Chemical fiber yarn tension buffer device capable of preventing yarn breakage

A tension buffering device and technology for chemical filaments, which are applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, can solve the problems of chemical filaments that cannot be buffered in motion, broken chemical filaments, etc., and achieve fast and convenient fixed connection. The effect of disassembling with activities, preventing wire breakage and entanglement, and reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

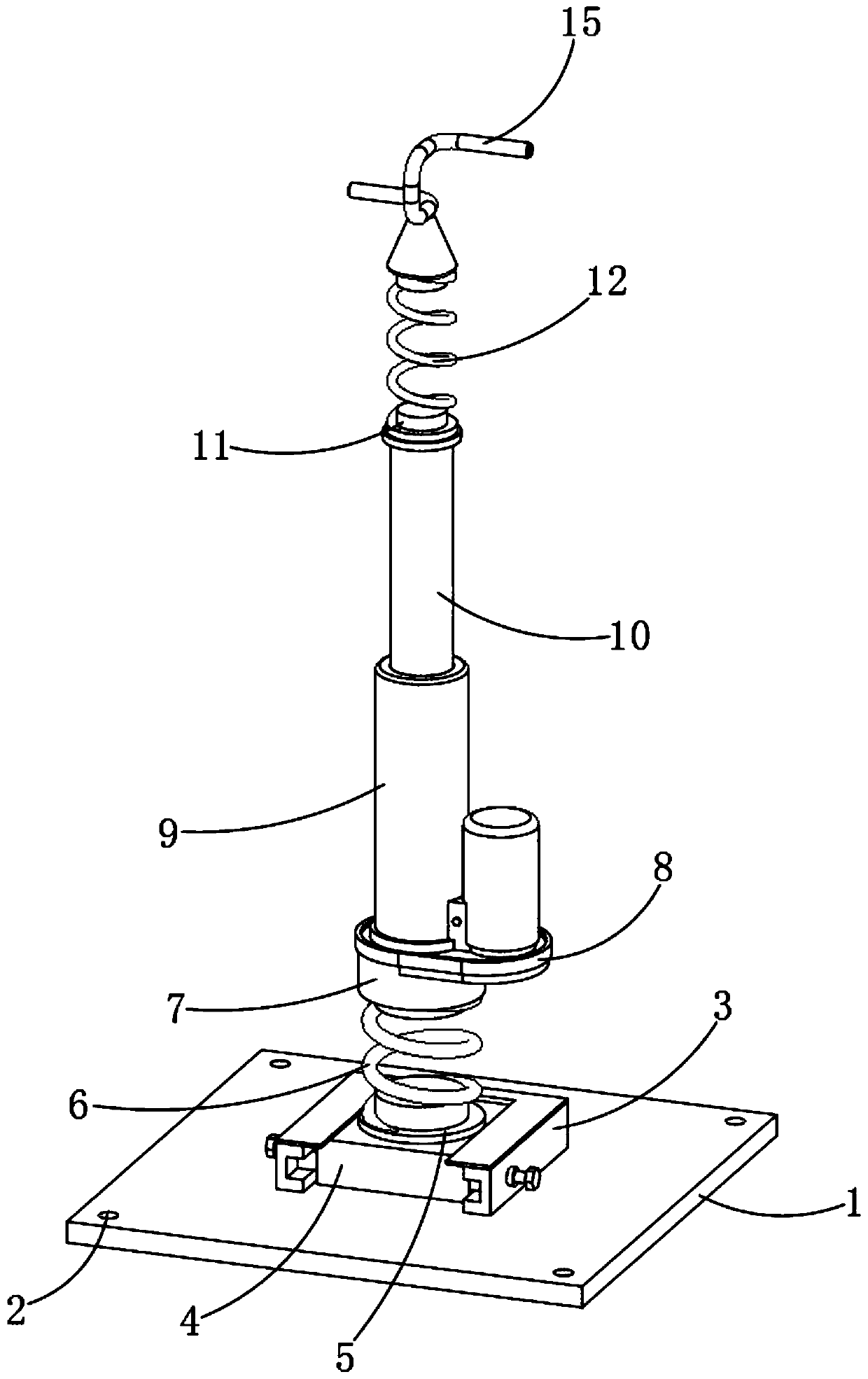

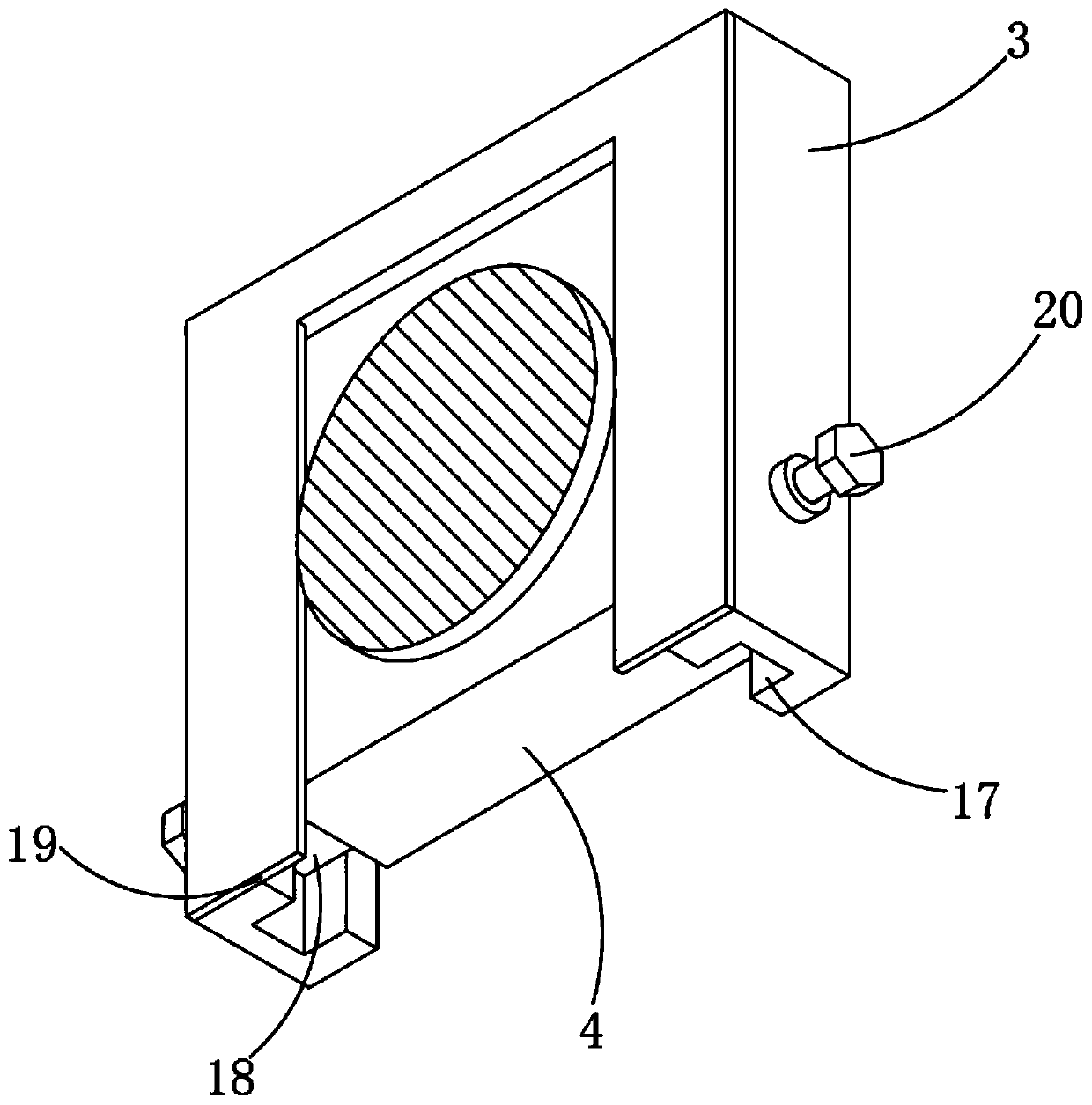

[0024] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a chemical fiber yarn tension buffer device for preventing yarn breakage, comprising a mounting plate 1, each corner of the mounting plate 1 is provided with fixing holes 2, and the middle part of the top end of the mounting plate 1 is fixed and installed There is a connection sleeve 3, and the inner side of the connection sleeve 3 is embedded with a disassembly base 4;

