Patents

Literature

37results about How to "Improve practical reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

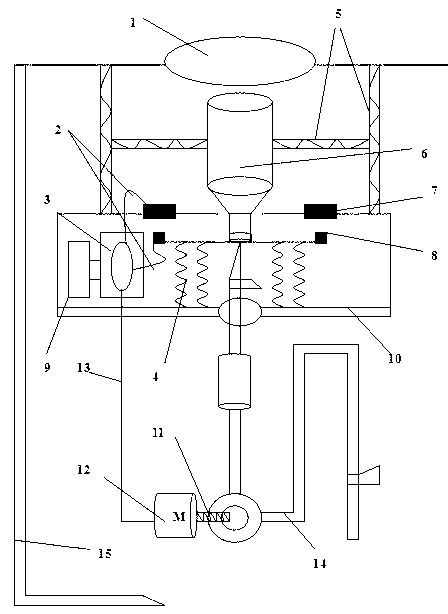

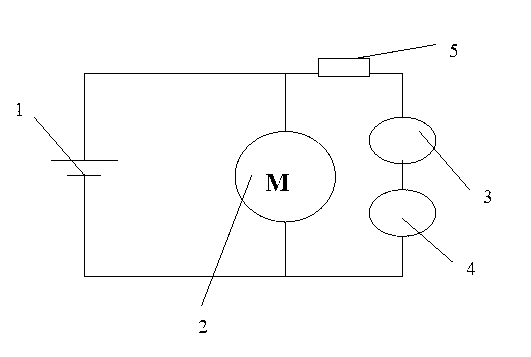

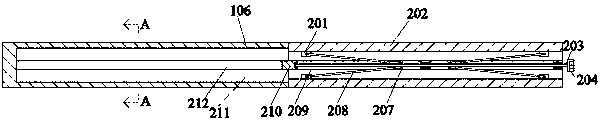

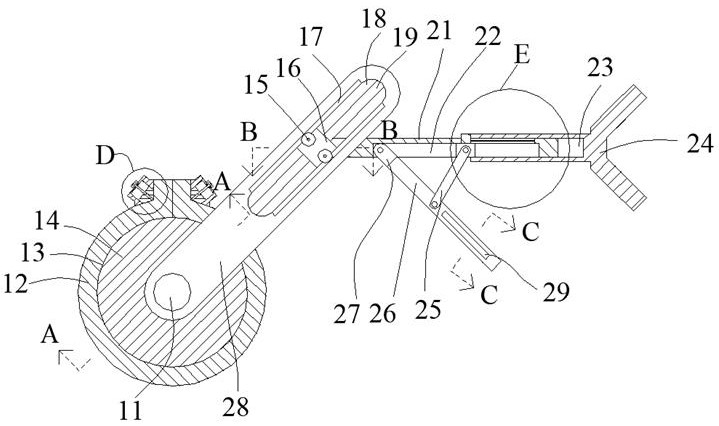

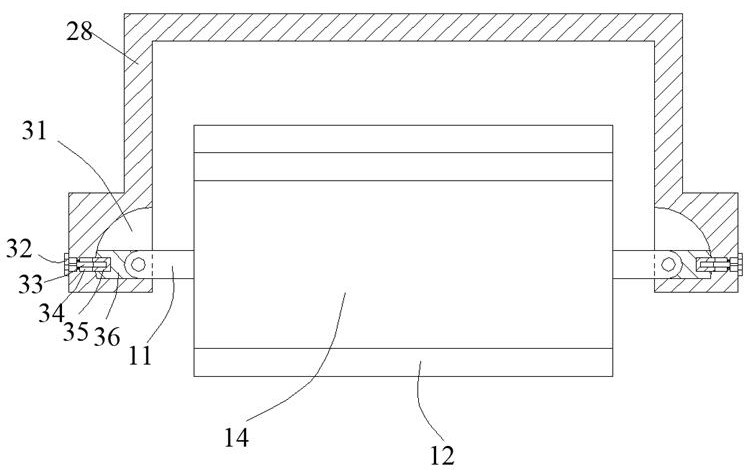

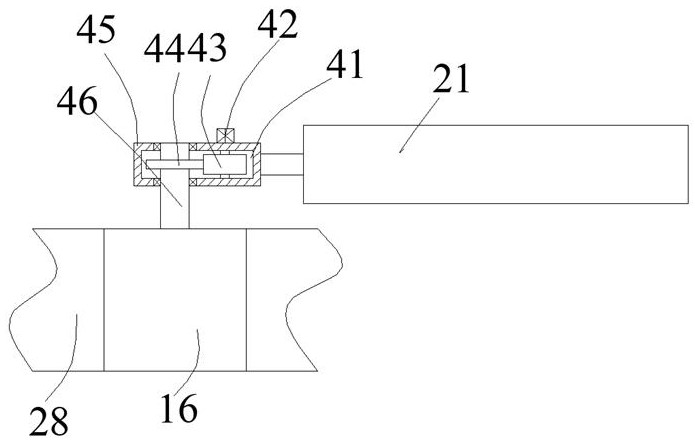

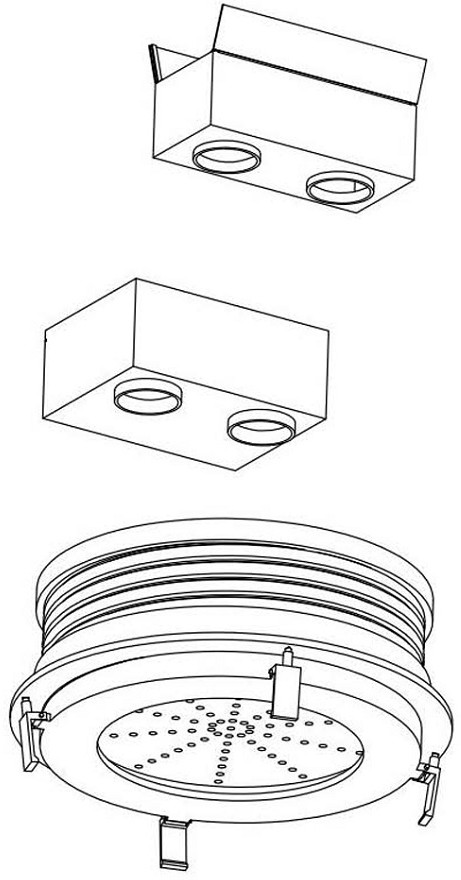

Novel venous transfusion switching and alarming device

Venous transfusion blood return and over low temperature of liquid medicine for venous transfusion are medical accidents which are caused by loose custody and occur easily in medical treatment, and can cause severe secondary harm to patients. Possibility of occurrence of venous transfusion blood return accidents is higher especially on the conditions that a hospital is in patient transfusion rush hours and the number of caring workers is not enough. The venous transfusion blood return accident is a big difficult problem for the hospital. In order to solve the difficult problems in venous transfusion and overcome the technical defects of an existing product, the invention provides a novel venous transfusion switching and alarming device. A simple and ingenious mechanical structure design is adopted for the device. Reduction of the self weight of an infusion bottle is utilized to control connection and disconnection of two contacts, and then connection and operation of an indication light, a micro-alarm and a stepping motor are controlled, so that stoppage of venous transfusion is controlled, and medical workers and patients are alarmed. The device is simple and ingenious in design and high in reliability, and brings great convenience to monitoring of venous transfusion of the patients.

Owner:CHONGQING UNIV

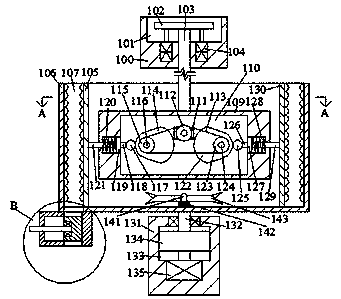

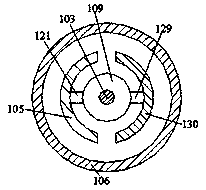

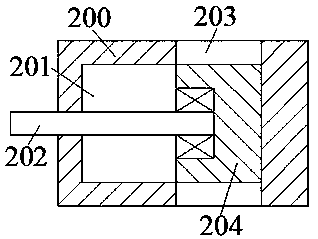

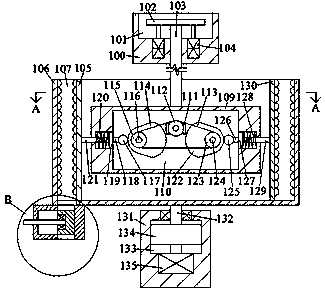

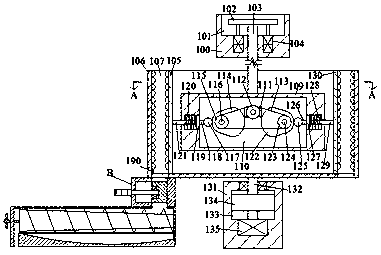

Improved biomass solid fuel densification machine shaping technology

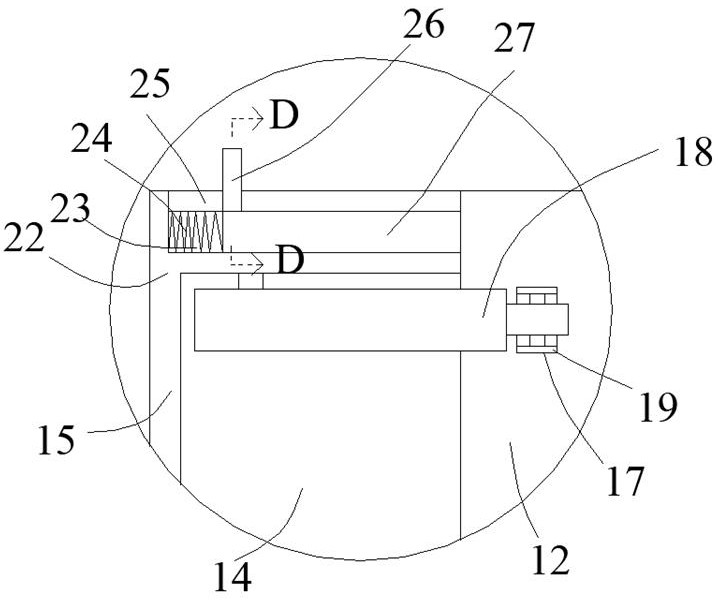

The invention discloses an improved biomass solid fuel densification machine shaping technology which comprises a box body D fixedly arranged on the ground, wherein a power cavity is formed in the boxbody D; a motor B is fixedly arranged in the lower end wall of the power cavity; a heat radiating fin is fixedly arranged at the external part of the outer side wall of the power cavity, penetrates through the box body D and communicates with the external space; the output shaft of the motor B is in power connection with a speed reducer in the power cavity; a fixed shaft E is in power connectionwith the upper end face of the speed reducer, rotatably penetrates through the upper end wall of the power cavity and extends out of the external space; a box body B is in power connection with the upper end face of the fixed shaft E; an opening cavity B with an upward opening is formed in the box body B; and an opening communicating with the external space is formed in the lower end wall of the opening cavity B. The improved biomass solid fuel densification machine shaping technology is simple in structure and convenient to use; and the equipment simultaneously adopts grinding and extruding to realize densification processing of biomass solid slag, so that one of working procedures in the improved biomass solid fuel densification machine shaping technology is realized, and the practical reliability of the equipment is effectively improved.

Owner:广州一恒科技有限公司

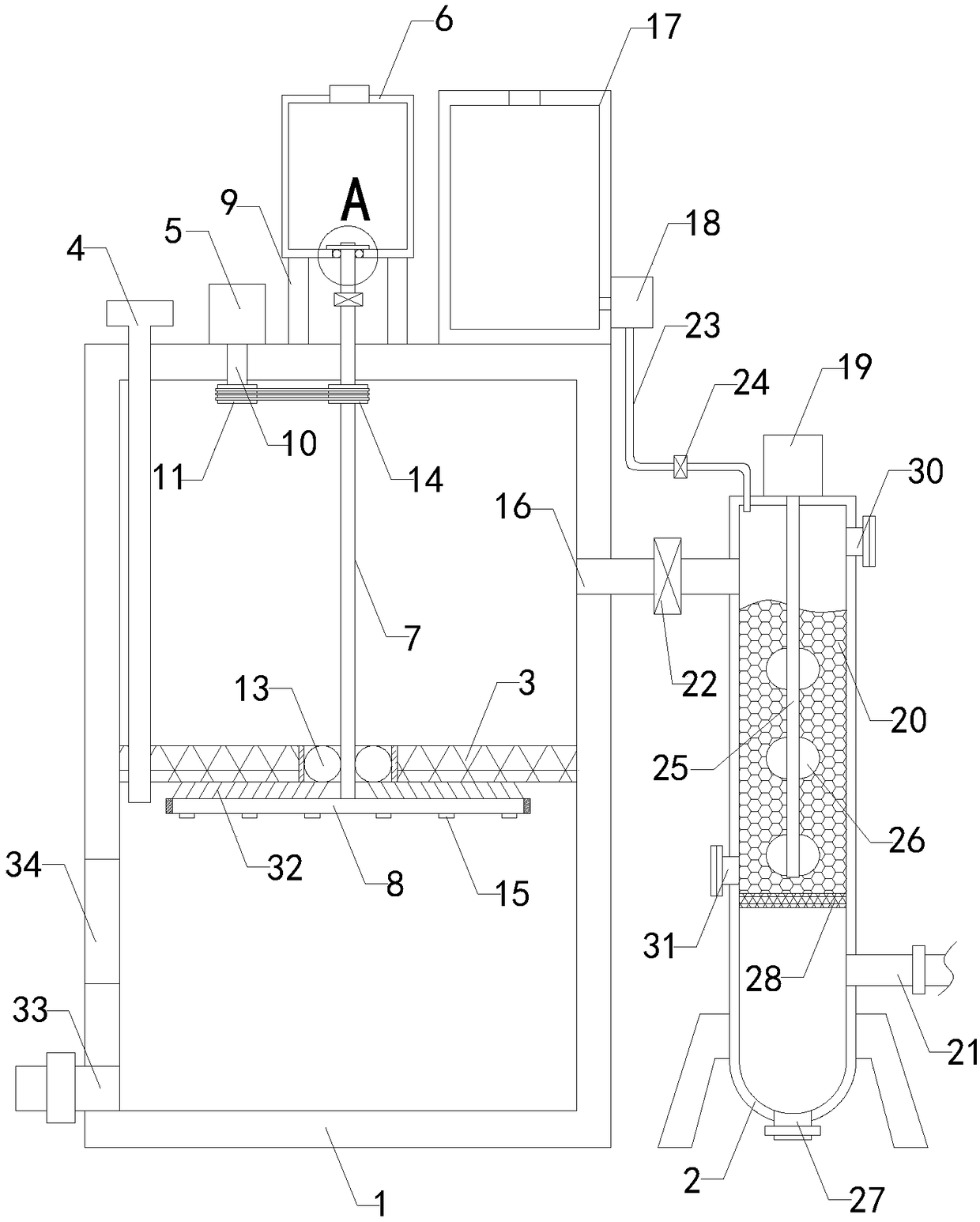

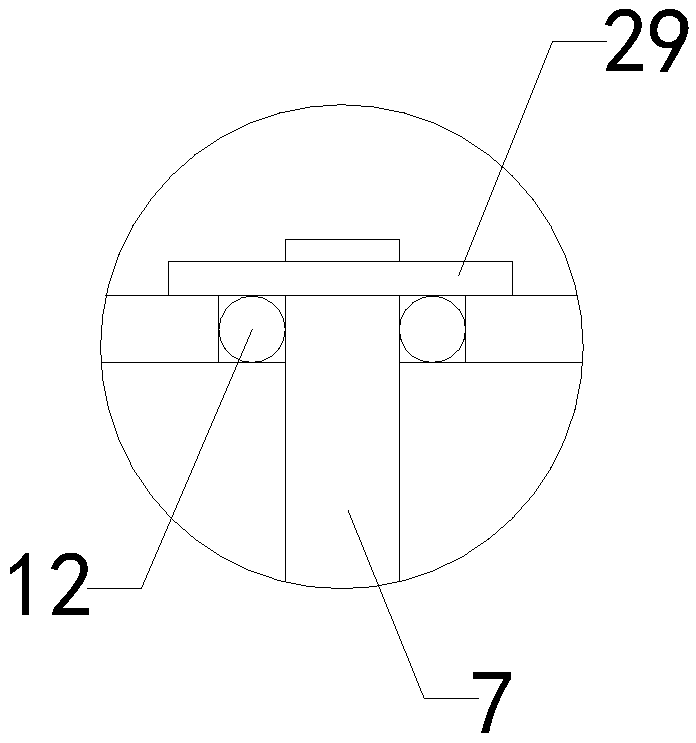

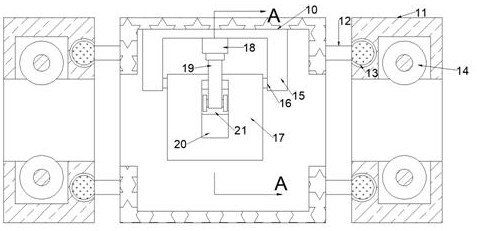

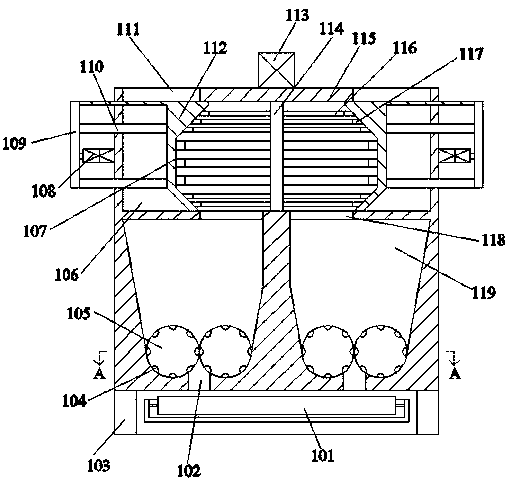

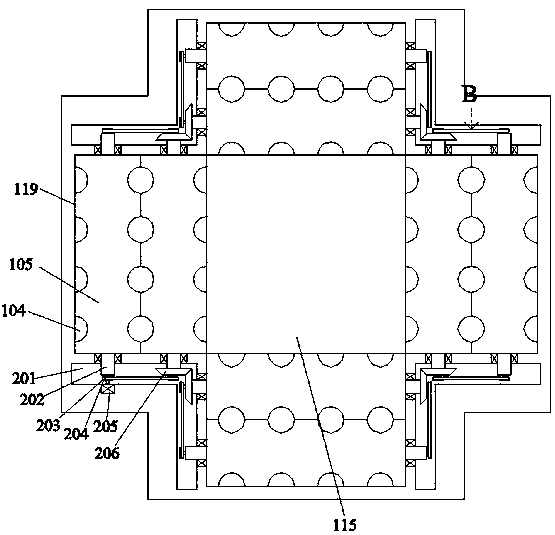

Electroplating wastewater treatment device for wheel hub cover production

InactiveCN108862740AGuaranteed normal processingImprove filtering effectSpecific water treatment objectivesWater contaminantsWater dischargeBall bearing

The invention relates to the technical field of a wastewater treatment auxiliary device, in particular to an electroplating wastewater treatment device for wheel hub cover production. The filtering effect on impurities in wastewater is improved; the load of a subsequent treatment process is reduced; the practicability is improved; saturated ion exchange resin can be regenerated without machine halt; the operation is simple; the wastewater treatment process is ensured; the practical reliability is improved. The electroplating wastewater treatment device comprises a filtering box and two groupsof ion exchange tanks, wherein a filtering net is transversely arranged in the filtering box; the top end of the filtering box is provided with a water inlet pipe; the electroplating wastewater treatment device also comprises a first motor, a chemical box, a conveying pipe, a chemical spraying pipe, support legs, a rotating shaft, a first belt wheel, a first ball bearing, a second ball bearing, asecond belt wheel, two groups of communication pipes, a regeneration box, a conveying pump and two groups of second motors; ion exchange resin are respectively filled inside the two groups of ion exchange tanks; the electroplating wastewater treatment device also comprises a water discharge pipe, a flexible pipe, an electromagnetic valve, a transmission shaft, a stirrer and a first blow-off pipe.

