Crankshaft bearing lubrication system suitable for drilling mud pump and using method of system

A crankshaft bearing and lubrication system technology, applied to crankshaft bearings, shafts and bearings, crankshafts, etc., can solve problems such as insufficient lubrication, high operating speed, failure of bearing inner raceway, etc., to achieve convenient installation and simple and effective lubrication structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

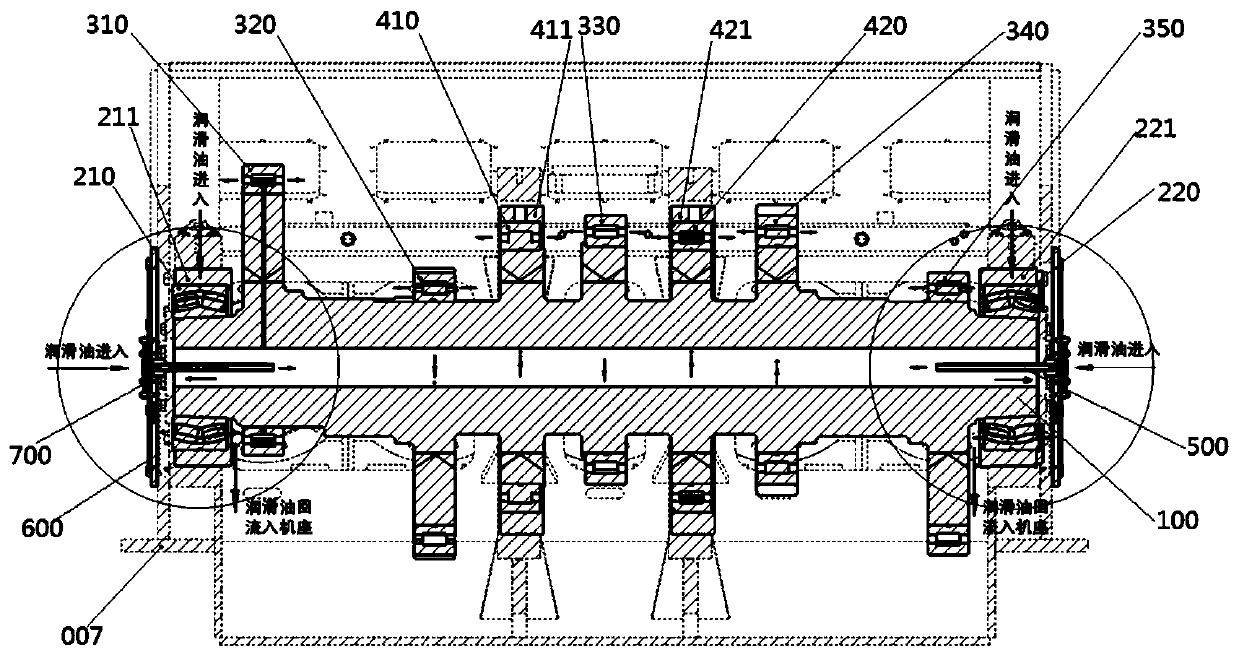

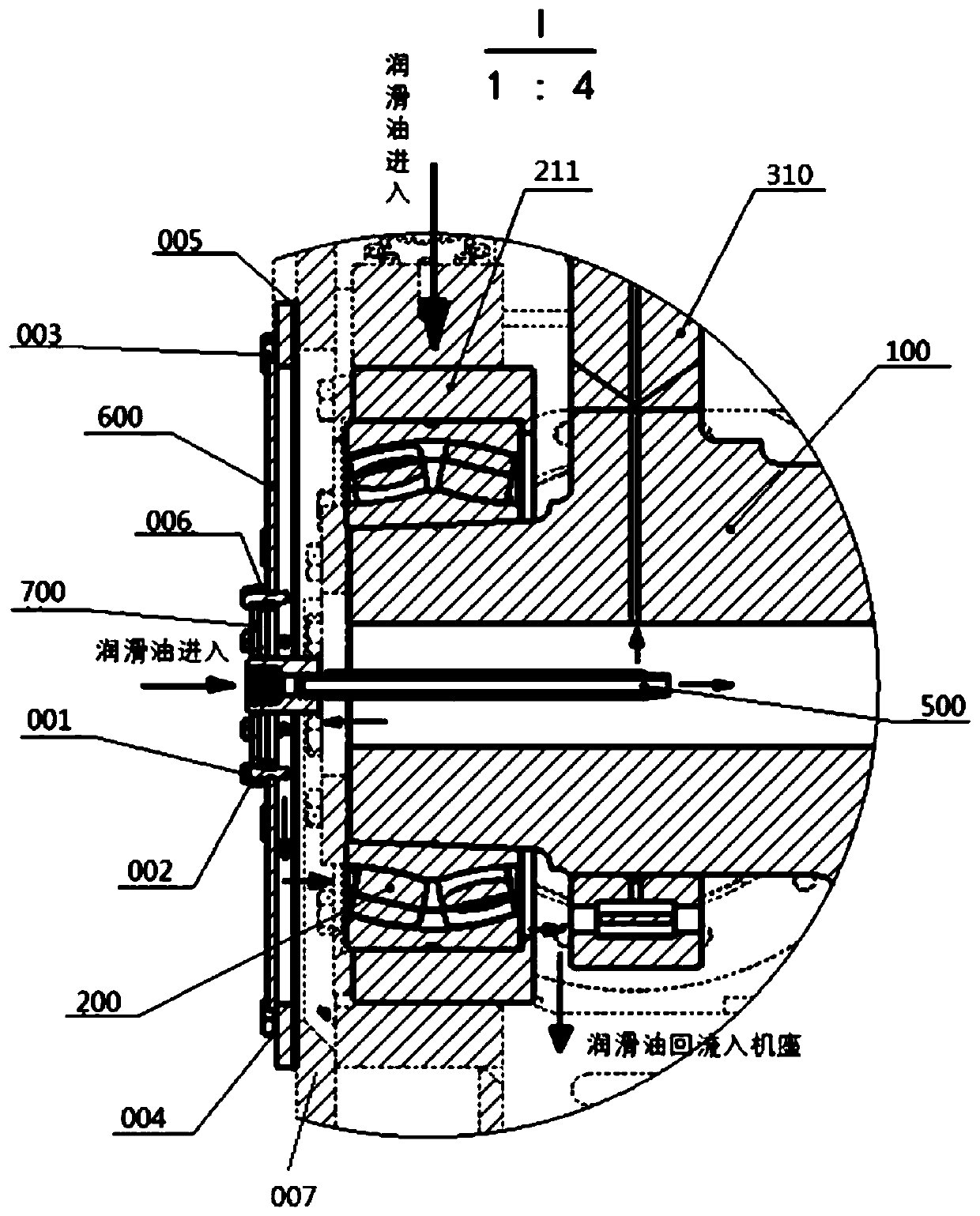

[0026] See figure 1 and figure 2, this embodiment provides a crankshaft bearing lubrication system suitable for drilling mud pumps, including a crankshaft 100, a first main bearing 210, a first eccentric bearing 310, a second eccentric bearing 320, a first A central main bearing 410, a third eccentric bearing 330, a second central main bearing 420, a fourth eccentric bearing 340, a fifth eccentric bearing 350, and a second main bearing 220. The end of the crankshaft 100 is provided with a main bearing cap plate 600, the main bearing cover plate 600 is installed with an end cover 700, and the center of the end cover 700 is provided with a nipple 500, and the lubricating oil enters from the center position of the end cover 700 and flows into the central passage of the crankshaft 100 after being accelerated and pressurized by the nipple 500. In the hole, the outer ring of the first main bearing 210 is provided with a first oil groove and the first oil holes distributed on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com