Metamorphic grabbing mechanism

A technology of grabbing mechanism and traversing mechanism, applied in the direction of conveyor objects, transportation and packaging, storage devices, etc., can solve the problems of narrow passages, difficult transformation, short and narrow doors, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

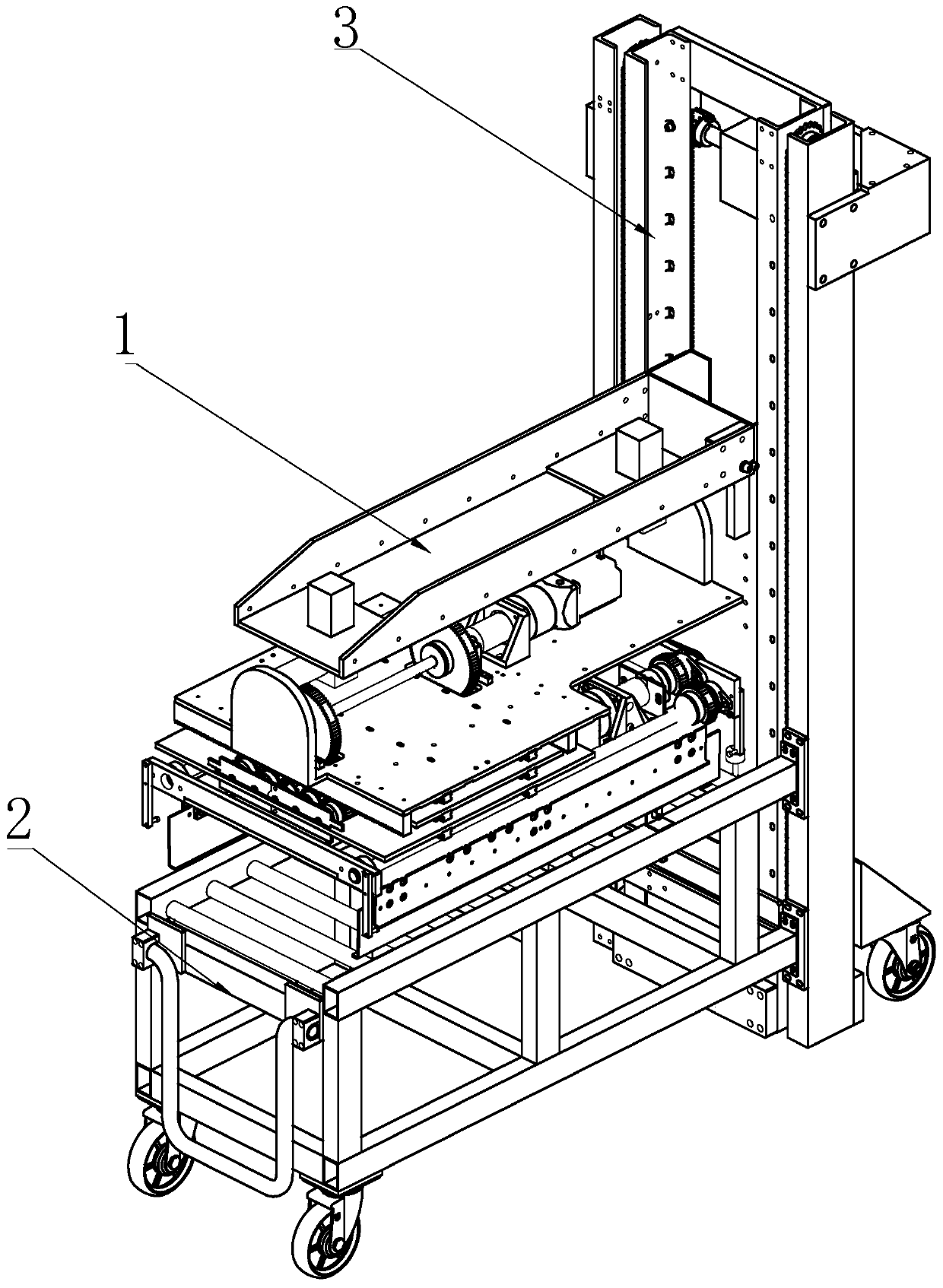

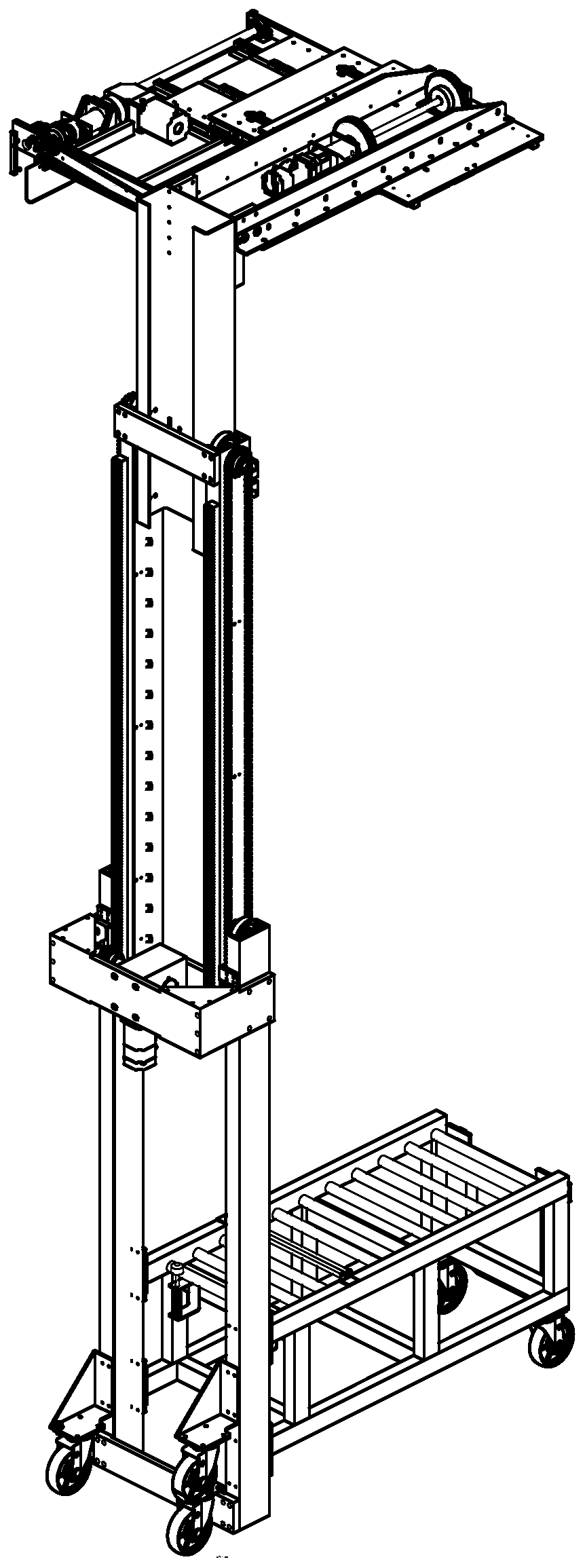

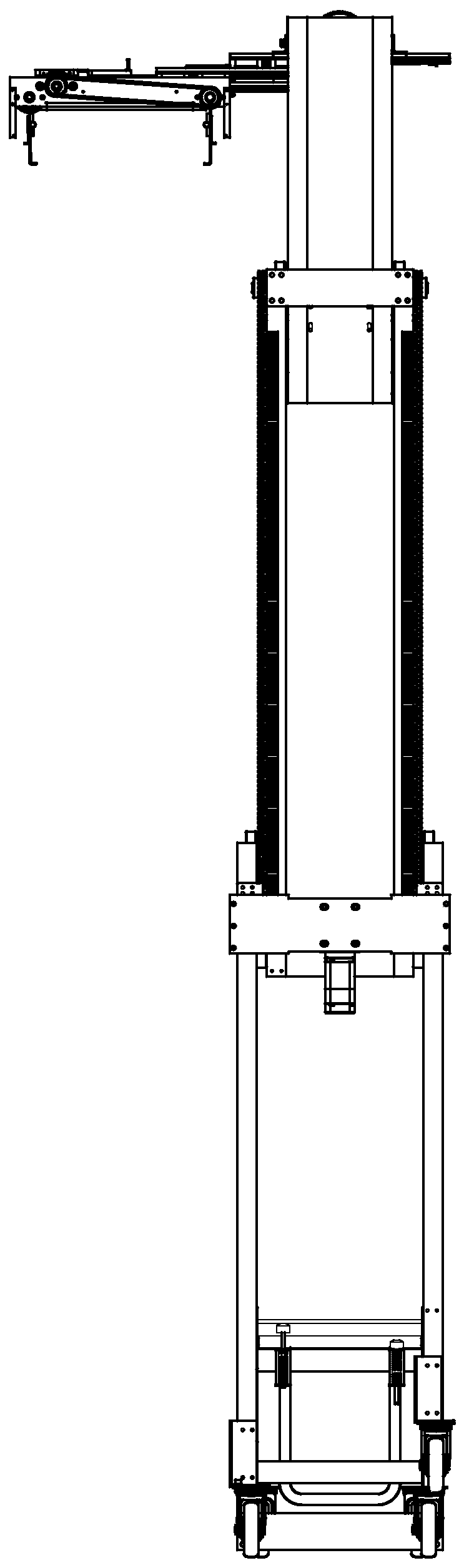

[0050] The metamorphic grasping mechanism includes a vertical support, a stage, a traverse mechanism that moves laterally relative to the stage, and a lifting device that drives the traverse mechanism to move up and down. One end of the stage is connected to the vertical On the bracket, the lifting device moves up and down on the vertical bracket. The traversing mechanism is connected with the lifting device and moves up and down following the lifting device. The vertical bracket and the stage are equipped with casters for easy walking. It is provided with a metamorphic grasping mechanism that is arranged in pairs facing the stage to perform synchronous reverse rotation.

[0051] like figure 1 , grabbing type loading and unloading machine includes 1 traverse mechanism, 2 loading platforms, 3 lifting devices,

[0052] like Figure 4 , The traversing mechanism includes four parts, a first traversing device 11 , a second traversing device 12 , a third traversing device 13 , and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap