Composite fabric manufacturing equipment

A technology for manufacturing equipment and composite materials. It is applied to the device for coating liquid on the surface, the spray booth, and the surface for pretreatment. It can solve the problems that the composite material textile fabric processing process has not yet been realized and the work efficiency is reduced, and achieve efficient and fast integration. And air drying, improve production efficiency, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

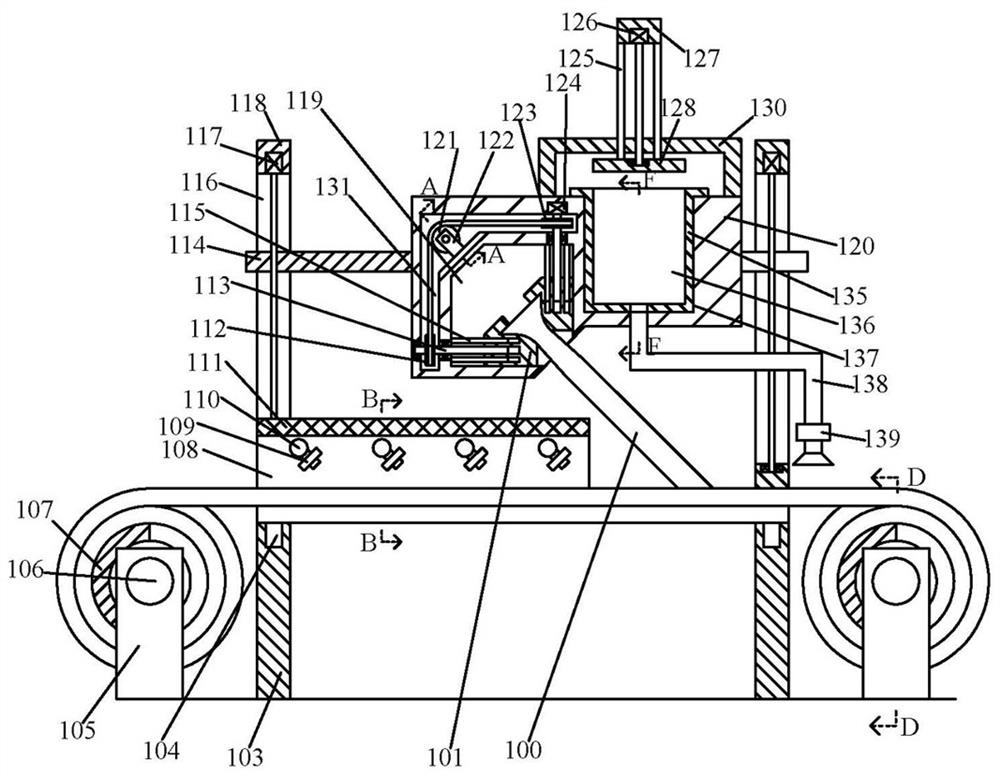

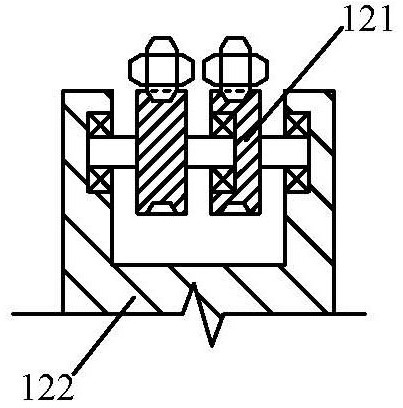

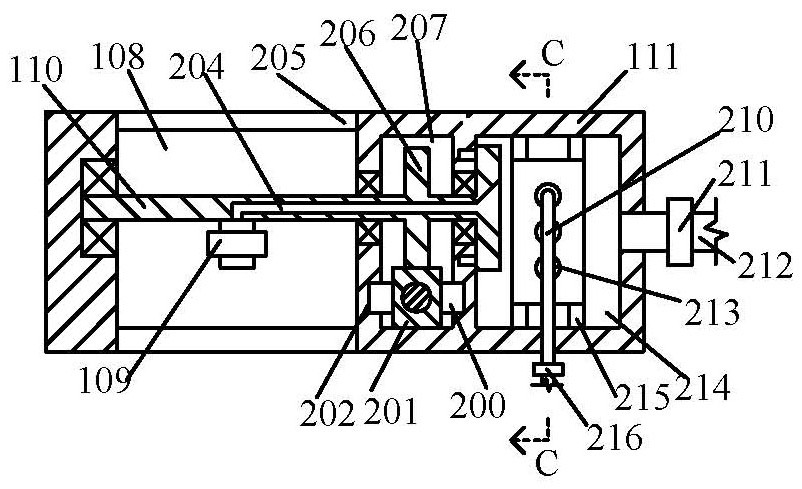

[0024] Combine below Figure 1-7 The present invention will be described in detail.

[0025] refer to Figure 1-7 , according to an embodiment of the present invention, a composite material textile fabric manufacturing equipment includes a foot 103, a roller device, a scraper device, a spraying device and an air-drying device. Plane plate 104 is arranged, and the left and right sides of foot 103 are provided with roller device, and the upper end surface of foot 103 is fixedly provided with lifting box 118, and the inner chamber 116 that penetrates left and right is fixedly provided in the lifting box 118, and the depth of inner chamber 116 is 60cm, and A lifting motor 117 is fixedly installed in the upper end wall of the cavity 116, and the output shaft of the lifting motor 117 is connected with the lower end wall of the inner cavity 116 in rotation, and the outer surface of the output shaft of the lifting motor 117 is screwed and connected with a lifting plate 114, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com