Owner:TAICANG GATZ AUTOMOTIVE COMPONENTS CO LTD

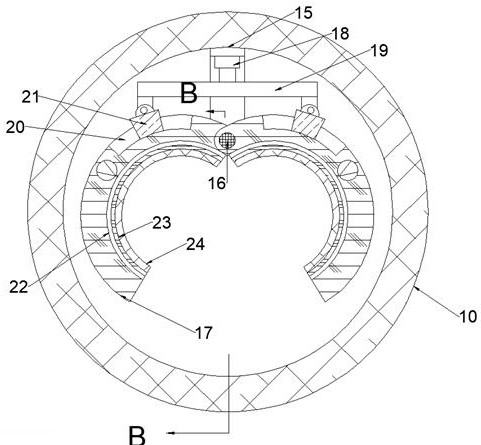

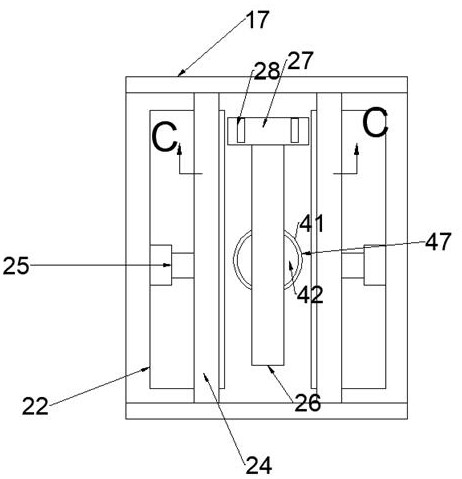

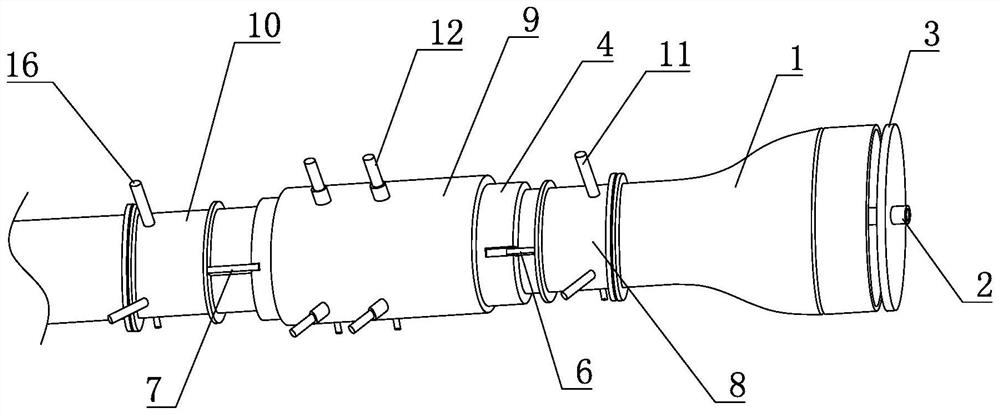

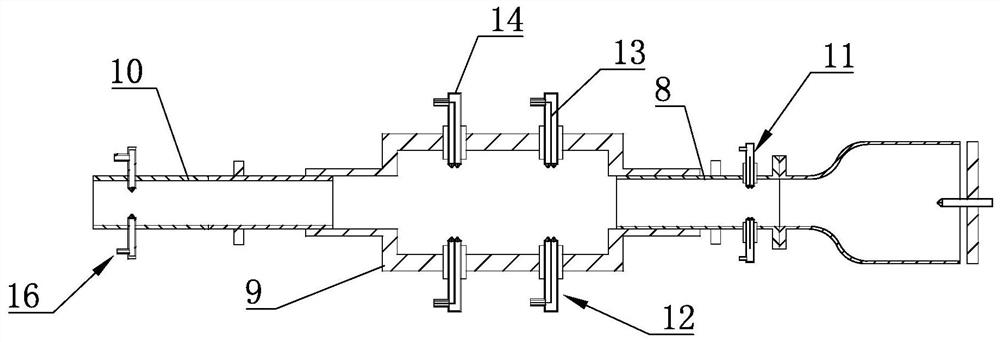

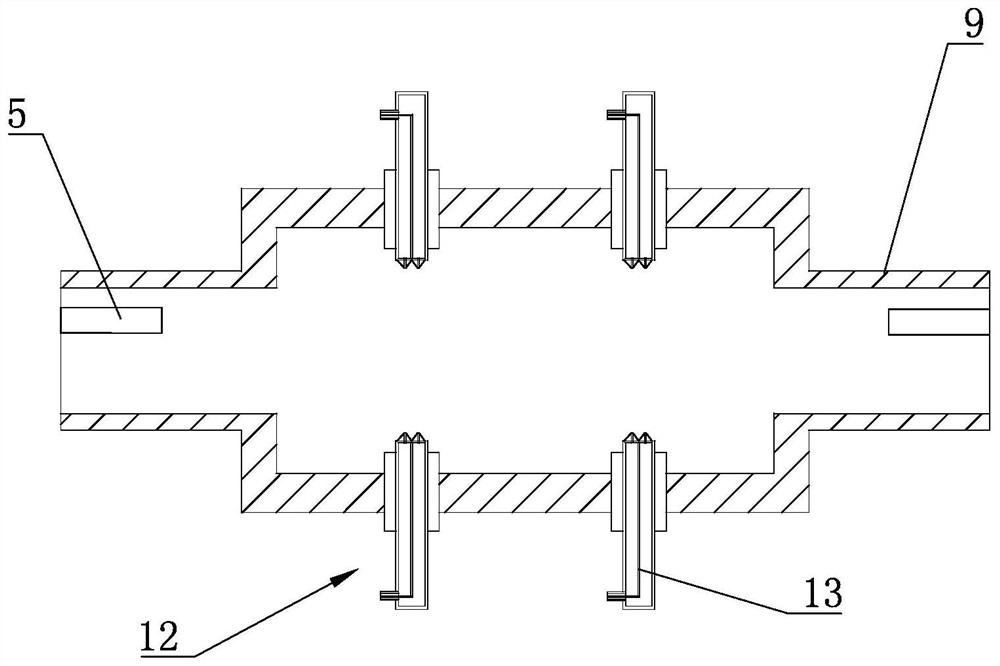

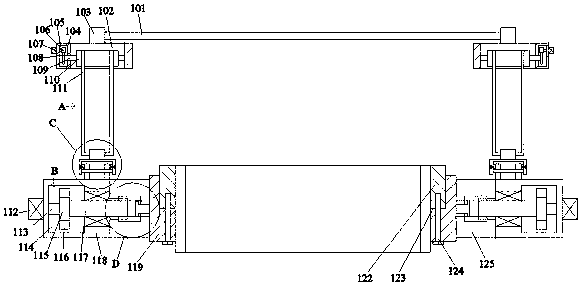

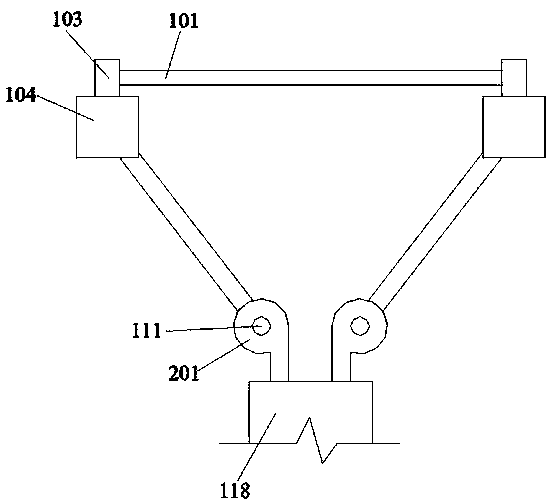

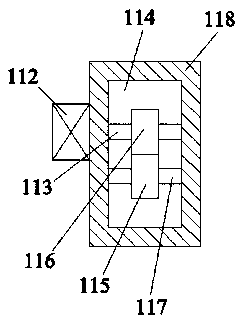

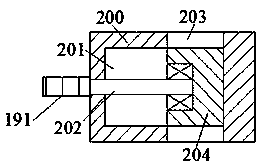

Splicing type pipeline welding position sealing detection device

InactiveCN113063555ASolve different anglesCheck tightnessMeasurement of fluid loss/gain rateButt weldingEngineering

The invention relates to the technical field of pipeline treatment, and discloses a splicing type pipeline welding position sealing detection device which comprises a working box, the outer end face of the working box is movably connected with an auxiliary turning box, the auxiliary turning box comprises moving rollers rotationally installed on the wall face of an inner cavity, and a fixing block is fixedly installed on the top wall of the inner cavity of the working box. According to the splicing type pipeline welding position sealing detection device, when sliding butt welding is carried out on a pipeline, the pipeline is wrapped by a specific part in a sealing processing mechanism, an air bag in the mechanism is processed and then makes contact with the pipeline, then the surface of the air bag is moist and free of dust, and the air bag becomes tighter; and at the moment, pressurization is carried out through a cavity formed between the sealing processing mechanism and the pipeline, and detection is carried out through an air pressure detection mechanism.

Owner:济南允超建材有限公司

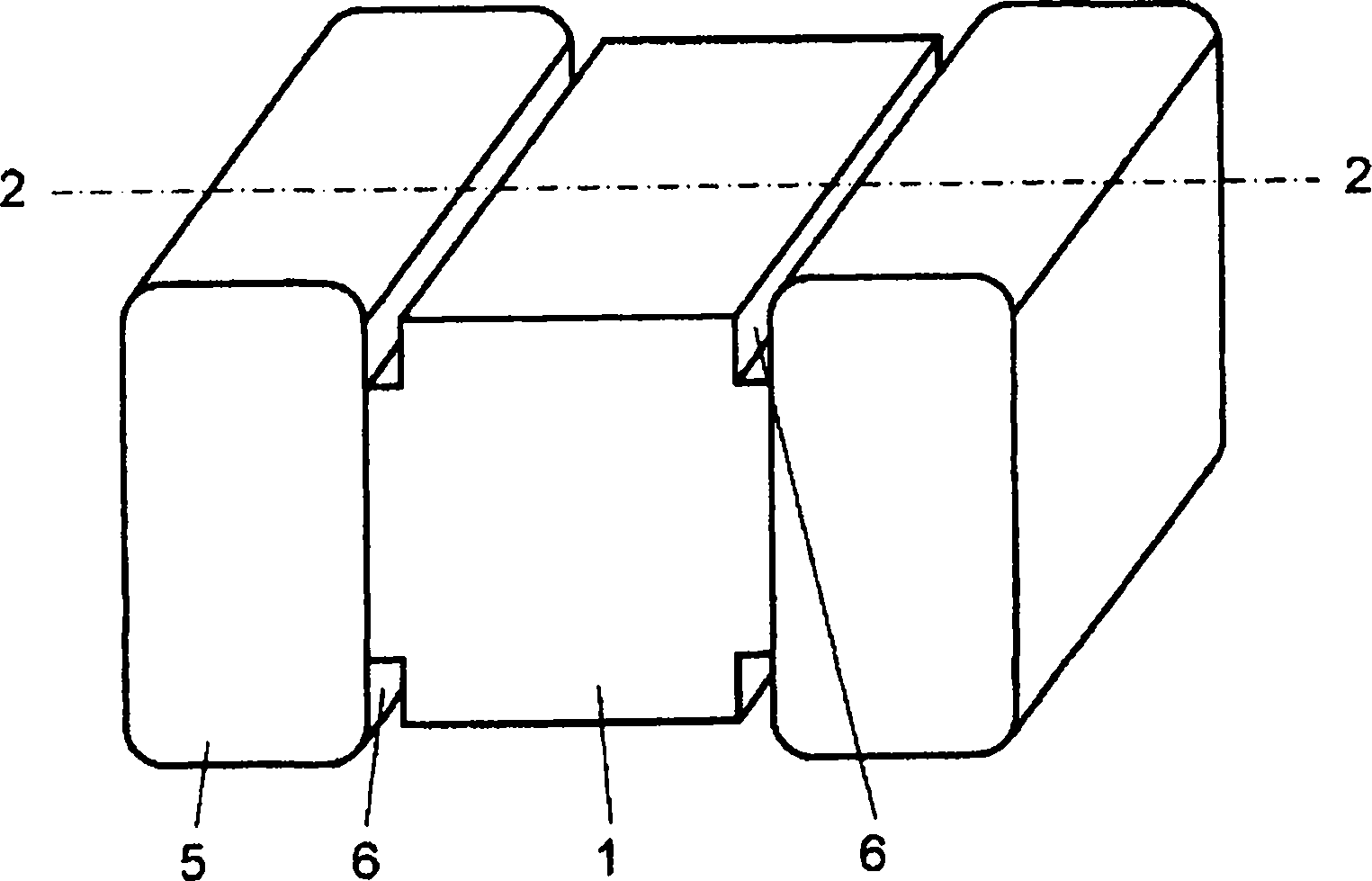

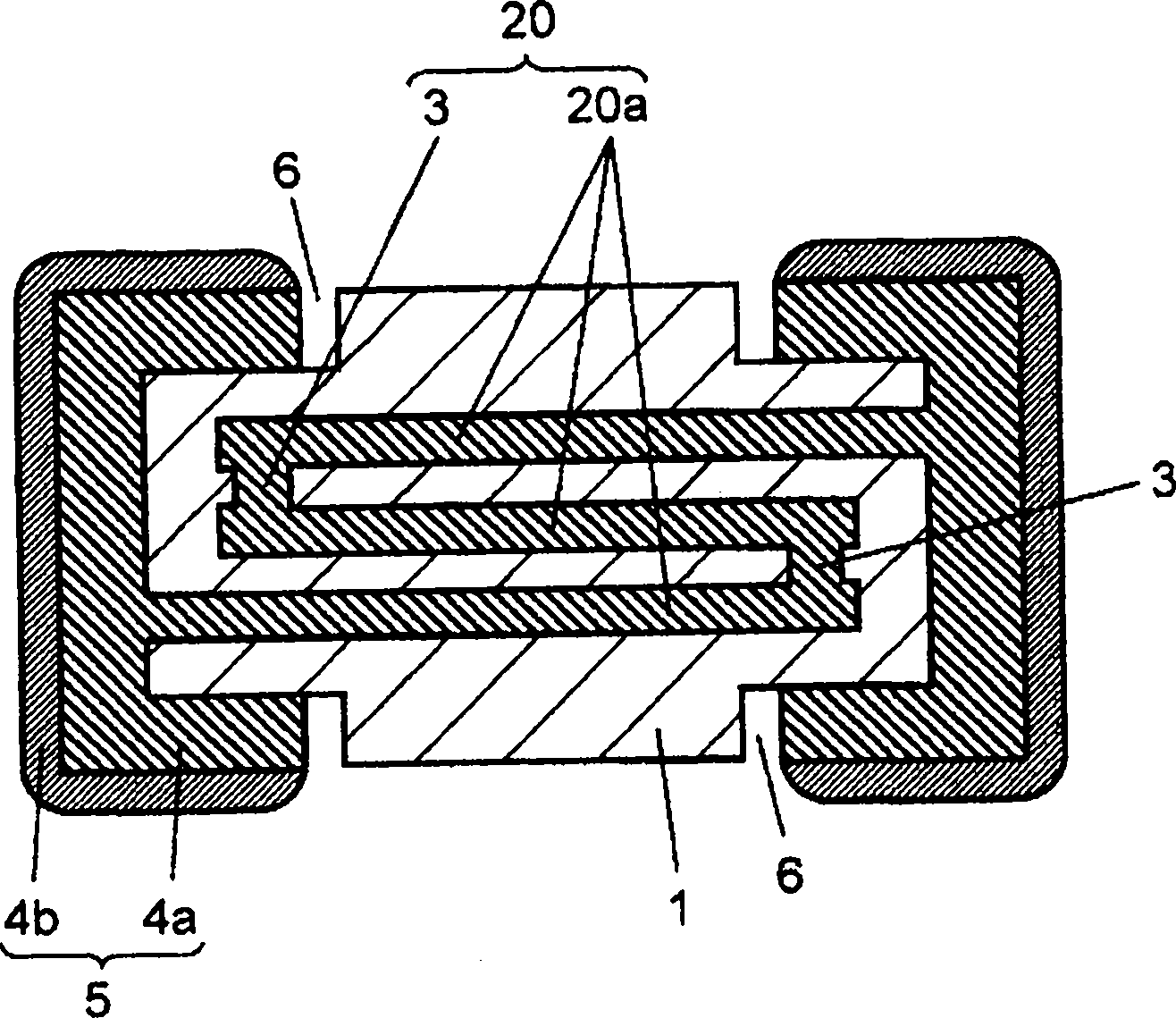

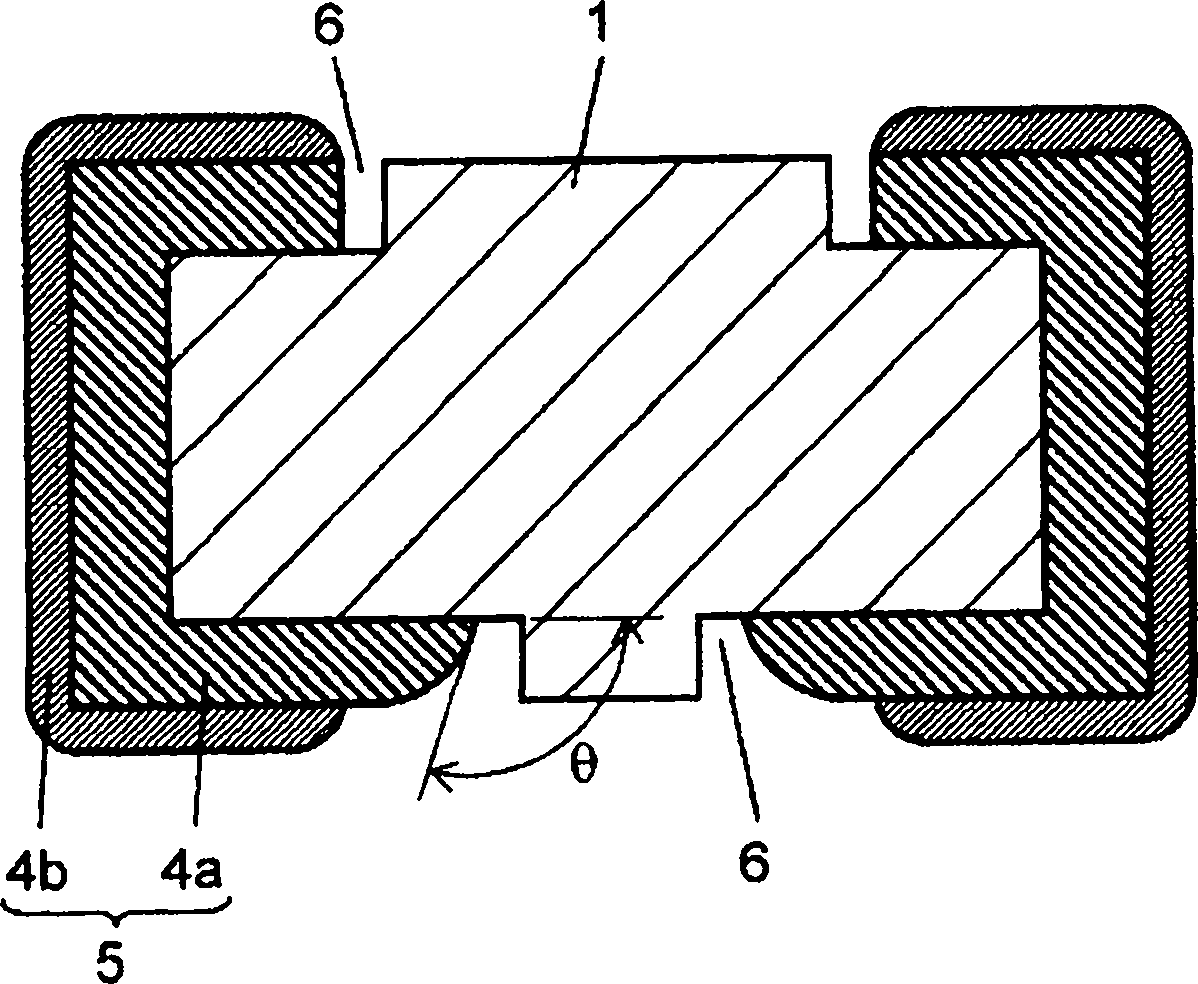

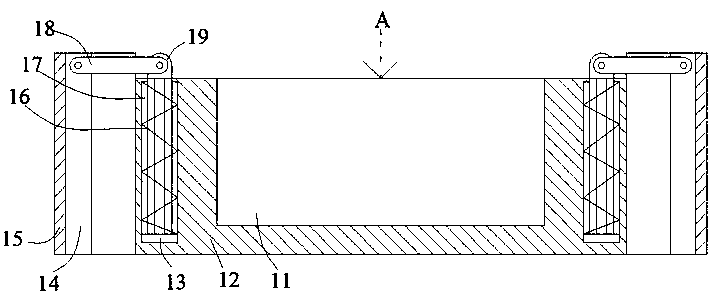

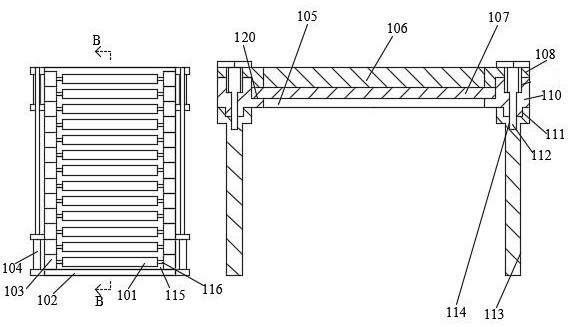

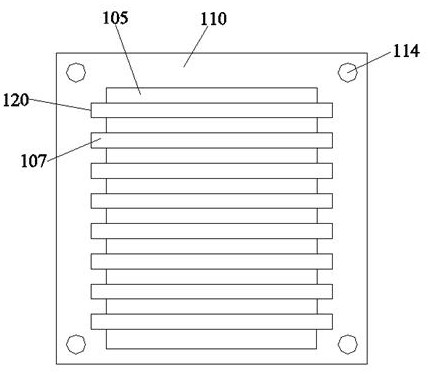

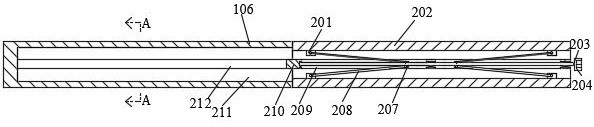

Inductive component and method for manufacturing the same

InactiveCN101842861BImprove practical reliabilitySuppress disconnectionCoils manufactureFixed signal inductancesElectricityThermal coefficient

An inductance component is disclosed. This inductance component includes base made of insulating material, coil section buried in base, and external electrode terminals electrically coupled to the ends of coil section. Stress buffering section is provided on the exposed interface between base and external electrode terminals, and this stress buffering section can ease the stress produced by the difference in thermal coefficients due to temperature changes. The foregoing structure thus allows improving the reliability of the inductance component with respect to a thermal shock.

