Liquid delivery equipment for textile industry

A technology of conveying equipment and textile industry, applied in the field of liquid conveying equipment in the textile industry, can solve problems such as reducing work efficiency, and achieve the effects of improving practical reliability, convenient operation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

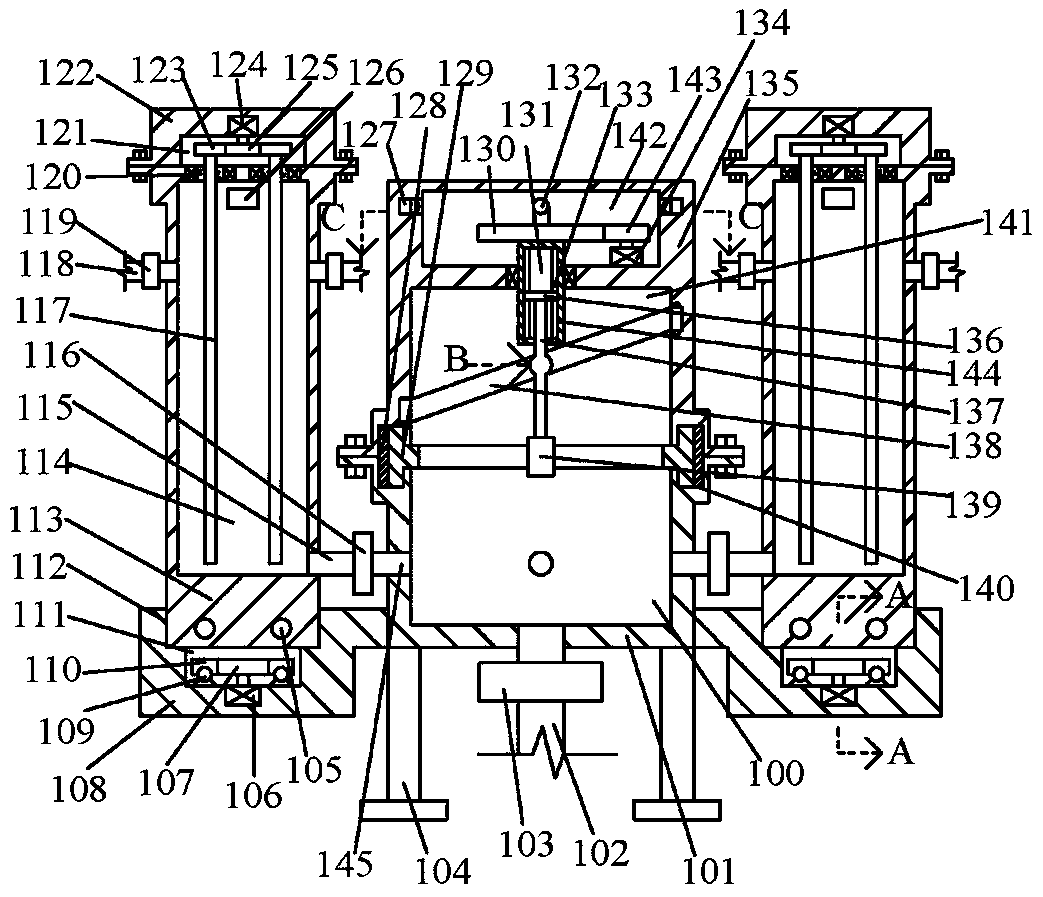

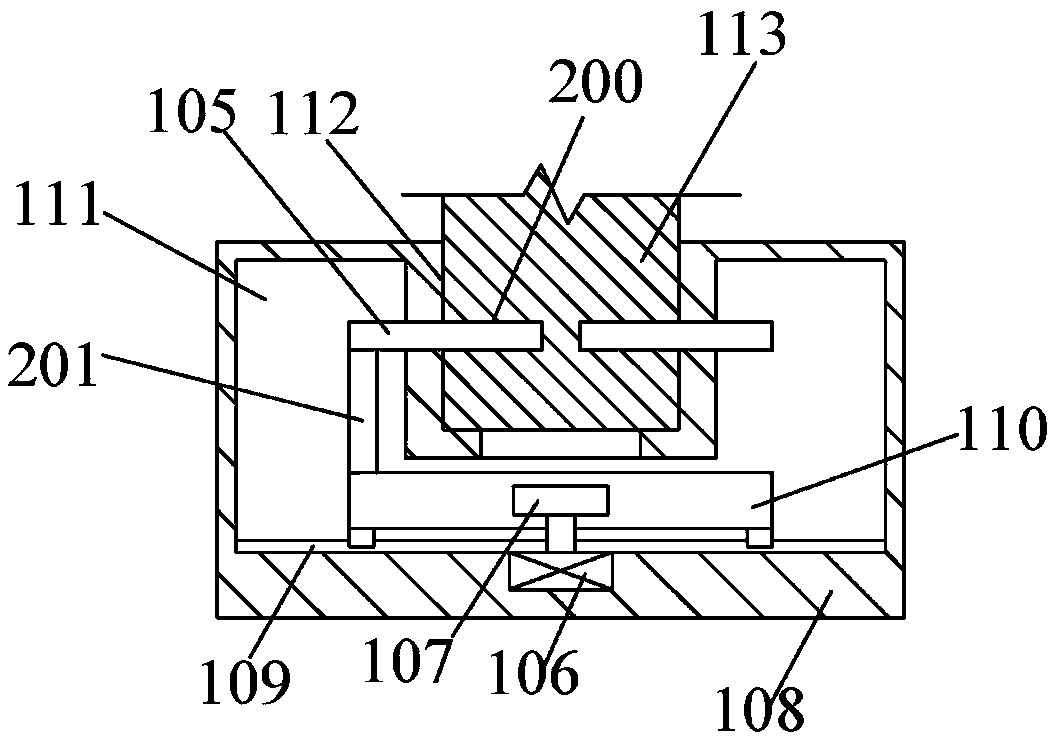

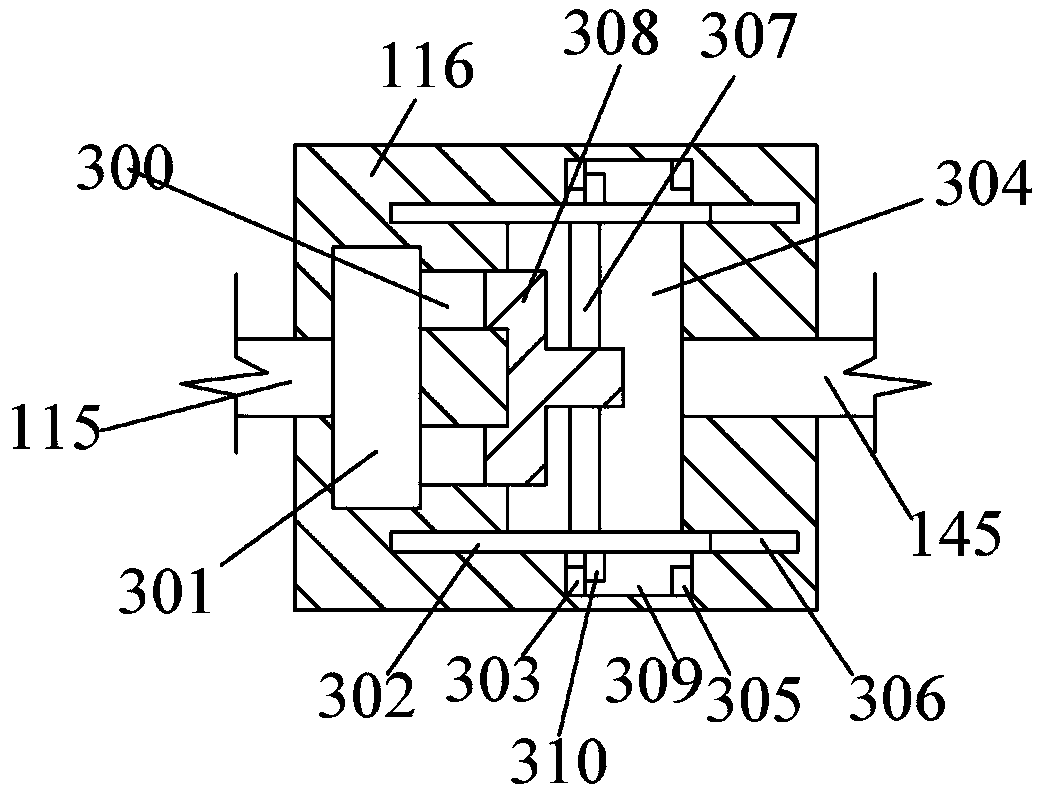

[0020] Combine below Figure 1-5 The present invention will be described in detail.

[0021] refer to Figure 1-5, according to an embodiment of the present invention, a liquid delivery device for the textile industry includes a box body 101, a liquid storage device and an electronic valve device. A storage chamber 100 with an upward opening is fixed inside the box body 101. The depth of the storage chamber 100 is 40cm~50cm, the upper end surface of the box body 101 is fixed and connected by bolts and is provided with a cover box 135, and the inner opening cavity 141 with the opening facing downward is fixed in the cover box 135, and the inner opening cavity 141 communicates with the storage cavity 100, and the inner opening cavity 141 and the storage cavity The end wall of 100 is communicated with and provided with the ring clip cavity 140 that is arranged annularly, and the ring clip cavity 140 end wall is provided with the annular backing plate 128 that is set annularly, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com