Patents

Literature

73results about How to "Accurate and efficient transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

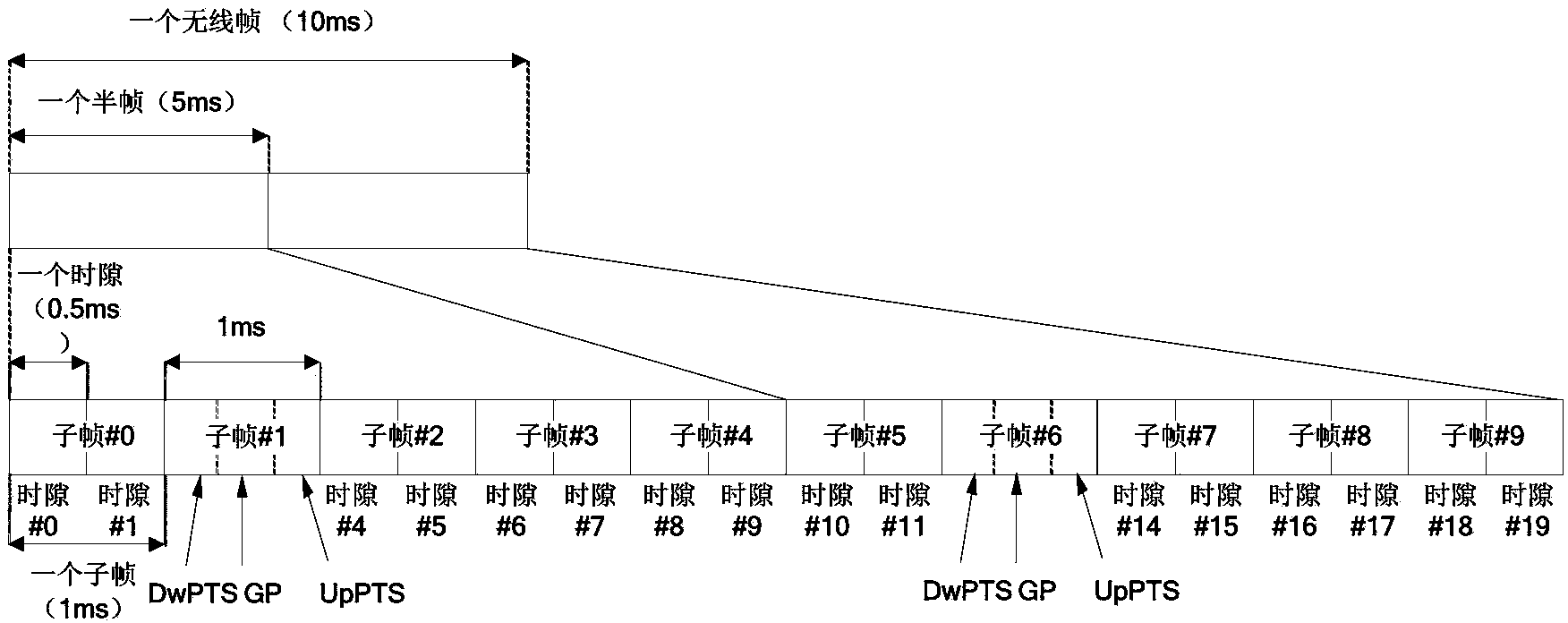

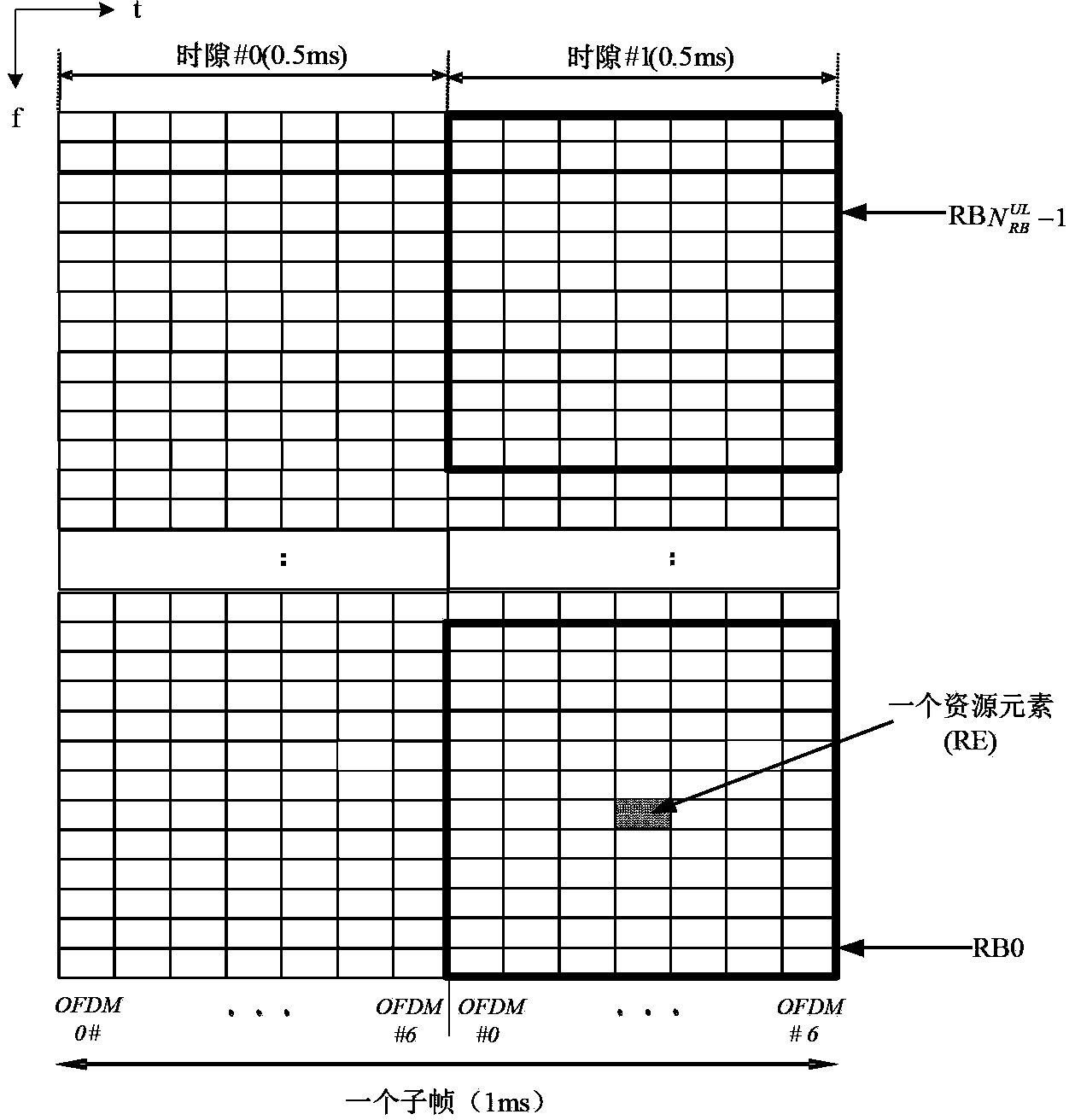

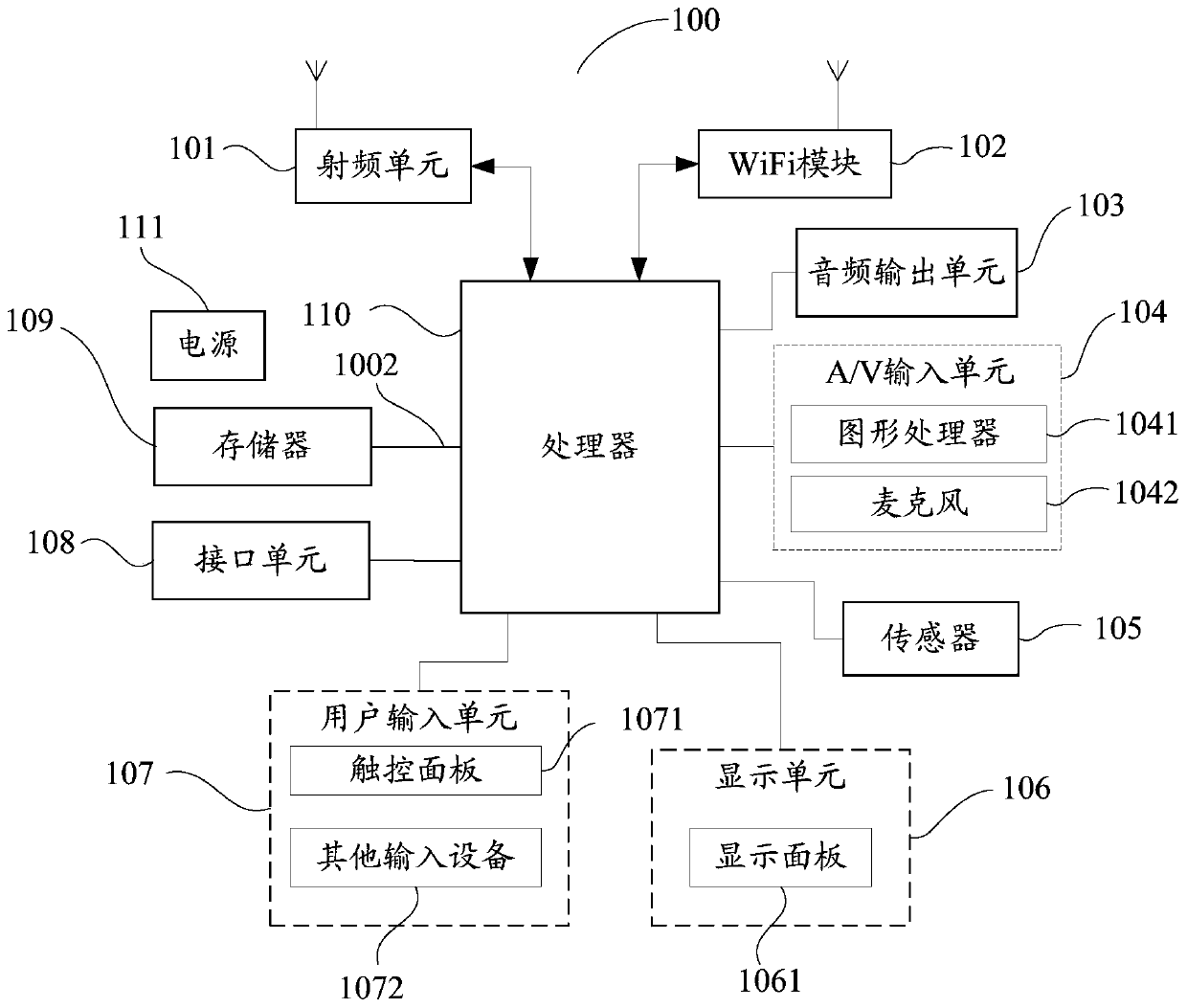

Method and device for processing uplink and downlink resource configuration information

ActiveCN104105203AAvoid inconsistenciesAccurate and efficient transmissionTransmission path multiple useWireless communicationRound complexityReal-time computing

The invention provides a method and a device for processing uplink and downlink resource configuration information. The method comprises a step of transmitting uplink and downlink resource configuration information on a downlink control signaling of a flexible subframe. The invention solves the problems that in a condition that the uplink and downlink configuration is dynamically adjusted in the related technology, when the high level signal realization is adopted, the cycle and the delay are long , and the execution for the signaling between the terminal and the base station is not constant, and that when the physic layer signaling realization is adopted, the cost for the physic layer control signaling is big and the complexity for the device realization is high. The invention can effectively avoid the problems that the high level signaling delay is long and that the understanding for the execution timing of the terminal and the base station inconsistent on the premises that the extra physic layer resources are not occupied, the extra cost for the control signaling is not added and the complexity of the device is not increased, and can realize the highly efficient and precise transmission of the uplink and downlink resource configuration information.

