Shaft-less direct-drive generator for wind power generation

A technology for generators and main shafts, applied in the direction of wind turbines, wind motor combinations, wind turbine monitoring, etc., can solve problems such as high cost, heavy machine weight, power generation system paralysis, etc., achieve good economic and social benefits, improve The effect of integration and intelligence, convenient unification and remote management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

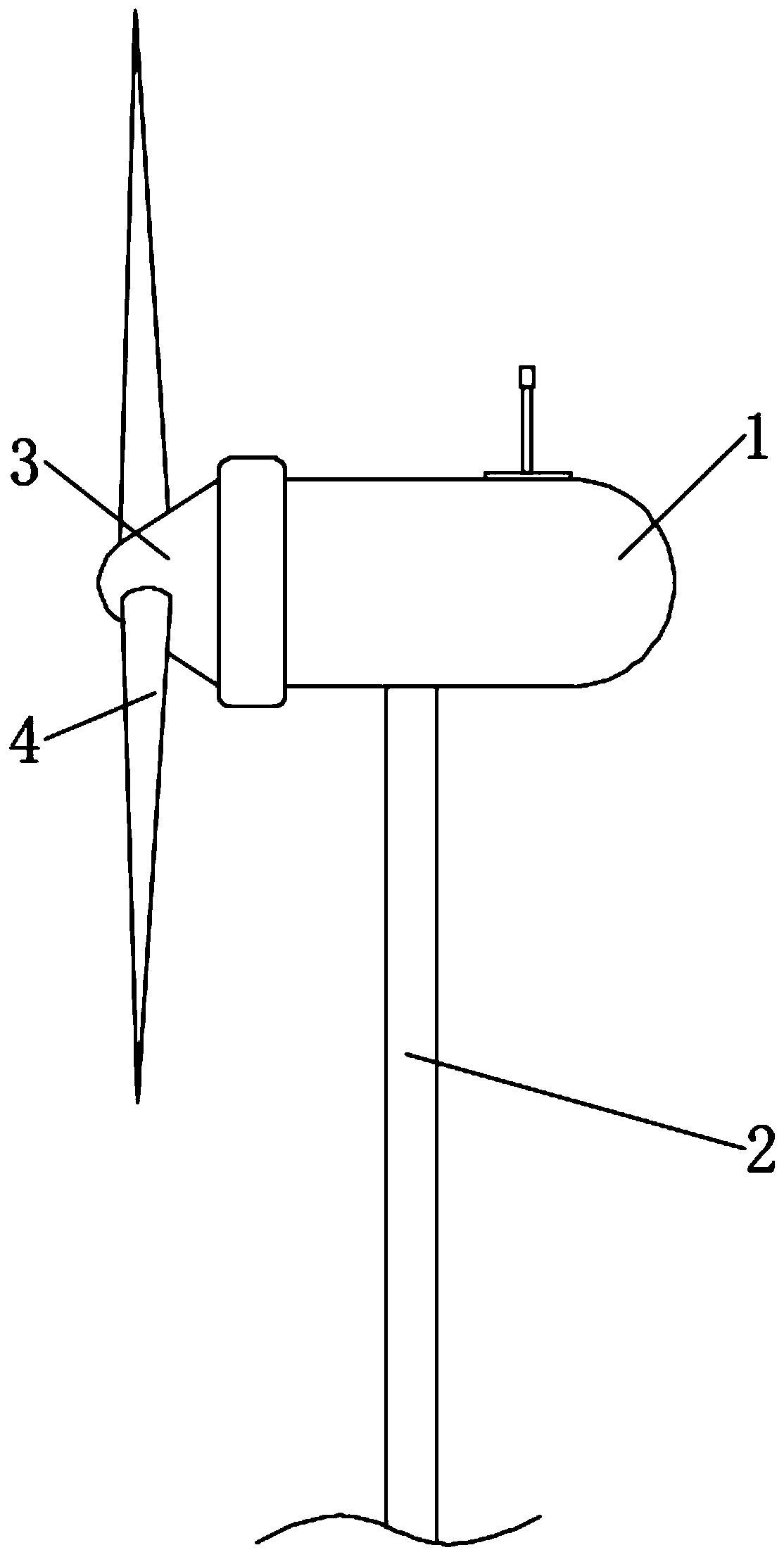

