Product transfer adsorption structure of braider

An adsorption structure and braiding machine technology, applied in the field of braiding machines, can solve the problems of inaccurate moving position, failure to meet requirements, low degree of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As shown in conjunction with the accompanying drawings, the technical scheme of the present invention is further described:

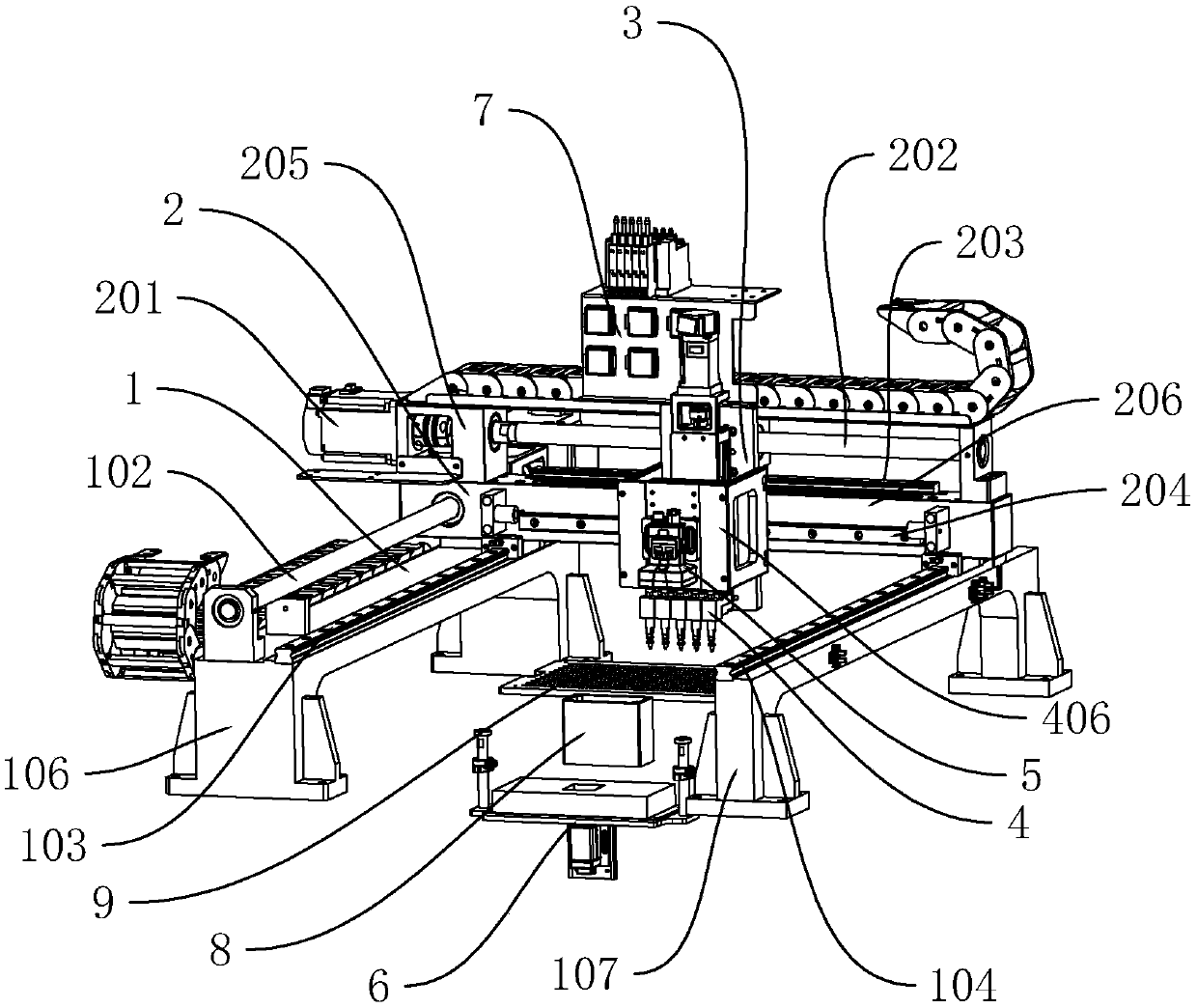