Owner:ZTE CORP

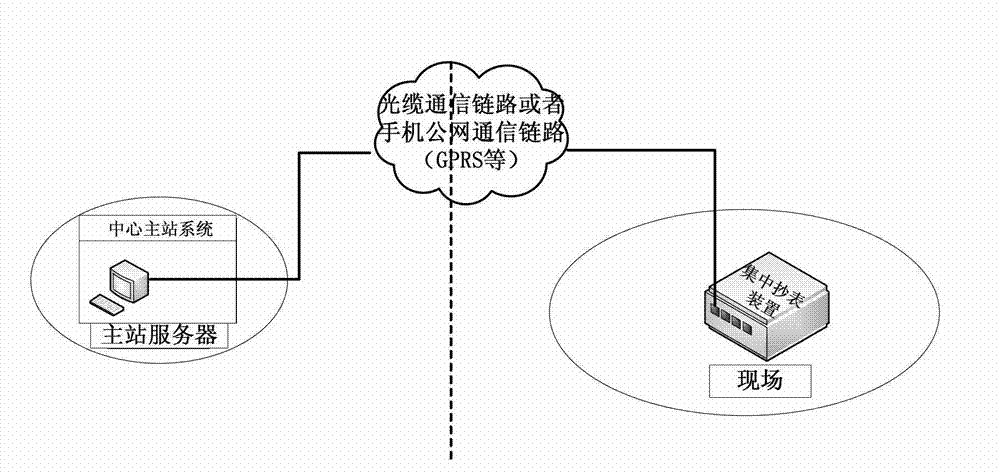

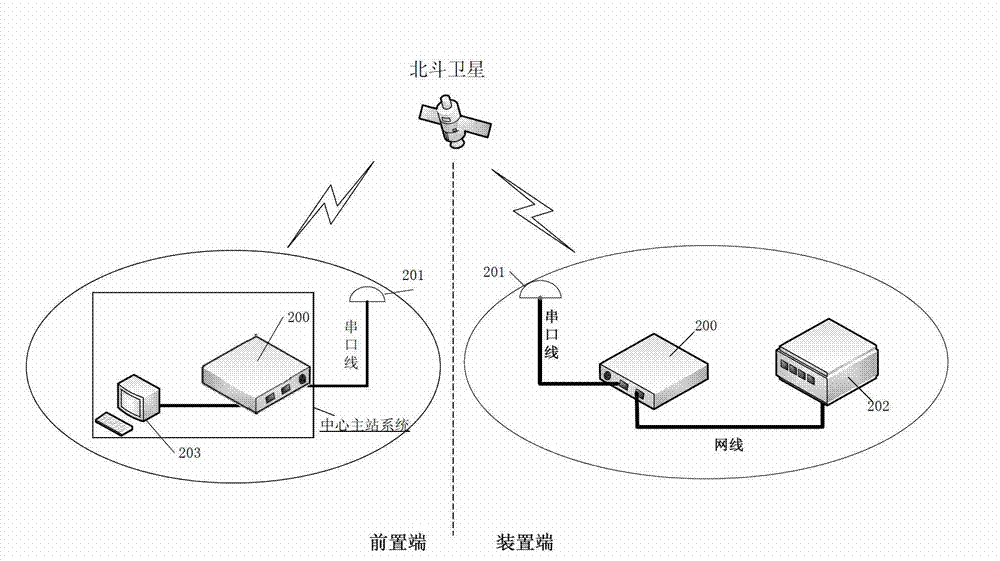

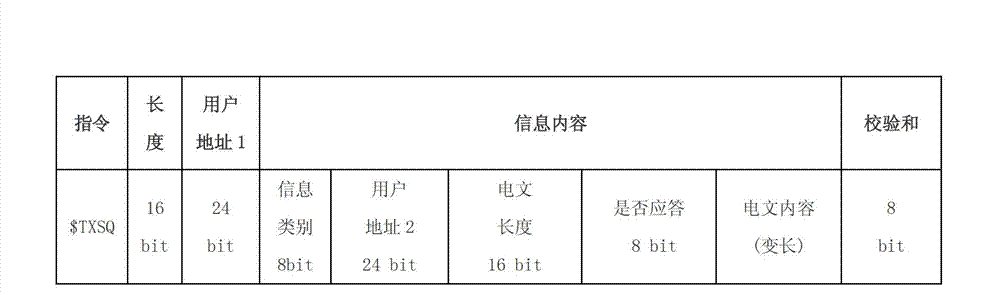

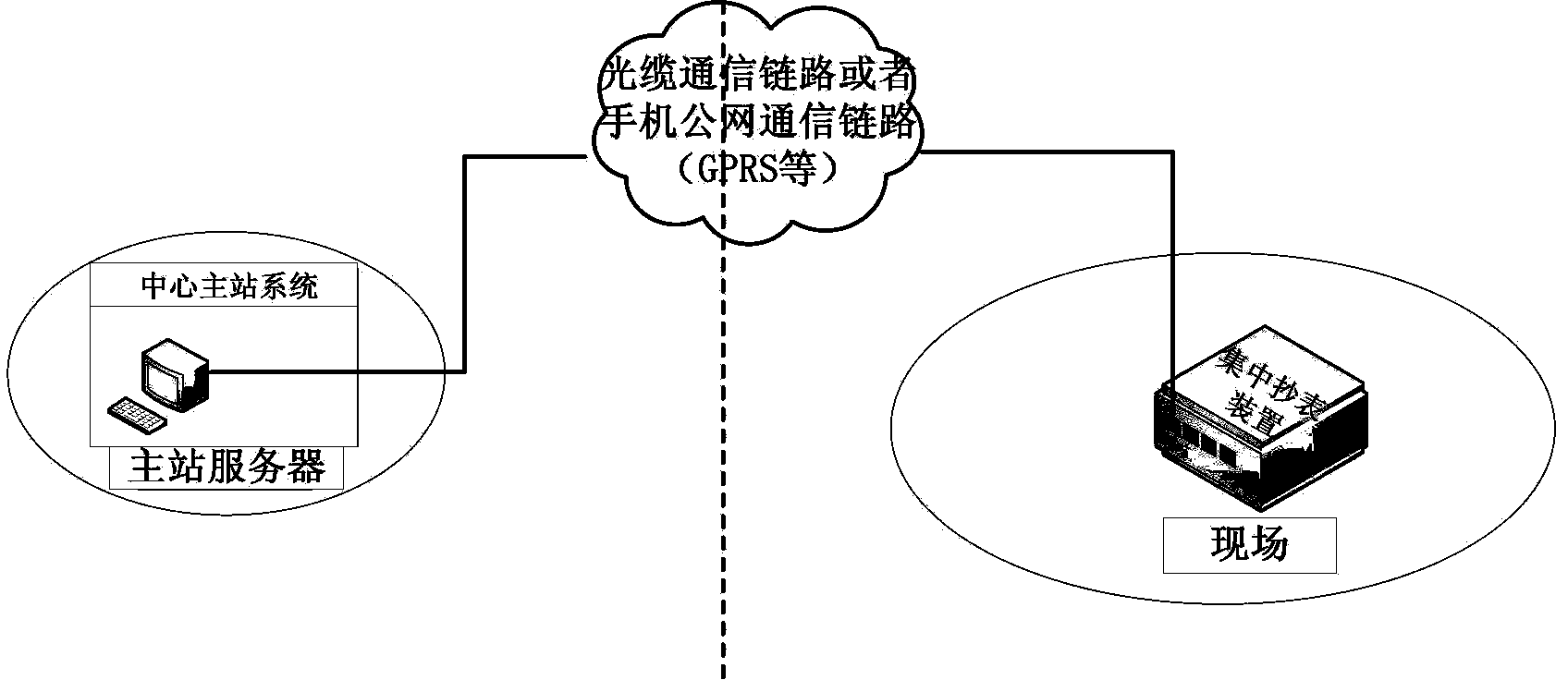

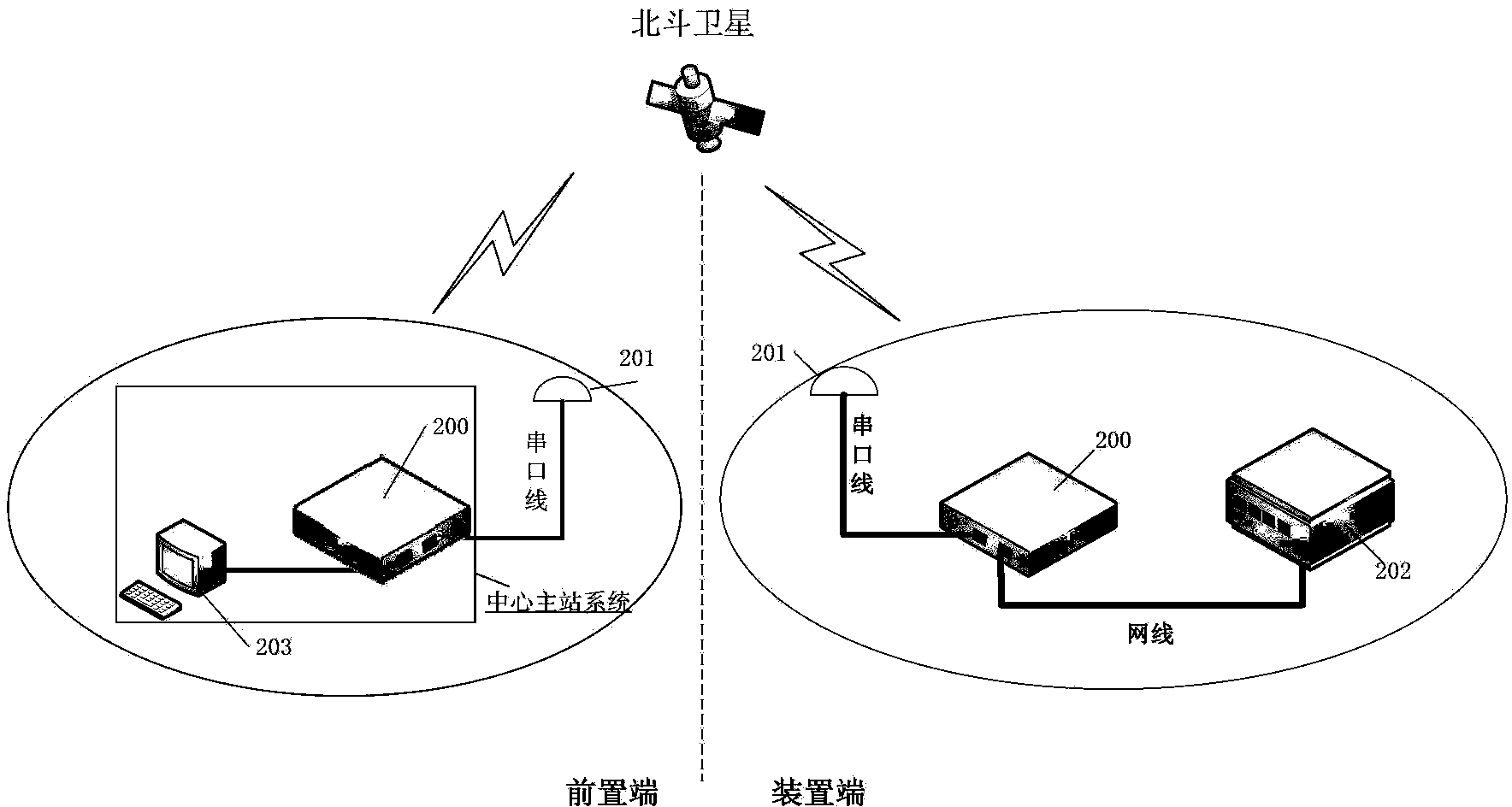

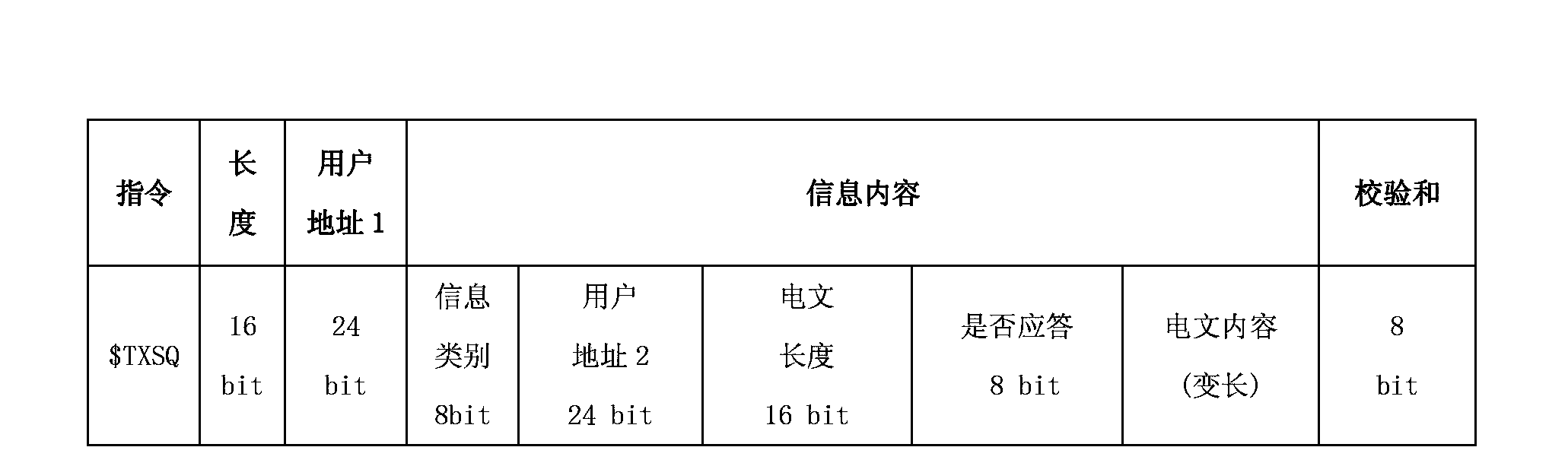

Power utilization information collection method and system based on technology of Beidou satellite navigation system

ActiveCN102810243AAvoid managementAccurate and efficient transmissionTransmission systemsRadio transmissionTelecommunications linkCommunication link

The invention provides a power utilization information collection method and a system based on a technology of a Beidou satellite navigation system. The technical scheme comprises the following steps of: obtaining a meter reading data message of collected power utilization information, also generating a Beidou communication message by the data conversion of the meter reading data message and transmitting the Beidou communication message to a prepositive end by a Beidou communication link; and reducing the Beidou communication message to the original format of the meter reading data message by the prepositive end and also transmitting to an application server of a central master station for carrying out united managing and monitoring. By adopting the method and the system which are provided by the invention, the power utilization information of residents in a site can be connected to a master station of a power utilization information management system in a seamless way by utilizing the two-way communication function of a Beidou satellite navigation system under the condition that traditional operation equipment is not reconstructed so as to realize the process from the collection of data in the site to the connection of a Beidou communication channel. The power utilization information of regions with undeveloped communication can be effectively and reliably obtained at real time.

