Low-cycle repeated loading test device

A technology of repeated loading and testing equipment, which is applied in the direction of measuring equipment, application of repetitive force/pulsation force to test the strength of materials, instruments, etc., can solve the problem of not easy to limit the out-of-plane instability of the test piece, and achieve convenient disassembly and strong adaptability , the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] specific implementation plan

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

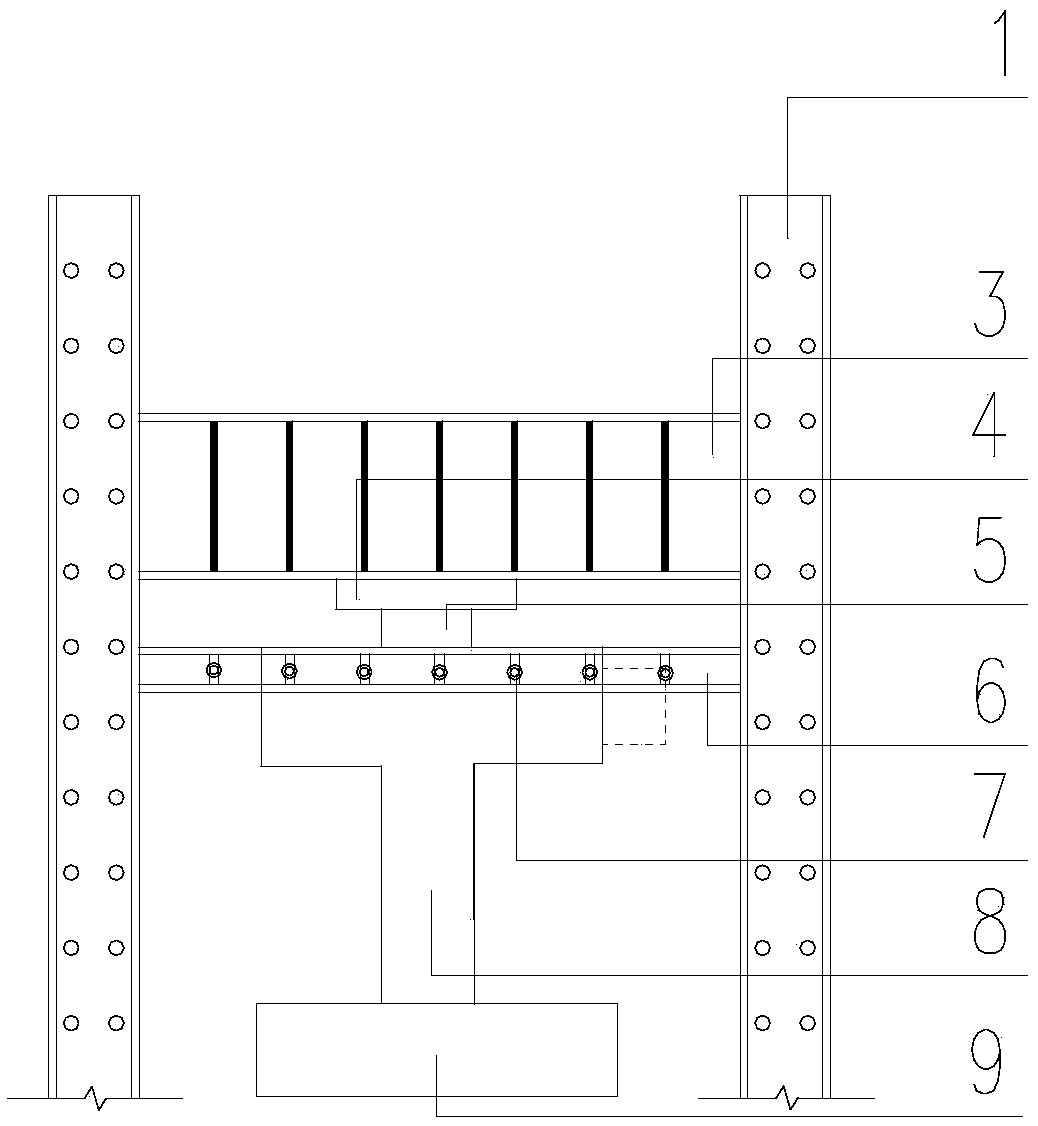

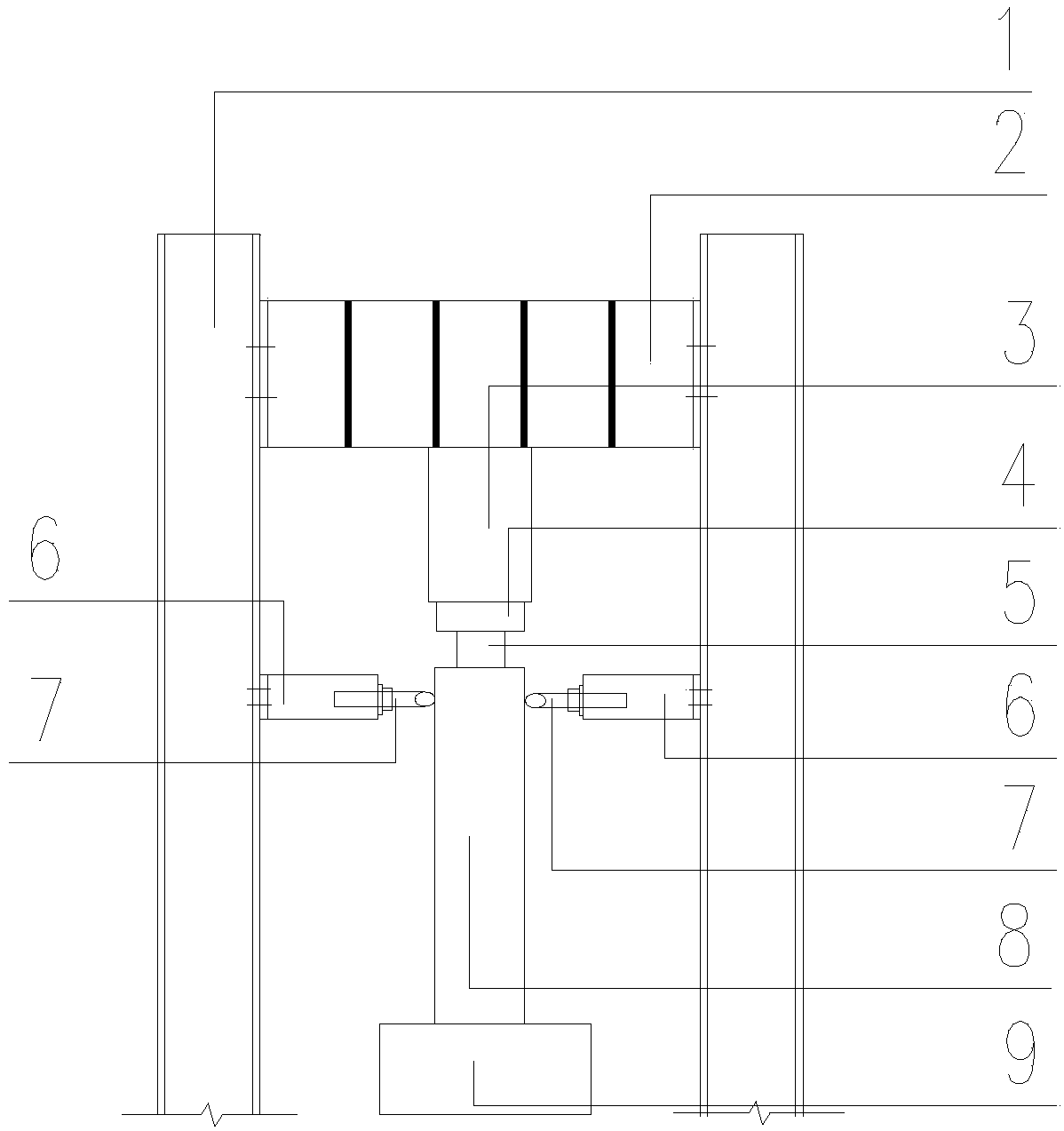

[0034] A low-cycle repeated loading test device, such as figure 1 . The test device includes: a steel column 1 , a first upper outer frame beam 2 , a second upper outer frame beam 3 , a roller 4 , a jack 5 , a U-shaped welded channel steel 6 , and a roller 7 .