Owner:PANASONIC CORP

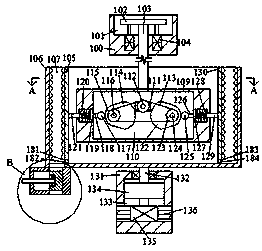

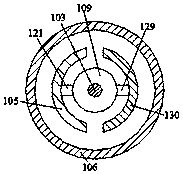

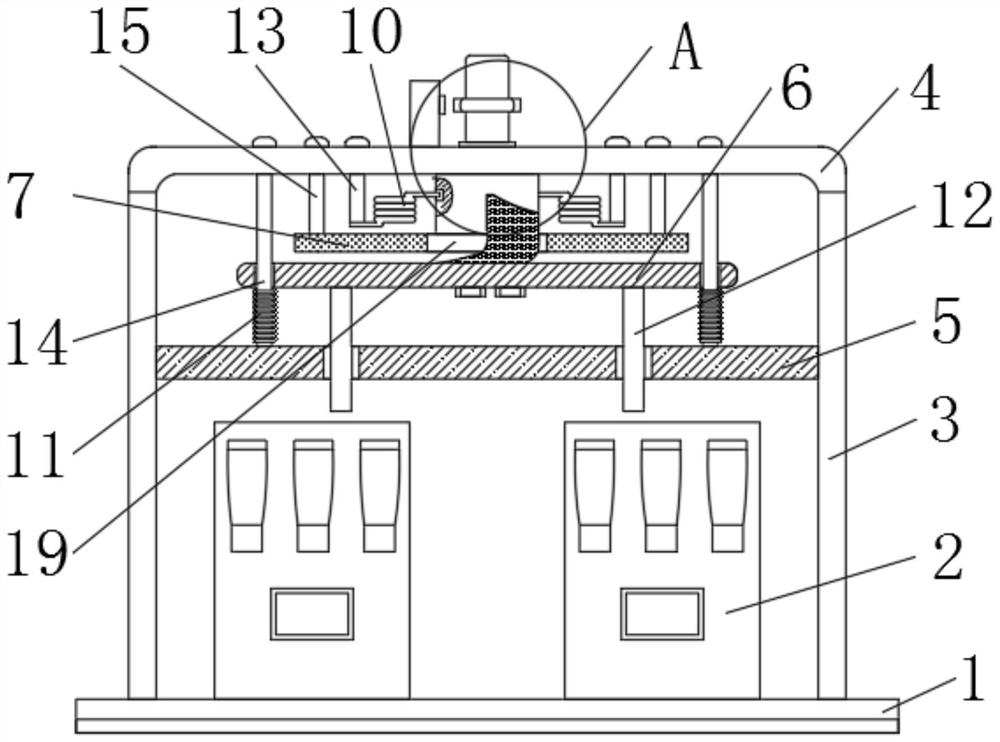

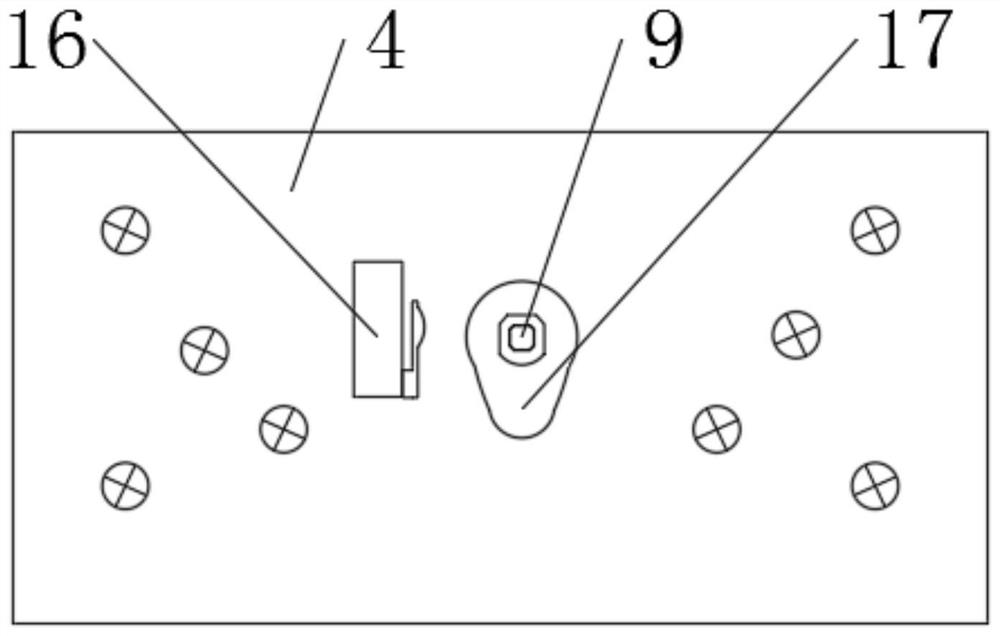

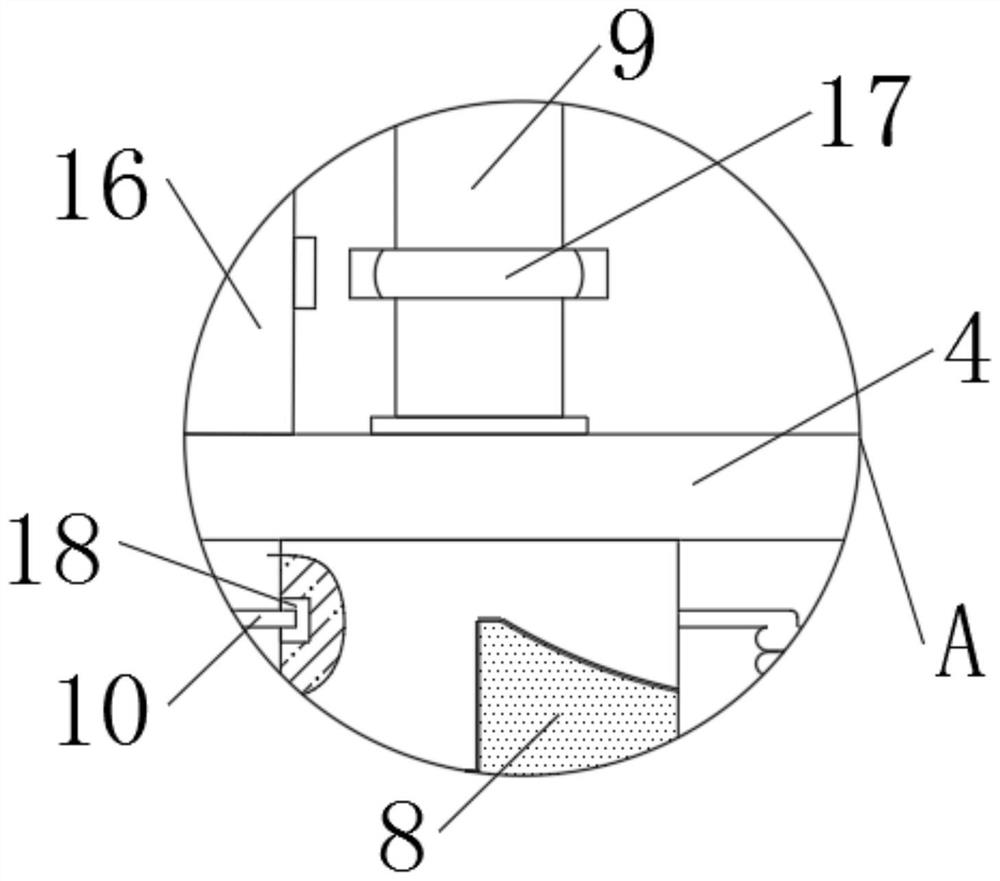

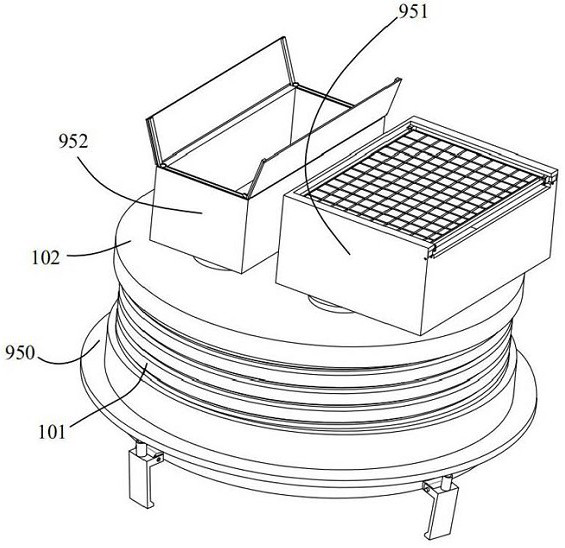

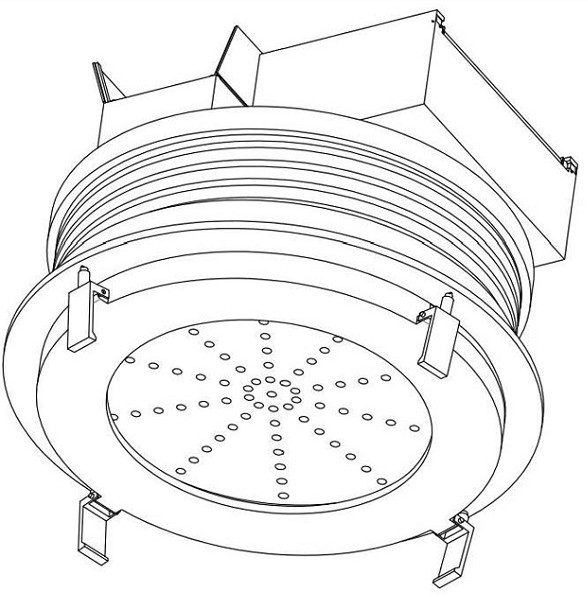

Organic fertilizer processing equipment

InactiveCN110256117AImprove shipping reliabilityGood effectClimate change adaptationExcrement fertilisersEngineeringOrganic fertilizer

The invention discloses organic fertilizer processing equipment. The equipment includes a box. A top cavity is arranged in the box. Symmetrical placement cavities are arranged in the upper end wall of the top cavity in a communicating manner. Symmetrical connection cavities are arranged in the lower end wall of the top cavity in a communicating manner. Storage cavities are arranged in the lower end walls of the connection cavities in a communicating manner. Material falling cavities are arranged in the lower end walls of the storage cavities in a communicating manner. The material falling cavities communicate with external space. A chopping device for pushing and chopping dried organic fertilizer is arranged in the top cavity. Granule forming devices for granulating the organic fertilizer are arranged in the storage cavities. The equipment of the invention is simple in structure, adopts a mode of efficiently cutting the dried organic fertilizer, and drives the organic fertilizer for granule forming operation by a group of motors, which greatly improves the forming effect of the dried organic fertilizer, is beneficial to the packaging and increases the transportation reliability of the granular organic fertilizer.

Owner:余杏花

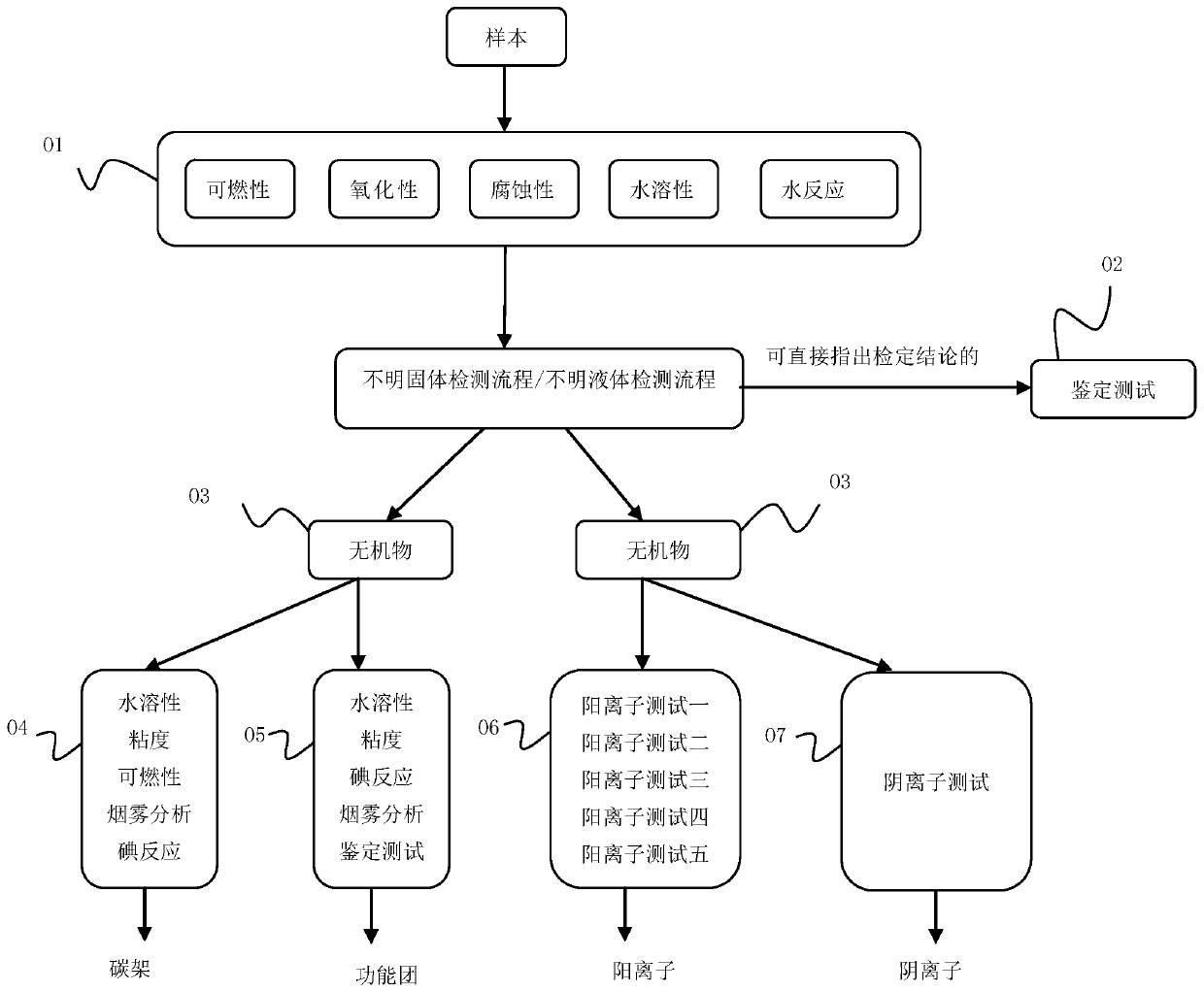

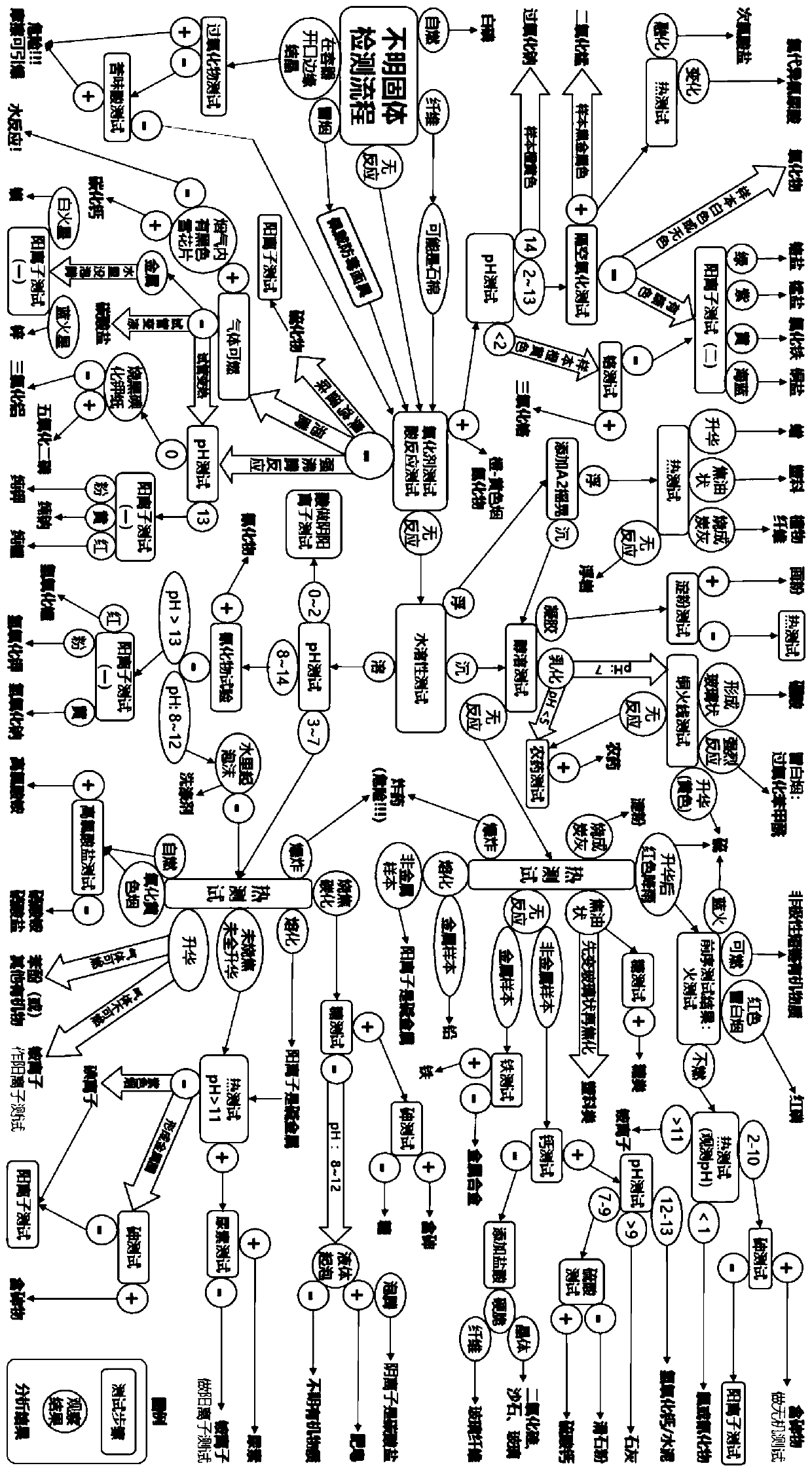

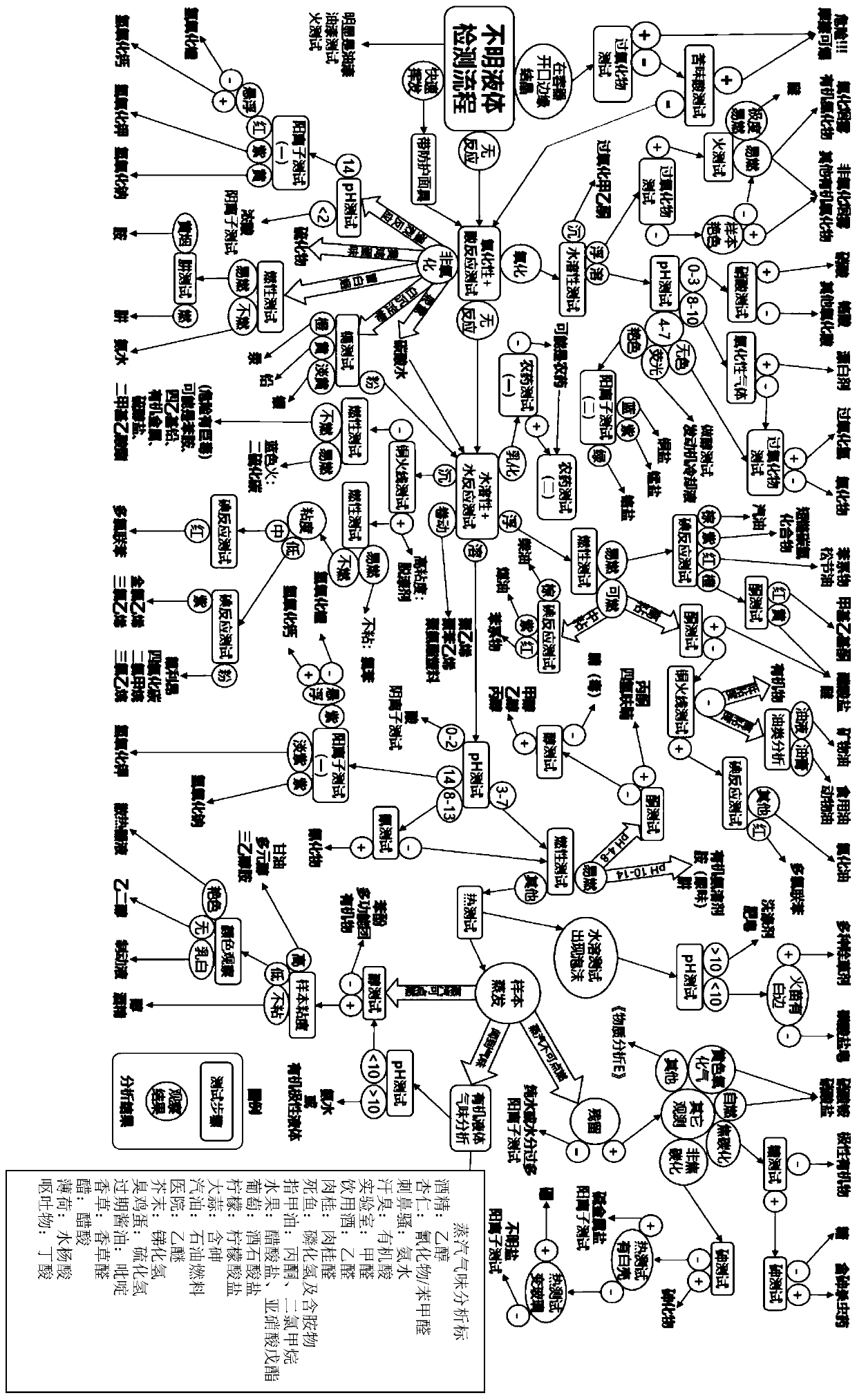

Small integrated dangerous chemical and waste classification and verification method and device

InactiveCN109991372AFully equippedEasy to carryMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsSolubilityWaste product

The invention provides a small integrated dangerous chemical and waste classification and verification method and device. According to the method, the using combustibility, oxidability, corrosivity, water solubility and water reaction of an unknown solid or unknown liquid are respectively tested, so as to judge the dangerous features of the unknown solid or unknown liquid; and classification is carried out according to the features, an unknown solid detection process is carried out on the unknown solid, and an unknown liquid detection process is carried out on the unknown liquid so as to complete the classification and verification operation. The device is a small and portable box designed on the basis of the method. The device is small, portable and high in flexibility; the method does not have requirement for the purity of samples; the verification is rapid; the cost is low; the practicability and reliability are high, the dangerous objects can be rapidly classified and treated, so that the practicability and professionality are strong, and the common technicians can familiarly use the device and the method through professional training; and the device and the method are suitablefor field emergency and field analysis.

