A low-speed continuous water-based ink printing process

A water-based ink and process technology, used in inks, printing, printing machines, etc., can solve the problems of difficult printing pattern adhesion, fast drying speed of ink, and inability to perform printing operations, so as to solve environmental pollution and personnel health problems. Gloss, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

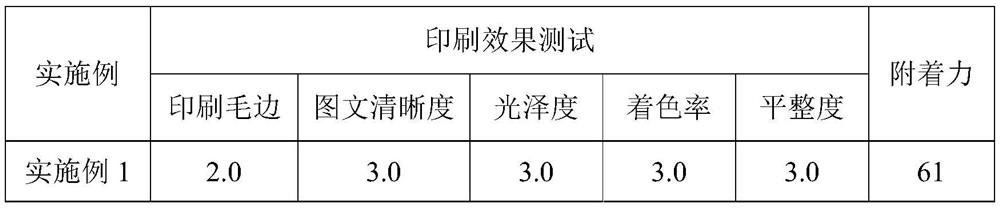

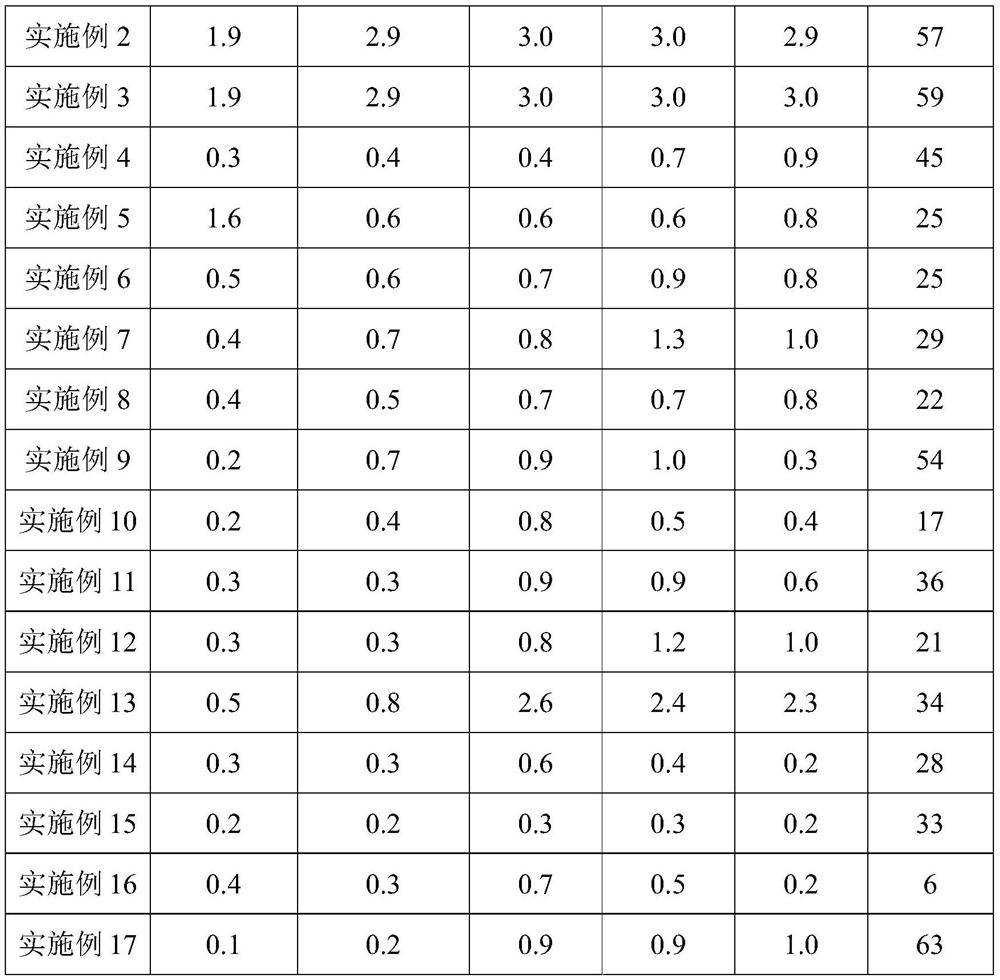

Examples

Embodiment 1

[0083] Embodiment 1 of the present invention provides a kind of low-speed continuous water-based ink printing process, comprises the following steps:

[0084] Step 1. Adjust the printing machine: ①Put the bag on the film blowing machine and the printing machine according to the bag threading procedure; ②Before the power of the printing machine is turned on, set the lifting mode of the plate roller gear and the take-off wheel to automatic, and the plate roller gear lift switch Set it to rise; ③Set the ink wheel of the C / D two-color printing seat to front printing, and then turn on the blower to preheat for 10 minutes for use.

[0085] Step 2. Extracting the film: ① Adjust the height of the ink tank poured into the ink, so that the ink can touch the ink wheel evenly, and fix it on the printing machine; ② Fix the printing plate on the printing machine by adhesive connection, and the printing plate The four sides are fixed with tape; ③ Adjust the speed of the main machine so that ...

Embodiment 2

[0091] Embodiment 1 of the present invention provides a kind of low-speed continuous water-based ink printing process, comprises the following steps:

[0092] Step 1. Adjust the printing machine: ①Put the bag on the film blowing machine and the printing machine according to the bag threading procedure; ②Before the power of the printing machine is turned on, set the lifting mode of the plate roller gear and the take-off wheel to automatic, and the plate roller gear lift switch Set it to rise; ③Set the ink wheel of the C / D two-color printing seat to front printing, and then turn on the blower to preheat for 5 minutes before use.

[0093]Step 2. Extracting the film: ① Adjust the height of the ink tank poured into the ink, so that the ink can touch the ink wheel evenly, and fix it on the printing machine; ② Fix the printing plate on the printing machine by adhesive connection, and the printing plate The four sides are fixed with tape; ③ Adjust the speed of the main machine so that...

Embodiment 3

[0099] Embodiment 3 of the present invention provides a kind of low-speed continuous water-based ink printing process, comprises the following steps:

[0100] Step 1. Adjust the printing machine: ①Put the bag on the film blowing machine and the printing machine according to the bag threading procedure; ②Before the power of the printing machine is turned on, set the lifting mode of the plate roller gear and the take-off wheel to automatic, and the plate roller gear lift switch Set it to rise; ③Set the ink wheel of the C / D two-color printing seat to front printing, and then turn on the blower to preheat for 15 minutes before use.

[0101] Step 2. Extracting the film: ① Adjust the height of the ink tank poured into the ink, so that the ink can touch the ink wheel evenly, and fix it on the printing machine; ② Fix the printing plate on the printing machine by adhesive connection, and the printing plate The four sides are fixed with tape; ③ Adjust the speed of the main machine so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com