Pulper for papermaking machinery, which is convenient for feeding and discharging

A technology for papermaking machinery and materials in and out, which is applied in papermaking, textiles, papermaking, fiber raw materials, etc. It can solve the problems of accidental flying of paper dust and inconvenient pulp in and out of materials, and achieves the effect of convenient material in and out and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

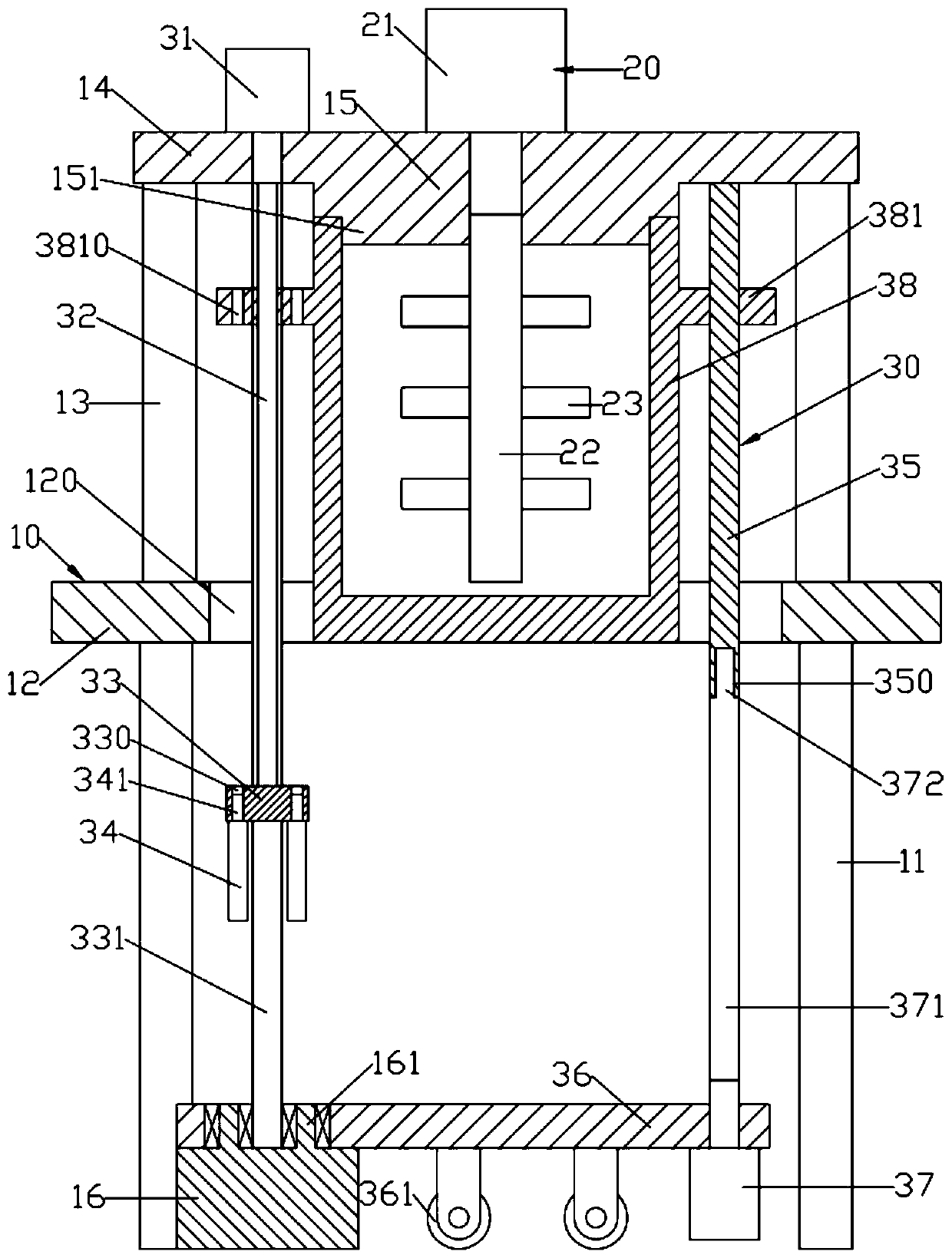

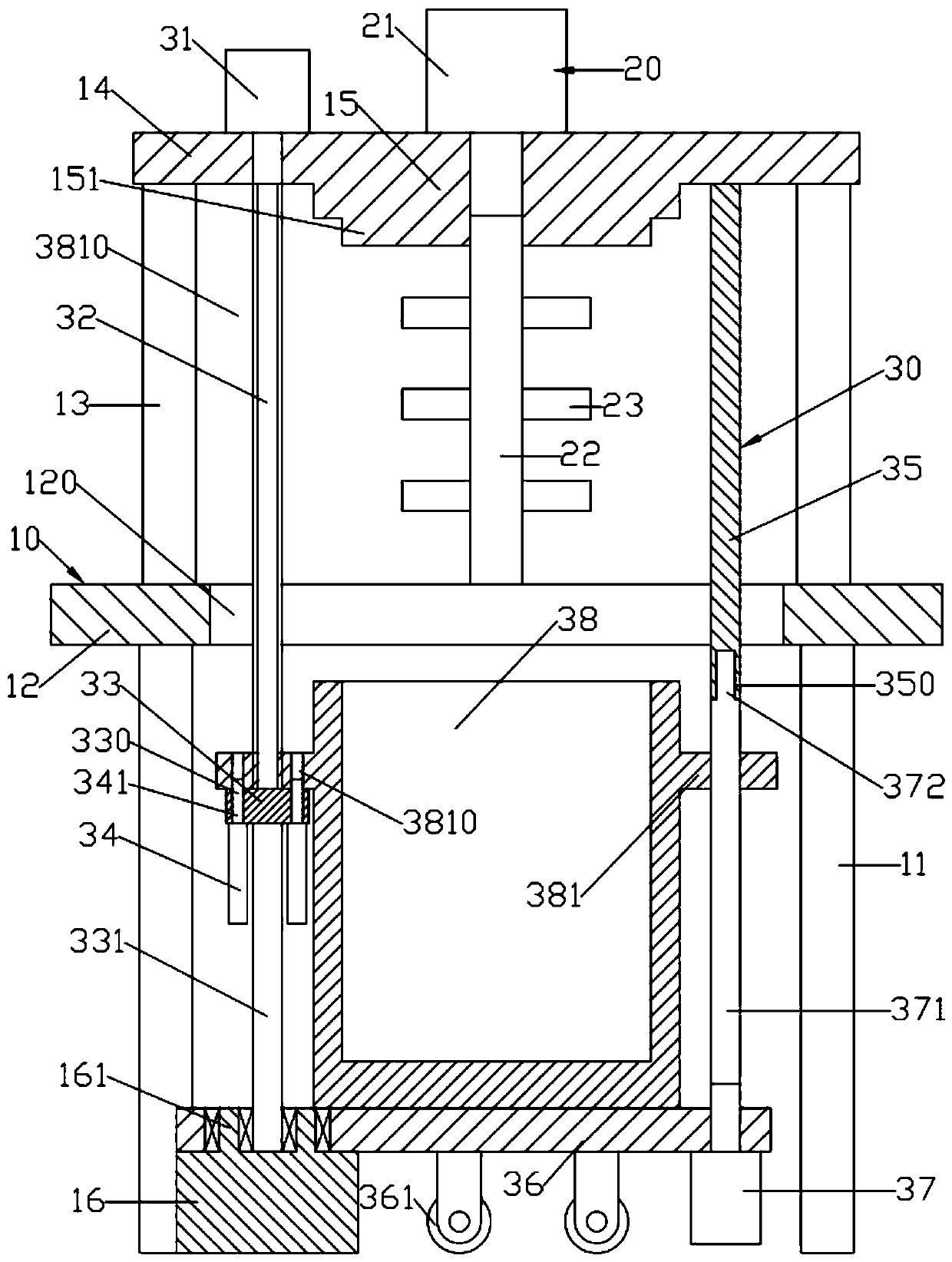

[0016] Such as figure 1 , figure 2 As shown, a pulper for papermaking machinery with convenient feeding and discharging includes a frame 10, a pulping unit 20 and a pulping cylinder lifting device 30; the frame 10 includes an upper support plate 14 distributed up and down, a lower support plate 12 and a Bottom support seat 16; The center of the bottom surface of the upper support plate 14 is provided with an upper closed seat; The pulping unit 20 includes a pulping central column 22; There are pulping blades 23 formed on the cylindrical surface of the upper support plate 14 and the lower support plate 12 through several evenly distributed vertical connecting rods 13; And the support feet 11 are set on the ground; the center of the lower support plate 12 is formed with a lifting and avoiding hole 120 that penetrates up and down; the bottom support seat 16 is fixed on the ground; the pulping cylinder lifting device 30 includes a cylindrical pulping cylinder 38 with an open upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com