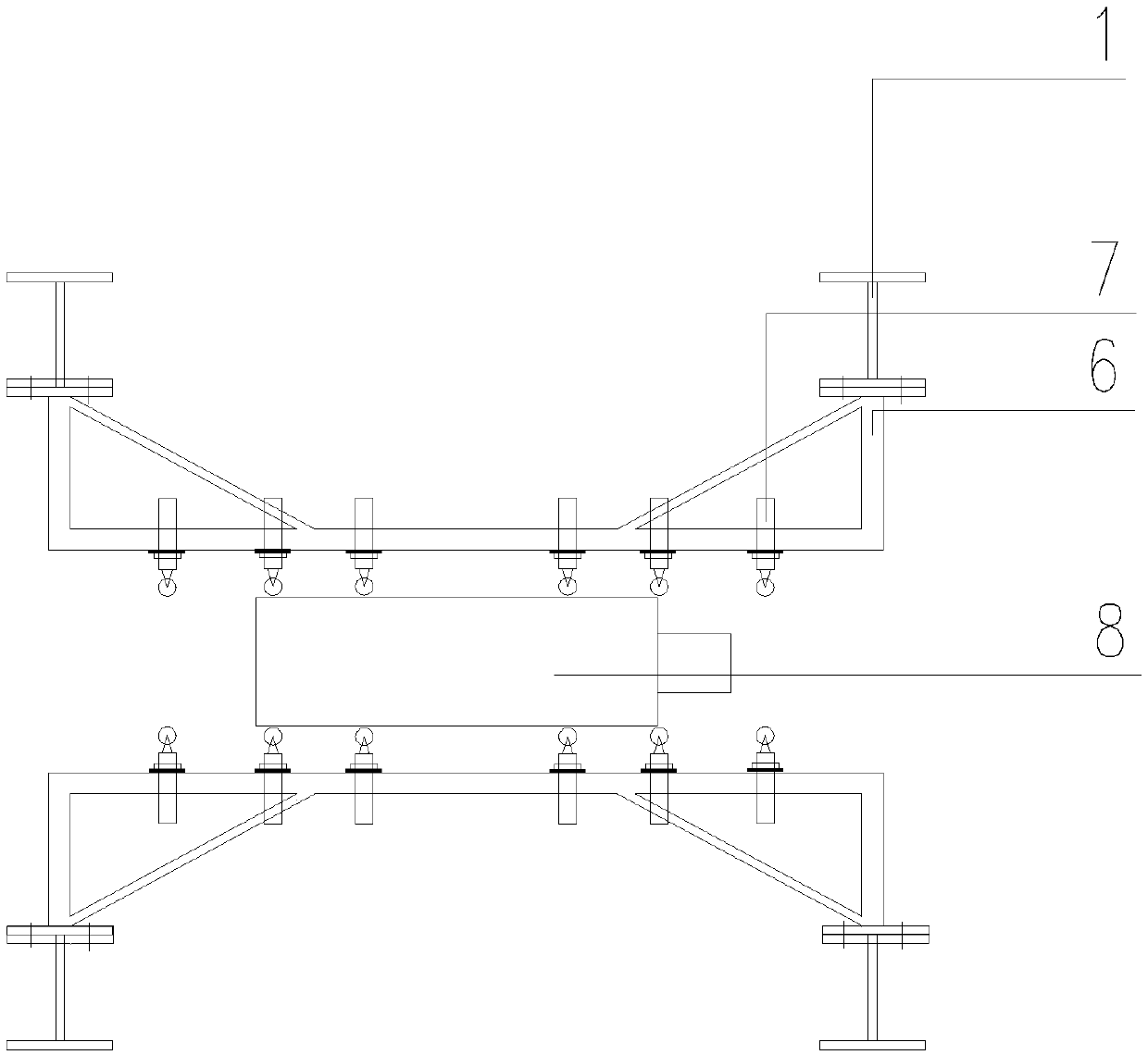

[0035] The test object component 8 needs to be connected to the abutment through the ground beam 9 and then installed in the middle of the low cycle repeated loading test device, see Figure 7 .

[0036] The steel column 1 is an I-beam with equal cross-section, and the flanges are provided with bolt holes at equal intervals, see figure 1 .

[0037] The first upper outer frame beam 2 and the steel column 1 are fixed by the bolt holes on the end plate of the upper first outer frame beam 2 and the bolt holes corresponding to the bolt holes on the wing plate of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap