Mixed carbon black reaction furnace

A reaction furnace and hybrid technology, applied in fibrous fillers and other directions, can solve the problems of reducing the production efficiency of the factory, reducing the production efficiency of the reaction furnace, and increasing the production cost, so as to increase the practical reliability, increase the production efficiency, and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

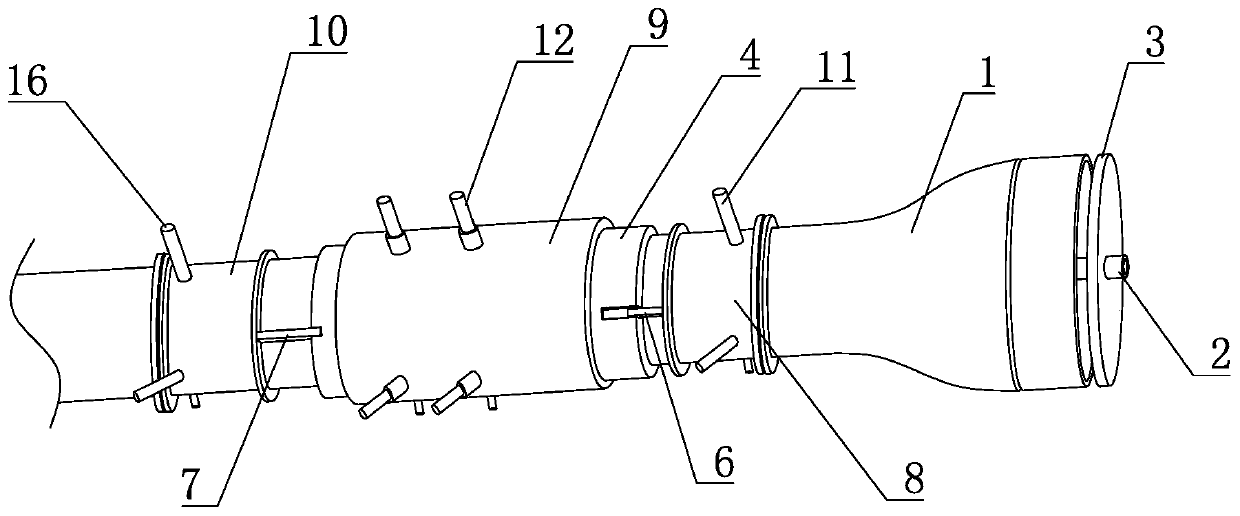

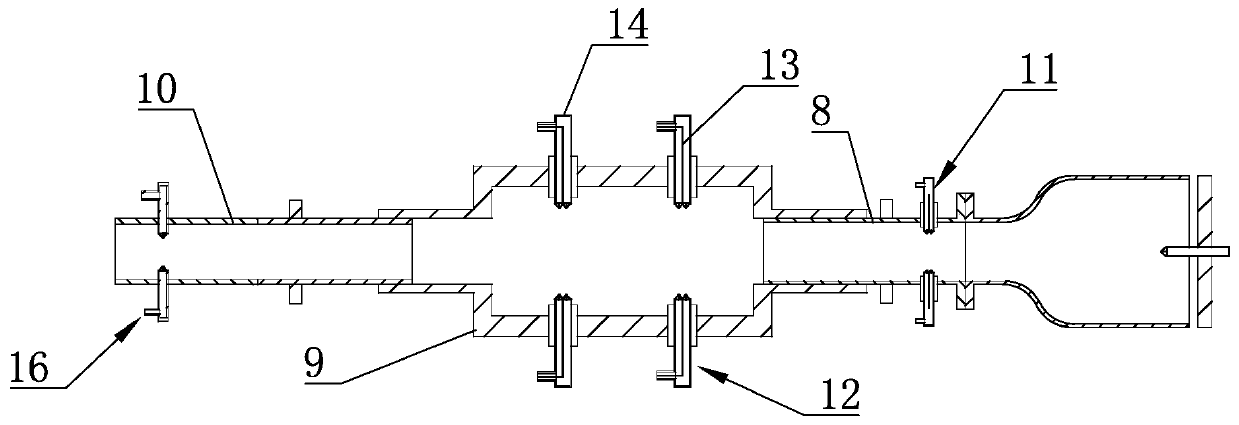

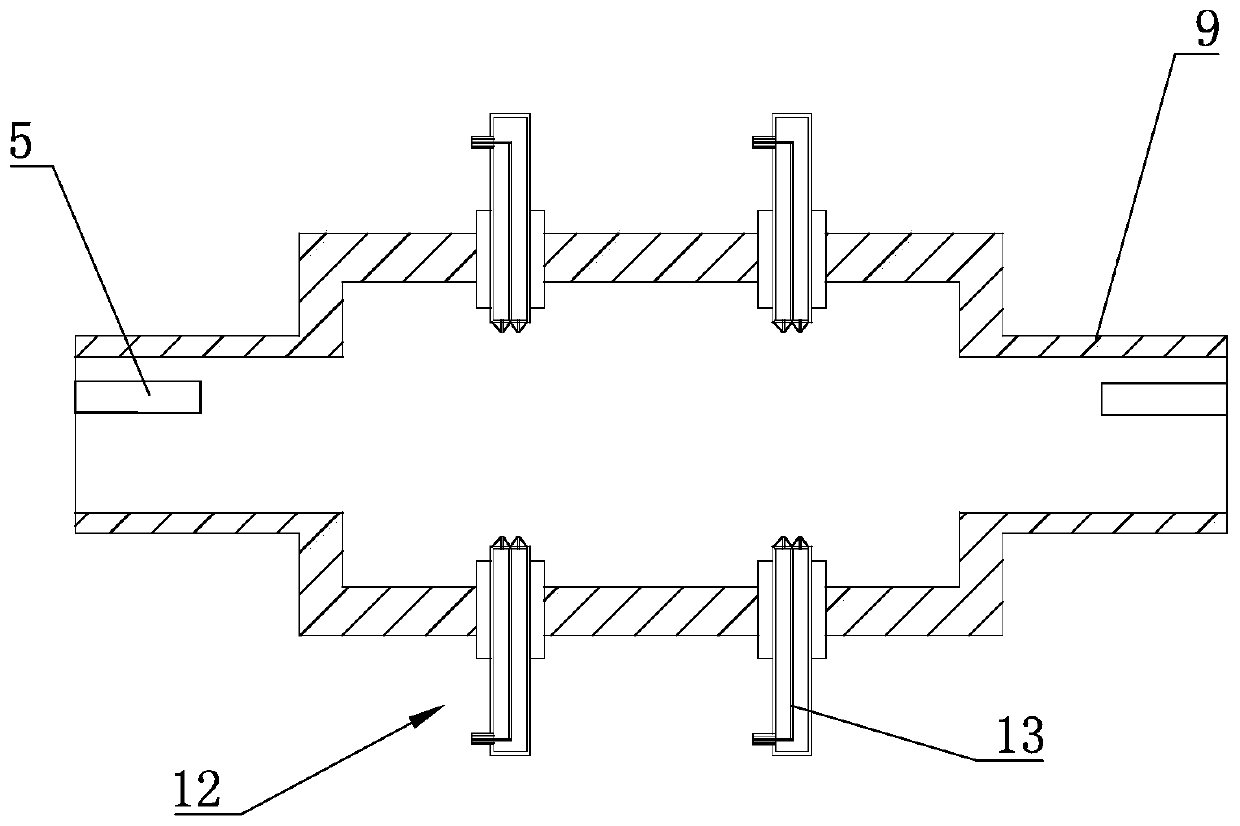

[0016] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

[0017] A hybrid carbon black reactor includes a combustion chamber 1, a reaction chamber, and a quenching chamber 10 that are sequentially connected and matched. The reaction chamber includes a first reaction section 8 and a second reaction section 9, the combustion chamber 1 and the first reaction section 8 The front end is detachably fixed by bolts. The two ends of the second reaction section 9 are integrally provided with a limit tube 4, the front end of the combustion chamber 1 is provided with a fuel nozzle 2 for injecting fuel oil, and the quenching chamber 10 is provided with a quenching chamber 10 The quench nozzle 16 is sprayed with quench water, the limit tube 4 at the front end of the second reaction section 9 is nested and the rear end of the first reaction section 8 is nested, and the limit tube 4 at the rear end of the second reaction section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com