Owner:GZH BEIDOU TECH GRP

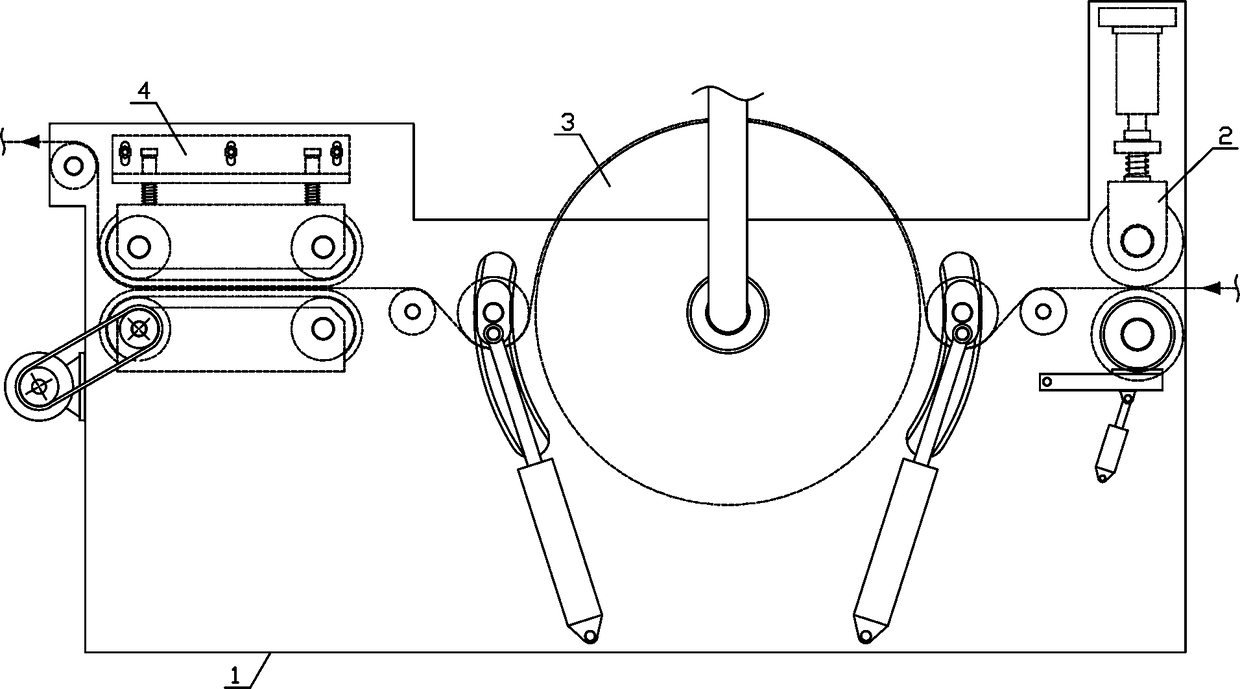

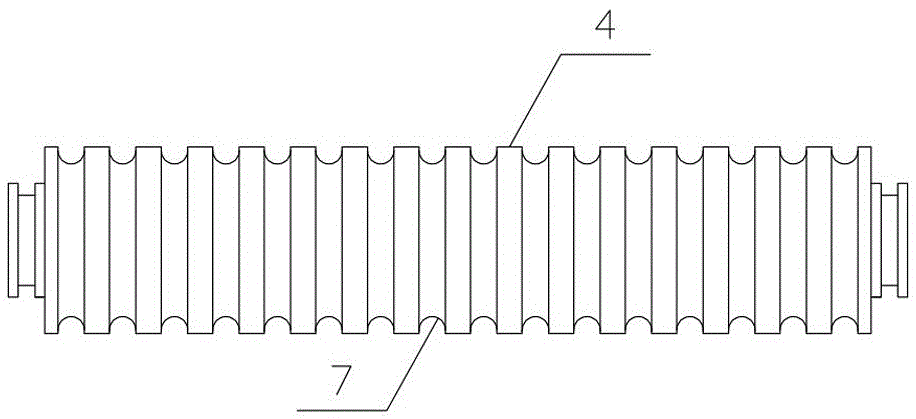

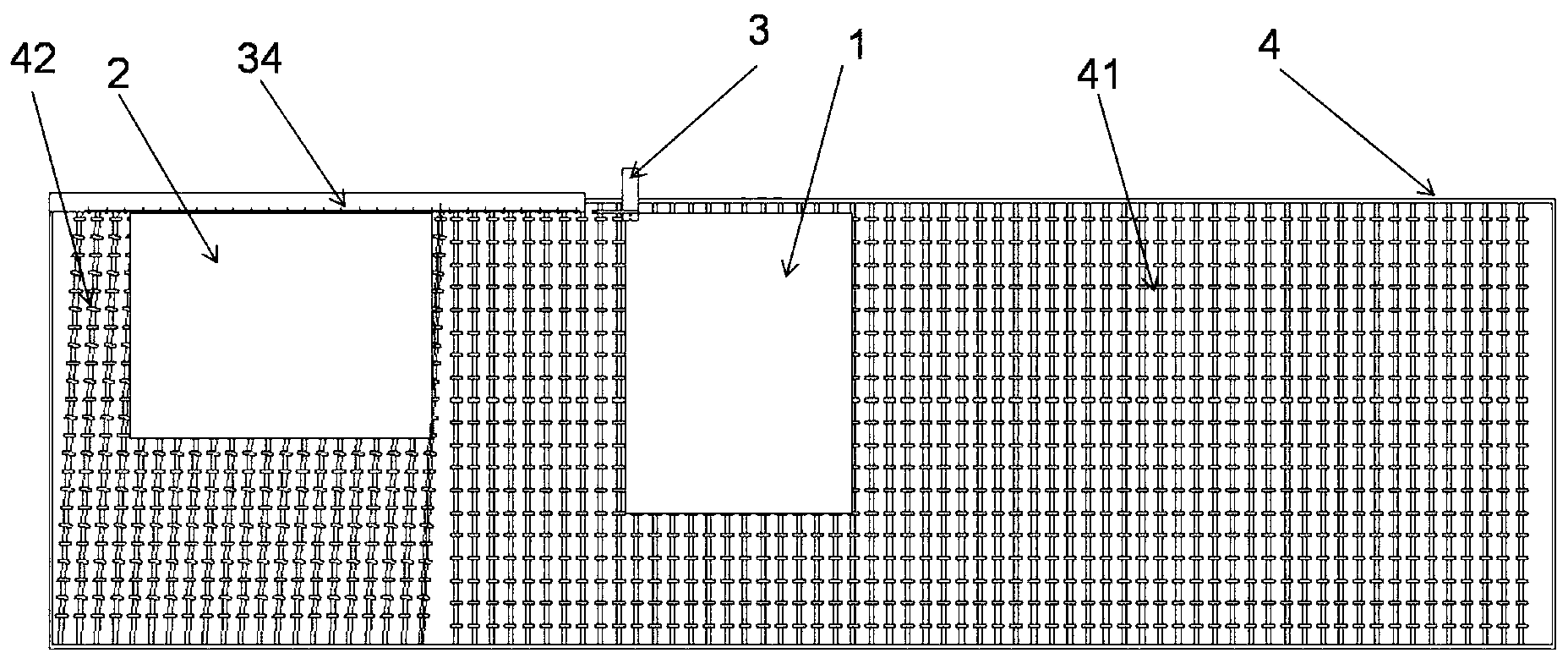

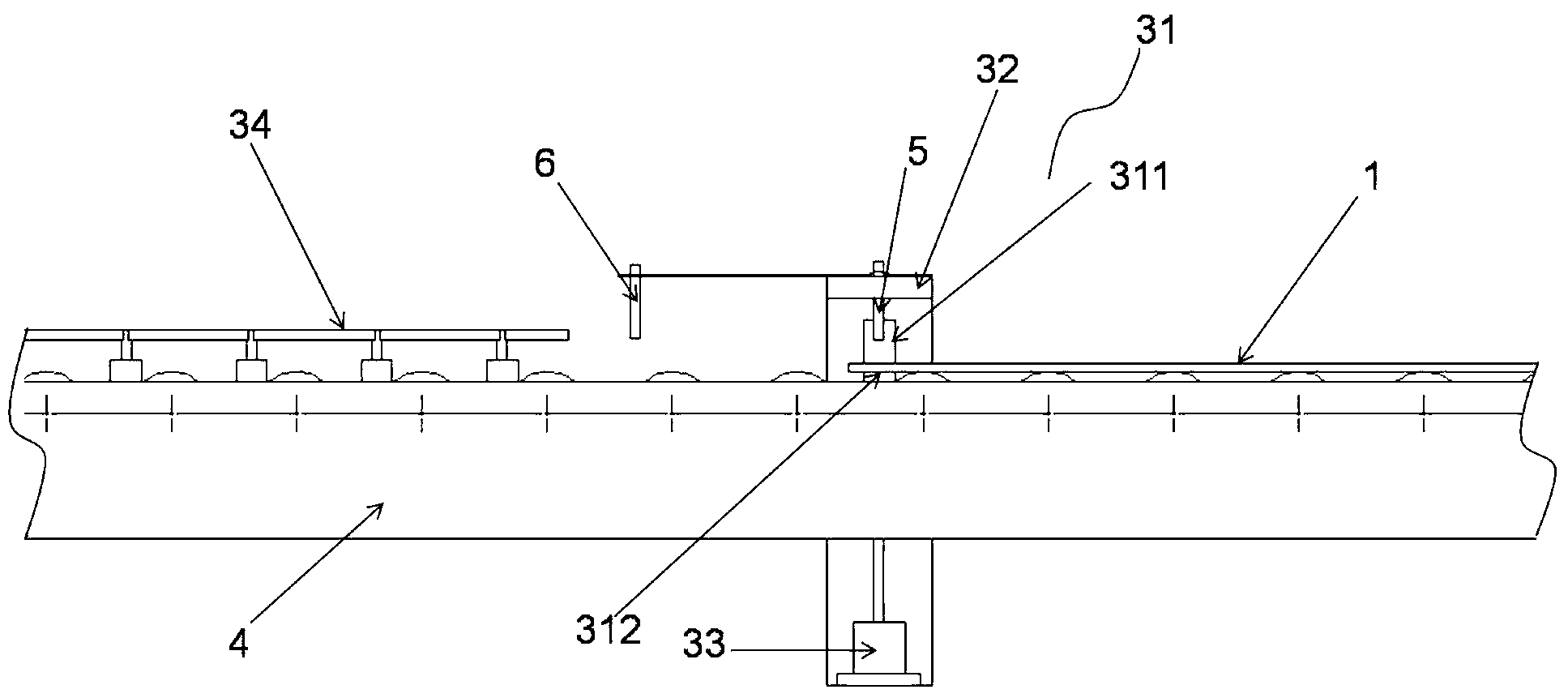

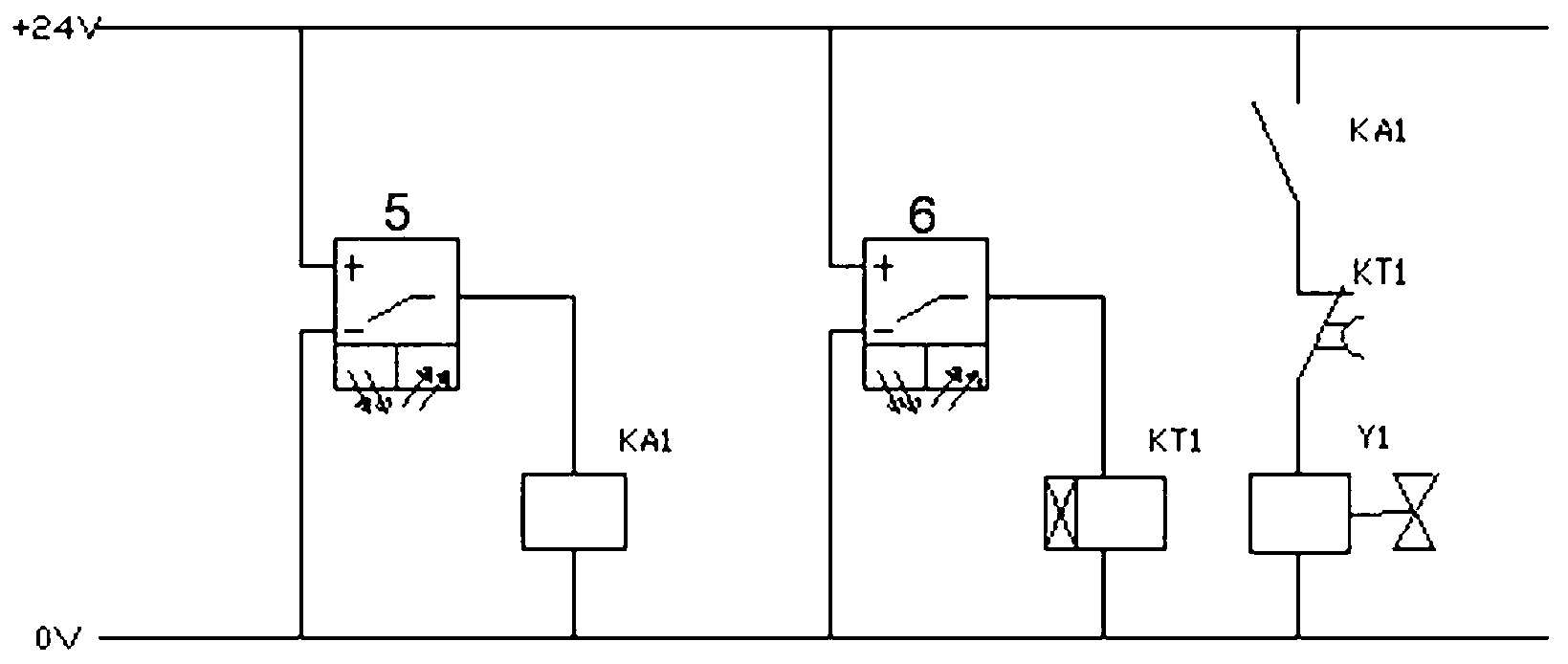

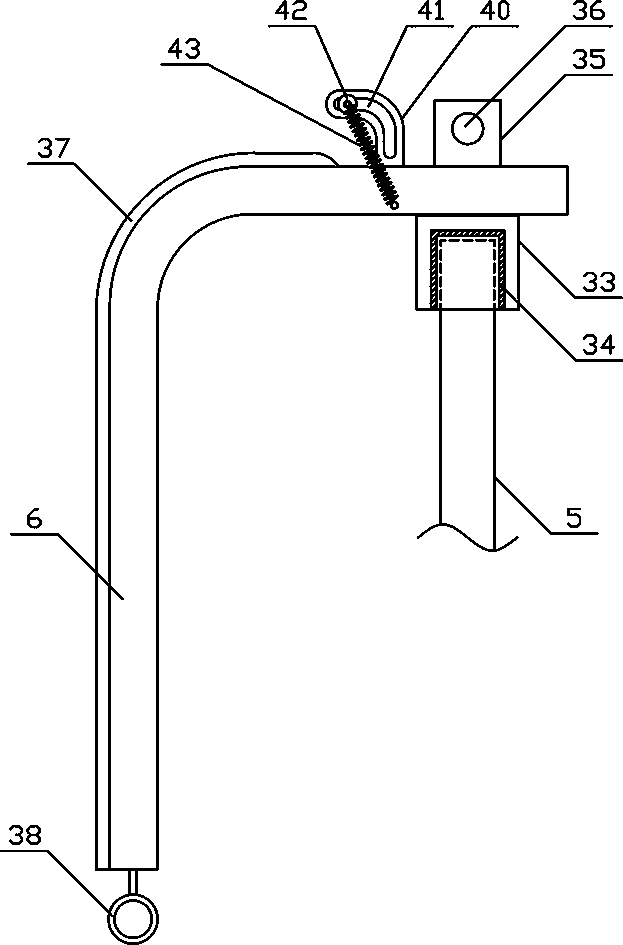

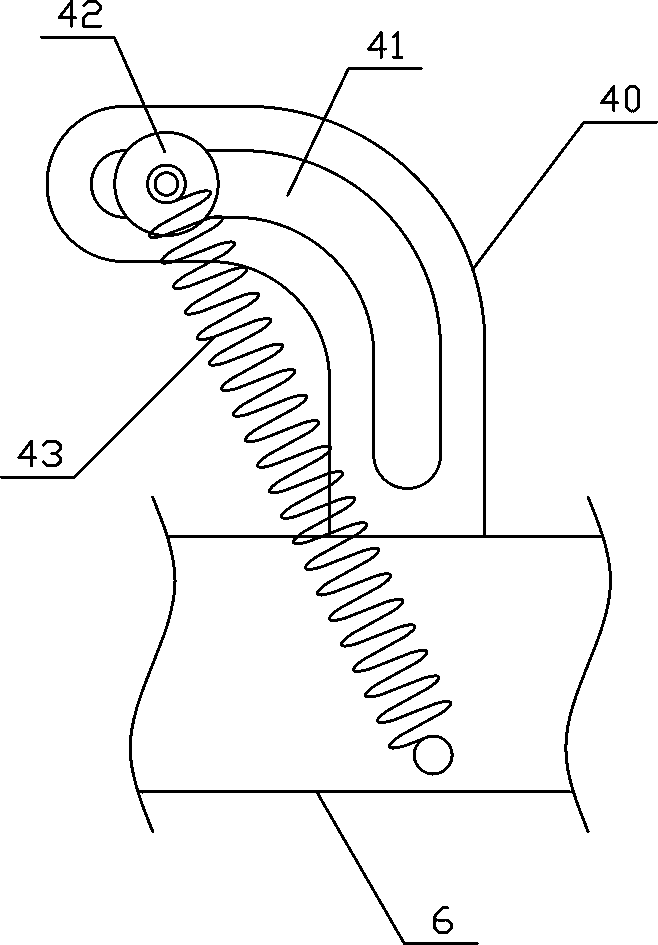

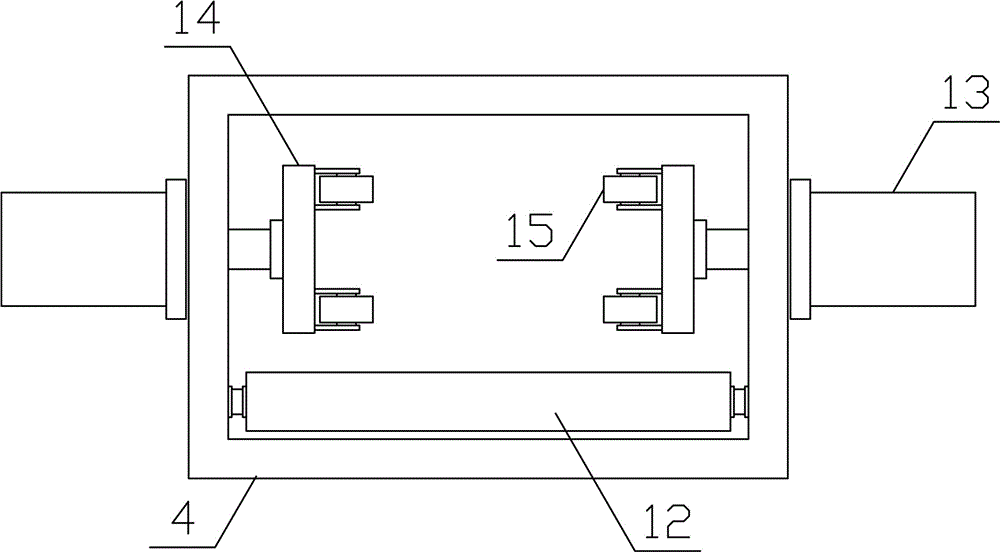

Yarn conveying and pulling mechanism

PendingCN108584532AStable and even stretchingEfficient heatingFilament handlingTextiles and paperYarnHeat conducting

The invention discloses a yarn conveying and pulling mechanism, and belongs to the field of textile processing mechanical equipment. According to the yarn conveying and pulling mechanism, a yarn feeding mechanism, a pulling mechanism and a yarn guide mechanism are arranged on a fixing support in sequence in the horizontal direction. A lower yarn bearing guide roller is connected with the portion,located on the lower side of an upper yarn press guide roller, of the fixing support in a horizontal rotation mode. A shaping rotating drum is connected to the portion, located between a front yarn guide roller and a rear yarn guide roller, of the fixing support in a horizontal rotation mode, and a heat-conducting oil pipe is arranged at the shaft ends of the two sides of the shaping rotating drumin a communicating mode. Pulling guide plates are arranged in pulling guide grooves in a sliding mode in the circular arc direction, and the pulling guide grooves are formed in the two sides of the shaping rotating drum. One end of one pulling rotating roller and the same end of the other pulling rotating roller are connected to the pulling guide plates on the two sides of the fixing support in arotating mode correspondingly. A yarn discharging guide roller is connected to the portion, located on one side of an adjusting support, of the fixing support in a horizontal rotation mode. The yarnconveying and pulling mechanism is reasonable in structural design, can efficiently and accurately convey yarn, and can conduct stable pulling shaping on the yarn section by section in the conveying process, the degree of automation of yarn processing is improved, and the requirements of production and usage are met.

Owner:嘉兴市华益股份有限公司

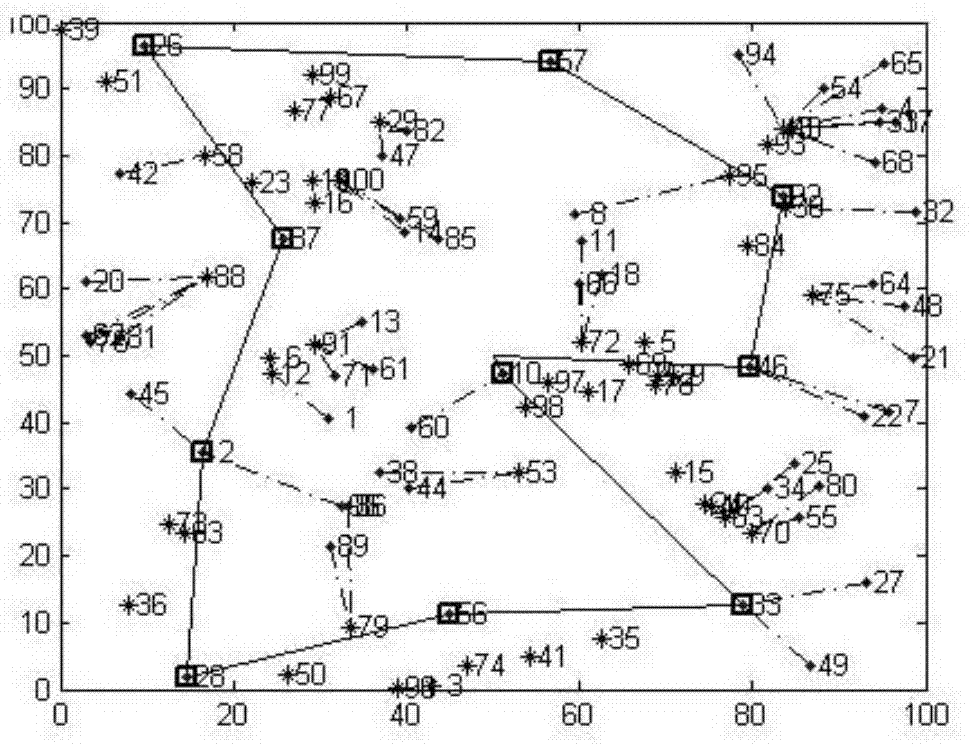

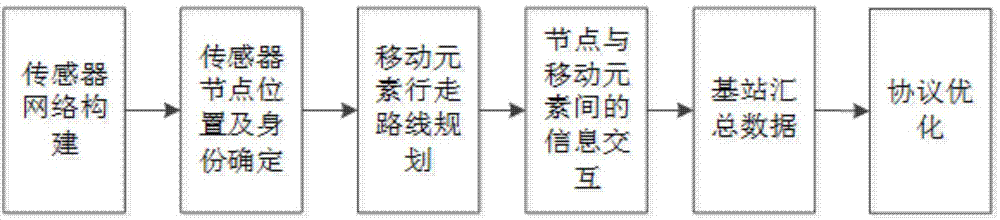

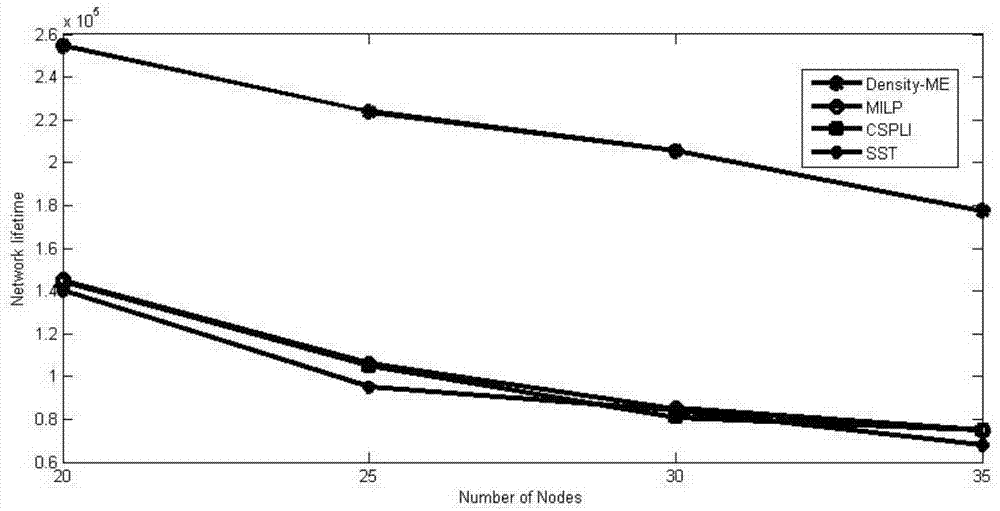

Wireless sensor network data acquisition method based on multi-hop routing and mobile elements

