Dual-edge scrap discharging mechanism for electric planer

An electric planing and bilateral technology, which is used in the manufacture of flat surface processing machines, wood processing appliances, manufacturing tools, etc., can solve the problem that the sealing performance of the chip baffle and the chip cylinder cannot be guaranteed, the manufacturing and installation are complicated, and the number of parts is increased. and other problems, to achieve the effect of reducing components, simplifying the structure and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

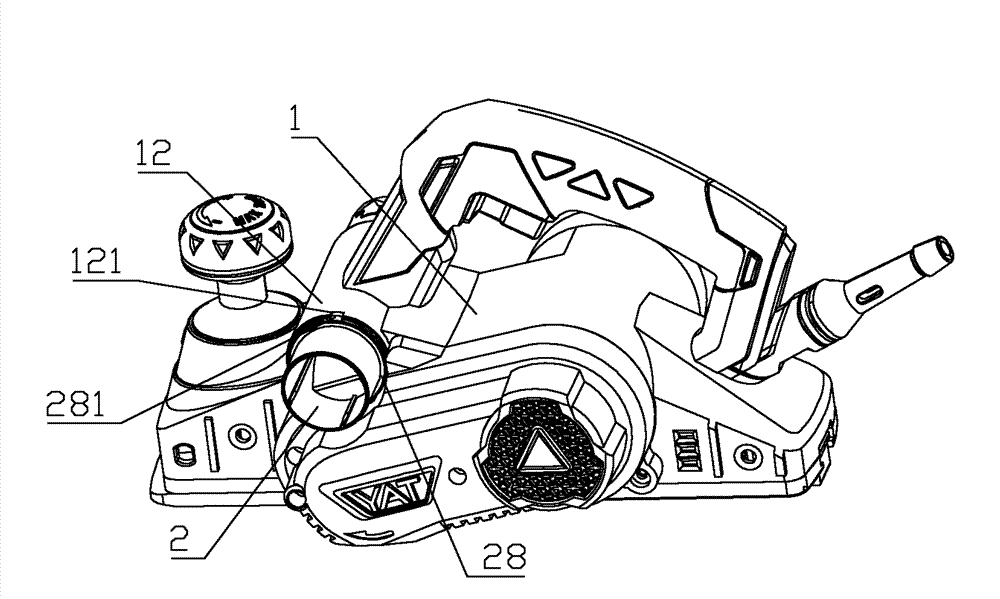

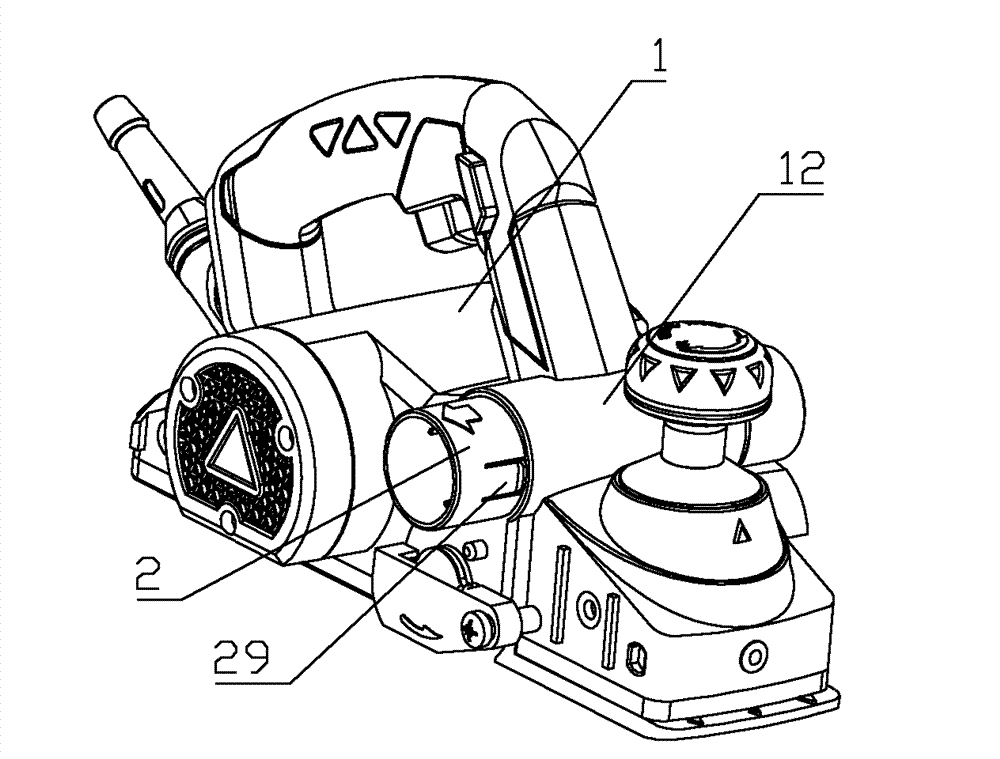

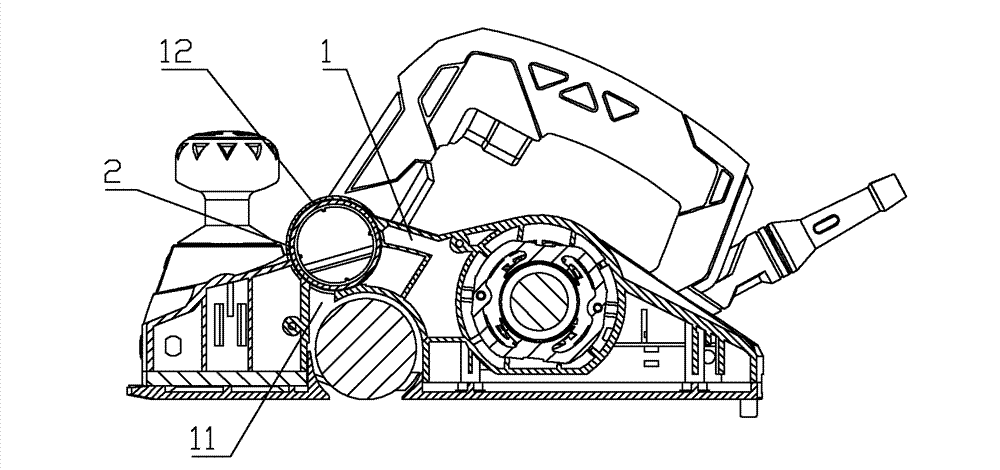

[0025] like Figures 1 to 5 Shown is a structural schematic diagram of an embodiment of the present invention, a double-sided chip removal mechanism for an electric planer, including a fuselage 1, a planer chamber 11 for installing a planer, and a mounting device communicating with the planer chamber on the fuselage. Sleeve 12, the chip discharge pipe 2 is provided in the installation sleeve, the chip discharge pipe rotates in the installation sleeve, and the chip discharge pipe is provided with the automatic positioning of the chip discharge pipe axially on the fuselage or releasing the axial positioning. The lock adjustment structure is provided with a bilateral air channel structure connected with the planer cavity in the chip discharge pipe, and the bilateral air channel structure includes a left air channel 21, a right air channel 22, and an air channel between the left air channel and the right air channel. Partition plate 23, the partition plate is closed and connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com