Owner:陈曦

Chinese medicinal extracting device

InactiveCN108785086AImprove practicalityEasy maintenancePharmaceutical product form changeEngineeringSpeed regulator

The invention discloses a Chinese medicine extracting device, which comprises a container D fixedly arranged on the ground. An electric cavity is arranged in the container D, a driving machine B is fixedly arranged in the lower end wall of the electric cavity, the power shaft of the driving machine B is in power connection with a speed regulator arranged in the electric cavity, the upper end surface of the speed regulator is in power connection with a rotating rod E which can rotatably pass through the upper end wall of the electric cavity and extends out to the external space. The upper end surface of the rotating rod E is connected with a container B, and the container B is internally provided with a discharging groove B with an upward opening, and the lower end wall of the discharging groove B is provided with an air opening communicating with the external space. The device has the advantages of simple structure and convenient use, and the device uses a mode of simultaneous workingof grinding and pulverizing to achieve the extraction of the Chinese medicine, thereby achieving one of the processes in the Chinese medicine extraction technology, and the practical reliability of the device is effectively improved.

Owner:珠海句宸光电科技有限公司

Compact processing molding technology for biomass solid fuel

InactiveCN108559565AImprove practicalityEasy maintenanceSolid fuelsWaste based fuelSolid fuelEngineering

The invention discloses a compact processing molding technology for biomass solid fuel. The technology involves a box body D fixedly arranged on the ground, the box body D is internally provided witha power cavity, the lower end wall of the power cavity is internally fixedly provided with a motor B, an output shaft of the motor B is dynamically connected with a reducer arranged in the power cavity, the upper end face of the reducer is dynamically connected with a fixing shaft E, the fixing shaft E rotationally passes through the upper end wall of the power cavity and extends out of external space, the upper end face of the fixing shaft E is dynamically connected with a box body B, the box body B is internally provided with an opening cavity B with an upward opening, and the lower end wallof the opening cavity B is provided with an opening communicated with the external space. The compact processing molding technology for the biomass solid fuel has the advantages that the structure issimple, the use is convenient, grinding and extrusion are simultaneously adopted to achieve the compact processing of biomass solid residues, thereby achieving one of the processes of the compact processing molding technology of the biomass solid fuel, and effectively improving the practical reliability of equipment.

Owner:广州一恒科技有限公司

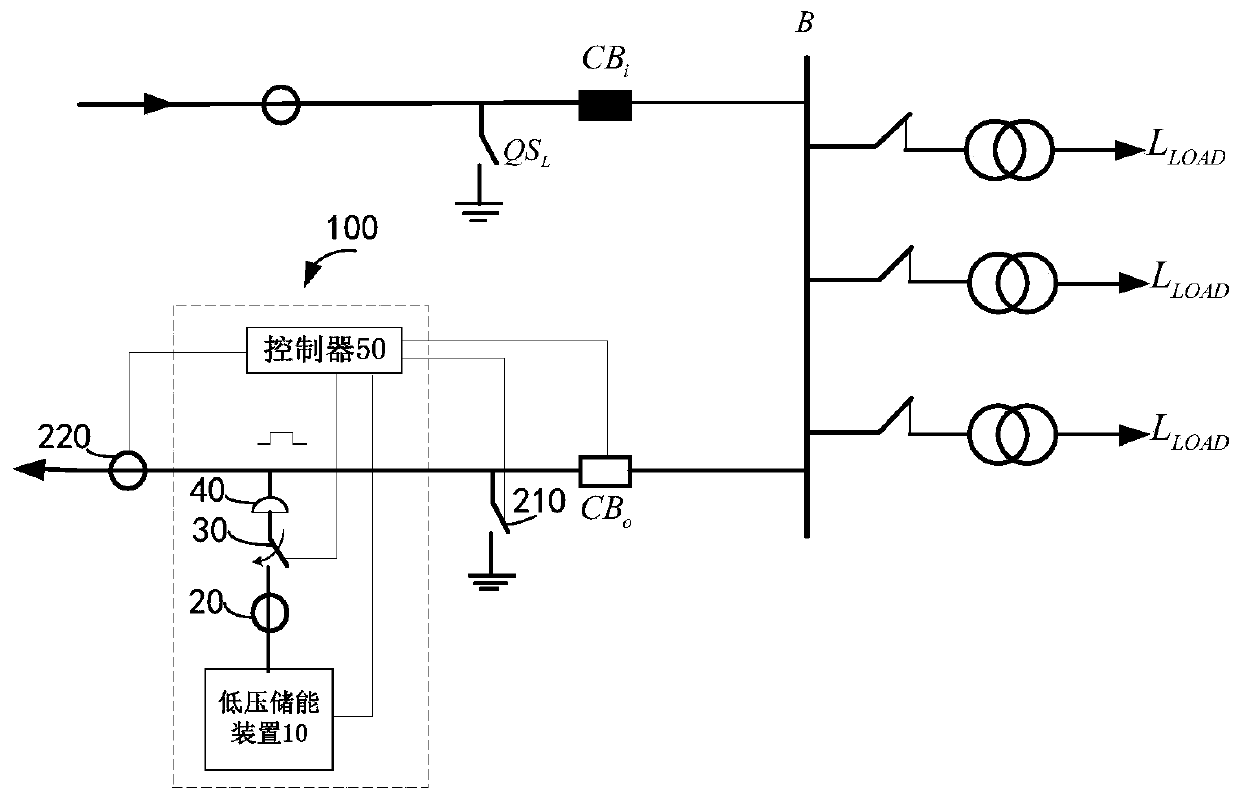

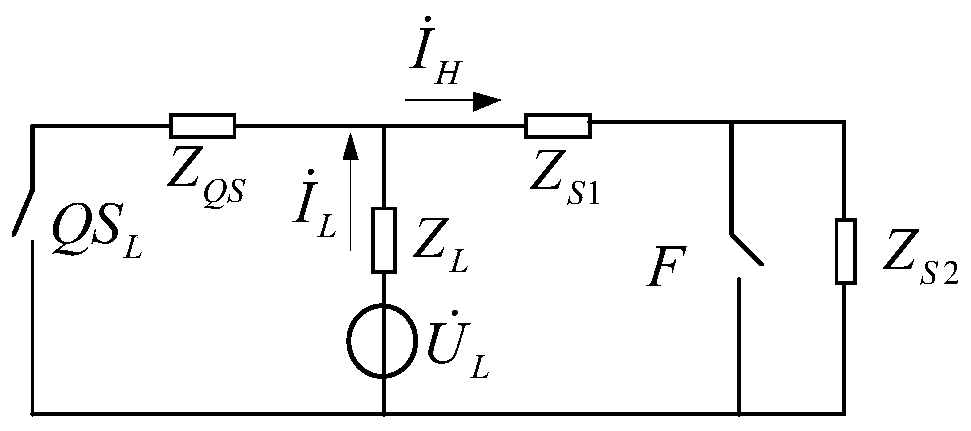

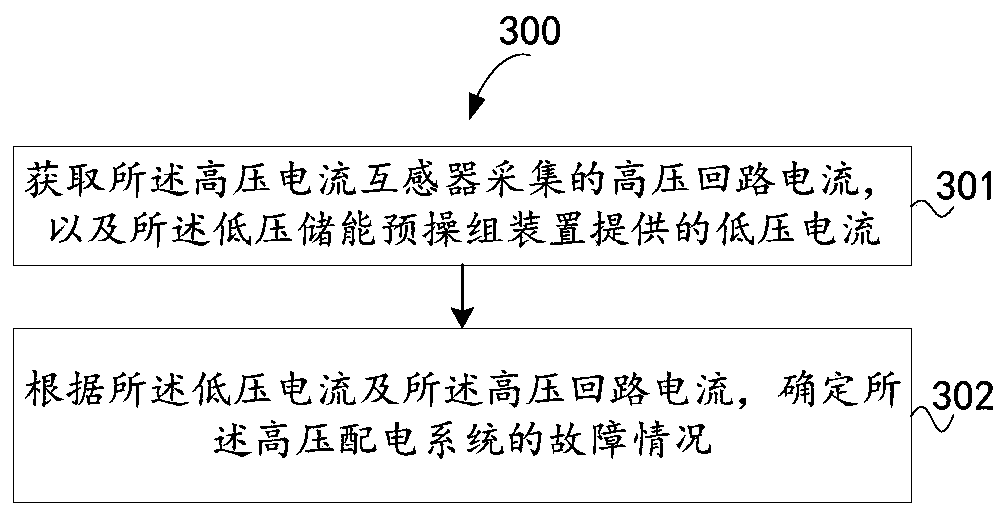

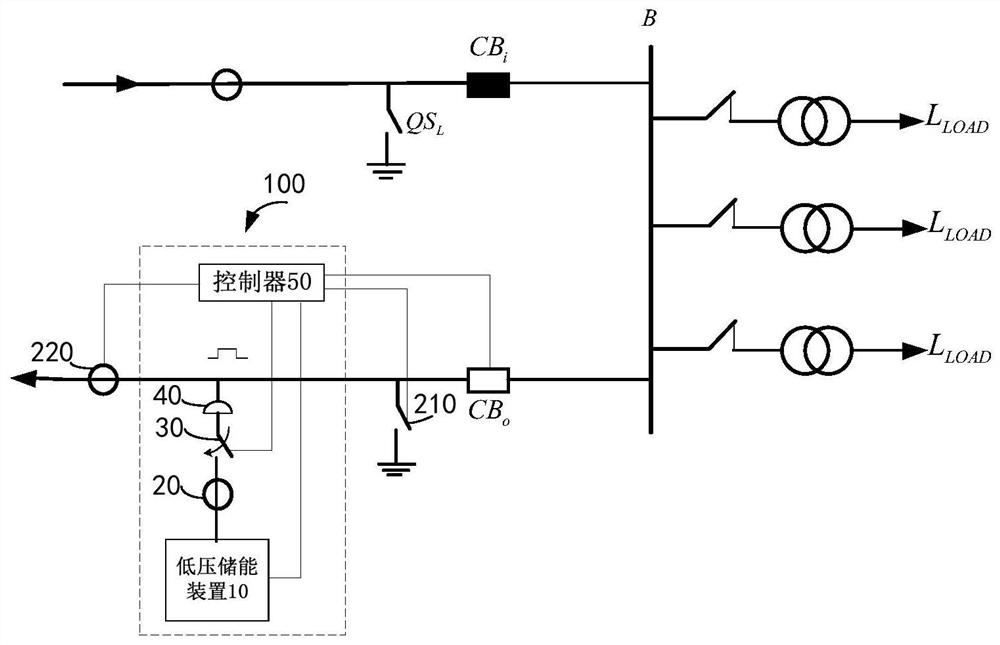

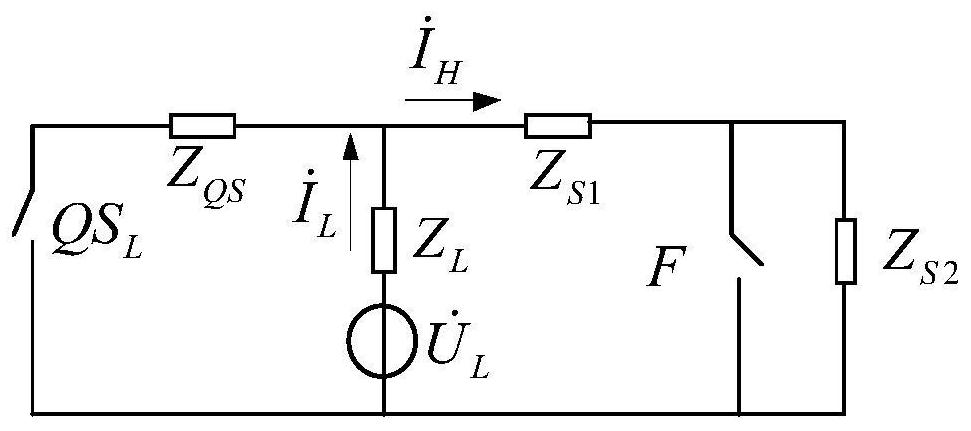

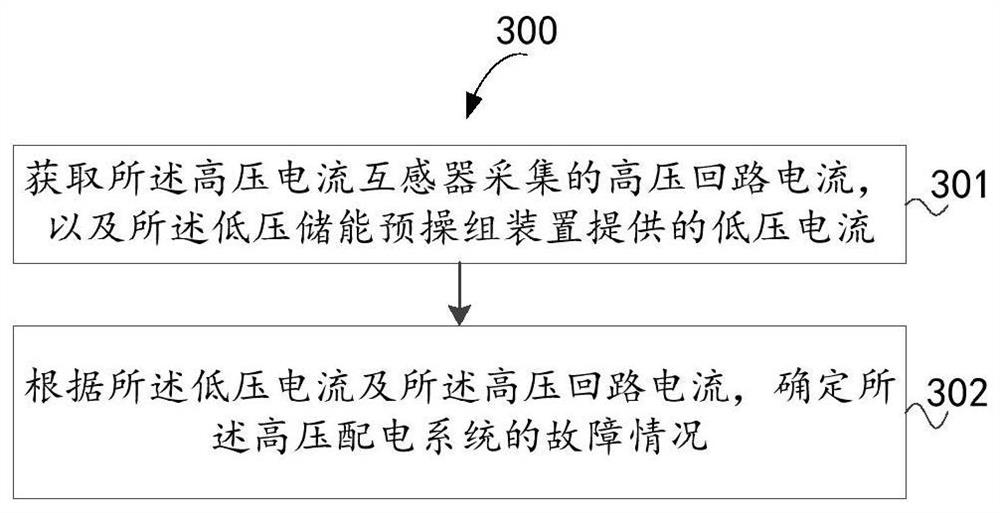

Fault detection method, low-voltage energy storage pre-operation group device and system, and controller

ActiveCN111123031AImprove practical reliabilityAccurate and reliable fault state detectionEmergency protective circuit arrangementsFault location by conductor typesLow voltageControl theory

The invention relates to the technical field of fault detection, in particular to a fault detection method based on a low-voltage energy storage pre-operation group device, a low-voltage energy storage pre-operation group device and system, and a controller. The fault detection method based on the low-voltage energy storage pre-operation group device comprises the steps that: high-voltage loop currents collected by a high-voltage current transformer and low-voltage currents provided by a low-voltage energy storage pre-operation group device are acquired, and then the fault condition of a high-voltage power distribution system is determined according to the low-voltage currents and the high-voltage loop currents. Therefore, before the high-voltage power distribution system is operated, thelow-voltage energy storage pre-operation group device performs fault detection on the high-voltage power distribution system, so that the fault state detection is accurate and reliable, and the practical operation reliability of the high-voltage power distribution system is further improved.

