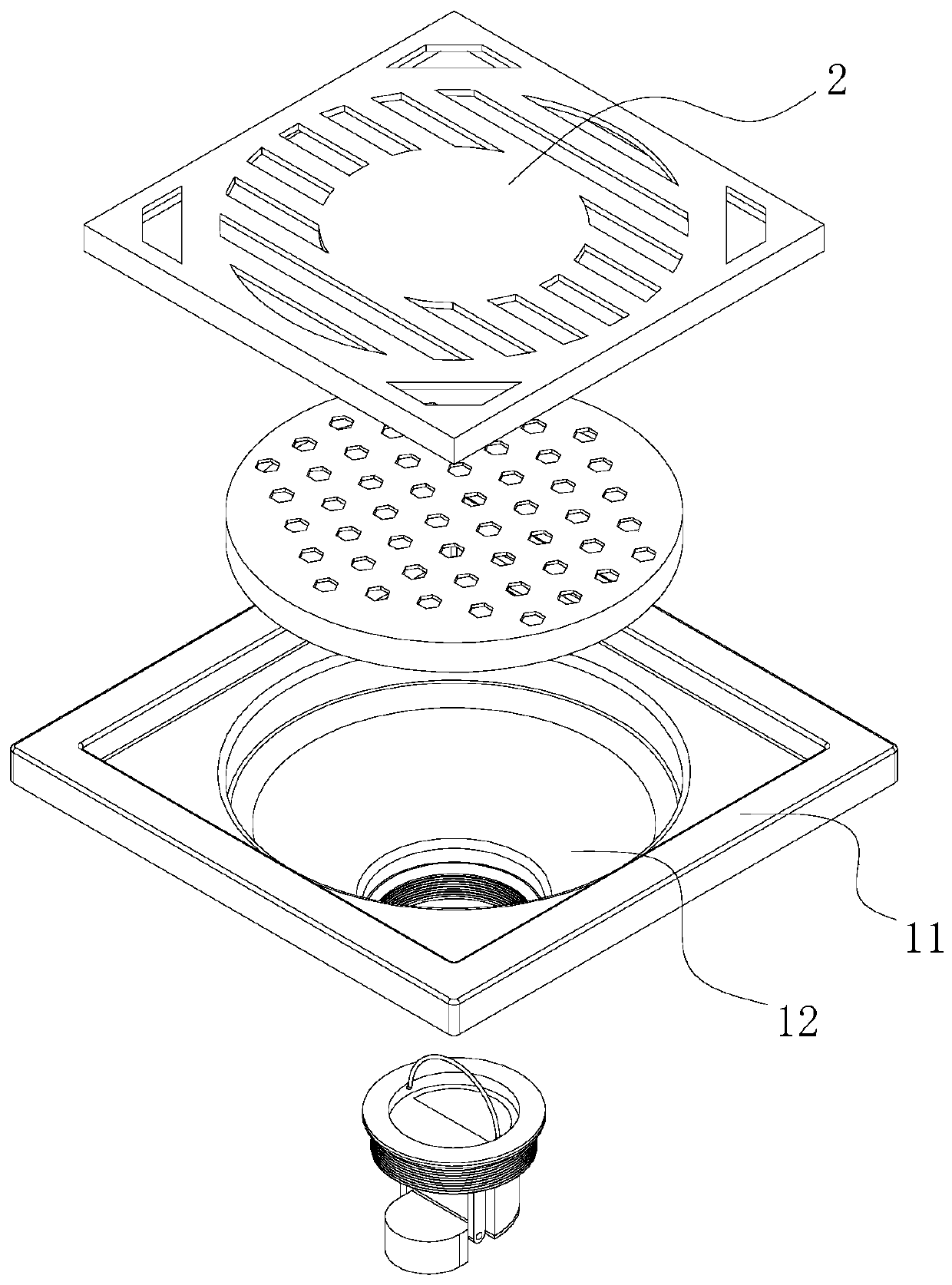

[0048] A floor drain, combined with figure 2 and image 3 As shown, it includes the floor drain body 1 whose main connection function and the lower end communicate with the drainage pipe, two pieces of grate plate 2 which are placed in the upper opening of the floor drain body 1 in sequence from top to bottom to intercept foreign matter, and installed on the lower end of the floor drain The blocking mechanism 3 used to prevent sewage and foreign matter from rushing back out of the floor drain from the drainage pipe.

[0049] like image 3 As shown, the floor drain body 1 includes a funnel-shaped main body 11 for installing the blocking mechanism 3 and an installation portion 12 arranged on the upper end of the main body 11 for installing various grate plates 2 .

[0050] combine image 3 and Figure 4 As shown, the body 11 includes a connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com