PC wallboard mounting structure and construction method thereof

A technology for installing structures and wall panels, applied to walls, building components, building structures, etc., to achieve the effects of high installation efficiency, convenient grouting, and low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

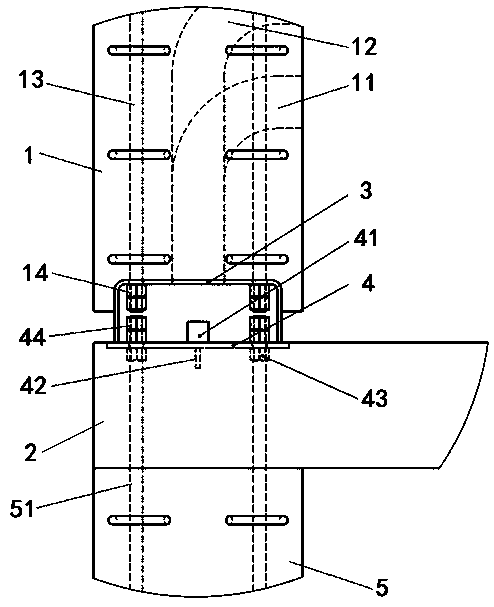

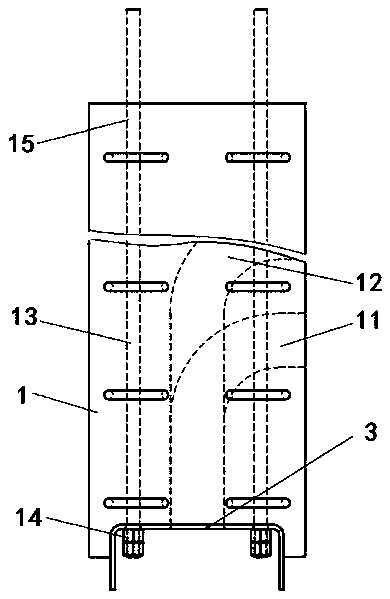

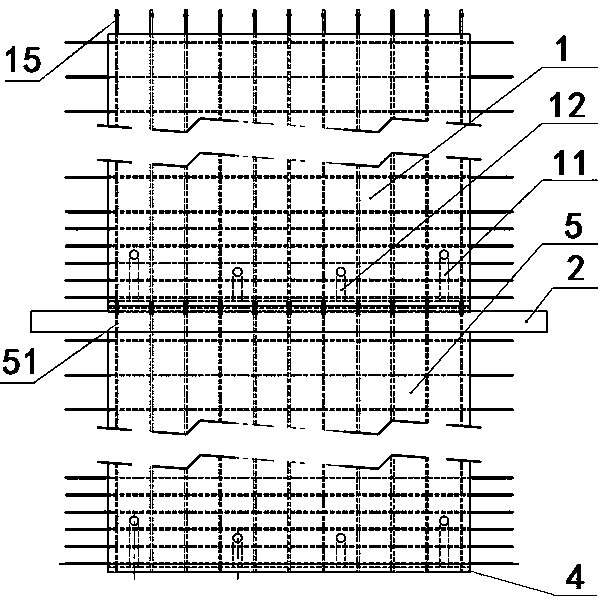

[0041] A PC wall panel mounting structure, such as figure 1 and 2 As shown, it includes a floor 2 , a first wall 5 supporting the floor 2 and a second wall 1 installed on the floor 2 . The second wallboard 1 has a lower rib, and a channel steel 3 with an opening downward and extending longitudinally is pre-embedded at the bottom end of the second wallboard 1 . The lower end surface of the channel steel 3 protrudes downward relative to the lower end surface of the second wallboard 1, which is convenient for closing the warehouse. The upper surface of the floor 2 is fixed with a pre-embedded steel plate 4 . The first wallboard 5 and the second wallboard 1 have the same structure, the first wallboard 5 and the second wallboard 1 are pre-embedded with reinforcing bars 13, and the upper ends of the reinforcing bars 13 stretch out relative to each wallboard to form upper ribs 51, The lower end of steel bar 13 protrudes relative to each wallboard to form a lower rib. It is worth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com