Owner:YICHANG POWER SUPPLY CO OF STATE GRID HUBEI ELECTRIC POWER CO LTD +1

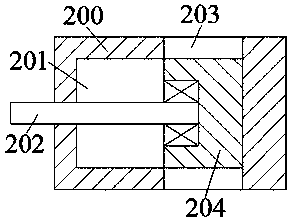

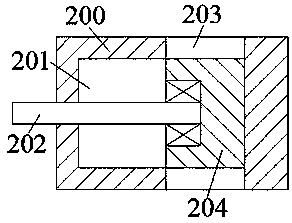

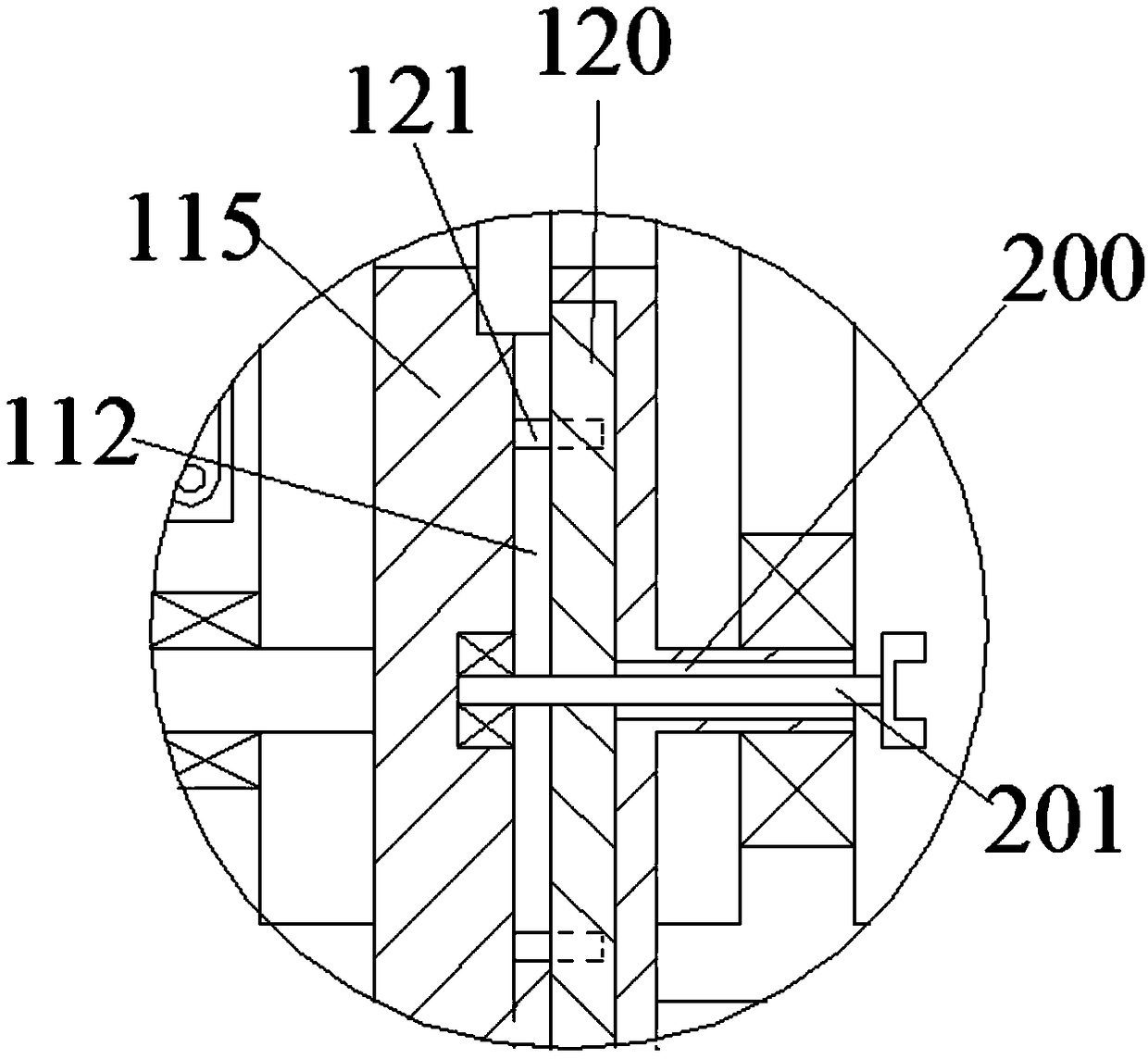

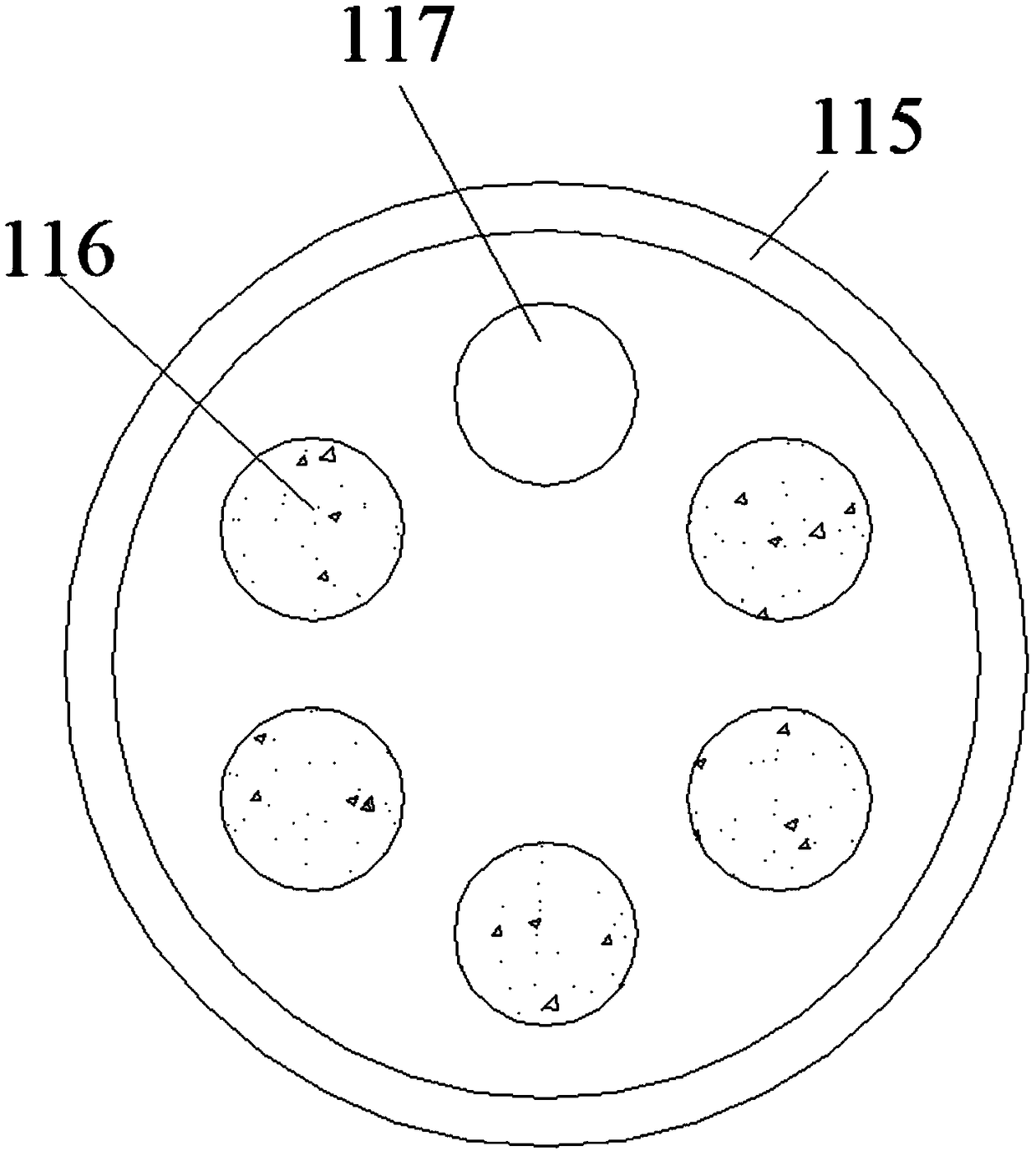

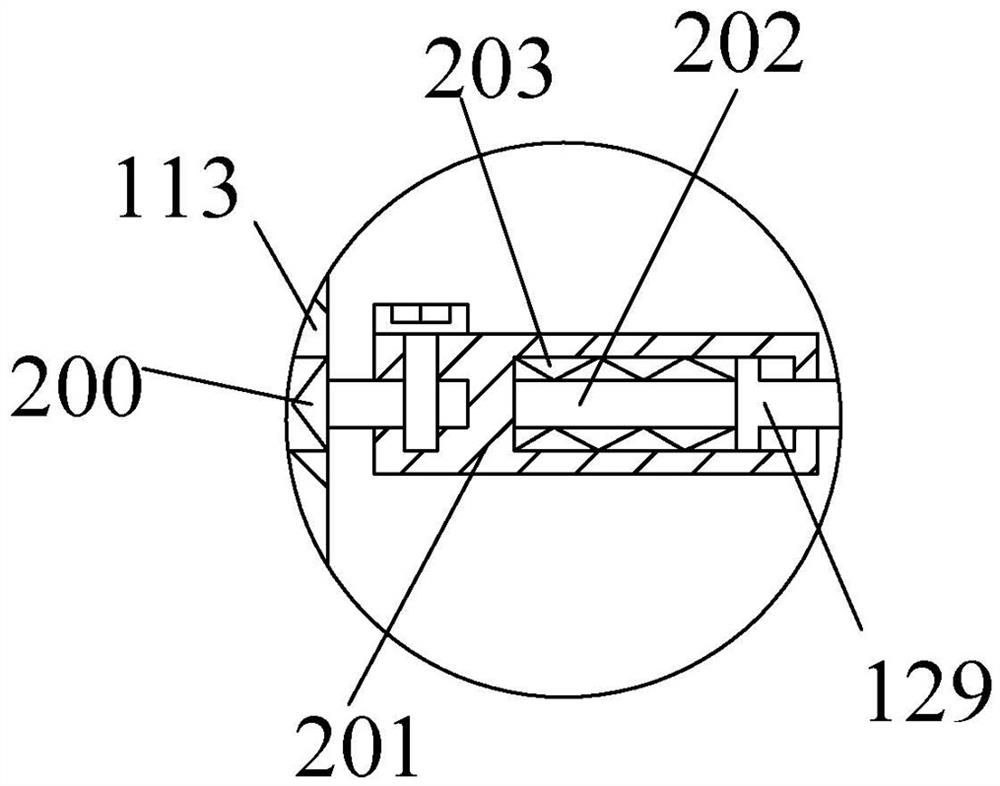

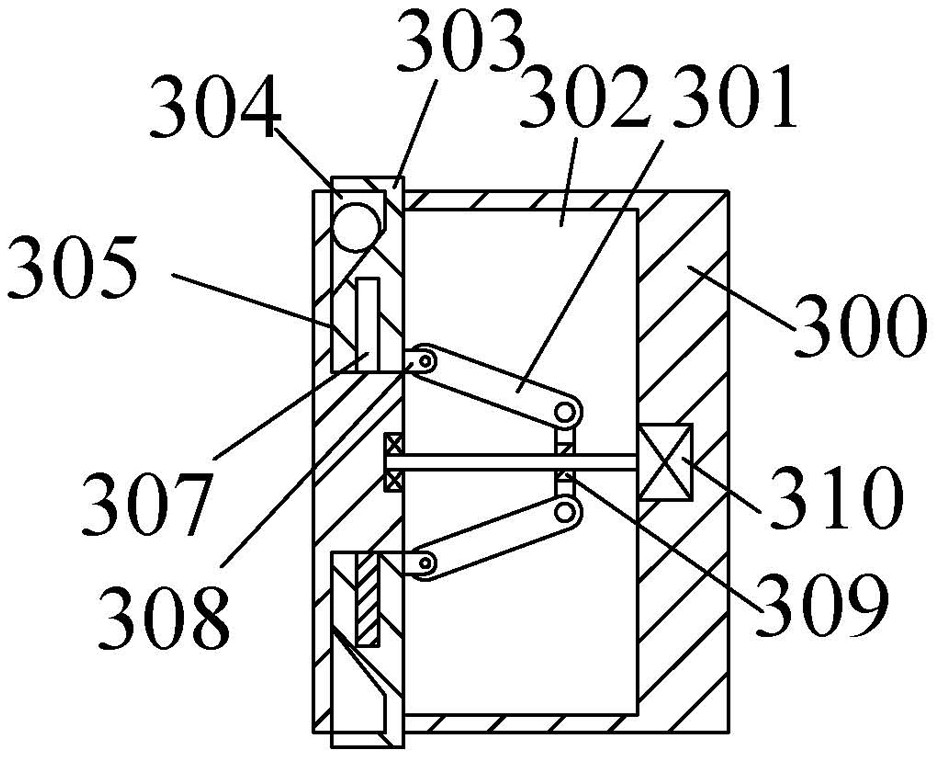

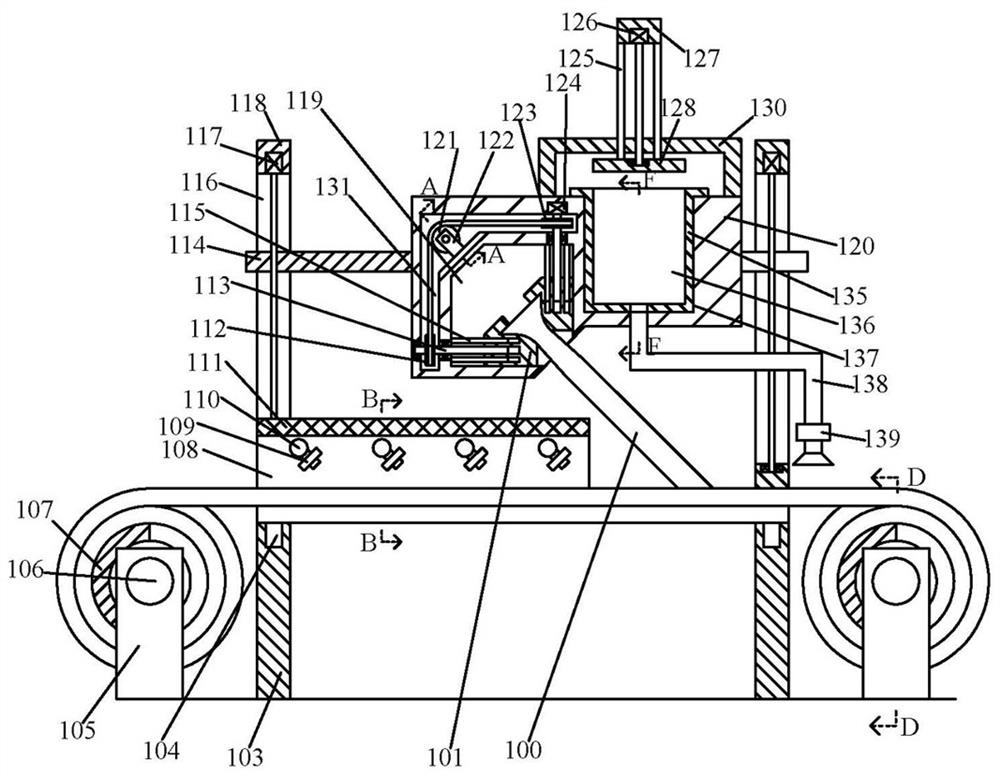

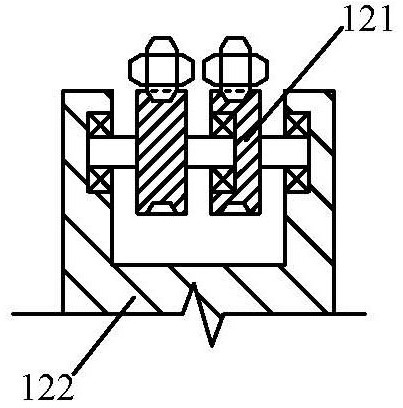

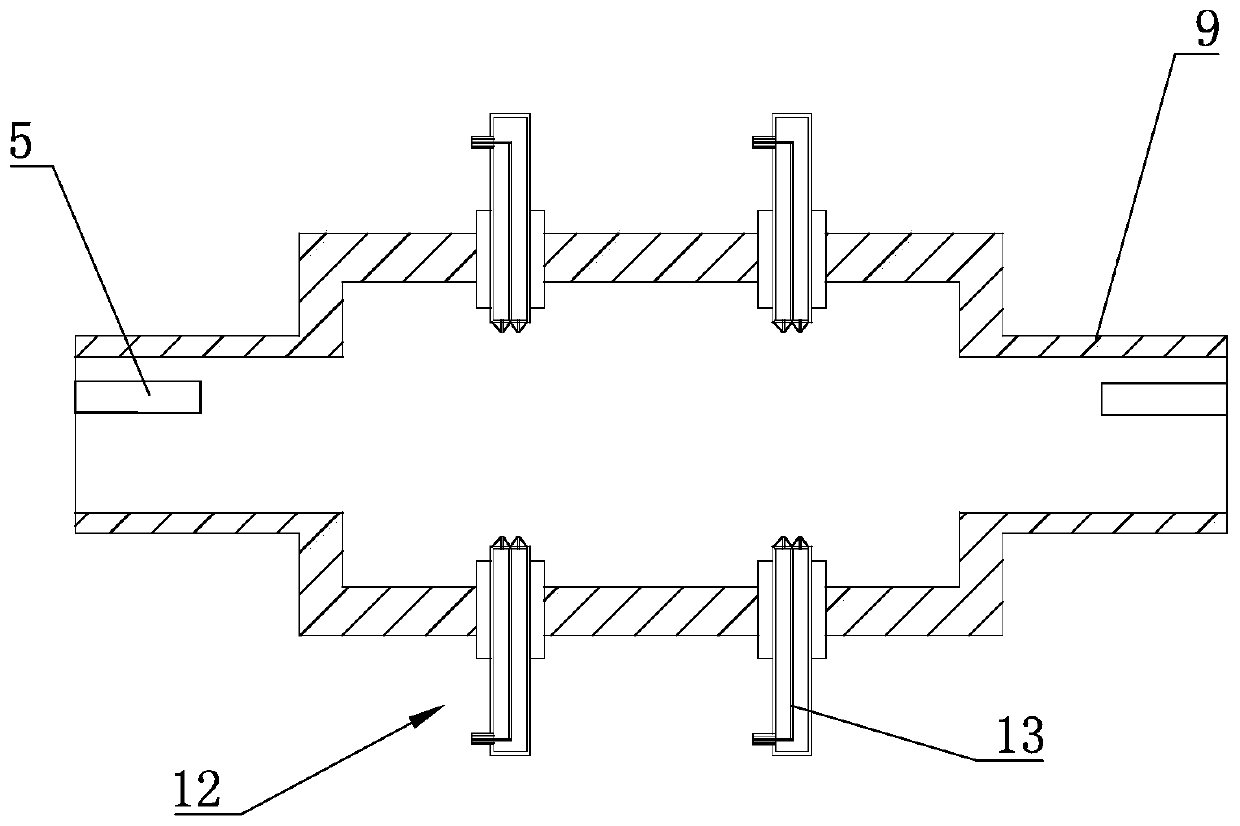

Manual operation linkage mechanism of alternating current contactor

PendingCN113421785AImprove utilization efficiencyImprove practical reliabilityContact operating partsControl engineeringProcess engineering

The invention provides a manual operation linkage mechanism of an alternating current contactor, and relates to the technical field of alternating current contactors. The manual operation linkage mechanism of the alternating current contactor comprises a bottom plate, wherein a contactor body is fixedly arranged at the upper end of the bottom plate, supporting plates are fixedly arranged on the two sides of the upper end of the bottom plate, a shell is fixedly arranged at the upper ends of the two supporting plates, four first supporting columns are fixedly connected to the lower end of the shell, the lower ends of the four first supporting columns are fixedly connected with a partition plate, the lower end of the shell is fixedly connected with two second supporting columns, and the lower ends of the two second supporting columns are fixedly connected with a fixing plate. According to the manual operation linkage mechanism of the alternating current contactor provided by the invention, the comprehensive utilization efficiency of components is improved by optimizing and integrating elements of an existing control cabinet, manual control is realized without additionally arranging the components, the practical reliability of complete equipment is improved, and the production cost of an enterprise is greatly reduced.

Owner:浙江博信电气有限公司

Fault detection method, low-voltage energy storage pre-operation device, controller and system

ActiveCN111123031BImprove practical reliabilityAccurate and reliable fault state detectionEmergency protective circuit arrangementsFault location by conductor typesLow voltageVoltage loop

The invention relates to the technical field of fault detection, in particular to a fault detection method based on a low-voltage energy storage pre-operation group device, a low-voltage energy storage pre-operation group device, a controller and a system. Among them, the fault detection method based on the low-voltage energy storage pre-operation group device includes first obtaining the high-voltage loop current collected by the high-voltage current transformer and the low-voltage current provided by the low-voltage energy storage pre-operation device, and then determining the high-voltage current according to the low-voltage current and the high-voltage loop current. Fault conditions in the power distribution system. Therefore, before the high-voltage power distribution system is operated, the low-voltage energy storage pre-operation group device detects the faults of the high-voltage power distribution system, and the fault state detection is accurate and reliable, thereby improving the reliability of the high-voltage power distribution system.

Owner:YICHANG POWER SUPPLY CO OF STATE GRID HUBEI ELECTRIC POWER CO LTD +1

Storage frame

ActiveCN111591552AEasy to placeSimple structureInternal fittingsStructural engineeringMechanical engineering

Owner:义乌市牵手电子商务有限公司

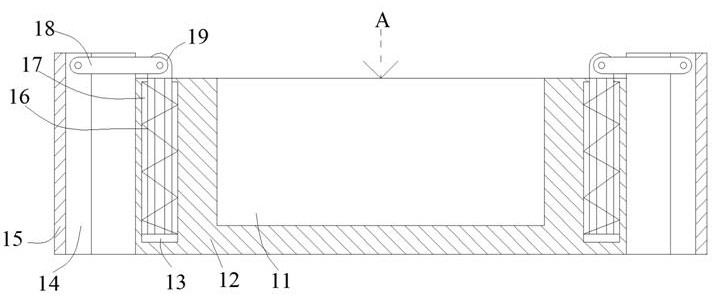

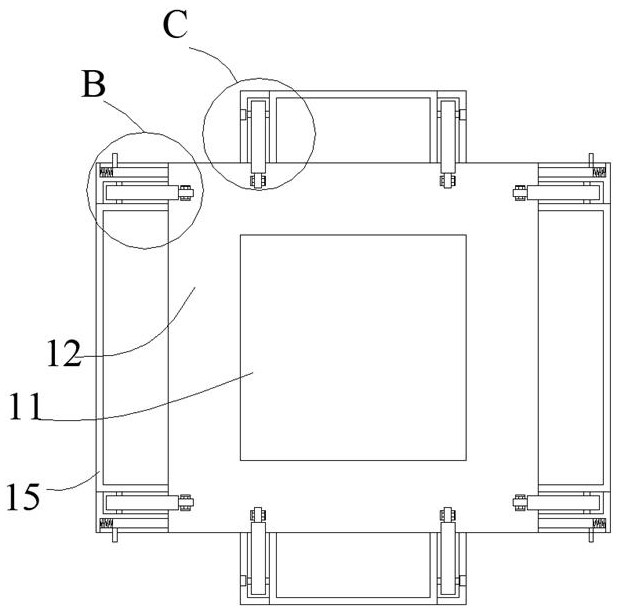

Building steel structure suspension device

Owner:SUZHOU WEIZHONG TECH DEV CO LTD

A car beauty grinding equipment

ActiveCN111571390BEasy to holdEasy to hold and useGrinding wheel securing apparatusPortable grinding machinesAutomotive paintPolishing

The invention discloses a car beauty and polishing equipment, which comprises a side swing rod, an open placement inner cavity is arranged in the side swing rod, and a grip that can be unfolded to form a grip is arranged in the placement inner cavity, which is convenient for people to hold and use. The handle device, one side of the side swing lever is provided with an extended locking device that uses threaded fit to lock the grip device and extend the length of the equipment, and the other end of the side swing lever is provided with a multi-angle adjustment and realizes the motor to provide power The polishing device for fully polishing the paint surface of the car. The device of the present invention has a simple structure. The device adopts a design that is convenient for folding and unfolding the handle structure, which makes it easy for personnel to hold and use the device. At the same time, the way of friction back and forth is used to save manpower, and The use of a convenient way to install friction pads increases the grinding efficiency of the equipment, and it can efficiently grind deep and vertical areas during grinding, improving the practical reliability of the equipment.

