Shear wall prefabricating system

A shear wall and double-teaming technology, which is applied in the direction of manufacturing tools, ceramic molding machines, mold auxiliary parts, etc., can solve problems such as redundancy of force-bearing components, increased cost of shear walls, and large steel consumption of steel pipe bundles, etc., to achieve The effect of firm and stable material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

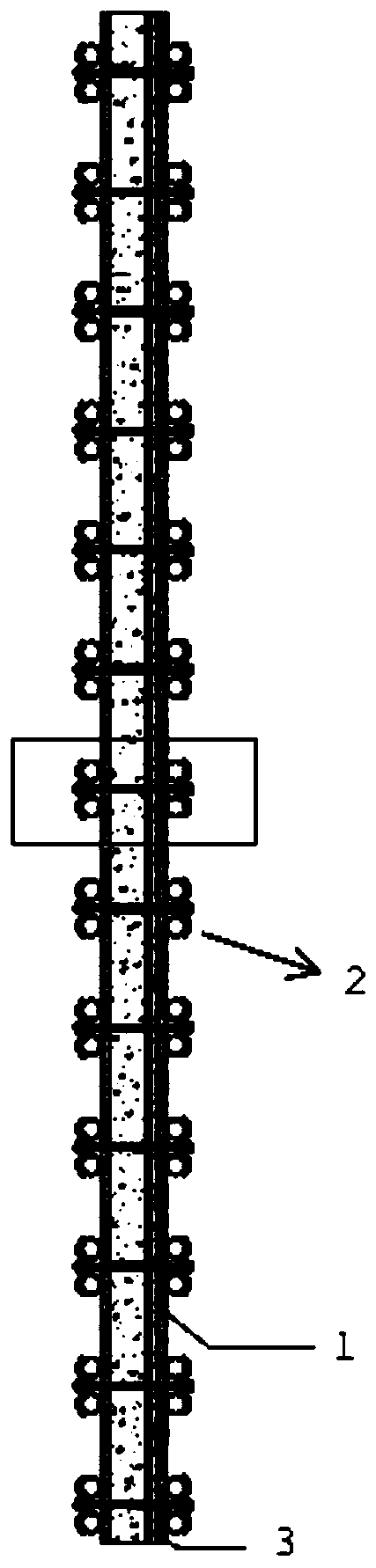

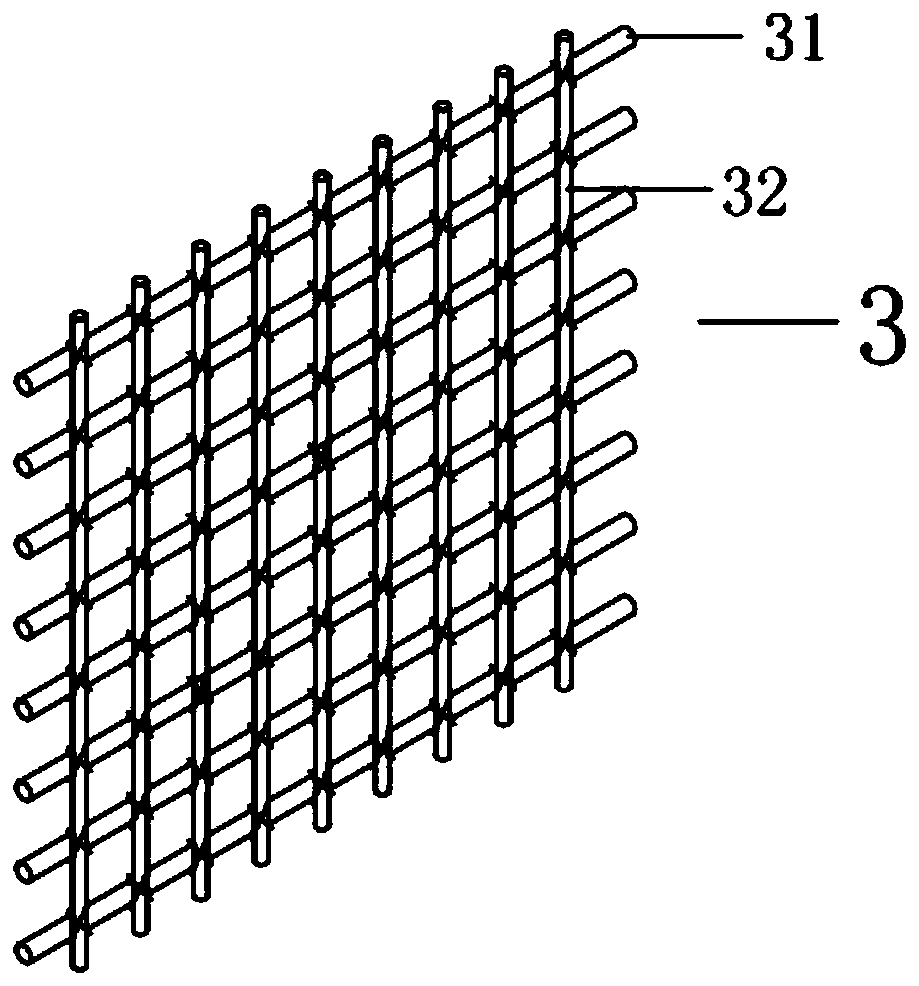

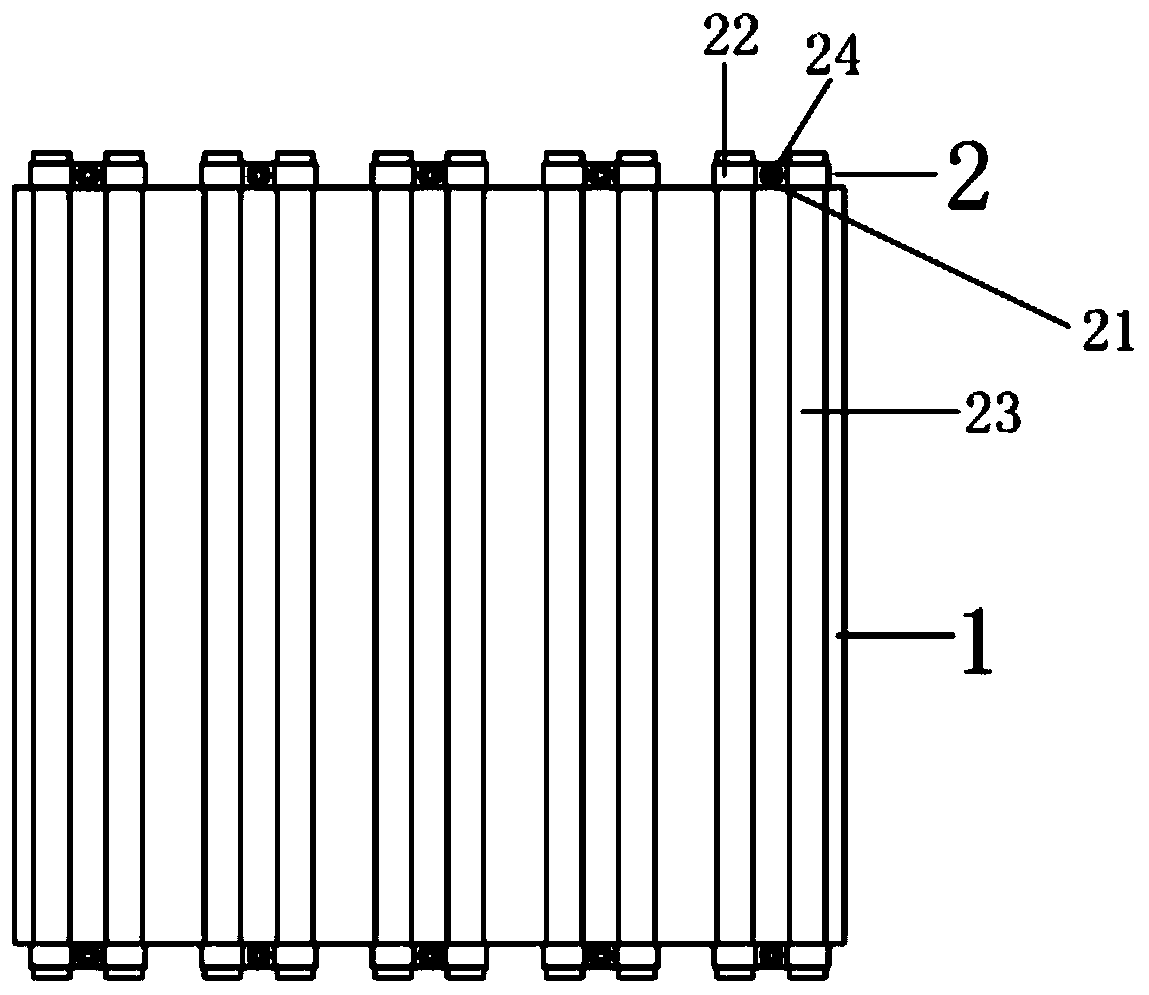

[0038] When the user uses the present invention, when the user uses the present invention, the horizontal and vertical rebars are first fixed through the iron connection, and then placed in the clamping formwork 1, and then through the clamping device 2 according to the thickness of the shear wall required by the user. The adjustment is fixed, and the clamping device 2 is twisted and adjusted respectively by twisting the nut 21 to realize the adjustment of the thickness of the clamping template 1 .

[0039] When twisting the nut 21 to adjust the clamping device 2, because the clamping tube 23 is a seamless tube, the seamless tube is lighter in weight when the bending and torsional strength is the same, and is an economical section The steel is used to adjust and fix the thickness of the clamping template 1 to ensure the firmness and stability of the template of the present invention.

[0040] And because the radian of the inner arc surface of the cladding hole 221 is equal to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com