A drafting and setting mechanism for textile yarn processing

A setting mechanism and textile yarn technology, applied in the field of textile processing machinery and textile yarn drafting processing, can solve the problems of reducing the quality of textile yarn, complex structure, difficulty in ensuring the drafting efficiency and quality of textile yarn, etc. , to achieve the effects of smooth and orderly drawing processing and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

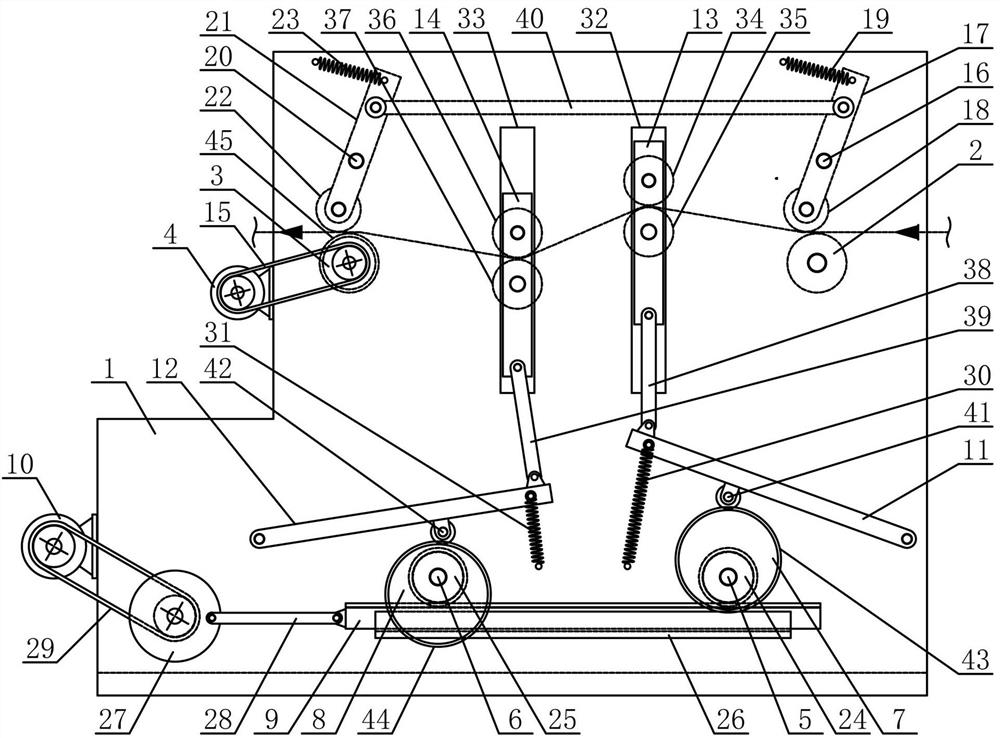

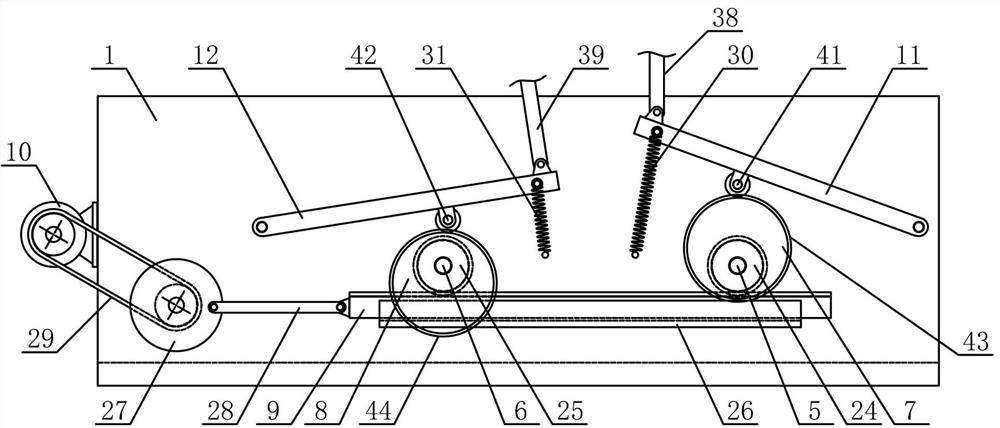

[0014] In order to further describe the present invention, a specific implementation of a drafting and setting mechanism for textile yarn processing will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0015] Such as figure 1 with figure 2 As shown, a drafting and setting mechanism for textile yarn processing of the present invention includes a processing material transfer support 1, a feeding roller 2, a pulling roller 3, a feeding motor 4, a front drafting shaft 5, a rear Drafting shaft 6, front rotating cam 7, rear rotating cam 8, drafting rack 9, drafting motor 10, front push plate swing bar 11, rear push plate swing bar 12, front lift guide plate 13 and rear lift guide plate 14, The feeding roller 2 and the pulling roller 3 are horizontally connected to the upper side of the processing material transfer support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com