Main lifting lug of booster station project and construction process for main lifting lug

A construction technique and booster station technology, applied in the direction of manufacturing tools, load hanging components, metal processing equipment, etc., can solve the problems of booster station main lifting lug error, manpower, financial loss, and increase construction costs, etc., to achieve extension The effect of improving service life, avoiding internal damage, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] The following is attached Figure 1-7 The present invention will be described in further detail.

[0063] Such as Figure 7 As shown, the upper module of the booster station is designed with 4 main lifting eyes, each of which is about 20 tons, all of DH460, DH36 high material Z-direction steel. Unless otherwise specified, the main lifting eyes are all fully welded. Weld.

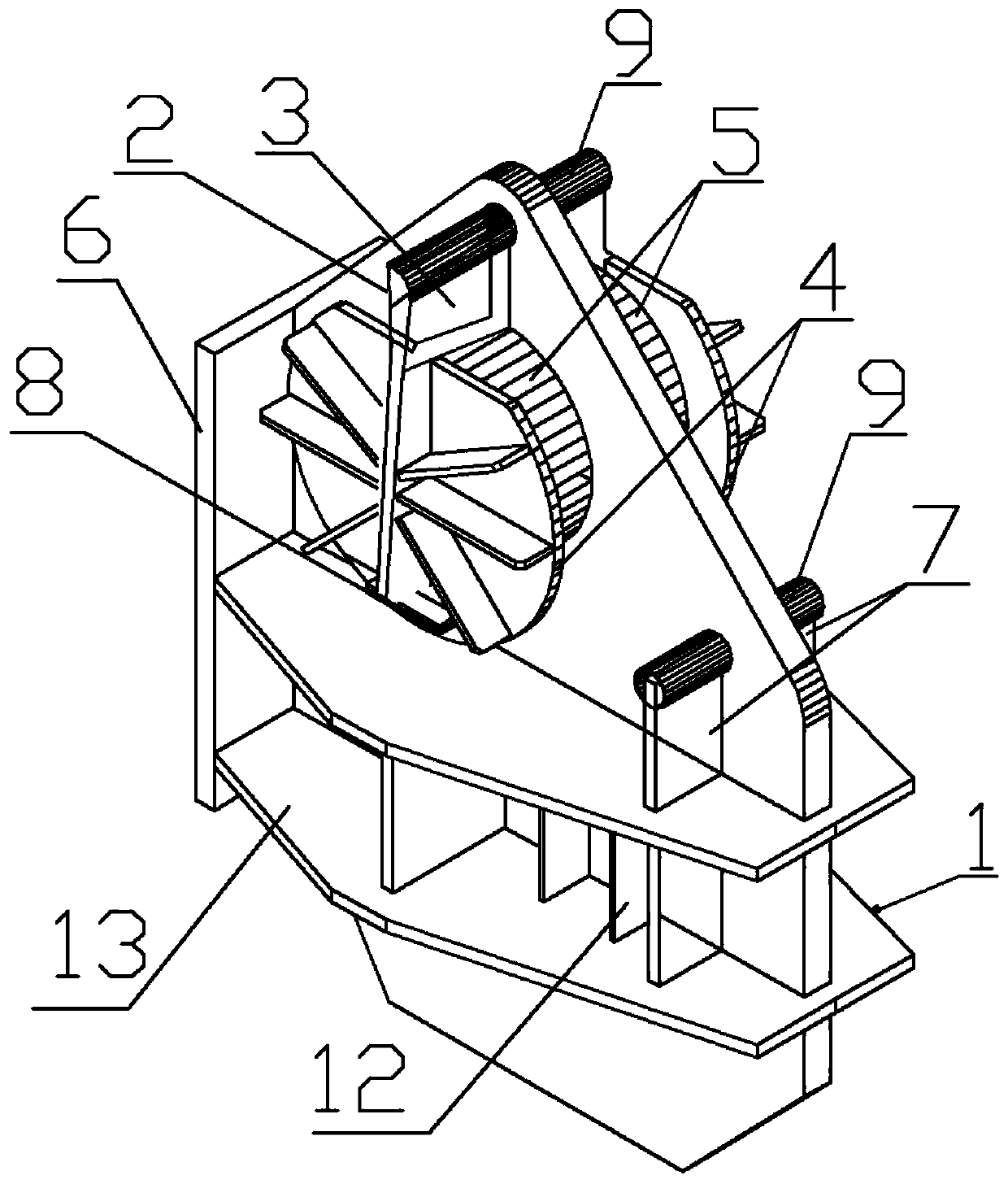

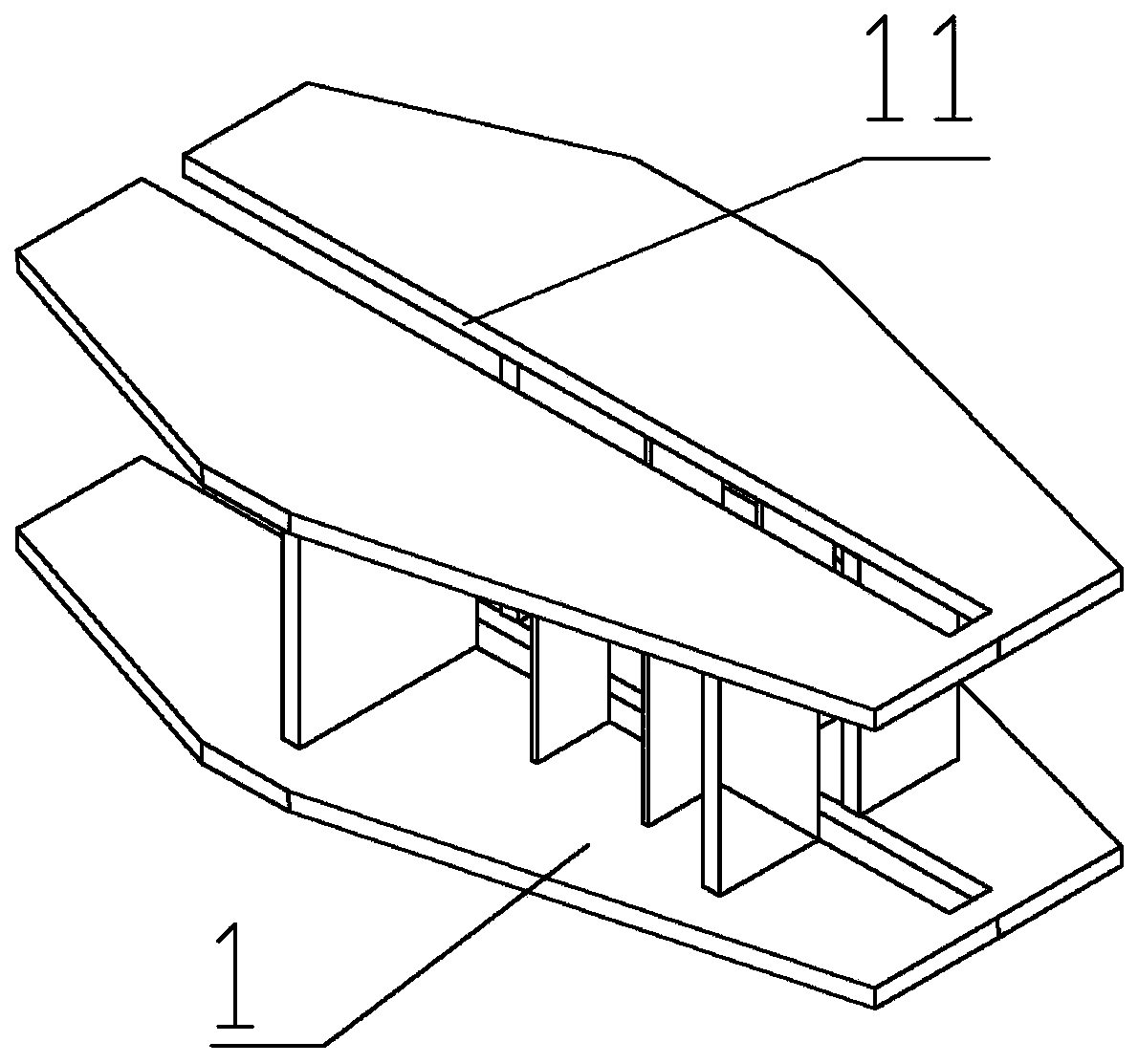

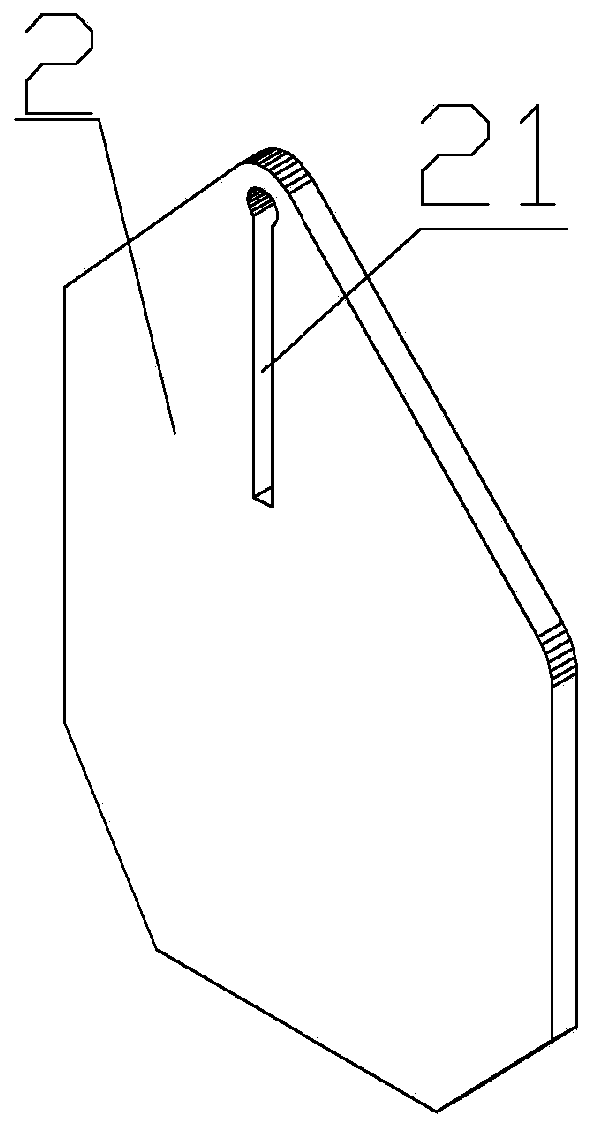

[0064] Such as figure 1 , figure 2 , image 3 with Figure 5 As shown, a main lifting lug of a booster station project includes a base structural plate 1 on which a first embedding groove 11 is formed along the vertical direction, and a lifting lug is provided in the first embedding groove 11 Reinforced plate 2, the lifting lug reinforcement plate 2 is provided with a second embedding groove 21 along the horizontal direction, the second embedding groove 21 is provided with a shear plate 3, and both ends of the shear plate 3 are respectively provided The sling locking plate 4 is provided with four liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com