Owner:HEFEI XIAKANG ELECTRONICS COMMERCE CO LTD

Liquid delivery equipment for textile industry

InactiveCN110791906ARealize the delivery functionSimple structureTransportation and packagingMixersThin membraneEngineering

The invention discloses liquid delivery equipment for textile industry, which comprises a box body, a liquid storage device and an electronic valve device; a storage cavity with an upward opening is fixedly arranged in the box body; the upper end face of the box body is fixedly fitly connected with a cover box through bolts; an inner open cavity with a downward opening is fixedly arranged in the cover box and is communicated with the storage cavity; circular clamping cavities in circular arrangement are arranged in the end walls of the inner open cavity and the storage cavity in communicated manner; and a circular base plate which is circularly arranged is arranged in the end wall of the circular clamping cavities. The liquid delivery equipment for textile industry for textile industry hassimple structure and is convenient to operate; an acidic or alkaline solution is pumped out of an external space under the driving of a corresponding structure by using a thin film between a bottom fixing plate and a circular bar; the liquid storage device is used for blending the acidic solution or alkaline solution; the electronic valve device is used for controlling flowing of a liquid, so that an acidic or alkaline solution delivery function of the equipment is achieved, and practical reliability of the equipment is further improved.

Owner:杭州衣变服饰有限公司

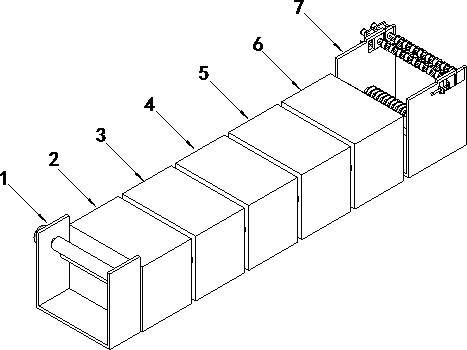

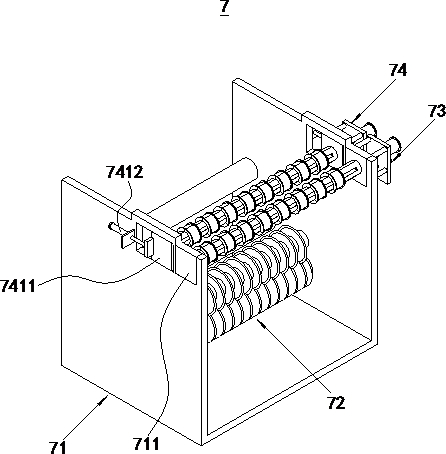

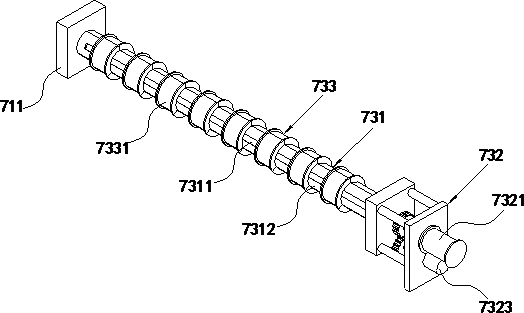

Colored alumite production line

PendingCN114506711AAchieve positioningPrecise positioningArticle deliveryWebs handlingProduction lineInformation layer

The invention relates to the technical field of alumite production and processing, in particular to a colored alumite production line which comprises an unwinding device, a separation layer coating device, an information layer coating device, a holographic mold pressing device, a vacuum aluminum plating device, an adhesive layer coating device and a slitting winding device which are connected in sequence. The slitting and winding device comprises a rack, and a slitting mechanism, a first winding mechanism and a second winding mechanism which are arranged on the rack; the first winding mechanism comprises a first winding shaft, a first driving assembly and a plurality of first mounting assemblies; a first ring groove for winding an alumite film is formed in the peripheral side of each first mounting assembly; the second winding mechanism comprises a transverse moving assembly, a second winding shaft, a second driving assembly and a plurality of second mounting assemblies, second annular grooves used for winding the alumite films are formed in the peripheral sides of the second mounting assemblies, the colored alumite production line can conveniently position the slit alumite films during slitting and winding, and the use reliability is improved.

Owner:YANGZHOU XIANGHUA NEW MATERIAL TECH CO LTD

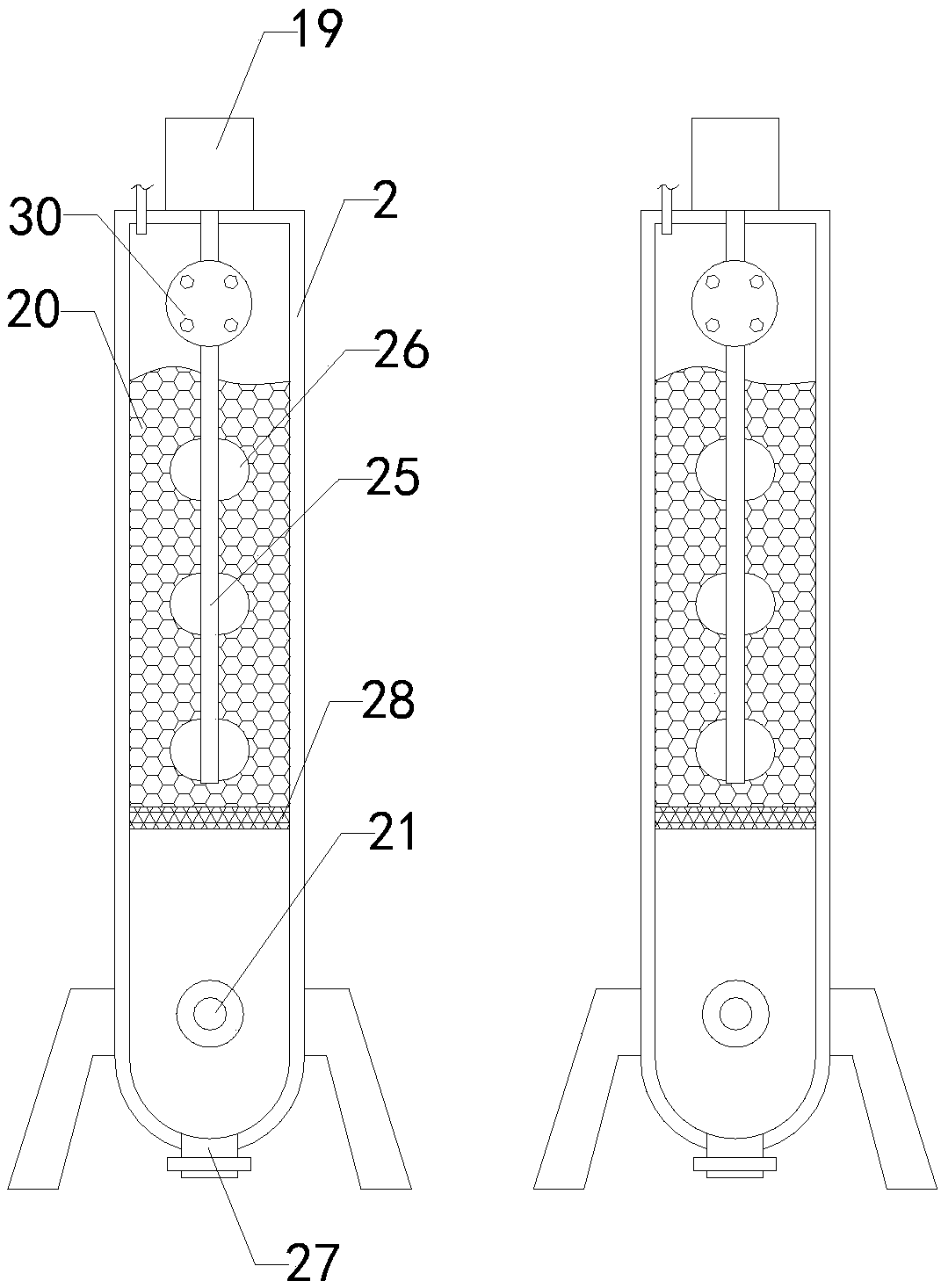

outdoor water filter

ActiveCN110790326BRealize secure card loadingEasy maintenanceSpecific water treatment objectivesTreatment involving filtrationWater filterPotable water

The invention discloses an outdoor water filtering device, the structure of which comprises a cylinder, and the cylinder is provided with a clamping bottle mouth device for matching with a general bottle mouth and for filtering water and liquid. The cylinder The upper end surface is fixed with a top cover, and the upper end surface of the top cover is provided with a preliminary filter device for preliminary filtering of the water liquid. The left side of the preliminary filter device is provided with a water liquid introduction device for directly introducing the water liquid into the equipment. Adopting the design of the clamping bottle mouth device, preliminary filtering device and water liquid introduction device, the equipment and the bottle mouth can be firmly installed and the water liquid can be fully filtered by various filtering methods to provide personnel with cleaner drinking At the same time, the smart structure is adopted to make the equipment easy to maintain and replace related parts.

Owner:泗阳康发电子有限公司

A kind of building steel structure suspension equipment

ActiveCN110230411BAvoid breakingEasy to carryShaping building partsArchitectural engineeringOpen cavity

The invention discloses a building steel structure suspension equipment, comprising a support frame, an open cavity is arranged inside the support frame, an inner cavity is connected to the lower end wall of the cavity, and an inner cavity is arranged on the lower end surface of the support frame. Left and right symmetrical supporting feet, the supporting feet are provided with an open matching cavity, and the lower end wall of the matching cavity is connected with a matching screw hole, and the supporting frame is connected with the matching cavity by clamping and fitting. A number of support cylinders are installed in the cavity, and the upper end of the support cylinder is provided with a flat plate device for unfolding to form a tiled structure. The upper end of the support frame is fixed with a cover plate. The structure of the device of the present invention is simple. The structure of flat device and ladder device is adopted, so that the equipment can be easily disassembled and quickly unfolded, so that the equipment can be easily carried, and at the same time, it can also be convenient for personnel to carry items to high places, and has the characteristics of convenient use by personnel. , which greatly improves the practical reliability of the equipment.

Owner:SUZHOU WEIZHONG TECH DEV CO LTD

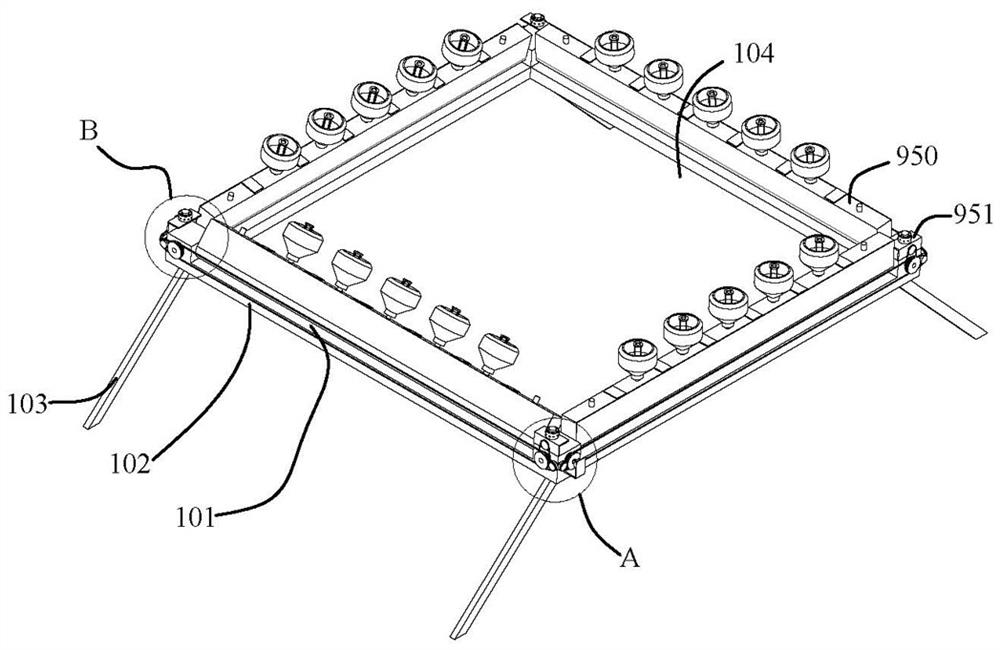

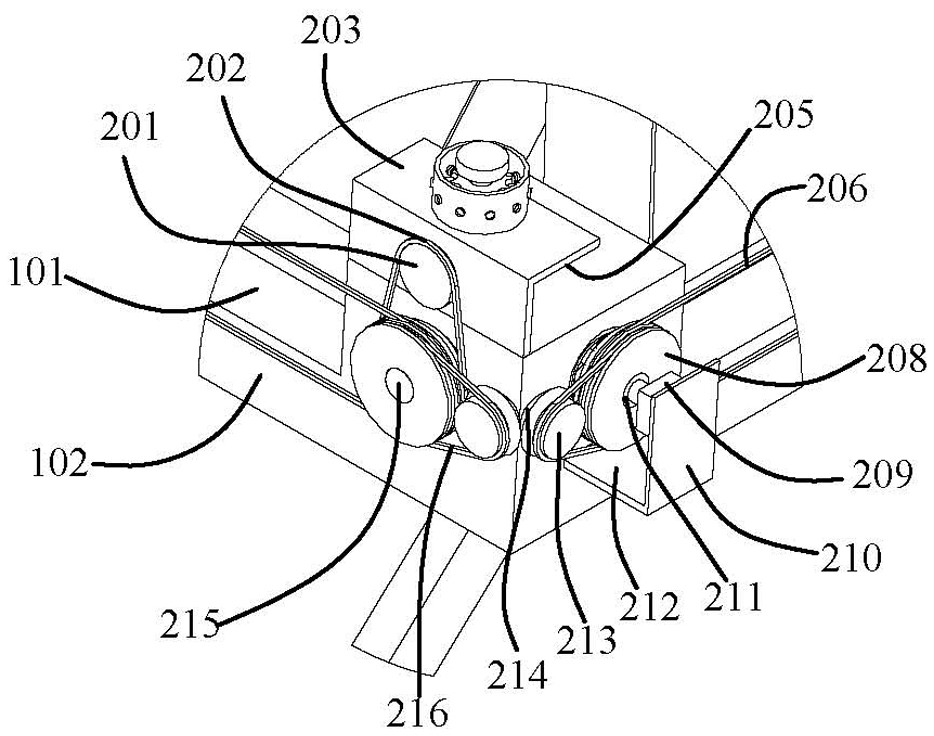

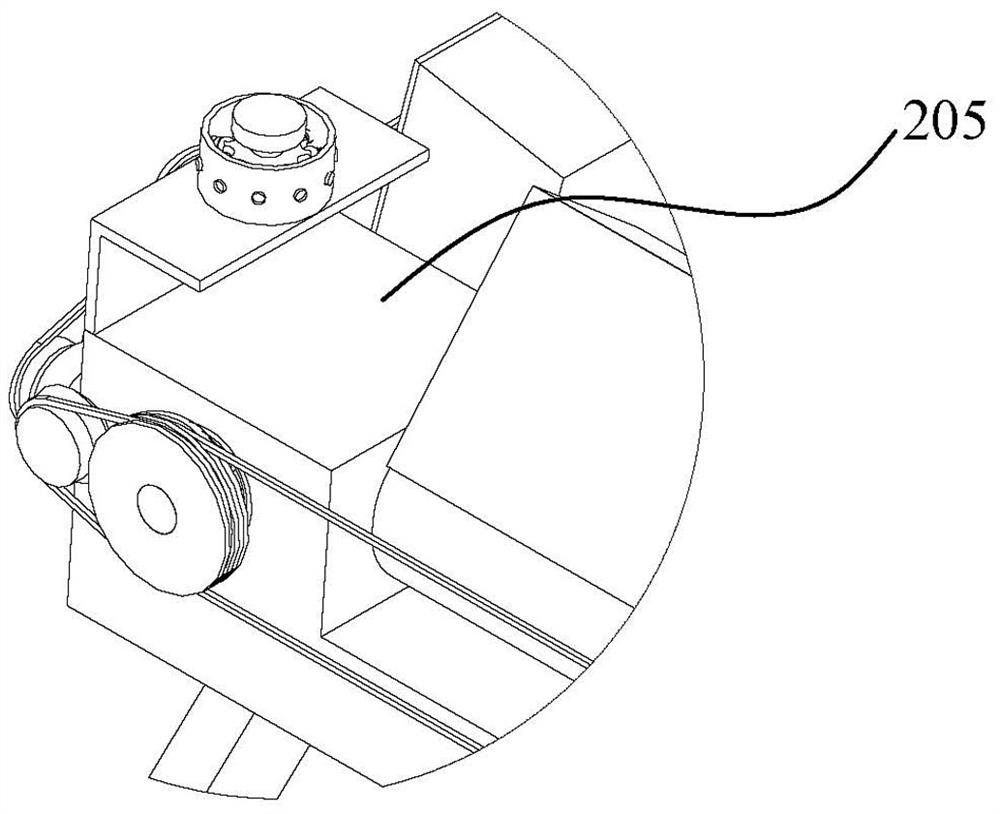

A kind of outdoor equipment

ActiveCN110916531BImprove the heating effectEasy to heat and cookFood scienceStructural engineeringFood material

The invention discloses outdoor article equipment. The outdoor article equipment structurally comprises frame type brackets, a plurality of opened inner cavities are formed in the brackets; the numberof the inner cavities is at least four. A plurality of supporting legs are fixedly arranged on the lower end faces of the brackets. Vertically-through containing cavities are formed in the support. Aplacing and rotating device for conveniently processing kebabs in batches is arranged between the brackets; the two sides of the inner cavities are provided with adjusting transmission devices whichare located in the brackets and can adjust the angle of the containing rotating device and rotate kebabs. The design of the placing rotating device and the adjusting transmission device is adopted, sothat the equipment can be stably supported to heat cooking food materials, meanwhile, the structure of the equipment can be adjusted, kebabs can be located at the optimal heating angle, the kebabs can rotate by themselves, and the cooking effect and the heating quality are improved.

Owner:济宁高新产业园运营管理有限公司

Automatic indicator lamp with different replaceable patterns

Owner:深圳市得润光学有限公司

a storage box

ActiveCN111591552BEasy to placeSimple structureInternal fittingsClassical mechanicsStructural engineering

The present invention discloses a packed box, including the bottom box, which has an open -mouth internal cavity in the bottom box.There are four number of sets setting in the container, and the setting between the side sliding box and the bottom box is used to expand the original area of the bottom box and can expand the height of the bottom box to meet the loading occupation.The large -scale objects and the telescopic installation device of the high height of the height, the device of the present invention is simple. This equipment uses a lifting and slippery method to enable the device to have the function of expansion and folding, Also use the deformation of the equipment to make the device switch back and forth in the direction of the height and the area, so that the practical reliability of the equipment will increase, and it is convenient to prevent items with large land area when the area is increased.It is easy to place items with different heights.