InactiveCN104754683AReduce energy consumptionProlong survival timeNetwork topologiesTransmissionInformation transmissionInformation transfer

The invention provides a wireless sensor network data acquisition method based on multi-hop routing and mobile elements. The method includes obtaining a network through wireless sensor nodes and a base station, by means of sensor node position determination and identifier determination, planing the mobile element walking routes, completing the information transmission between the wireless sensor nodes and the mobile elements, and allowing the mobile elements to transmit the information acquired during walking to the base station until the network dies. The method is adaptive to large scale, self organization, random arrangement, environment complexity and other characteristics of the wireless sensor network and can be arranged and used in a large amount in the field which is populated sparsely, the mobile elements and the traditional clustering algorithm are combined, the data can be transmitted effectively and accurately, the energy consumption of the sensor nodes is reduced, the topology structure changes while the nodes die, the cluster head node and the second level cluster head are re-selected, the energy consumption of the cluster head node is reduced to the utmost extent, and the total survive time of the network is prolonged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

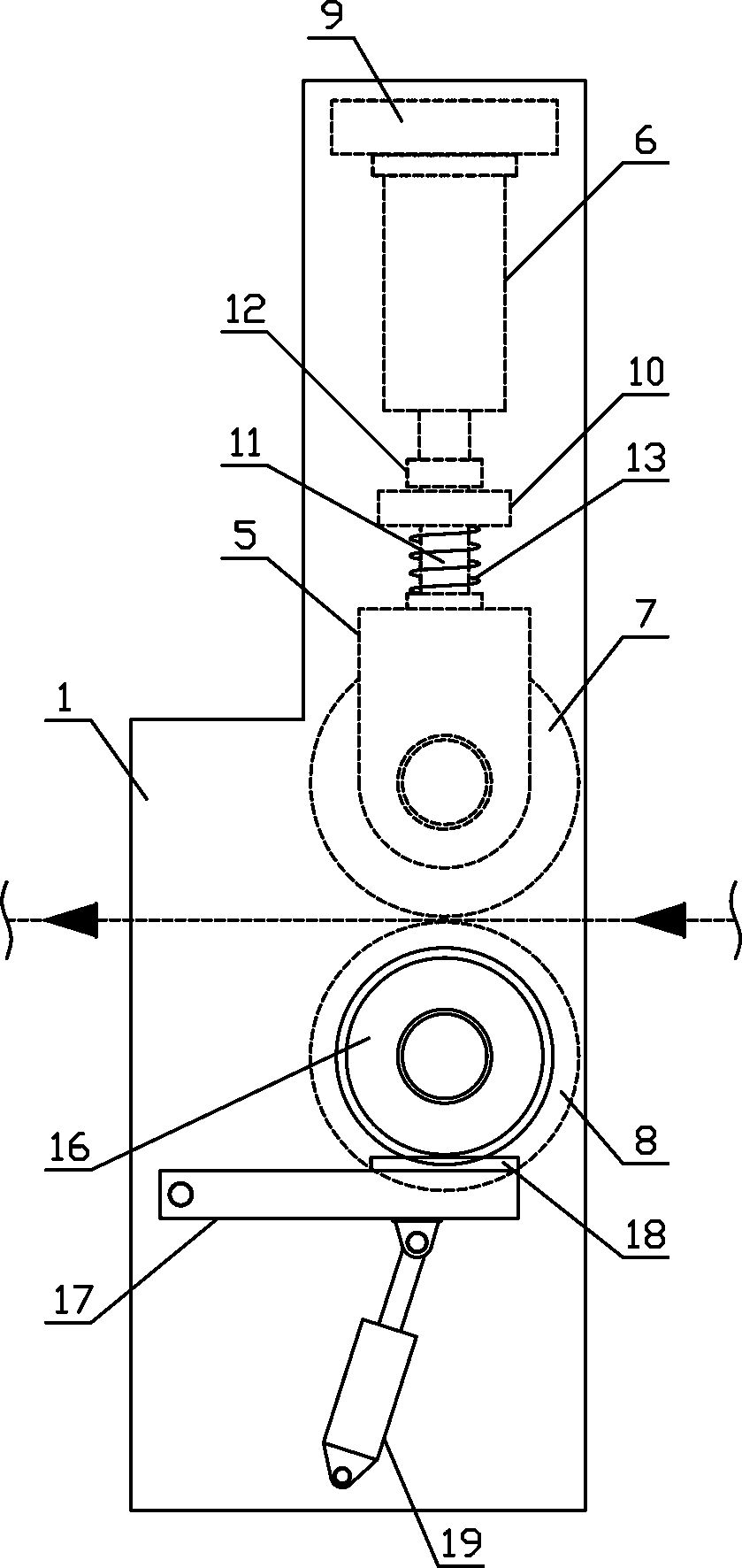

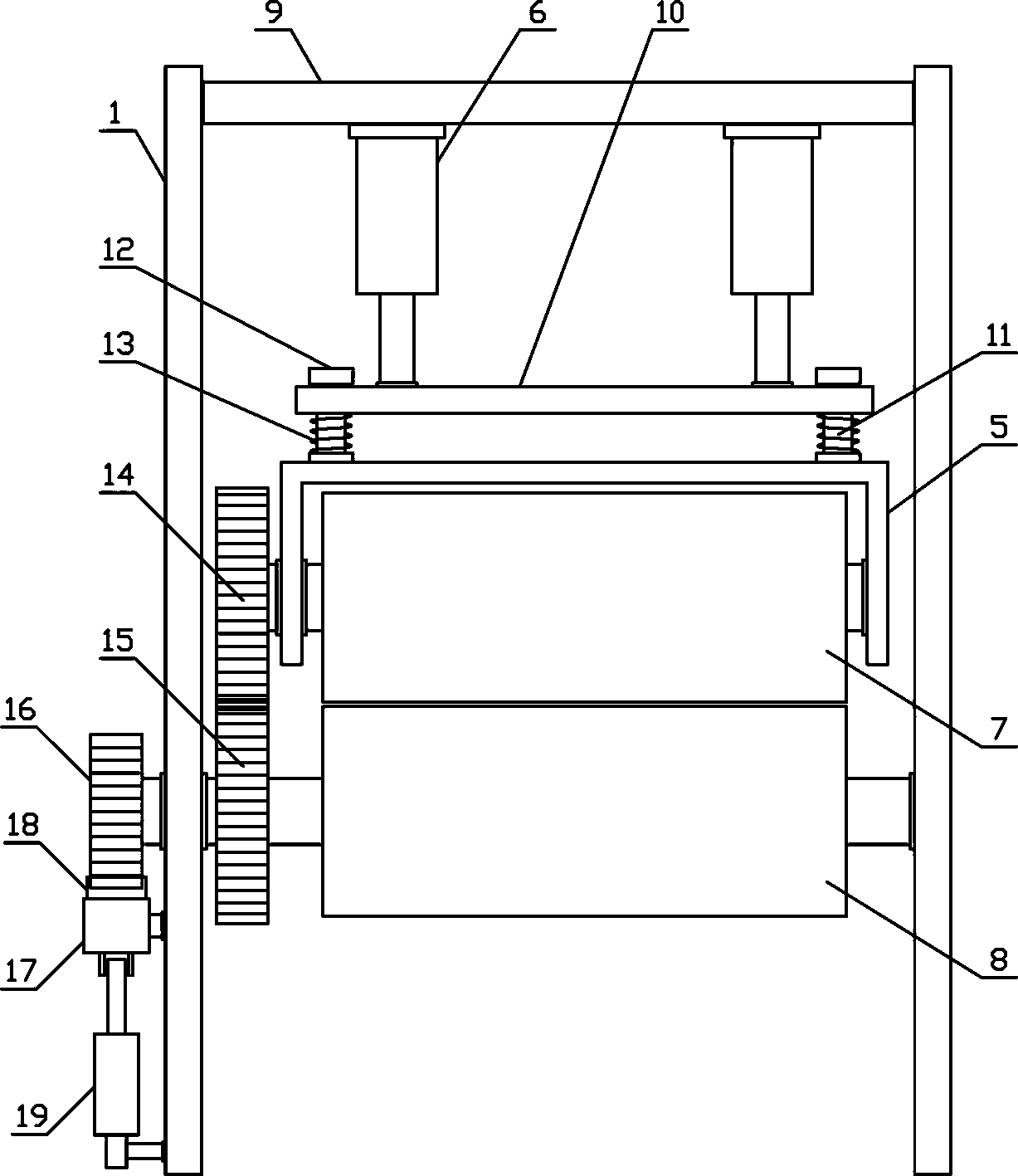

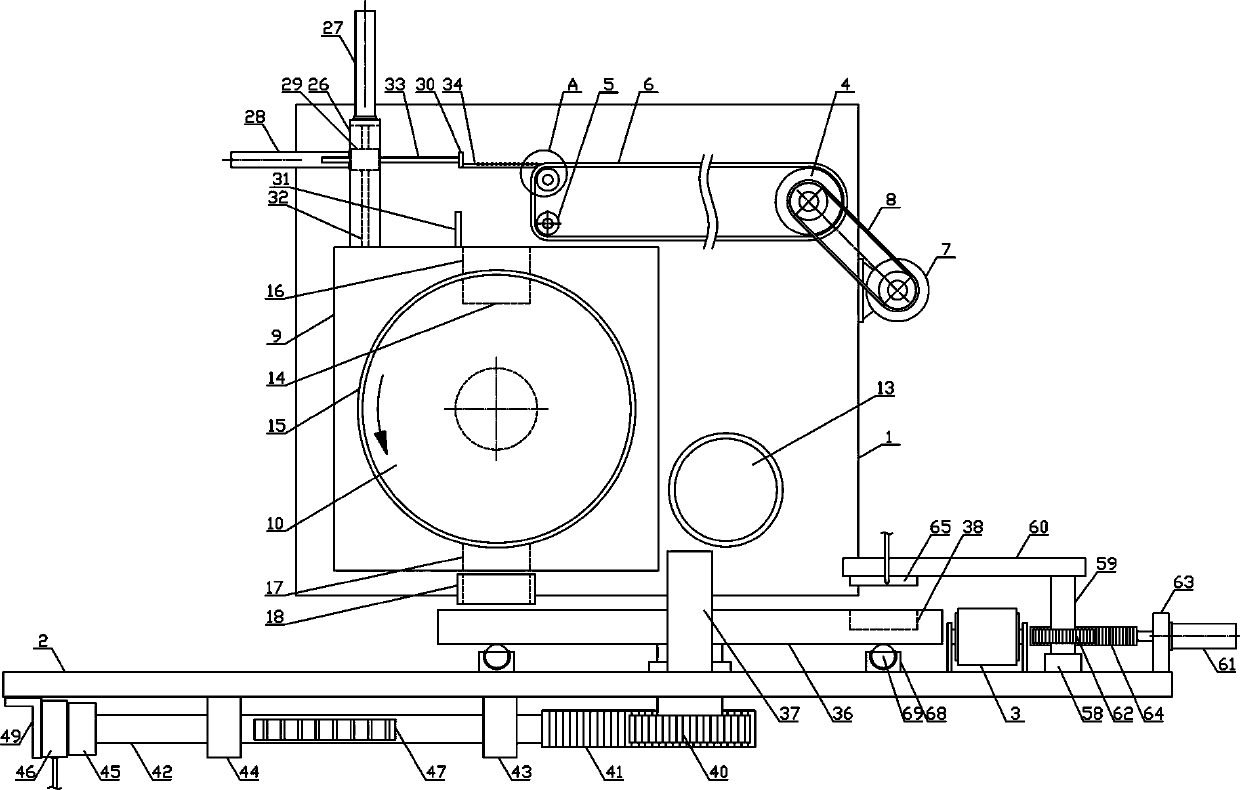

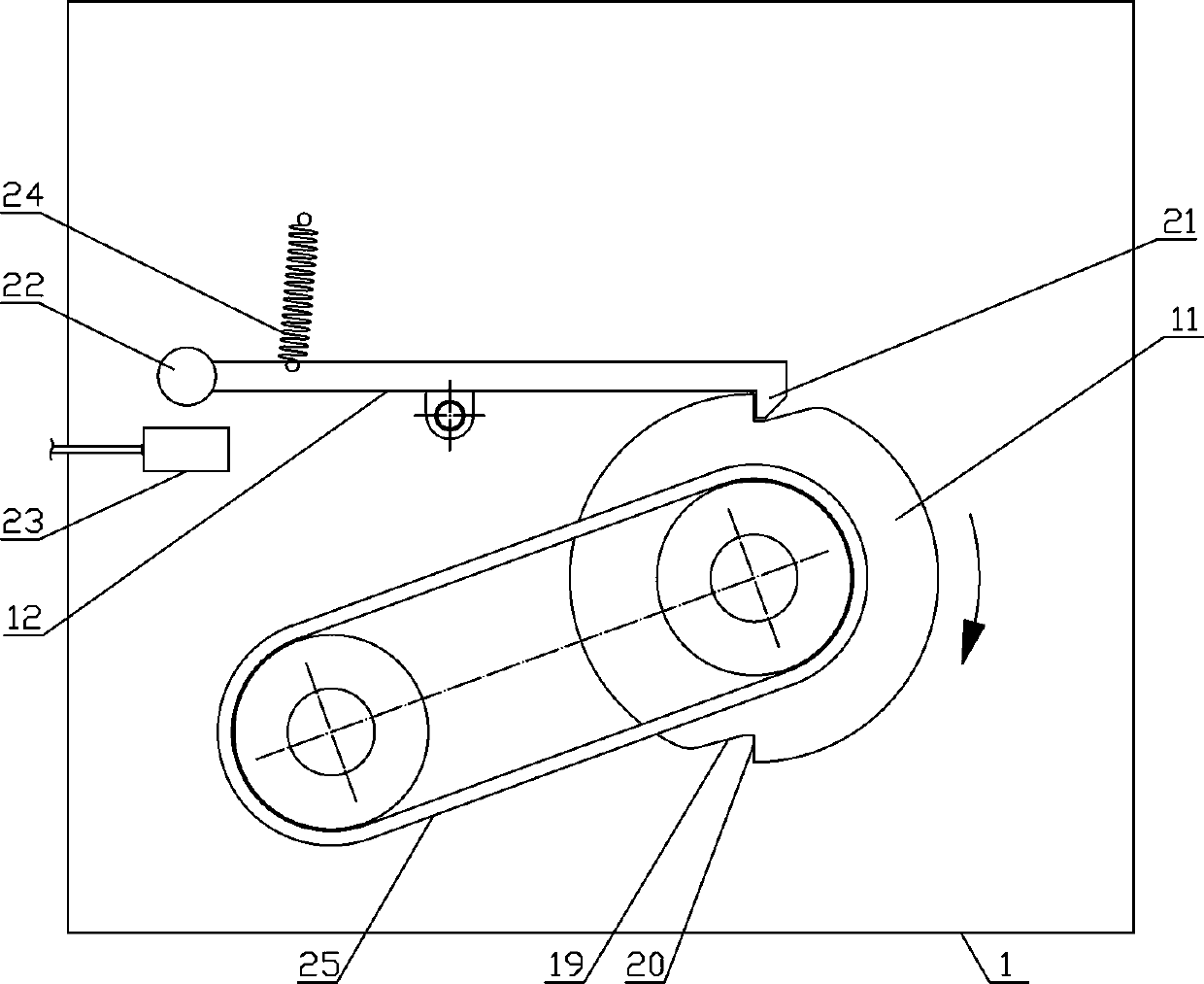

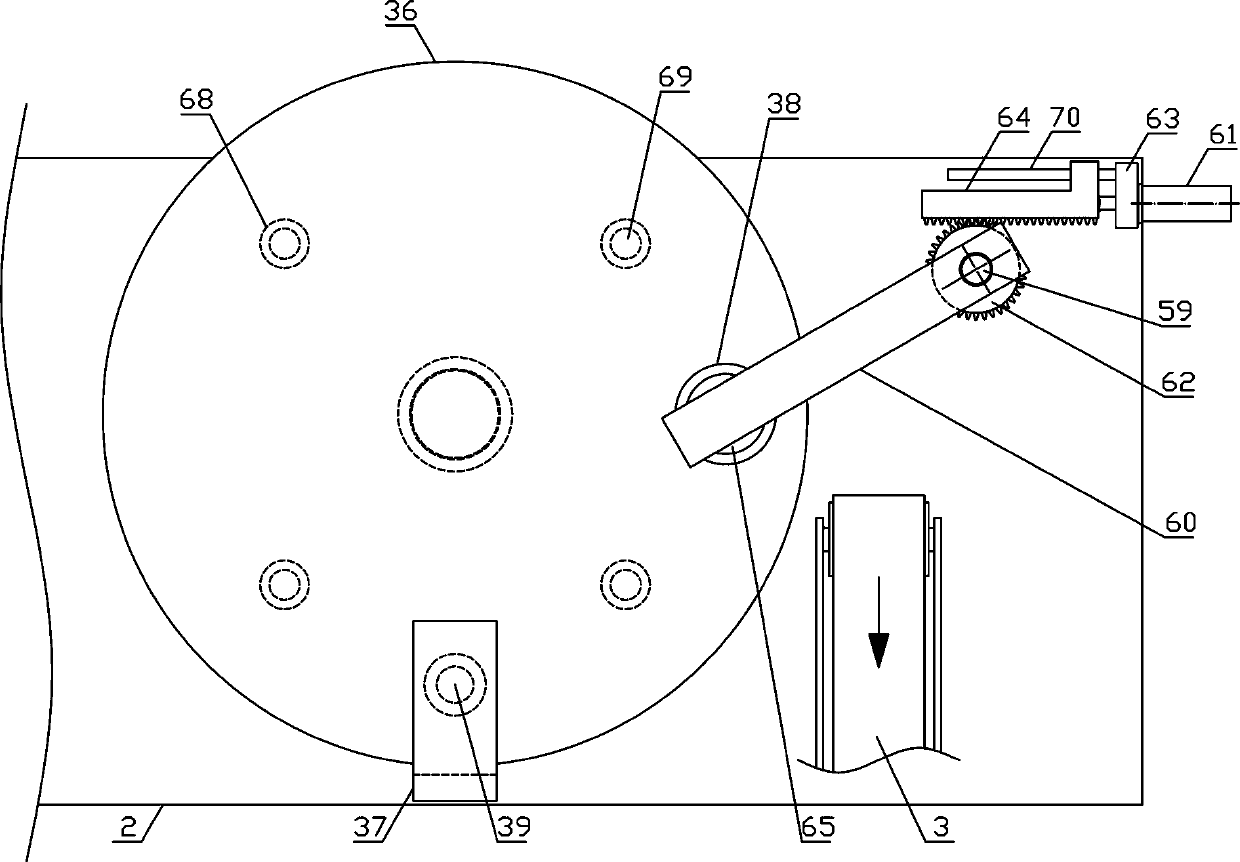

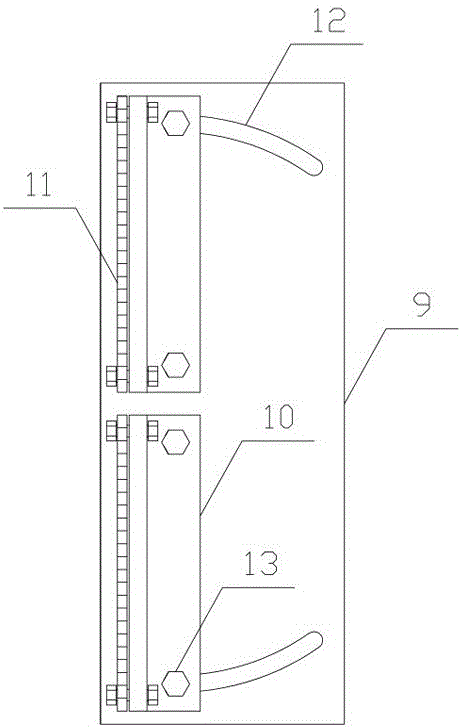

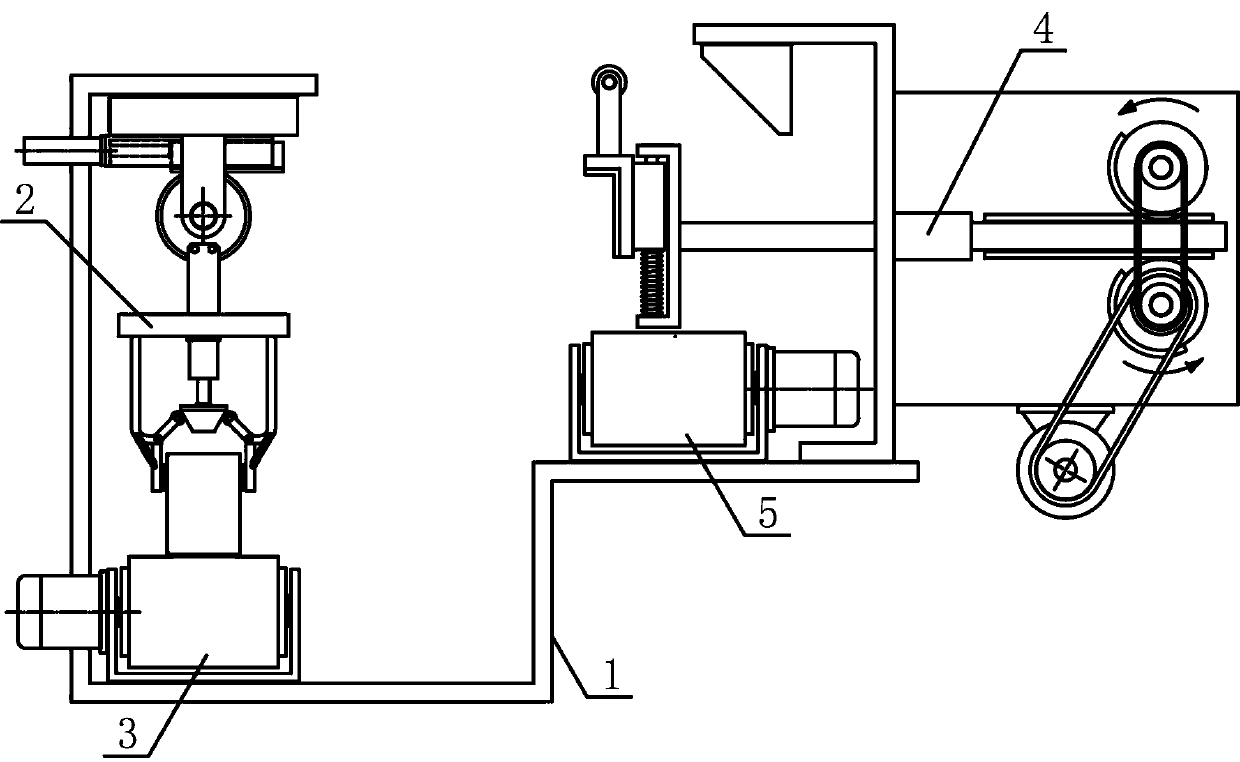

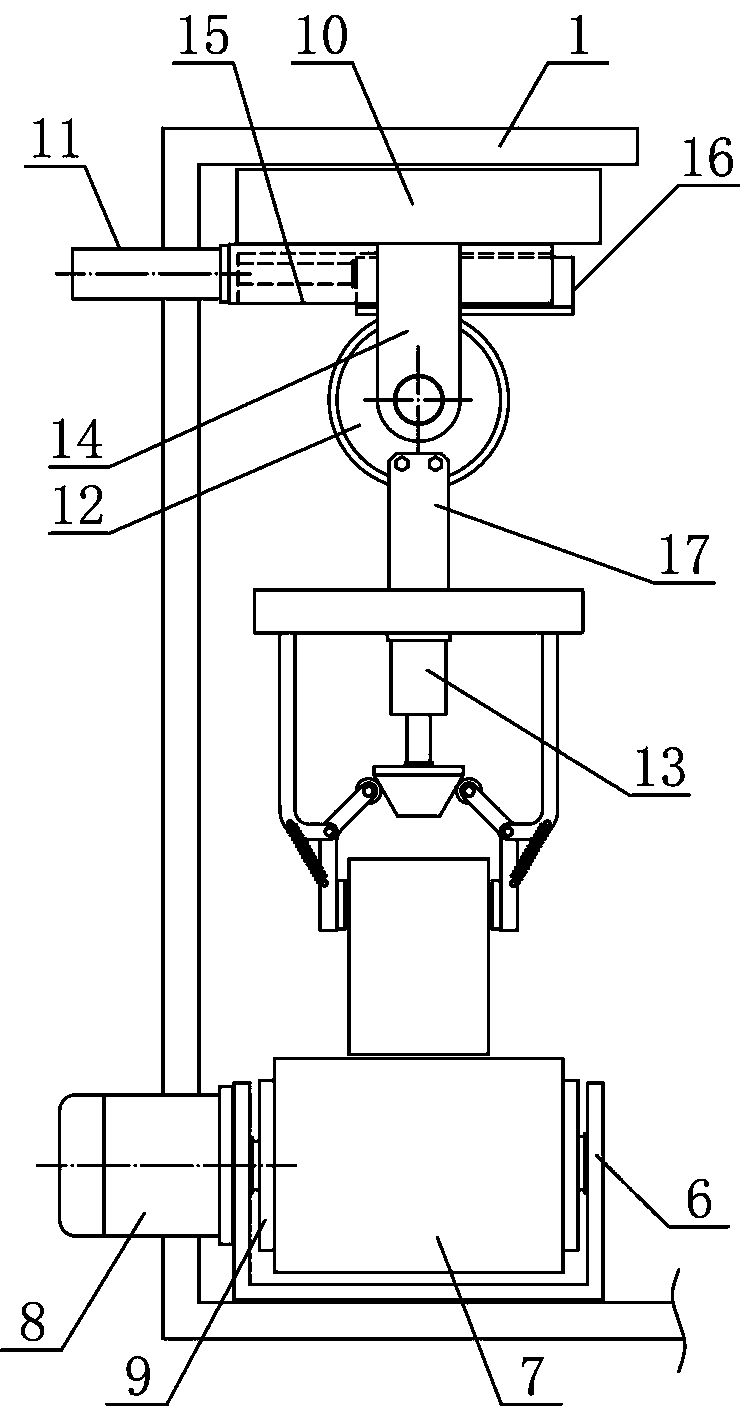

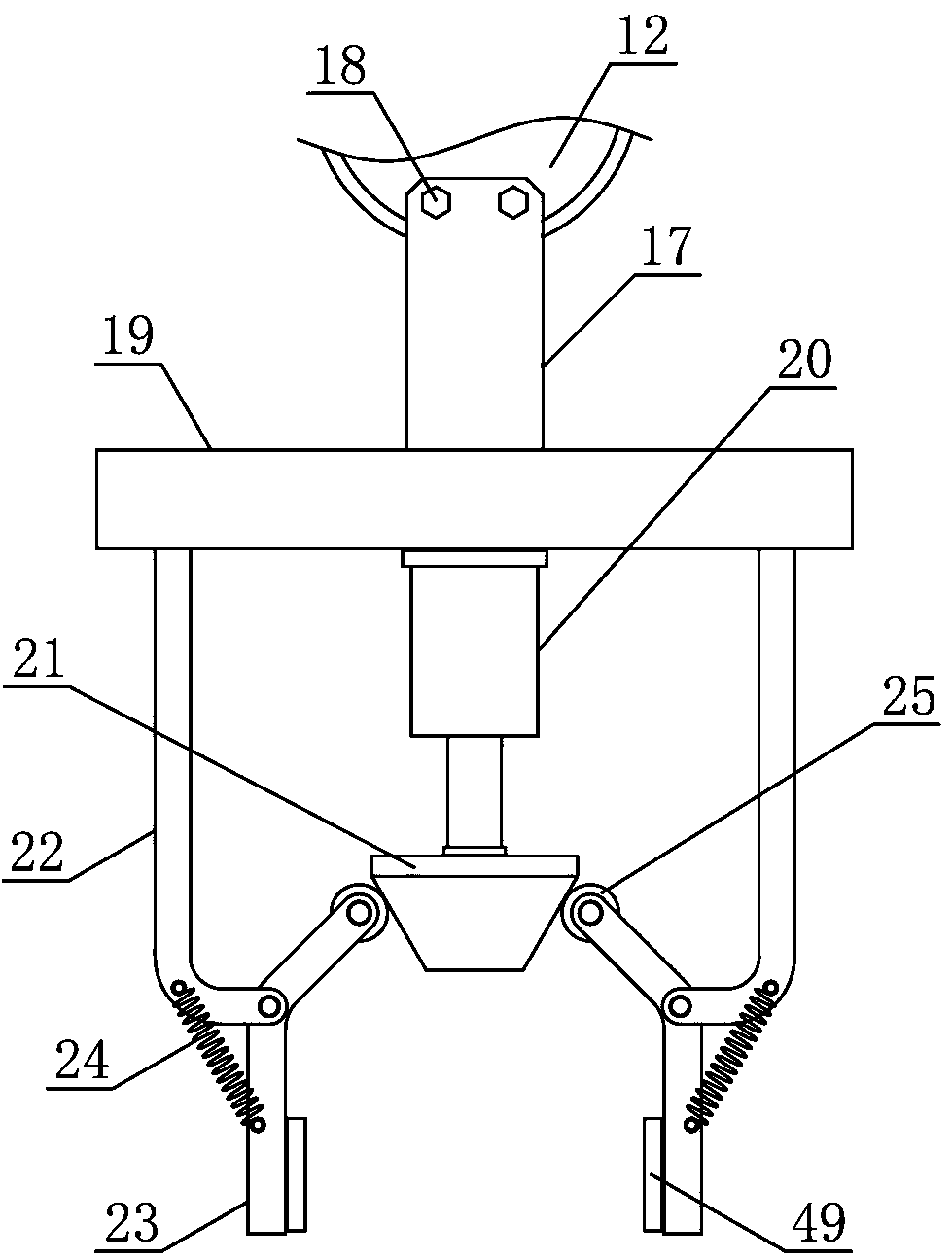

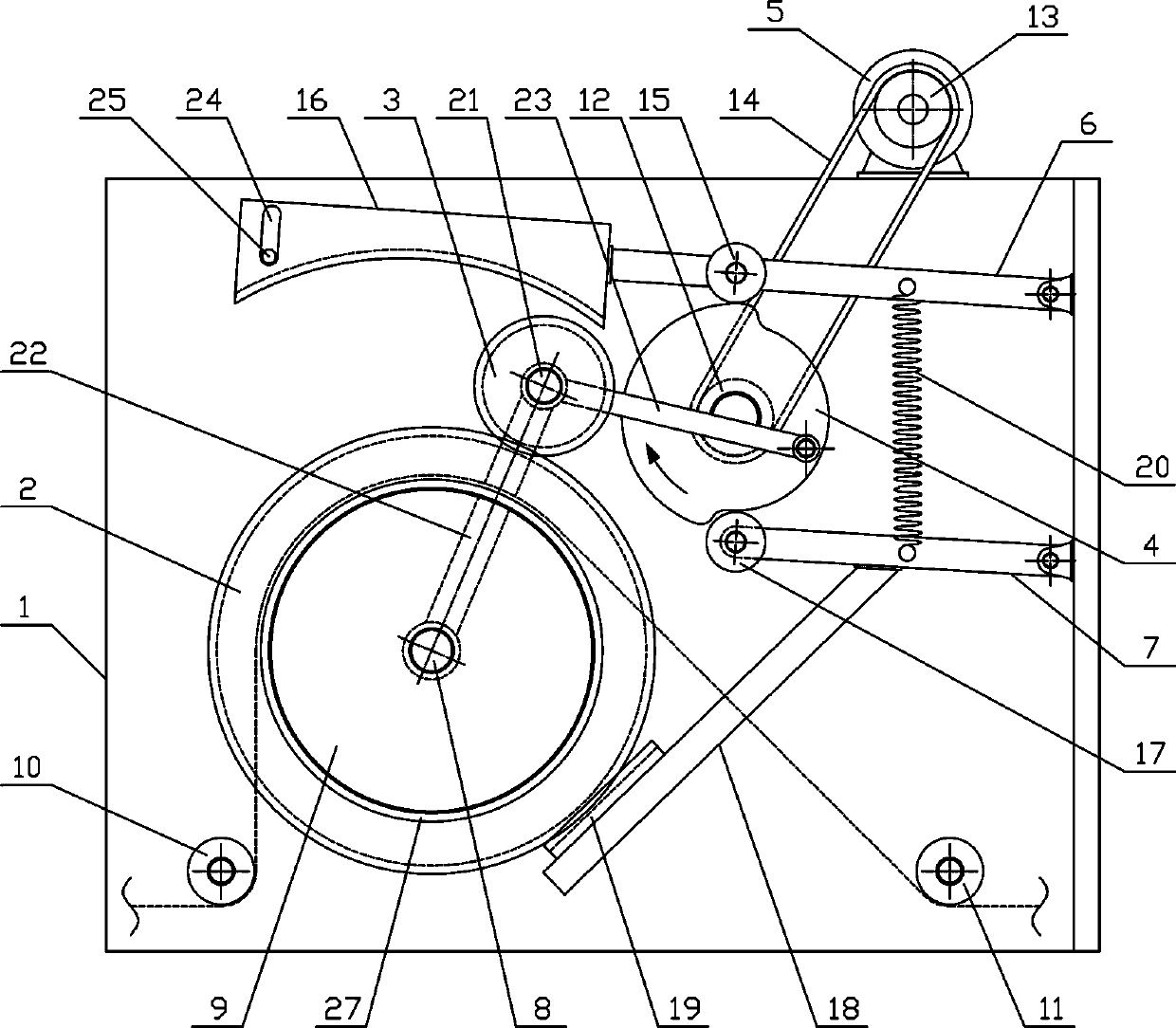

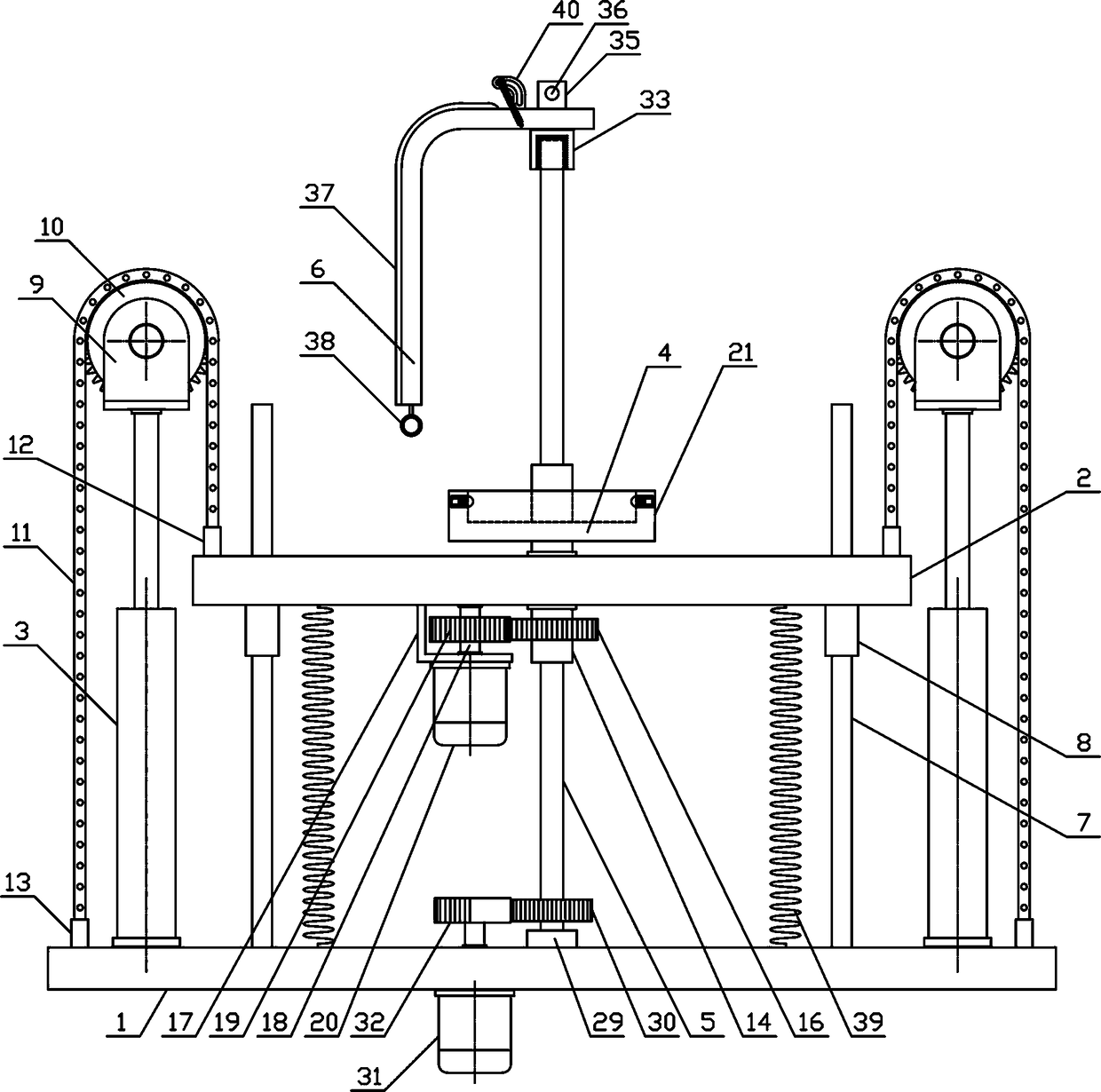

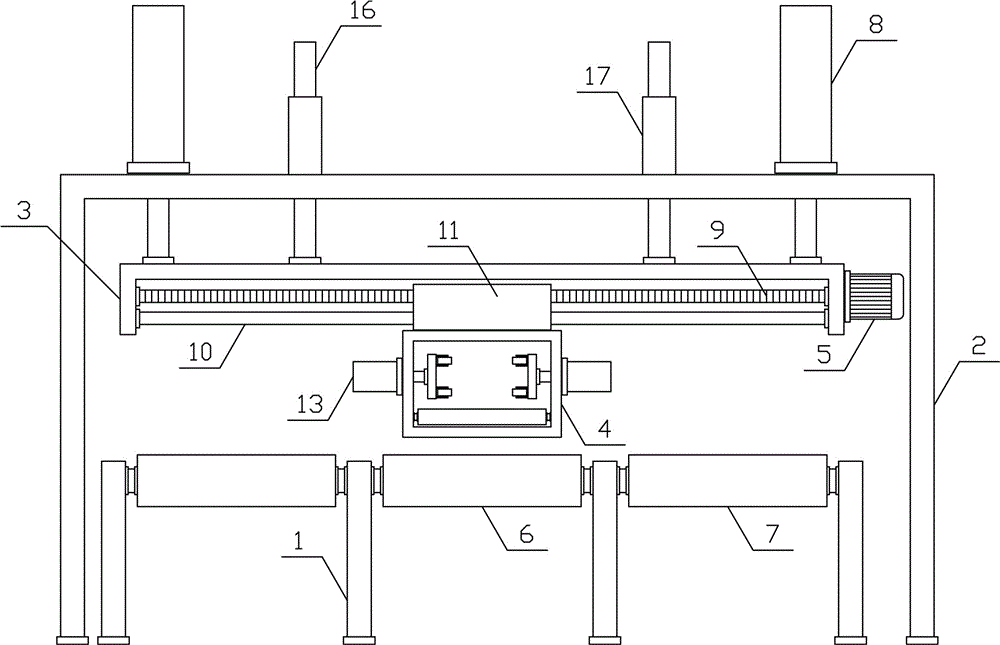

