Shielding cover assembly

A shielding cover and component technology, which is applied in the fields of magnetic field/electric field shielding, electrical components, electrical equipment structural parts, etc., can solve problems affecting heat dissipation efficiency and blocking air flow, etc., to improve heat dissipation efficiency, increase heat dissipation efficiency, and facilitate assembly with quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0162] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

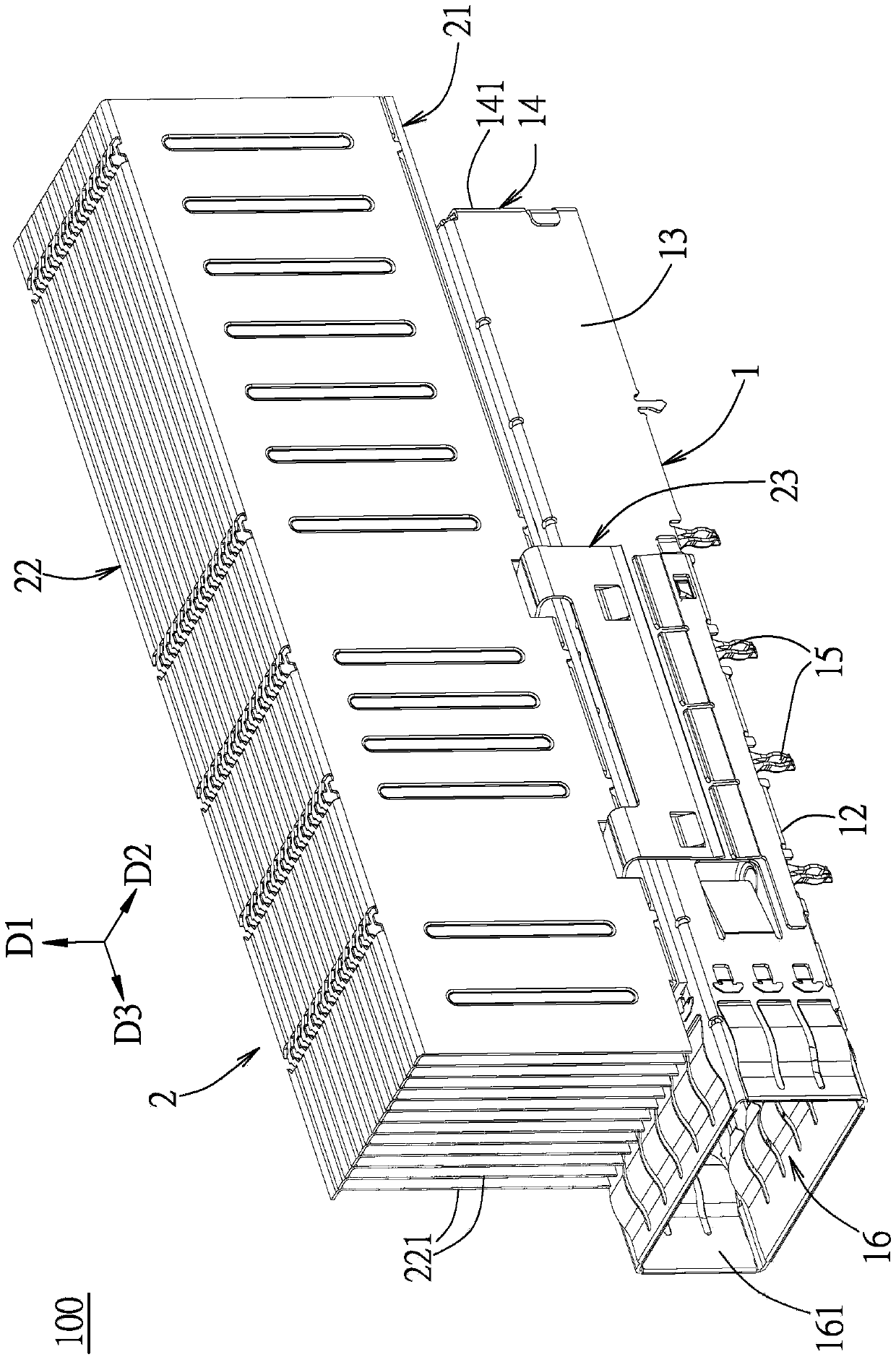

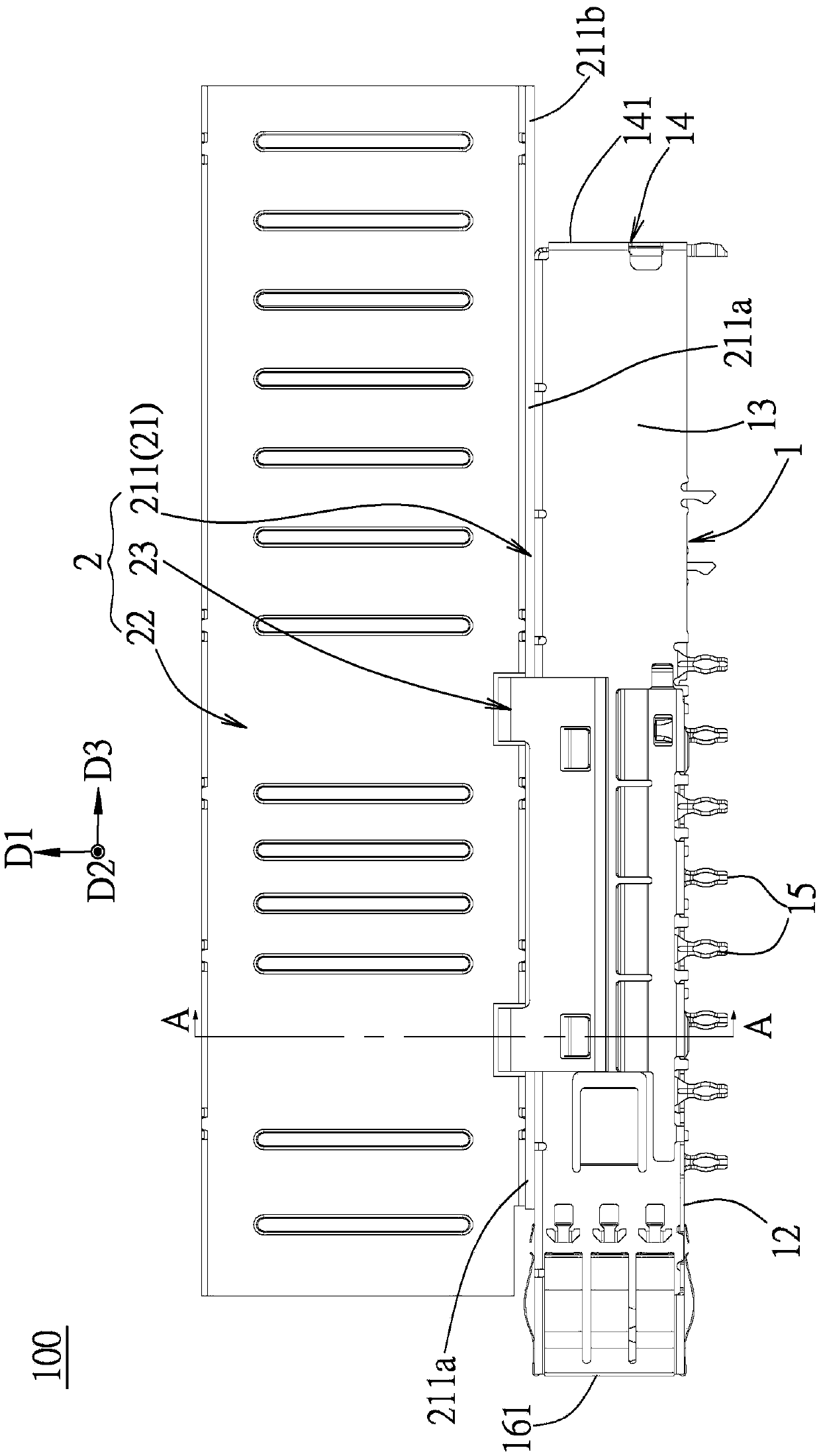

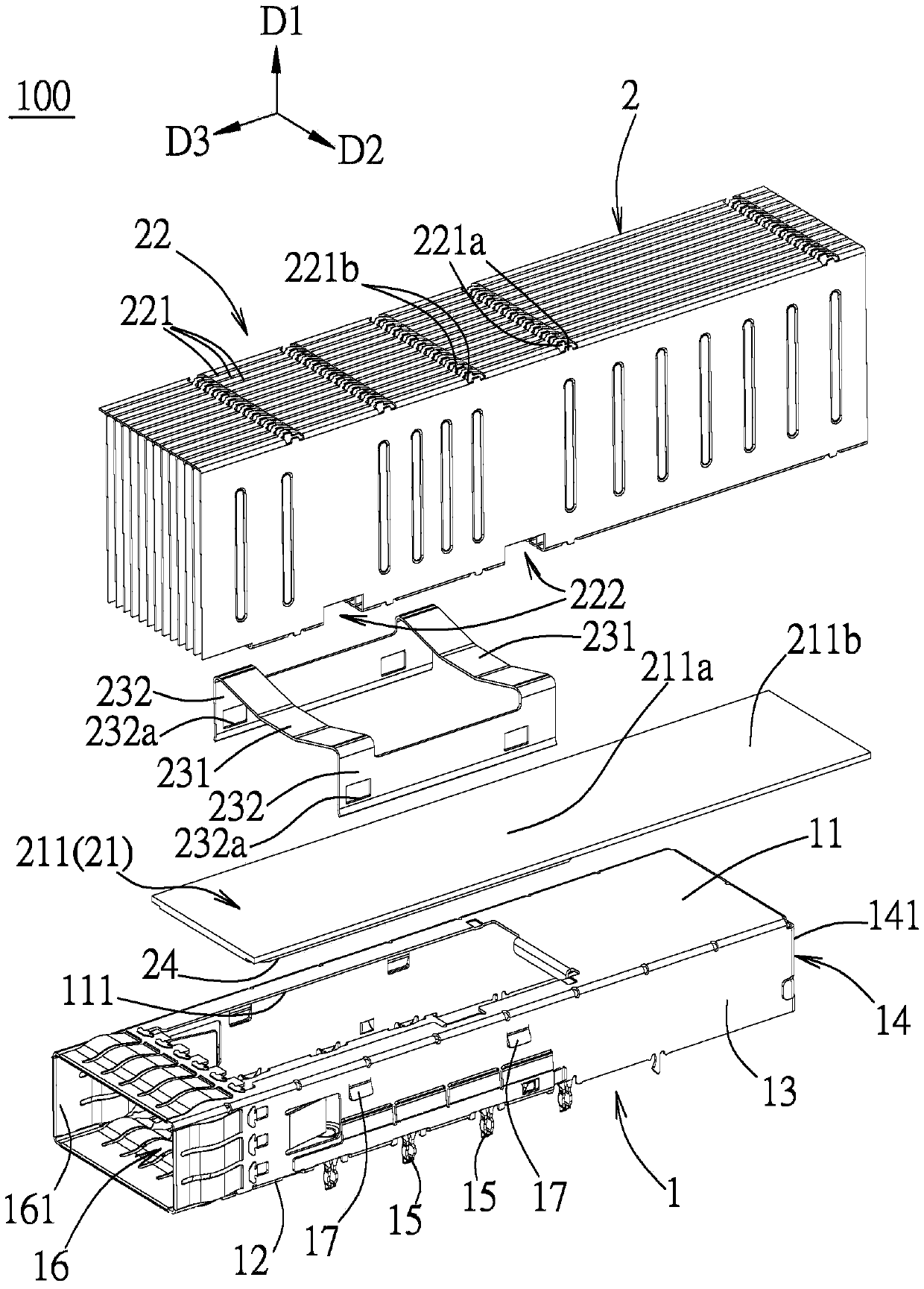

[0163] Figure 1 to Figure 6 For a first embodiment of the shield assembly 100 of the present invention, see figure 1 and figure 2 , the first embodiment includes a metal shielding case 1 and a heat dissipation module 2 .

[0164] refer to figure 2 and image 3 , the metal shielding case 1 is made of a metal plate and is used to accommodate electronic modules (including sockets and plugs, not shown in the figure), the metal shielding case 1 has a plurality of walls, and a housing composed of a plurality of said walls In the space 16, a plurality of walls include a top wall 11, a bottom wall 12 spaced opposite to the top wall 11 along a vertical direction D1, two spaced apart from each other along a left-right direction D2, and connected to the bottom wall 12 and the bottom wall 12 respectively. The side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com