Owner:义乌市牵手电子商务有限公司

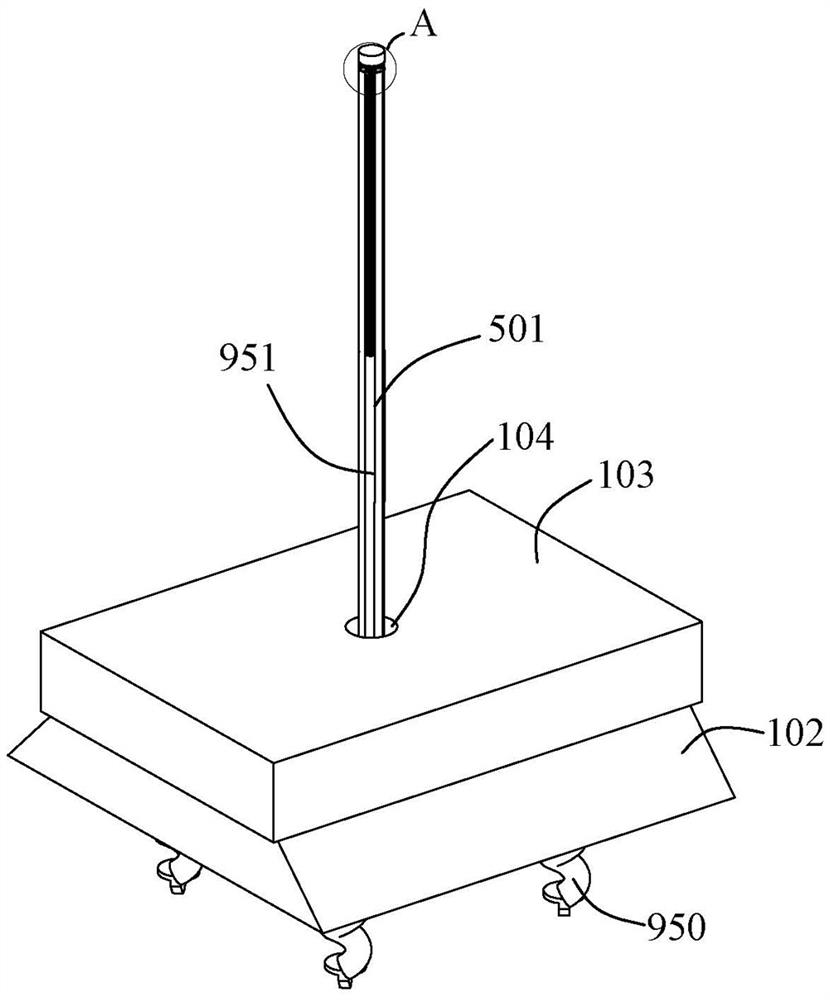

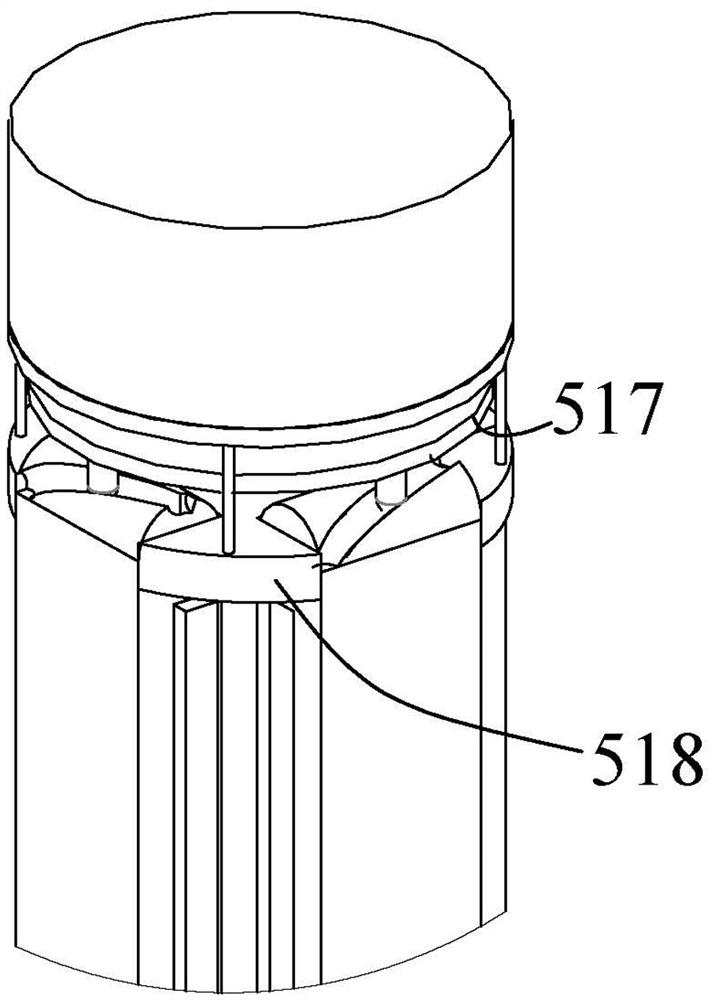

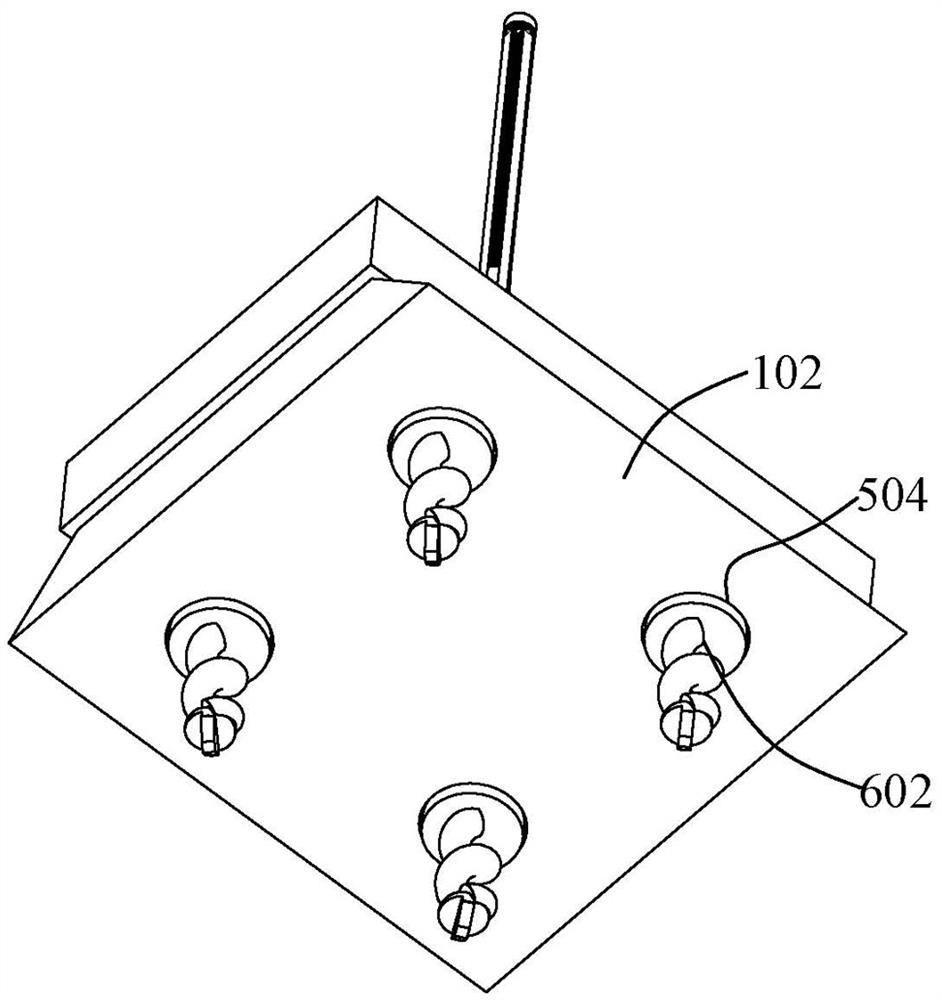

A kind of outdoor parasol equipment

ActiveCN110876519BFold in timeAffect personal safetyWalking sticksUmbrellasEngineeringStructural engineering

The invention discloses an outdoor sunshade equipment, the structure of which comprises a box, the box is surrounded by inclined surfaces, the upper end of the box is provided with a top box, and the top box is a shell structure. The top box is provided with a perforation that penetrates up and down, the box is provided with an inner cavity, an umbrella device for unfolding to form an umbrella structure is arranged between the perforation and the inner cavity, and several The ground-drilling fixture set in a circular array, this equipment adopts the design of the ground-boring fixture, umbrella device and power transmission device, so that the equipment can be stably fixed on the working plane, effectively preventing the equipment from being displaced by strong winds and other reasons. And the umbrella-like structure is formed by using a convenient unfolding method, which is convenient for personnel to fold the equipment in time when encountering bad weather and prevents the personal safety of personnel from being affected after the equipment is displaced.

Owner:FOSHAN SHUNDE MEIYAXIN FURNITURE IND CO LTD

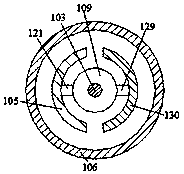

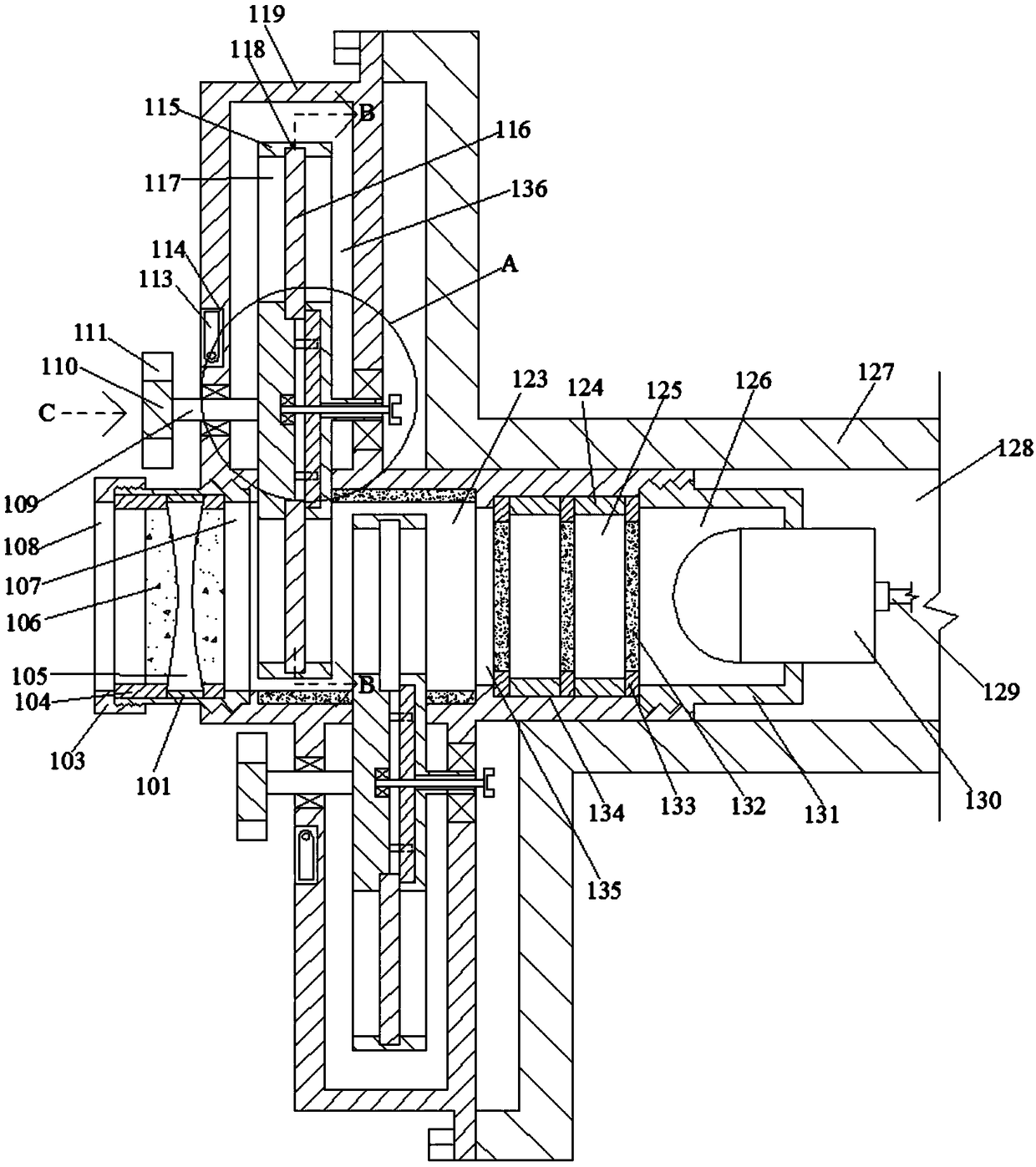

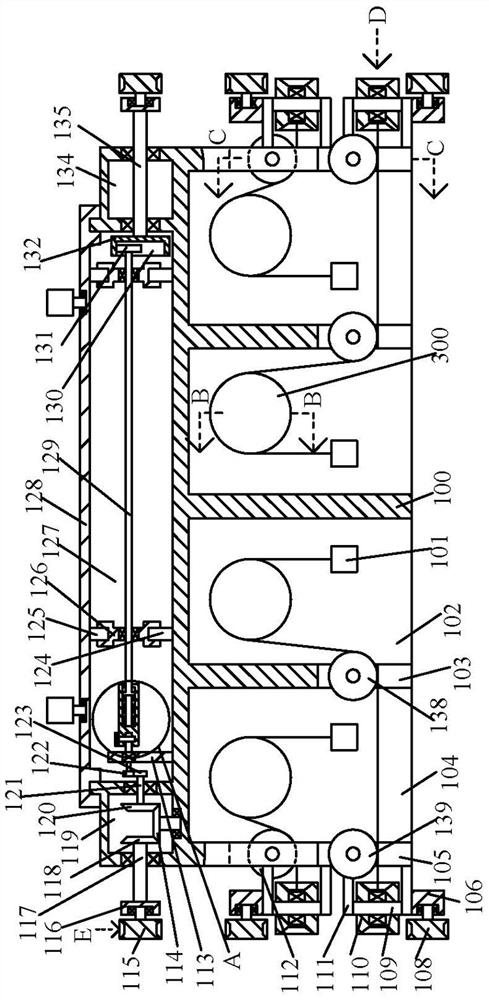

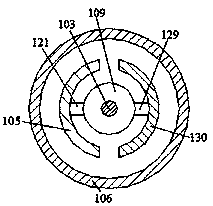

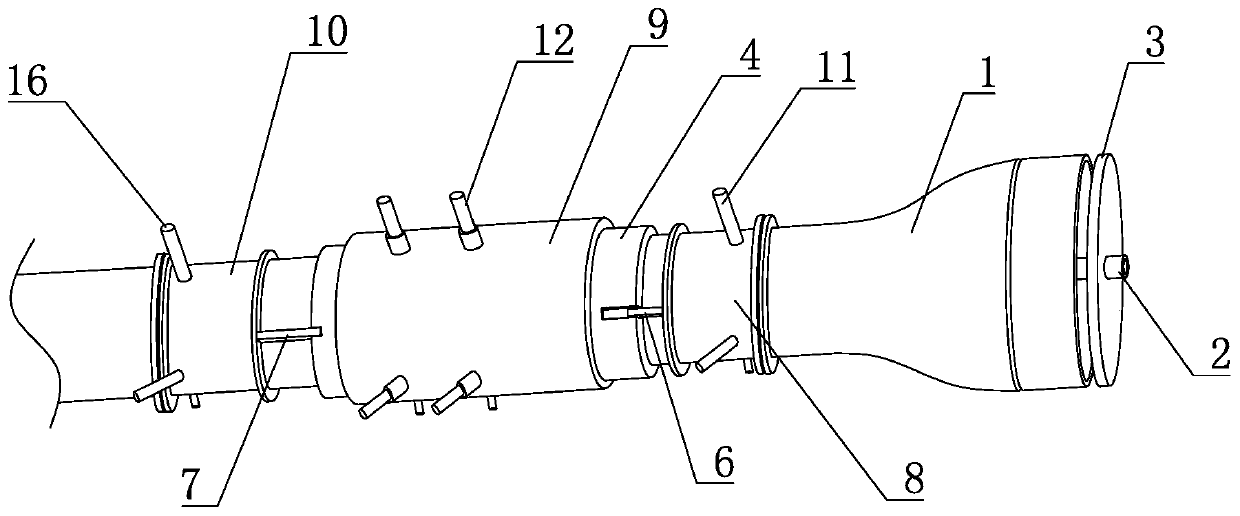

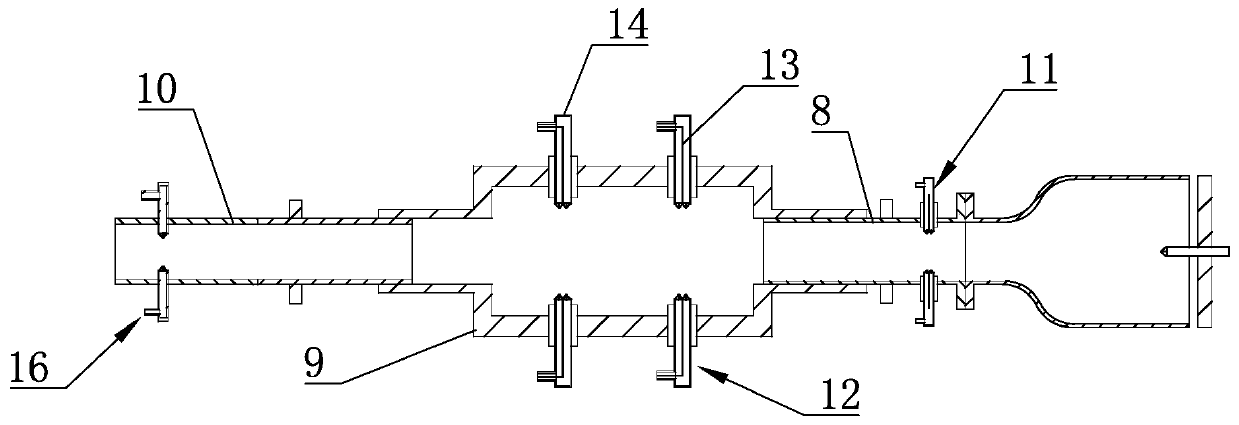

A hybrid carbon black reaction furnace

ActiveCN110746797BImprove practical reliabilityThe ratio is easy to controlPigmenting treatmentCombustion chamberEngineering

The invention discloses a hybrid carbon black reaction furnace, which includes a combustion chamber, a reaction chamber and a quenching chamber. The reaction chamber includes a first reaction section and a second reaction section. The combustion chamber is fixed to the front end of the first reaction section. The front end of the reaction section is fixedly matched with the rear end of the first reaction section, and the rear end of the second reaction section is fixedly matched with the quench chamber. The first reaction section is provided with a plurality of first raw material nozzles evenly distributed around the axis, and the second reaction The section is provided with at least one group of second raw material nozzle groups, and the second raw material nozzle group consists of a plurality of second raw material nozzles evenly distributed around the axis of the second reaction section; Nesting fit, the distance between the second raw material nozzle and the fuel nozzle can be different by adjusting the position of the second reaction section, thereby changing the temperature at the second raw material nozzle, and the particle size of the carbon black produced by the cracking of the raw material oil is different when the temperature is different. Therefore, carbon black with different particle sizes and controllable ratio can be produced in the same reaction furnace.

Owner:NINGBO DETAI CHEM

An unmanned aerial vehicle bait-throwing fishing equipment

The invention discloses a bait-throwing fishing device for an unmanned aerial vehicle, which comprises a box body, a release device and a locking device. The box body is fixed with a transmission cavity with an opening facing upwards, and the left and right sides of the transmission cavity are provided with The bevel gear cavity and the built-in cavity in the box, the upper side of the box is provided with a top shell, the top shell is fixed with the box, and the lower end surface of the passing shaft is fixed with left and right symmetrical embedded blocks, the transmission The lower end wall of the cavity is fixed with a left-right symmetrical fixed platform, and an inner rotary block is installed between the fixed platform and the embedded block. With a fixed platform, the present invention is simple in structure and easy to operate. By adopting the method of integrating with the UAV, the UAV can drive the equipment to the designated position above, and use the connecting rod slider to push the throwing of the bait and fishing line, and use the The method of swinging and separating separates the upper and lower fishing lines from each other to prevent entanglement, thereby improving the practical reliability of the device.