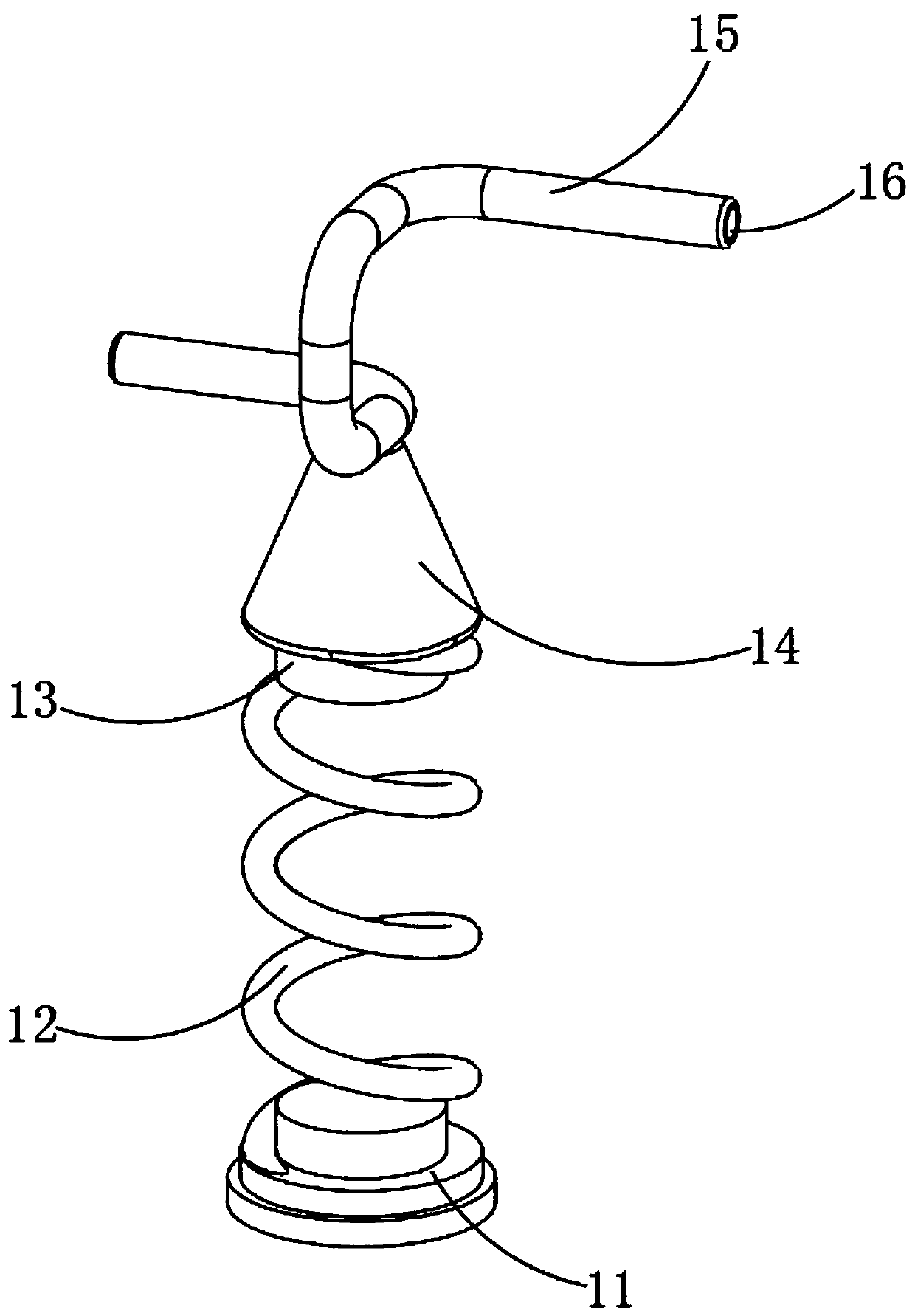

[0025] A spring base 5 is fixedly installed on the top of the dismountable base 4, a first buffer spring 6 is fixedly connected to the top of the spring base 5, a buffer connection seat 7 is fixedly installed on the top of the first buffer spring 6, and a mounting platform 8 is installed on the top of the buffer connection seat 7 An electric telescopic rod 9 is fixedly installed on the inner side of the mounting platform 8, and the inner side of the electric telescopic rod 9 is embedded with a movable rod 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com