Method for protecting heat supply pipe paved after shallow soil covering under road surface

A technology for heating pipelines and shallow soil covering, which is applied in the directions of pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/pipe fittings, etc. It can solve the problems of large amount of concrete works, long construction period and inconvenience, and achieve significant economic and social benefits. , the effect of shortening the construction period and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

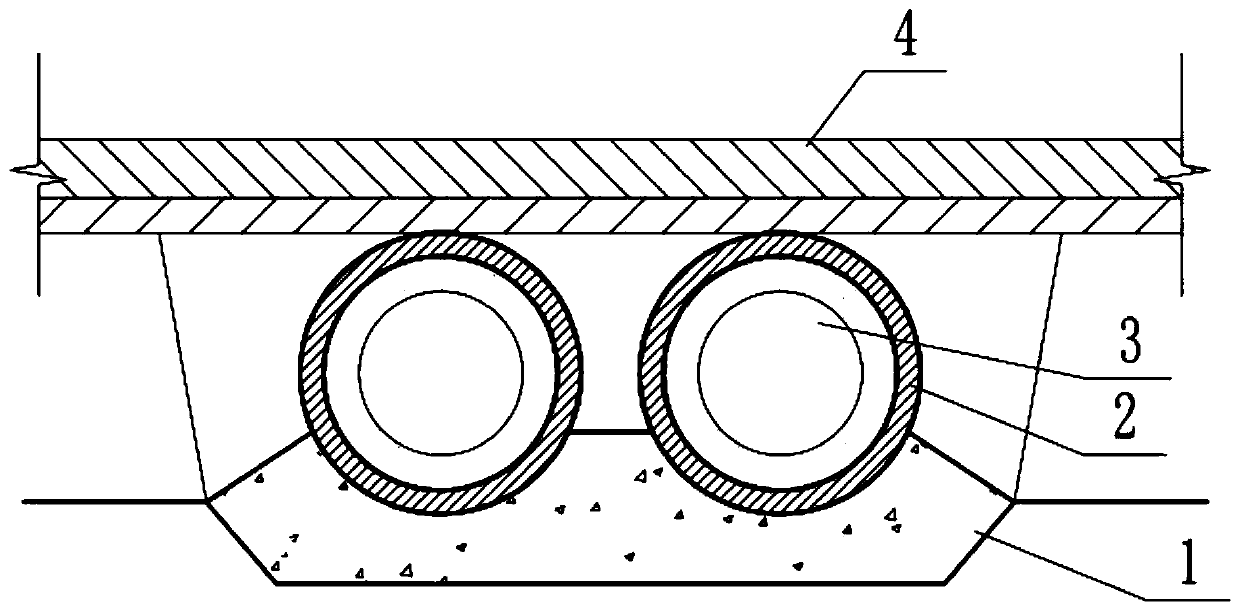

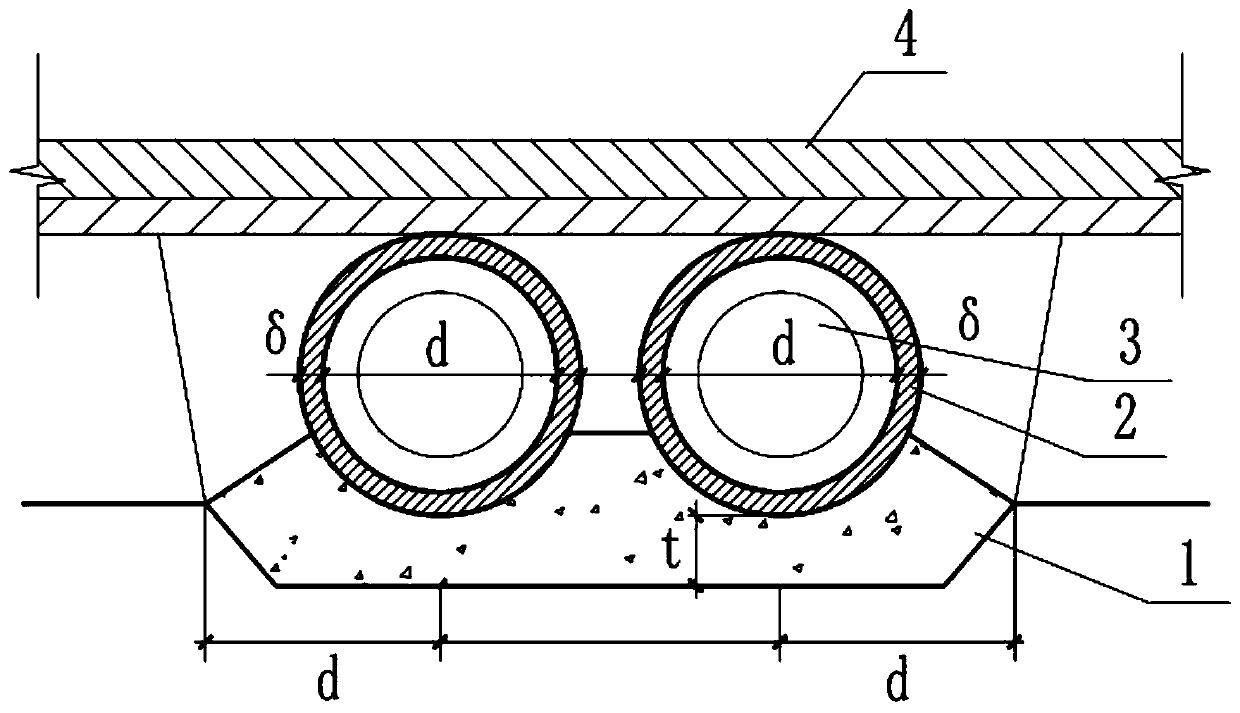

[0029] Such as figure 1 , figure 2 As shown, a method for protecting heating pipes after laying shallow soil under the pavement according to an embodiment of the present invention includes the following steps:

[0030] (1) Excavate the pipe groove and tamp the base

[0031] (2) Pouring concrete pipe foundation

[0032] On the flattened base, the formwork is set up according to the double pipe position, and the concrete pillow foundation 1 is poured;

[0033] (3) Layout concrete casing 2

[0034] After the pillow foundation 1 reaches the strength, the concrete casing 2 is hoisted on the pillow foundation 1 and temporarily fixed, and the length of the concrete casing 2 hoisted each time does not exceed the length of a section of the heating pipeline 3;

[0035] (4) Wear the heating pipe and weld it

[0036] Wear the heating pipe 3 in the concrete sleeve 2 and weld it section by section;

[0037] (5) Connect the concrete casing

[0038] Adjust the position of the concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com