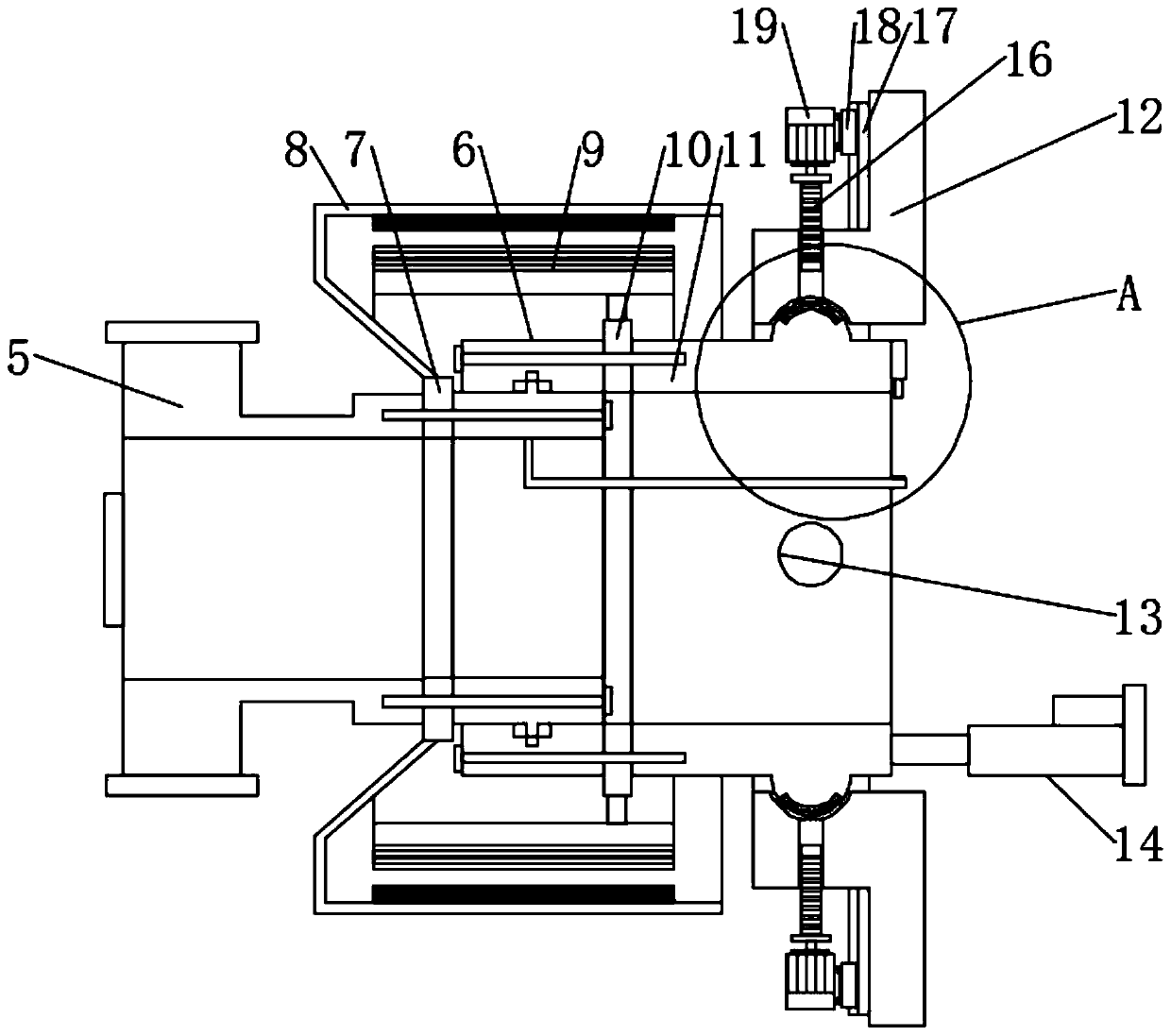

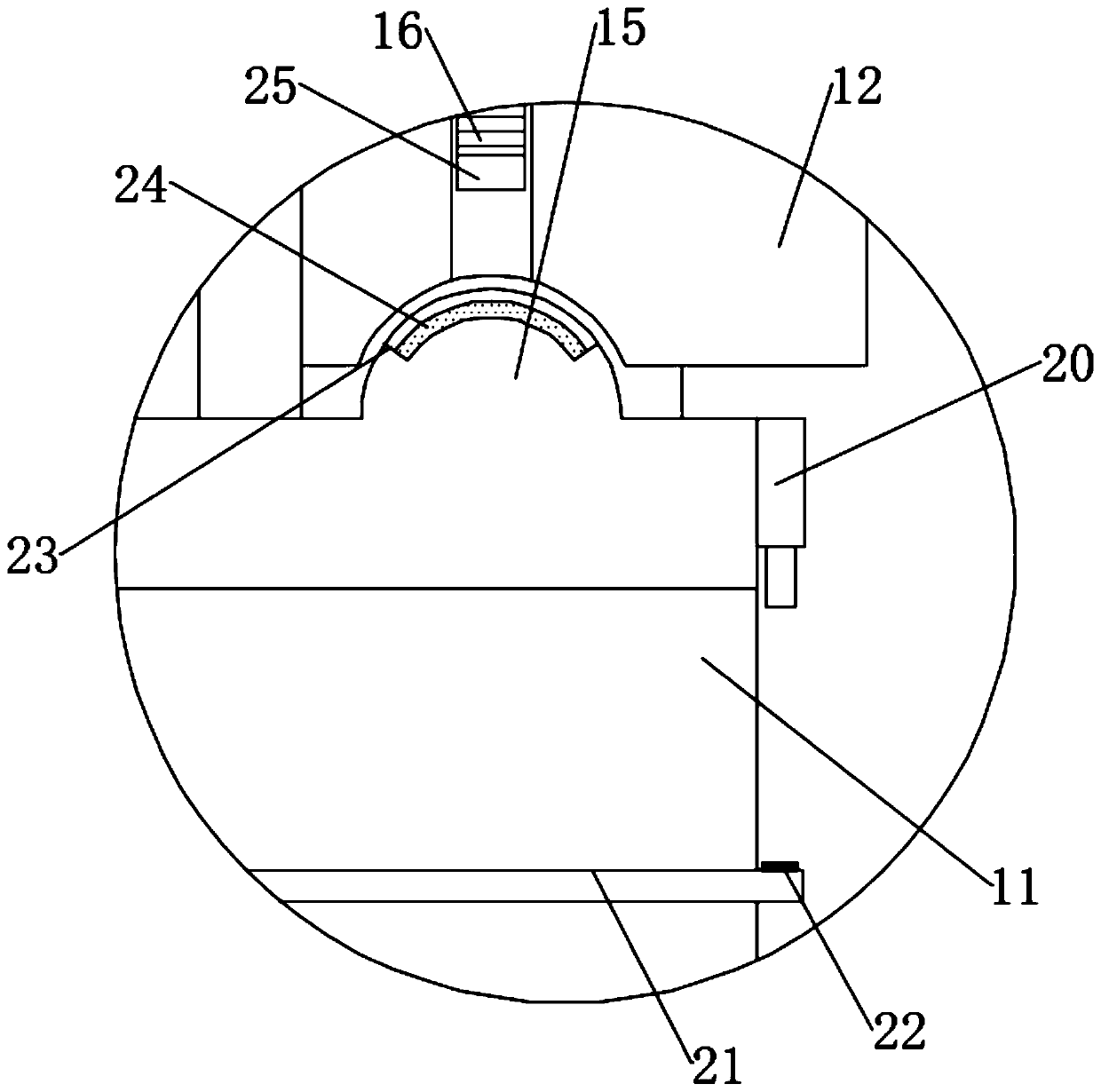

[0045] see figure 1 , a shaftless direct-drive generator for wind power generation, comprising a nacelle 1, a tower 2 fixedly connected to the lower end of the nacelle 1, a wind wheel assembly installed at the front end of the nacelle 1, and the wind wheel assembly includes a shroud 3, blades 4 and hub 5, see figure 2 , there is a non-shafting assembly installed in the nacelle 1, and the non-shafting assembly includes a slewing bearing 6, a rotor mounting flange 7, a rotor 8, a stator 9, a stator mounting flange 10 and an adjustment base 11, and the slewing bearing 6 has three rows Roller combination slewing bearings, three-row cylindrical roller combination slewing bearings bear axial load, overturning moment and radial load at the same time. Compared with the crossed cylindrical roller slewing bearing, the load of each roller is reduced. Compared with the double-row ball slewing bearing with different diameters, it is changed from point contact to line contact, which reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com