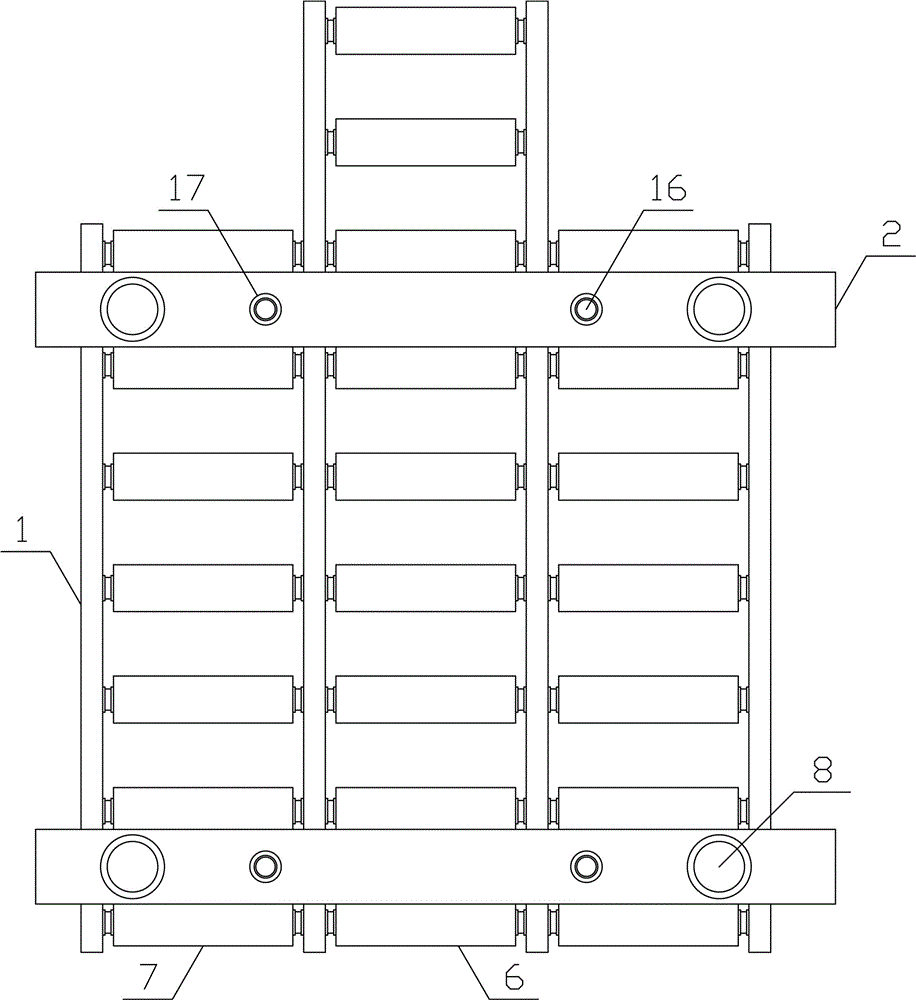

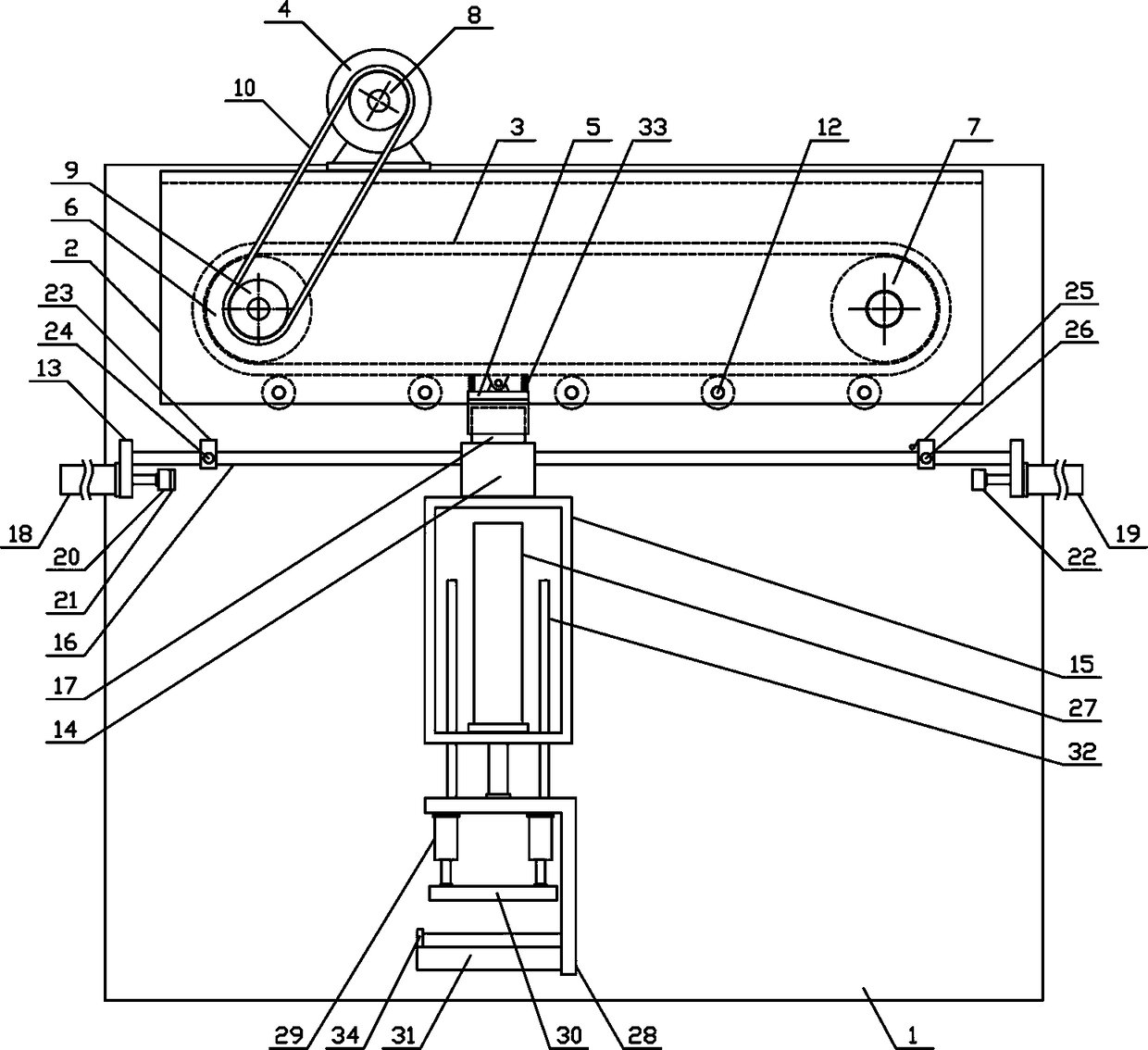

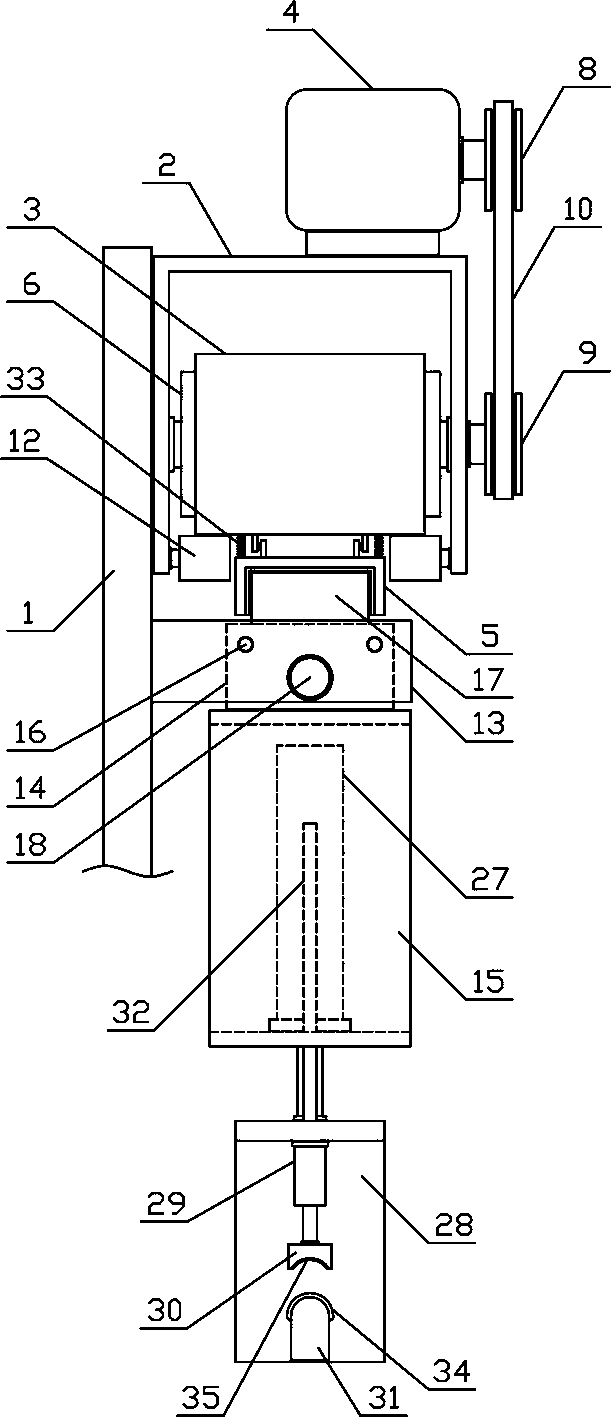

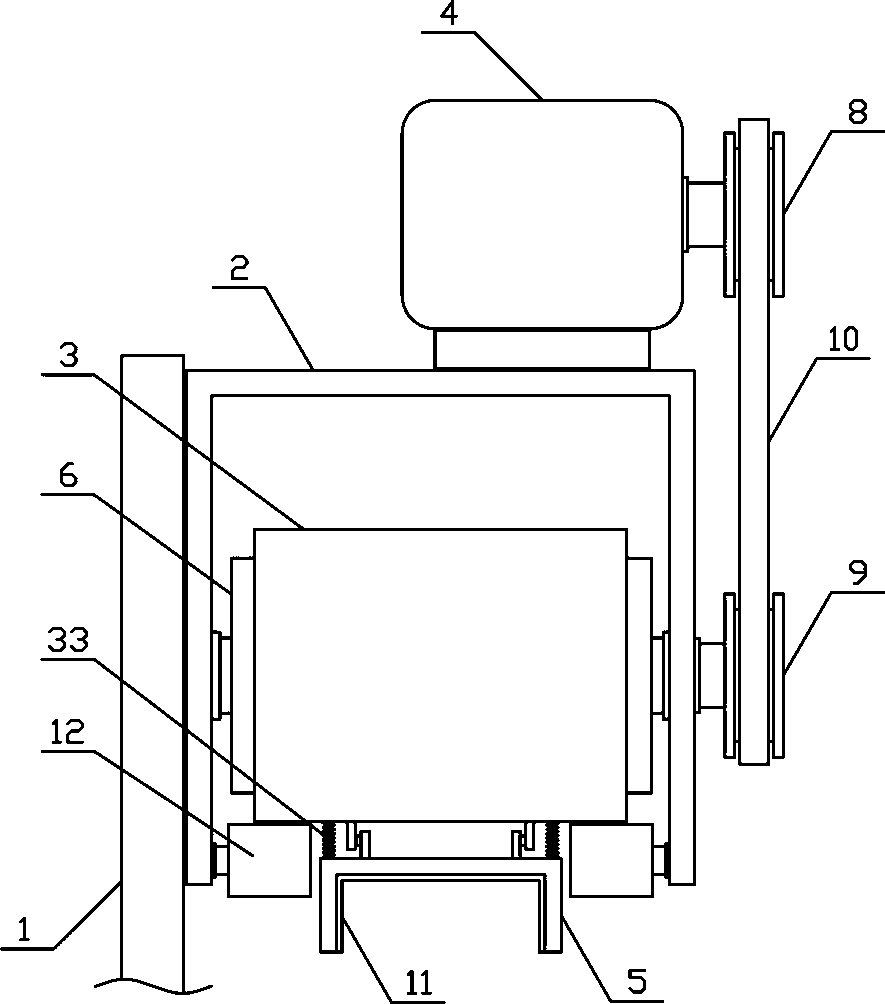

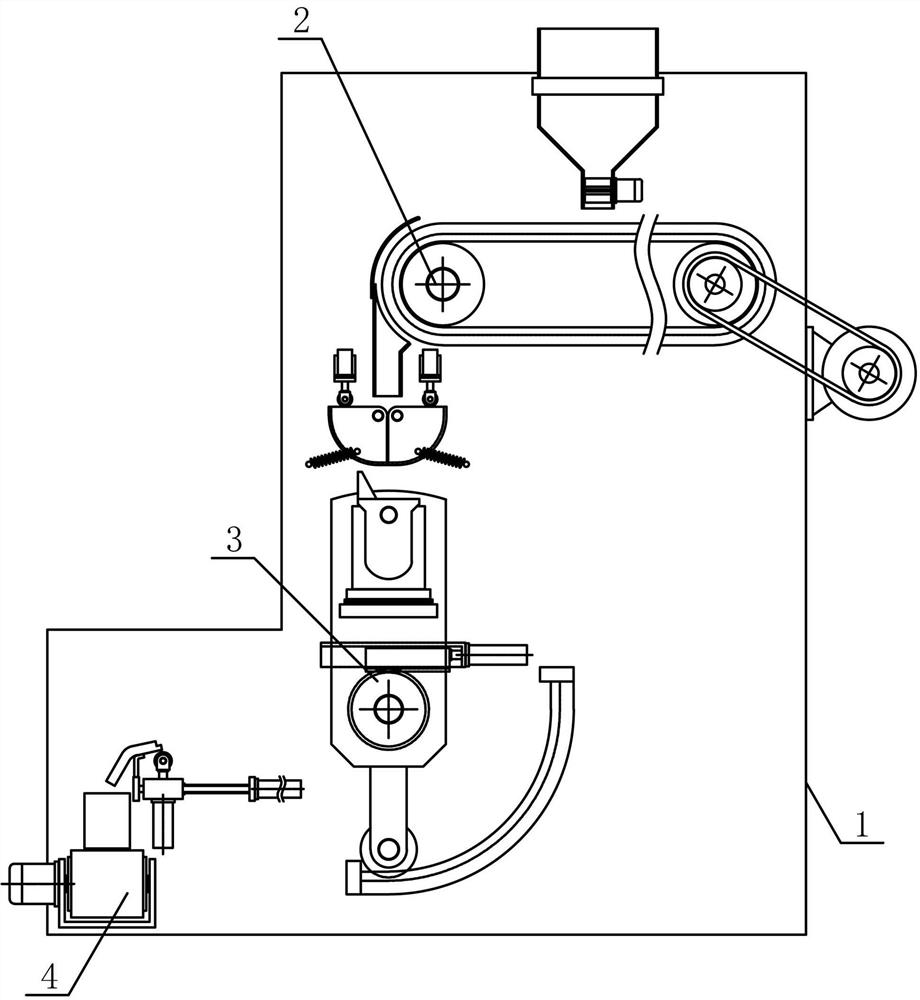

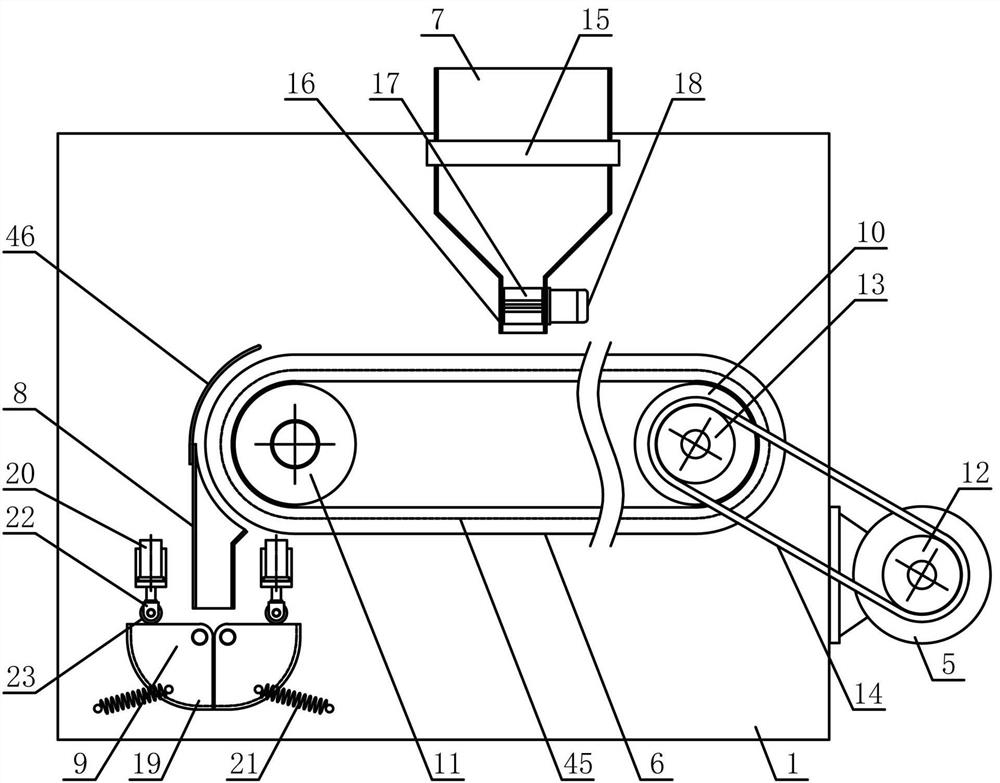

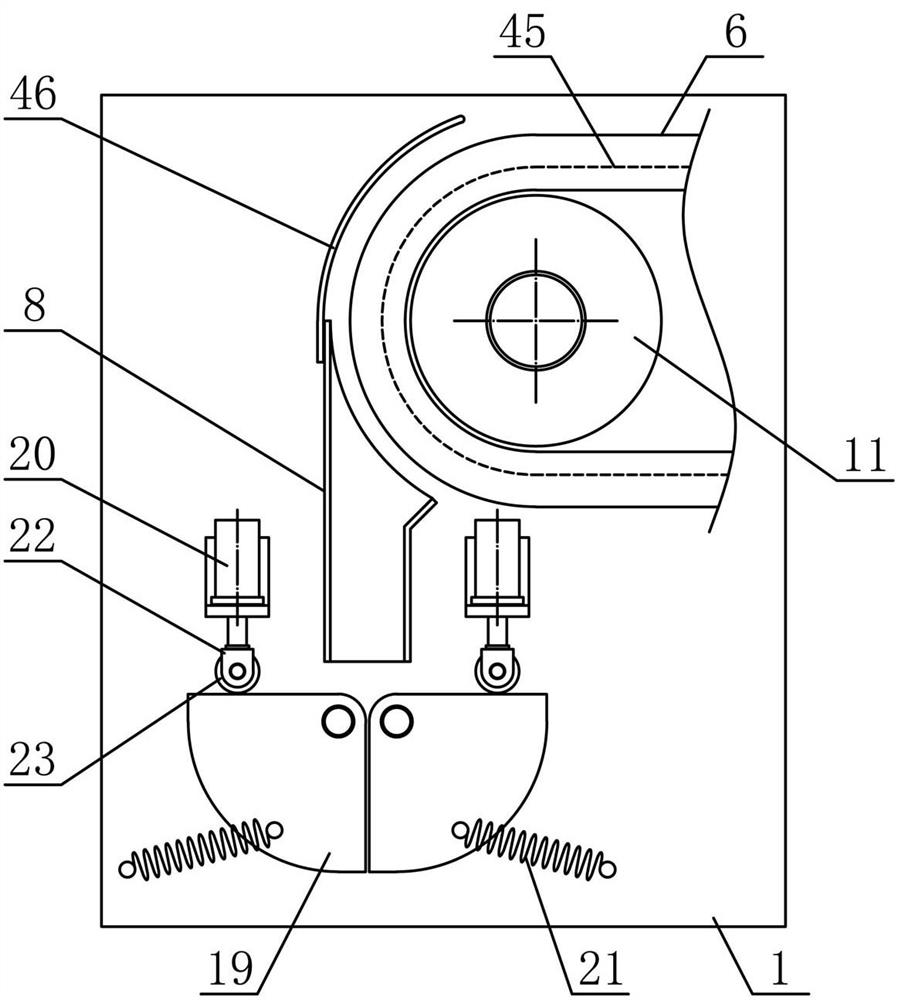

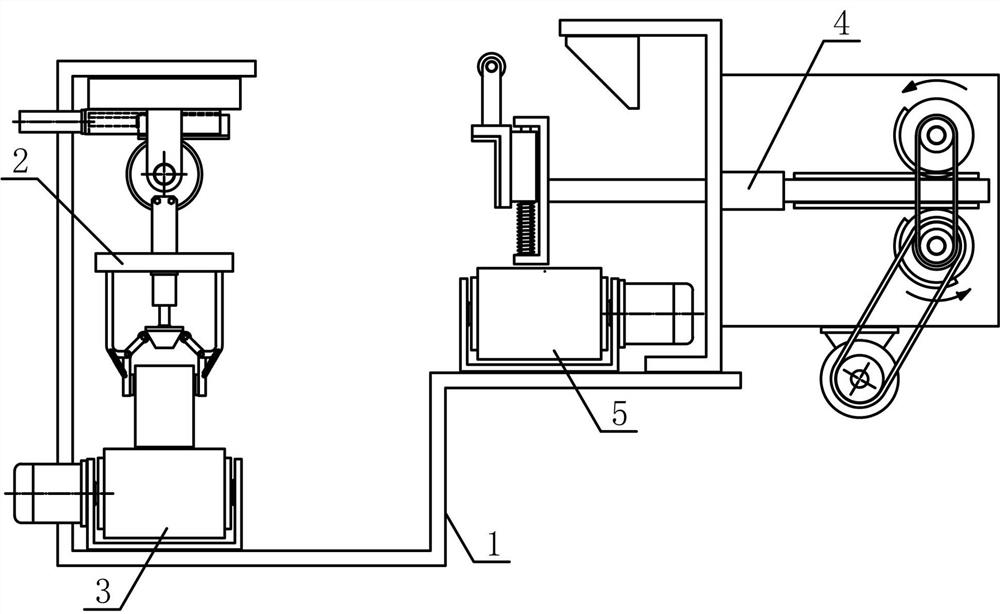

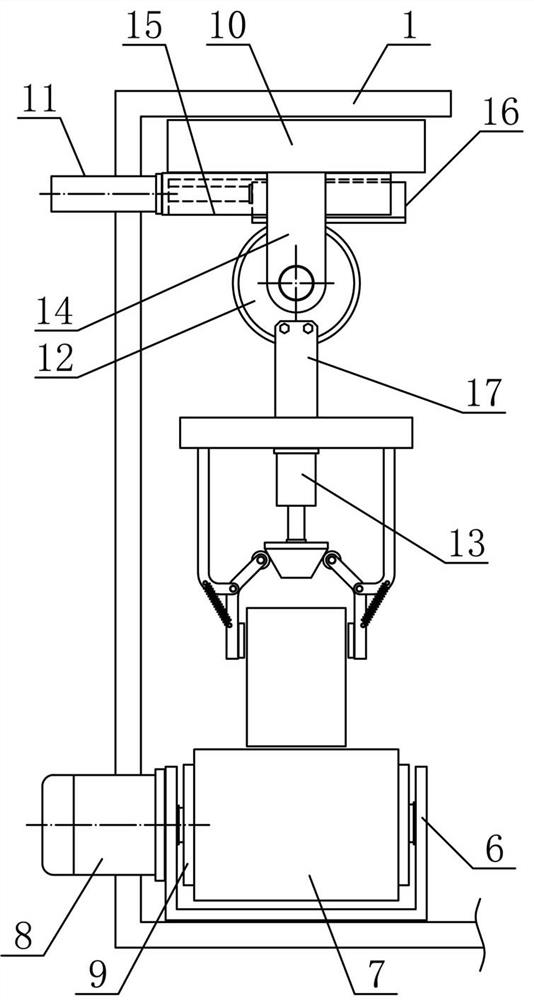

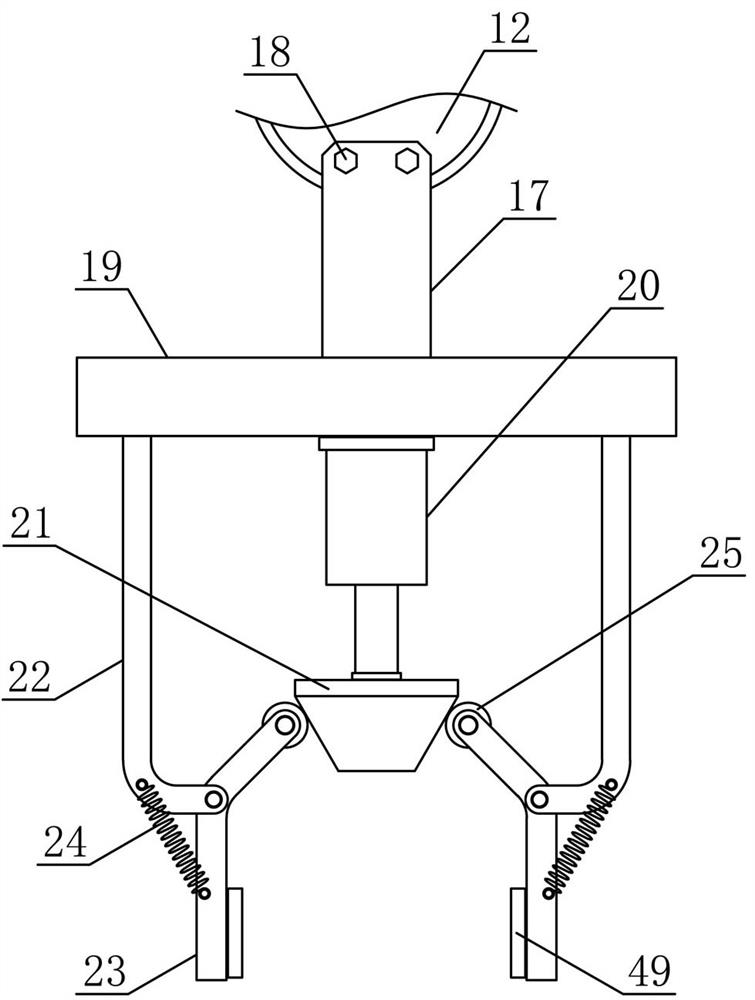

Mechanism for turning and processing disk workpiece

ActiveCN108673219AEasy to sendReasonable structural designMetal working apparatusConveyor partsCircular discMechanical equipment

The invention discloses a mechanism for turning and processing disc workpiece, which belongs to the field of workpiece continuous processing auxiliary mechanical equipment. According to the invention,an upper fixing bracket is vertically disposed on the upper side of a lower fixing bracket, a front conveying mechanism is horizontally disposed on the upper side of the upper fixing bracket, a feeding mechanism is horizontally fixed and disposed on one side of the front conveying mechanism, a turning mechanism is vertically disposed on the upper fixing bracket at the lower side of the feeding mechanism, a material guiding mechanism is horizontally disposed on the upper side of the lower fixing bracket at the lower side of the turning mechanism, an unloading mechanism is horizontally disposedon the lower fixing bracket at one side of the material guiding mechanism, and a rear conveying mechanism is horizontally fixed and disposed on the lower fixing bracket between the unloading mechanism and a material-guiding rotating plate. The invention is reasonable in design, and can turn the disc workpiece over one by one smoothly and steadily, and can further process and convey the disc workpiece after turning efficiently and accurately, which improves processing efficiency and quality of workpiece and meets the needs of production and use.

