Inductive component and method for manufacturing the same

A manufacturing method and component technology, which are applied in the field of chip inductor components and their manufacturing, can solve problems such as cracks in welding parts, and achieve the effects of increasing the number of stacks, improving practical reliability, and suppressing wire breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024] Hereinafter, an inductance component and a method for manufacturing the same according to Embodiment 1 of the present invention will be described with reference to the drawings.

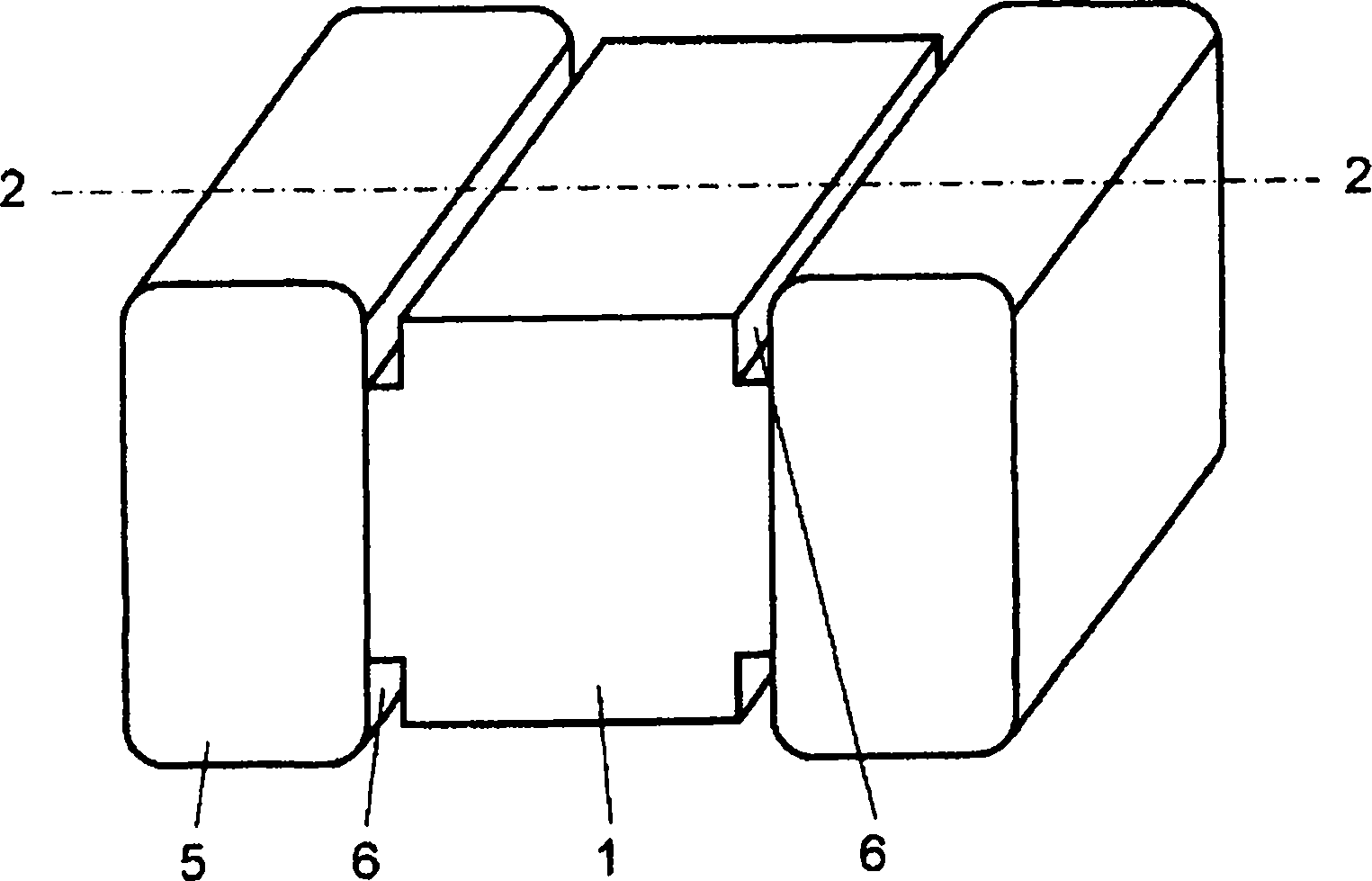

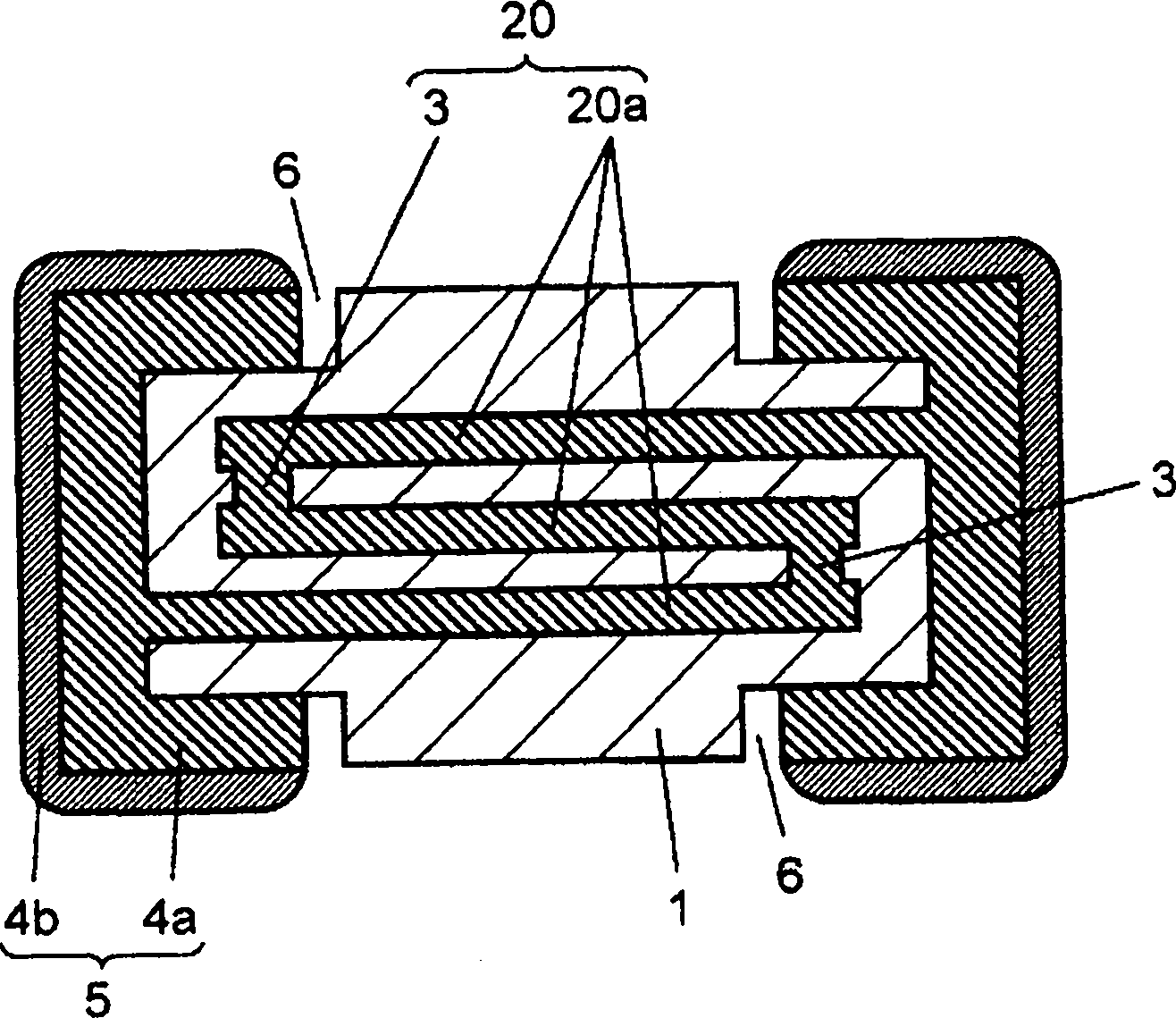

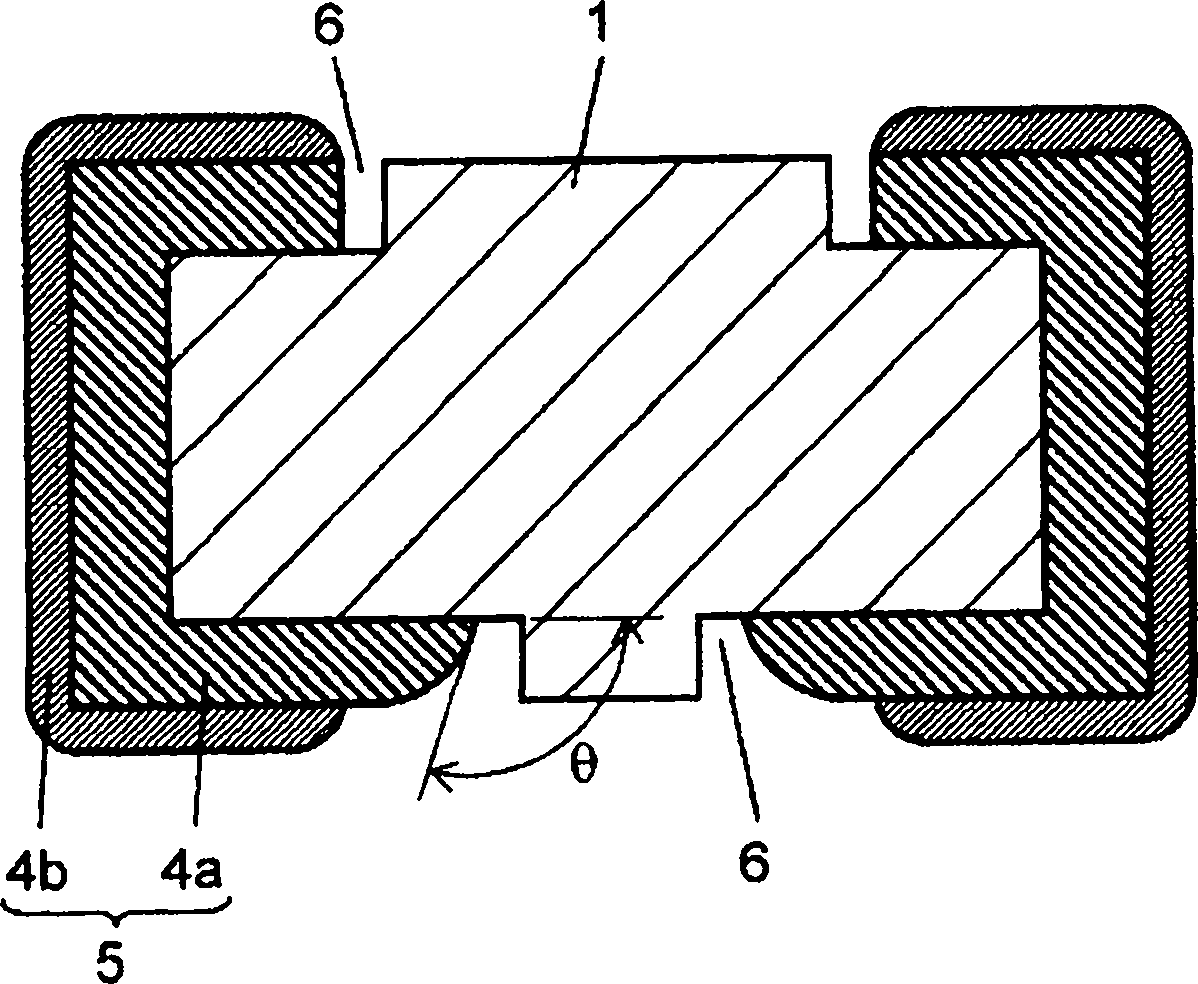

[0025] figure 1 It is a perspective view of the inductance component in Embodiment 1 of this invention. figure 2 Yes figure 1 Sectional view of part 2-2. exist figure 1 , figure 2 Among them, the inside of the body 1 made of an insulating resin obtained by curing a photosensitive resin is laminated using a plating technique and a photolithography technique so that the coil pattern 20a is formed into a spiral shape via the through electrodes 3 Thus, the coil portion 20 is formed.

[0026] The through electrodes 3 correspond to the interlayer connection portions of the plurality of coil patterns 20a. The coil patterns 20a formed of multiple layers are connected in a spiral shape or a coil shape via the through electrodes 3 formed at predetermined positions. At this time, in order to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com