Owner:泰安晟智智能科技有限公司

Composite fabric manufacturing equipment

ActiveCN110976134BSimple structureEasy to operatePretreated surfacesCoatingsMaterial typeElectric machinery

Owner:沅江市兴旺服饰有限公司

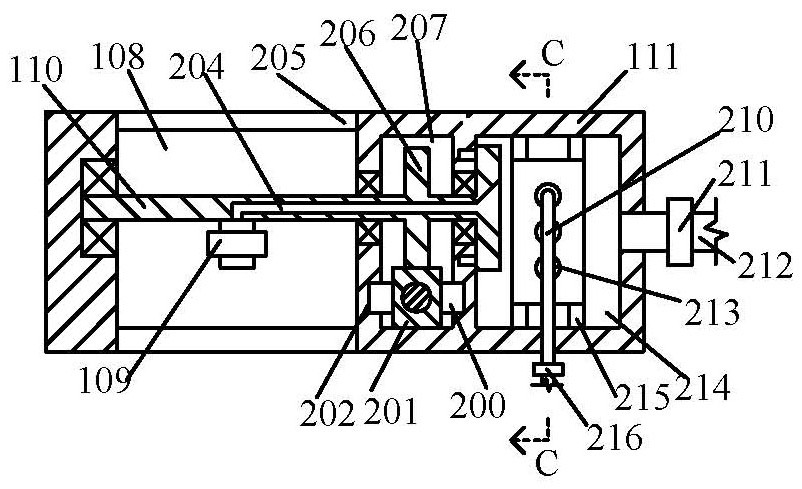

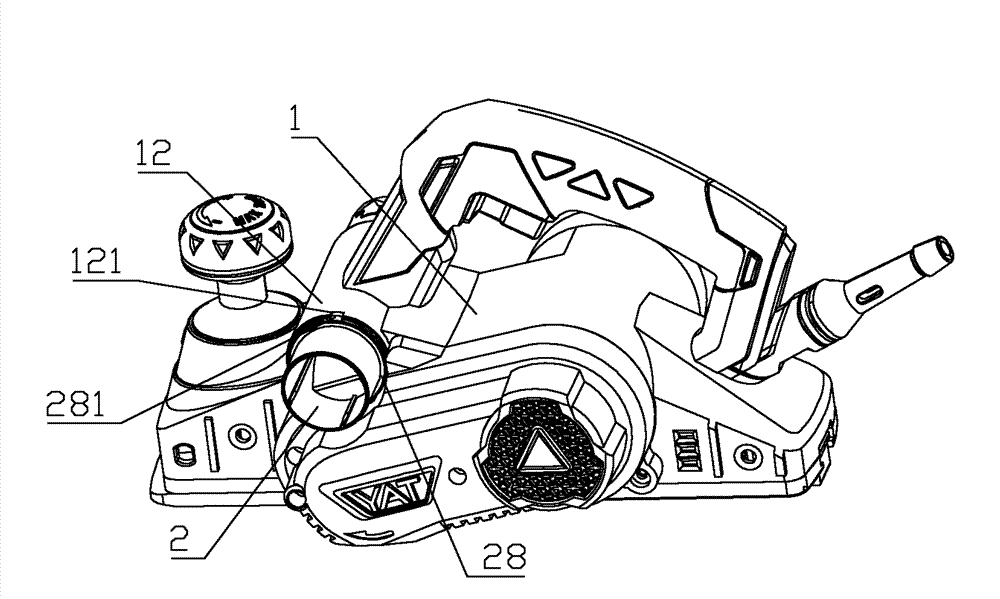

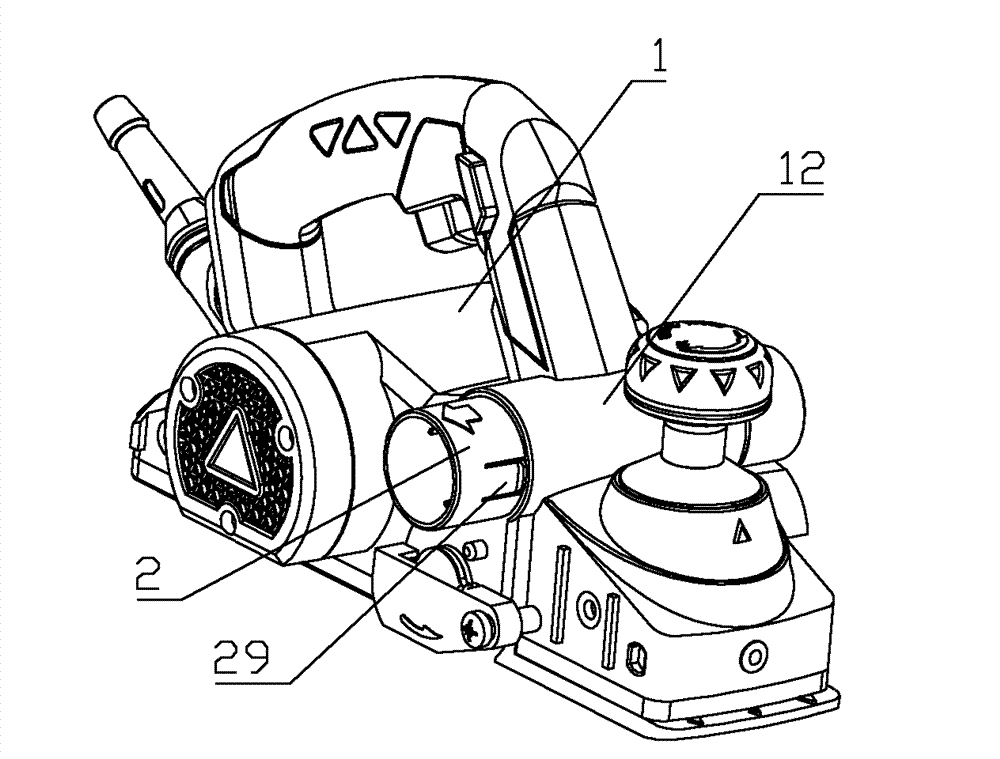

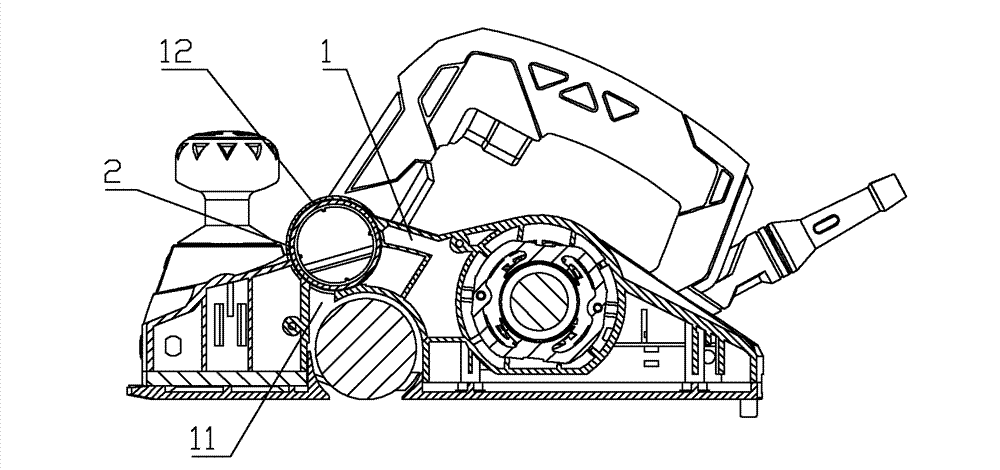

Dual-edge scrap discharging mechanism for electric planer

The invention discloses a dual-edge scrap discharging mechanism for an electric planer, which comprises a machine body, wherein a plane cutter cavity with a plane cutter is formed in the machine body; an installation sleeve communicated with the plane cutter cavity is arranged on the machine body; a scrap discharging pipe is sleeved in the installation sleeve; a self-locking regulating structure for positioning the scrap discharging pipe on the machine body axially or relieving axial positioning is arranged on the scrap discharging pipe; a dual-edge air flue structure communicated with the plane cutter cavity is arranged in the scrap discharging pipe, and comprises a left air flue, a right air flue and a baffle arranged between the left air flue and the right air flue; the baffle is in closed connection with the inner wall of the scrap discharging pipe; a scrap inlet I communicated with the left air flue is formed on the pipe wall of the scrap discharging pipe; a scrap inlet II communicated with the right air flue is formed on the pipe wall of the scrap discharging pipe relative the scrap inlet I; and a regulating positioning structure which converts the scrap inlet I or the scrapinlet II to be communicated with the plane cutter cavity is also arranged on the scrap discharging pipe. The dual-edge scrap discharging mechanism has a simplified structure and fewer parts and is low in cost, convenient for operation and very reliable in application.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

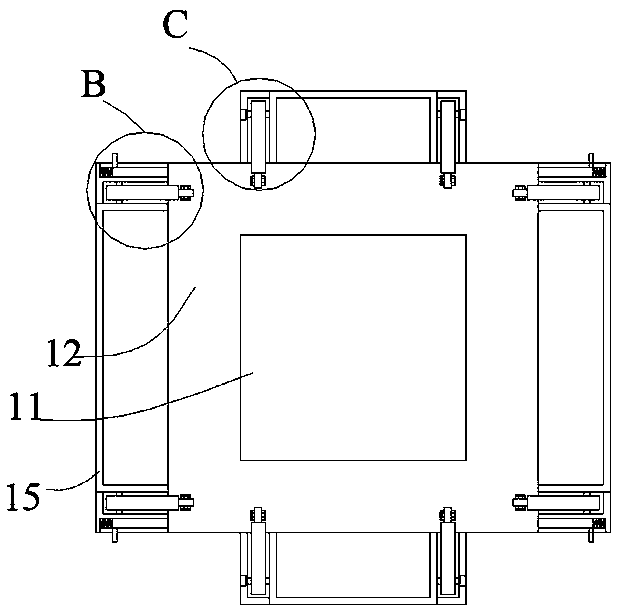

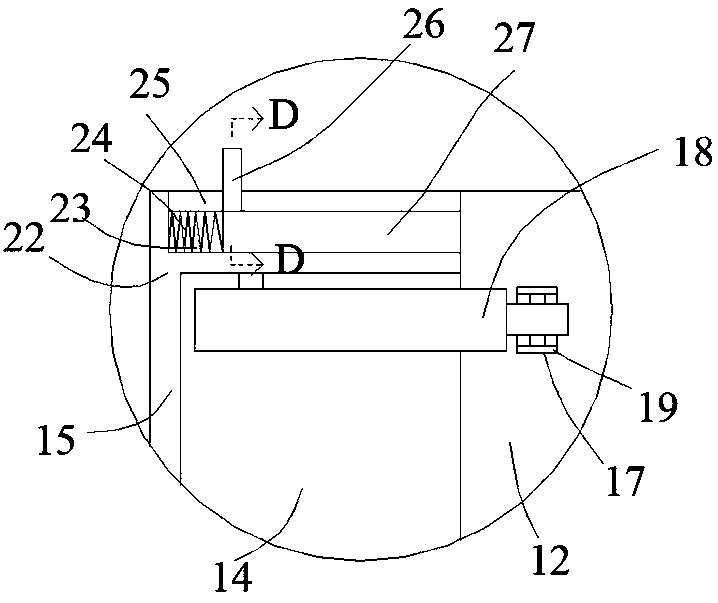

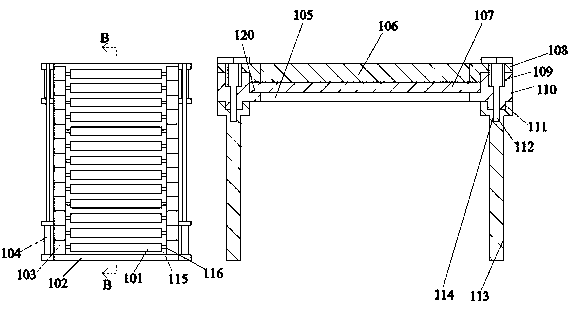

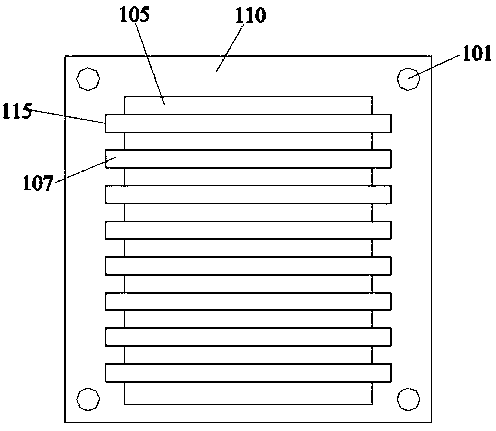

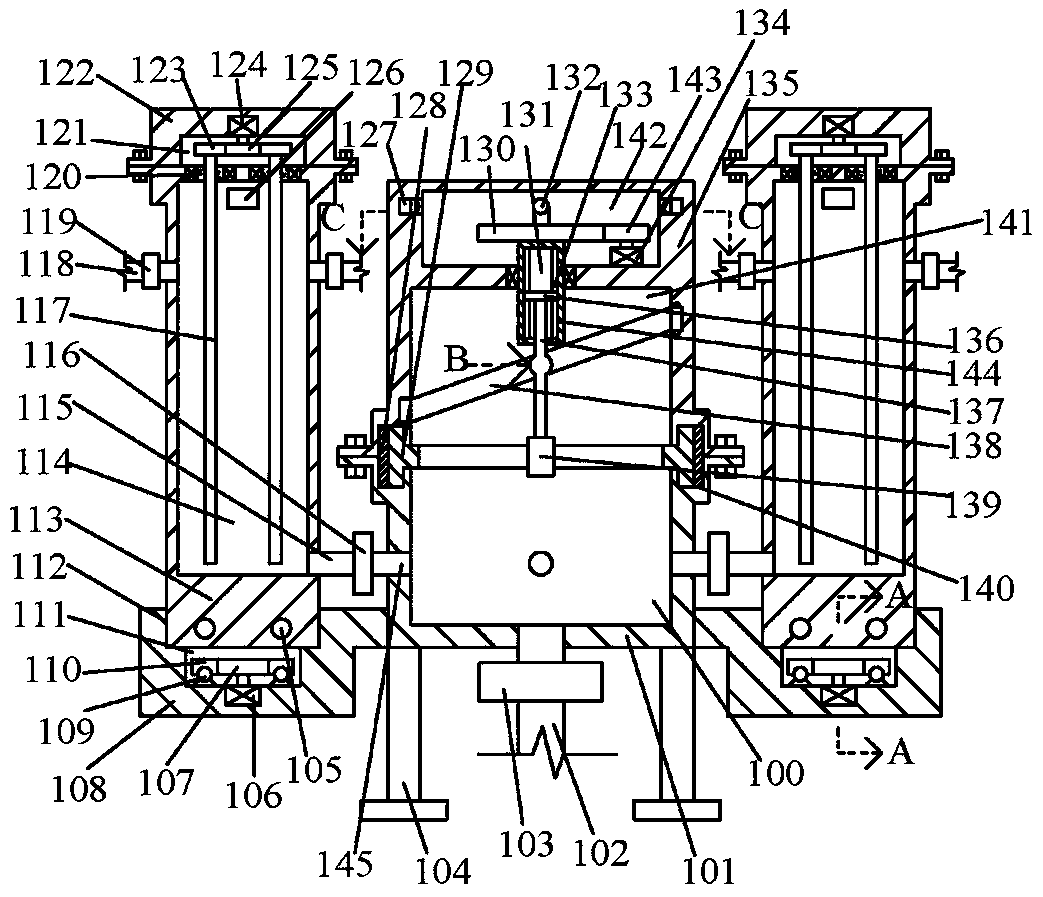

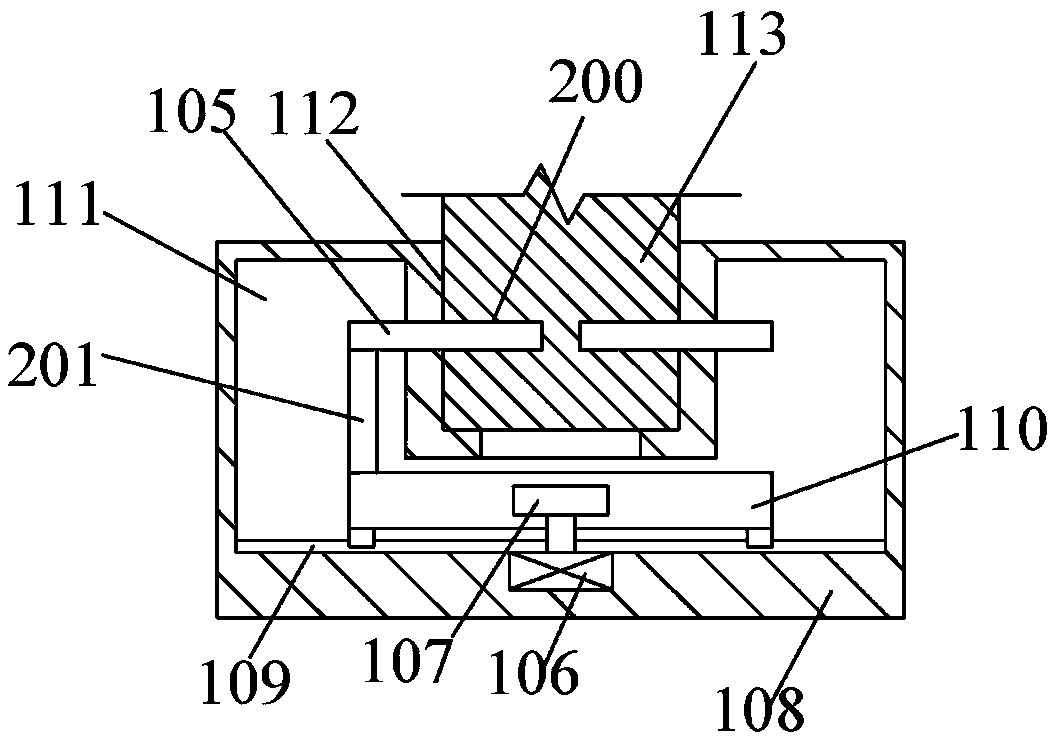

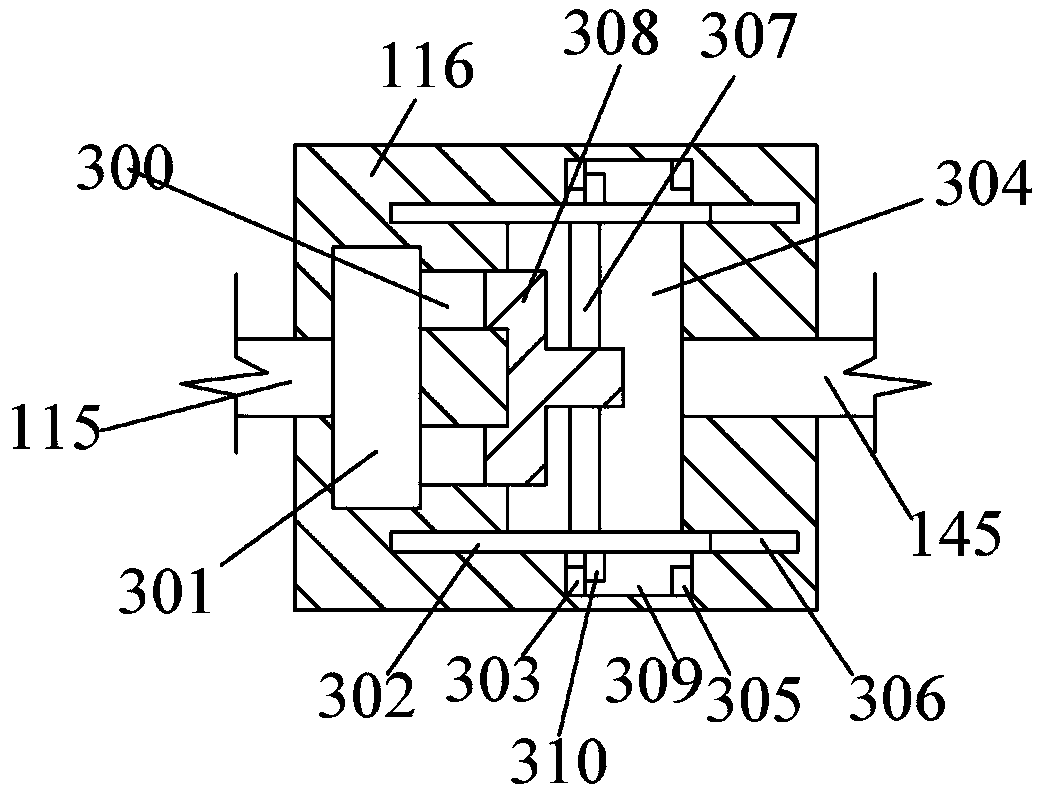

A casting mold handling equipment

ActiveCN110127508BAvoid frictional damageSimple structureLoad-engaging elementsEngineeringCasting mold

The invention discloses casting mold transferring equipment. The equipment comprises a suspension rod matched and connected with indoor mobile equipment, wherein top bases which are symmetric to eachother laterally are fixedly arranged on left and right end surfaces of the suspension rod; a box body is fixedly arranged at the lower end surface of each top base; an accommodation device used for accommodating casting molds is arranged below the box bodies, and a lifting device which is symmetric longitudinally and used for driving the accommodation device to change the height is arranged in each box body. The equipment is simple in structure and provided with the accommodation device and the lifting devices, so that the equipment can turn over the cast molds by being matched with external mobile equipment; additionally, the equipment has elaborate design, workers can disassemble the equipment conveniently, wear-resistant capacity of steel ropes in the equipment is enhanced, and practicability and reliability of the equipment are further improved.

Owner:山西华恩实业有限公司

Novel papermaking pollutant emission reducing device

InactiveCN108557911AImprove practicalityEasy maintenanceWaste water treatment from plant processingWater/sewage treatment apparatusPollutant emissionsPulp and paper industry

The invention discloses a novel papermaking pollutant emission reducing device. The novel papermaking pollutant emission reducing device comprises a cavity box D fixedly arranged on the ground, a driving cavity is formed in the cavity box D, and a driver B is fixedly arranged in the lower end wall of the driving cavity. An output shaft of the driver B is in power connection with an accelerator arranged in the driving cavity, the upper end face of the accelerator is in power connection with a shaft rod E, and the shaft rod E rotationally penetrates through the upper end wall of the driving cavity and stretches out to the external space. The upper end face of the shaft rod E is in power connection with a cavity box B, an open groove B with an upward opening is formed in the cavity box B, andan opening communicated with the external space is formed in the lower end wall of the open groove B. The novel papermaking pollutant emission reducing device is simple in structure and convenient touse, grinding and extruding work at the same time, pollutant emission reduction of papermaking polluted water is achieved, therefore, one procedure of the novel papermaking pollutant emission reducing device is achieved, and the practical reliability is effectively improved.

Owner:广州酷汇电子科技有限公司

Mixed carbon black reaction furnace

ActiveCN110746797AImprove practical reliabilityThe ratio is easy to controlPigmenting treatmentCombustion chamberMetallurgy

The invention discloses a mixed carbon black reaction furnace. The mixed carbon black reaction furnace comprises a combustion chamber, a reaction chamber and a quenching chamber, the reaction chambercomprises a first reaction section and a second reaction section, the combustion chamber is fixed to the front end of the first reaction section, the front end of the second reaction section is fixedly matched with the rear end part of the first reaction section, the rear end of the second reaction section is fixedly matched with the quenching chamber, the first reaction section is provided with aplurality of first raw material nozzles which are uniformly distributed around the axis, the second reaction section is provided with at least one second raw material nozzle group, and the second rawmaterial nozzle group consists of a plurality of second raw material nozzles which are uniformly distributed around the axis of the second reaction section. The second reaction section is nested andmatched with the first reaction section and the quenching chamber, different distances from the second raw material nozzles to a fuel nozzle can be realized by adjusting the position of the second reaction section in order to change the temperature of the second raw material nozzles, and the particle sizes of the carbon black generated by cracking the raw oil are different due to different temperatures, so the carbon black with different particle sizes and controllable proportion is generated in the same reaction furnace.

Owner:NINGBO DETAI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com