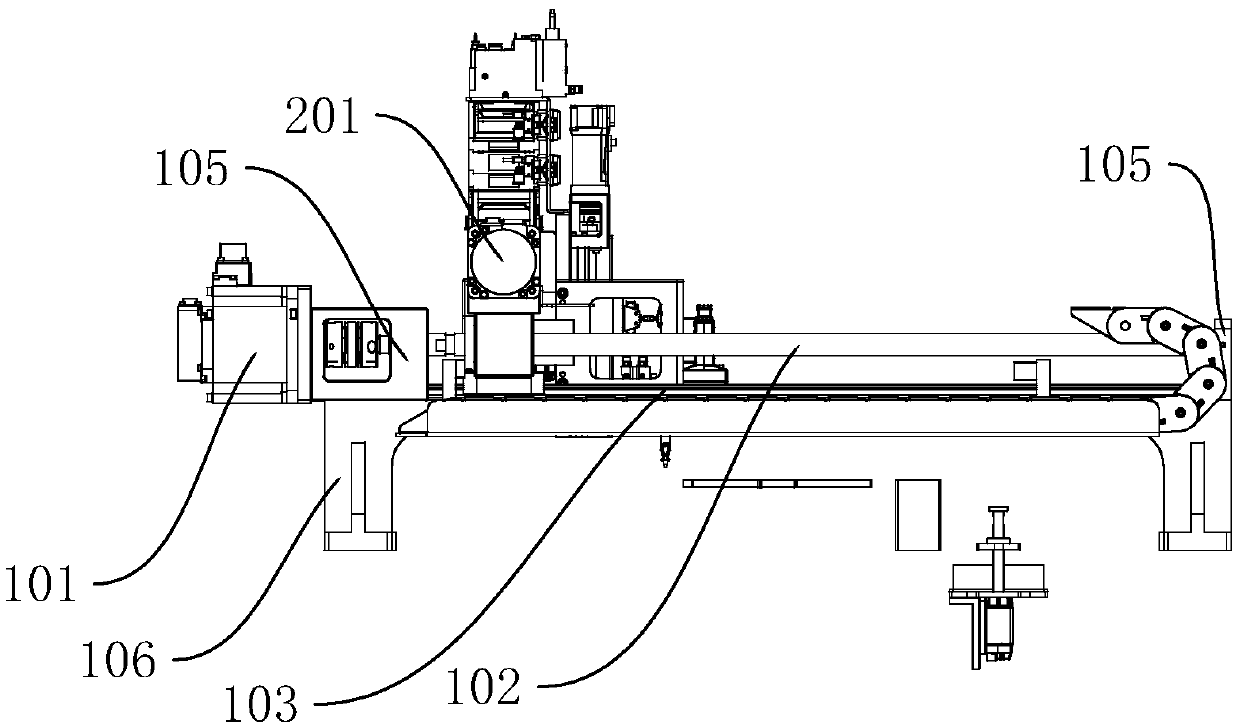

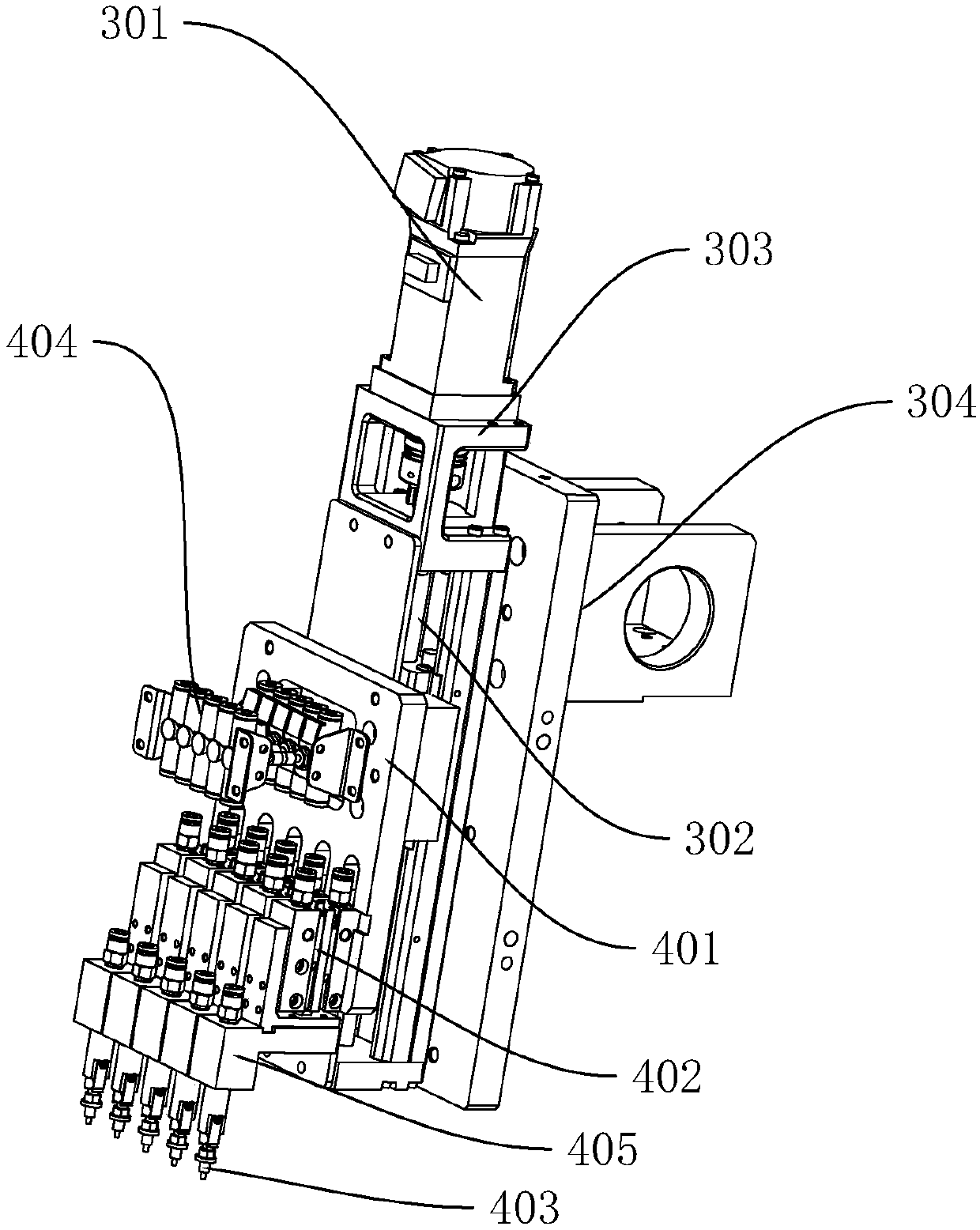

[0034] as attached figure 1 and attached figure 2 As shown in the figure, a product transfer adsorption structure of a tape machine, the adsorption structure is fixedly arranged on the table top, and the adsorption structure includes a Y-axis module 1, an X-axis module 2, a Z-axis module 3, a suction The material device 4, the structure 5 is detected first, and the structure 6 is detected later. Among them, the movement of Y-axis module 1, X-axis module 2, and Z-axis module 3 in three directions ensures that any position of the suction device 4 can be adjusted. The first detection structure 5 and the latter detection structure 6 play a detection role. The detection structure 5 detects whether the position of the product is accurate before the suction device 4 picks up the product, and the post detection structure 6 detects whether the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com