Owner:NANTONG HAIGAO CNC MACHINERY CO LTD

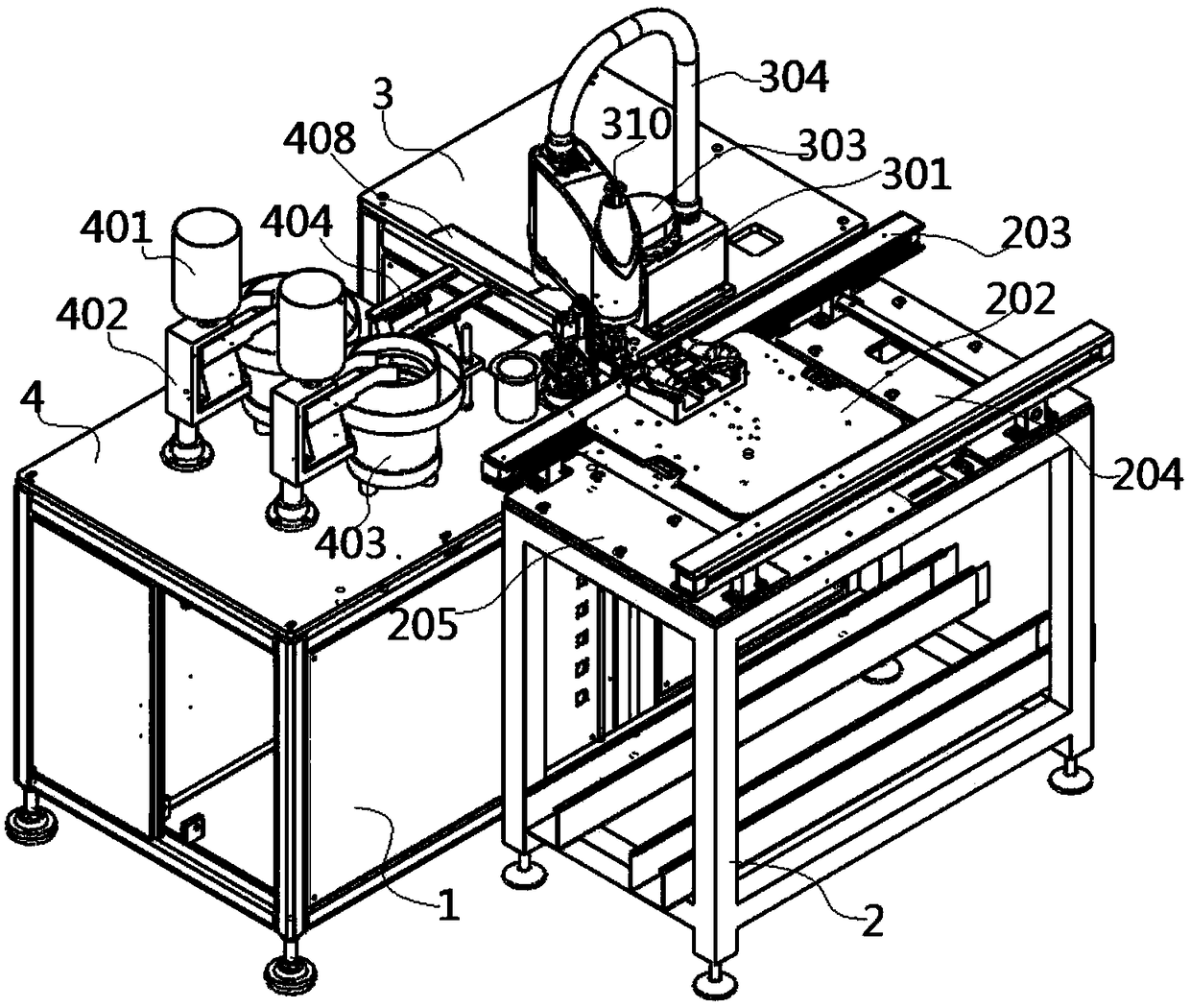

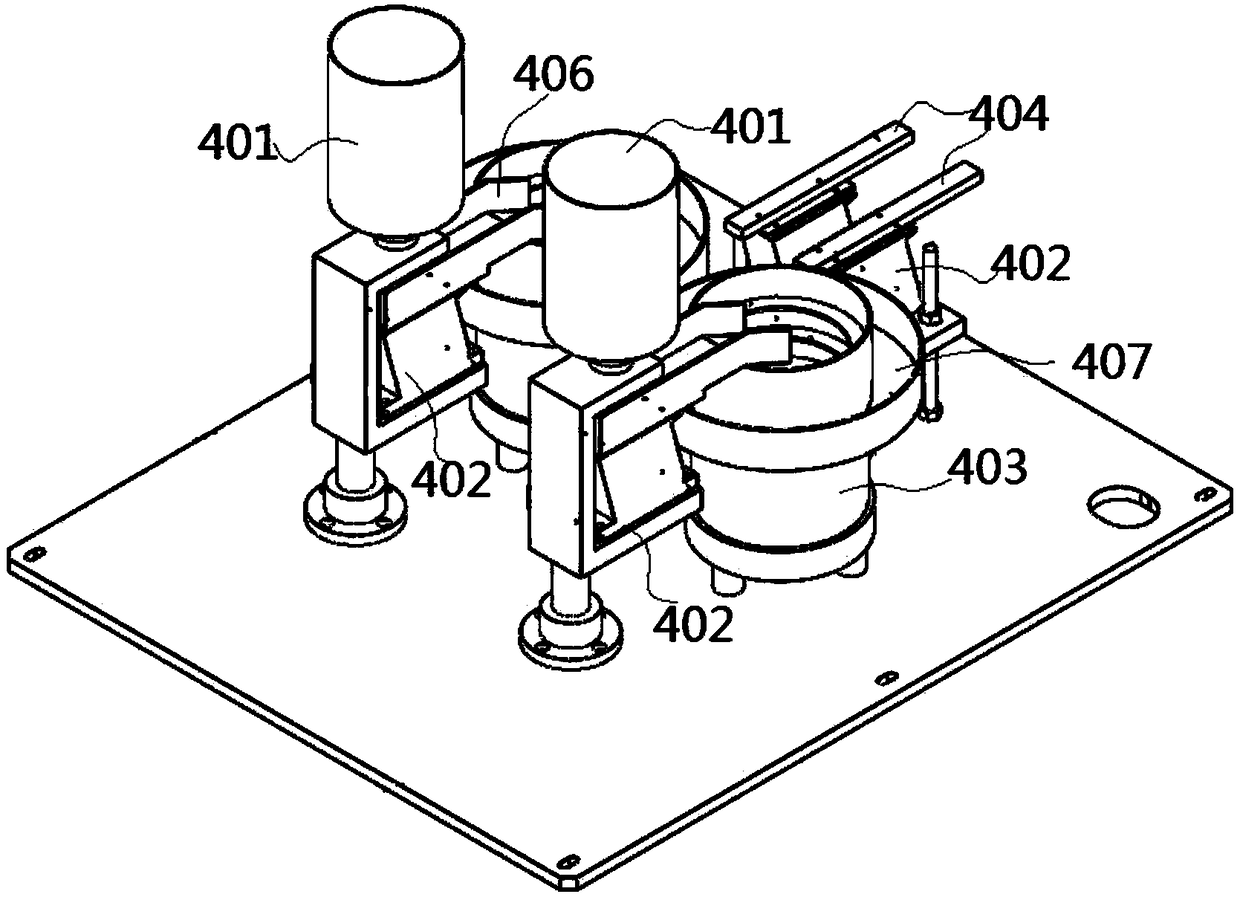

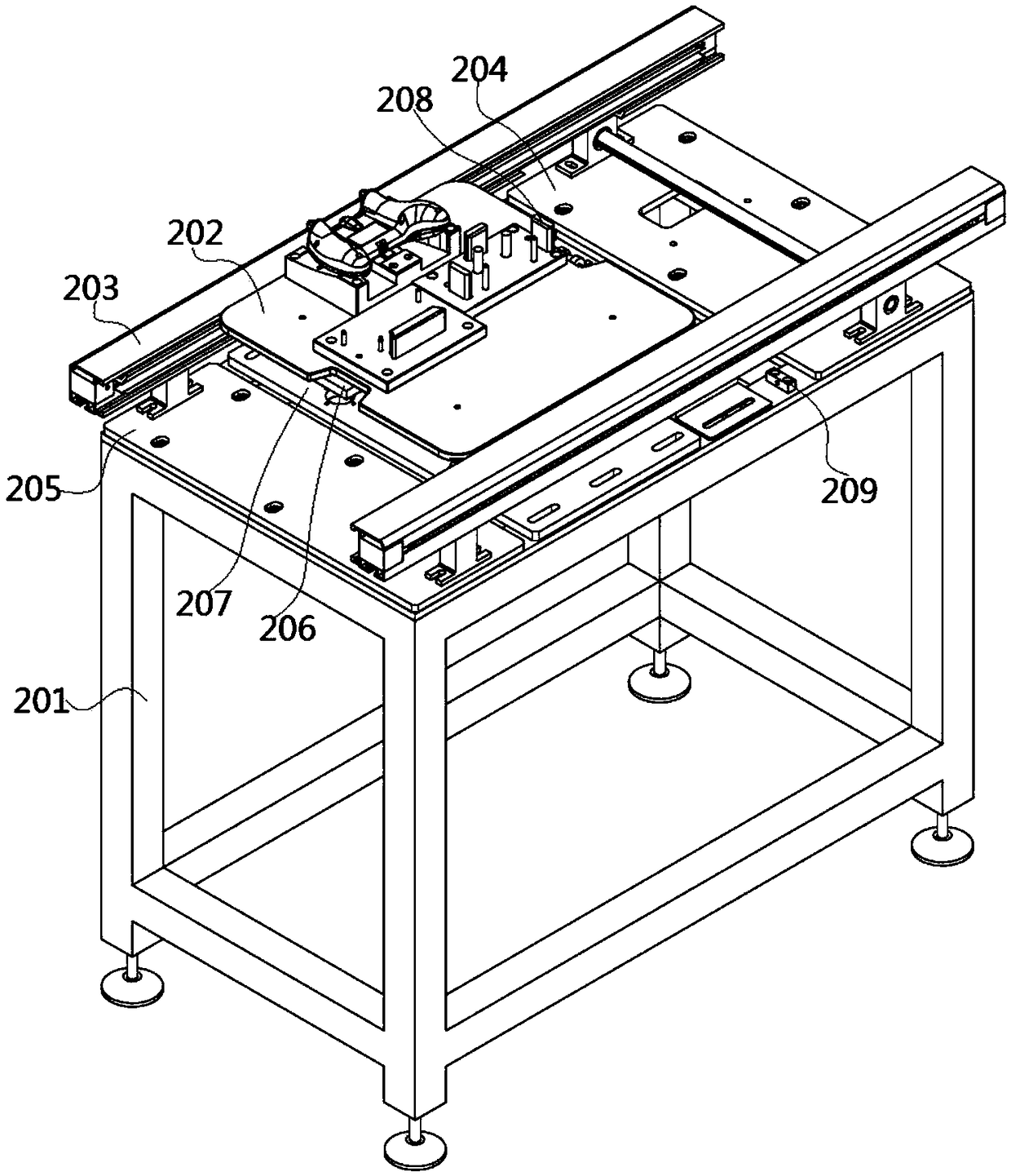

Automatic four-axis manipulator assembly system

PendingCN108237400AAccurate and efficient transmissionGuaranteed accuracyAssembly machinesMetal working apparatusComputer moduleMultiple sensor

The invention discloses an automatic four-axis manipulator assembly system. The system comprises a rack, wherein an assembly module and a manipulator module are arranged on one side of the rack, and afeeding module is arranged on the rack; the feeding module is ensured to efficiently and accurately delivering materials and parts and grabbing materials on the correct position by utilizing electromagnetic vibration of a round vibration disc and an output rail, vision detection devices are arranged on the manipulator module, and whether a material is complete and direction and position are positioned or not can be conveniently determined; and the assembly module is positioned by adopting multiple sensors to ensure the accuracy of a tooling plate, and the tooling plate is jacked up by adopting a cylinder to fix the tooling plate and improve the assembly stability. According to the automatic assembly system, two vision detection devices for accurate positioning and direction discriminatingare used to automatically identify in a certain deviation area, the whole assembly is not influenced, cost increased generated by the client product accuracy requirement required by the assembly requirement can be reduced. The system can be suitable for large-batch production.

Owner:SHENZHEN GRANDSEED TECH DEV

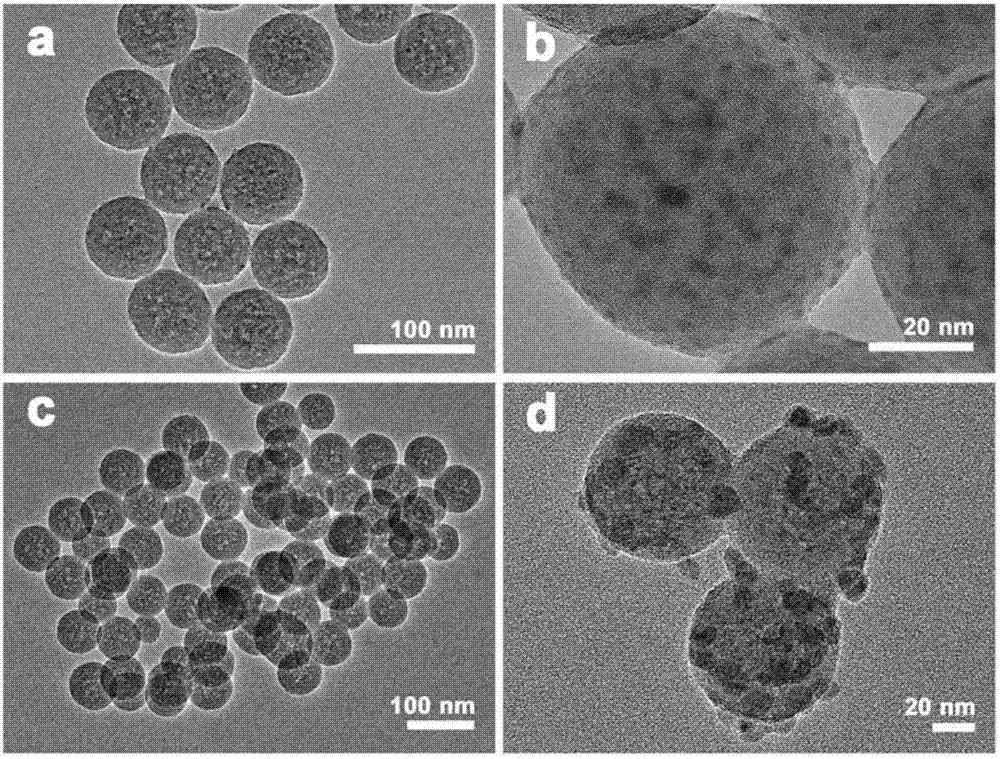

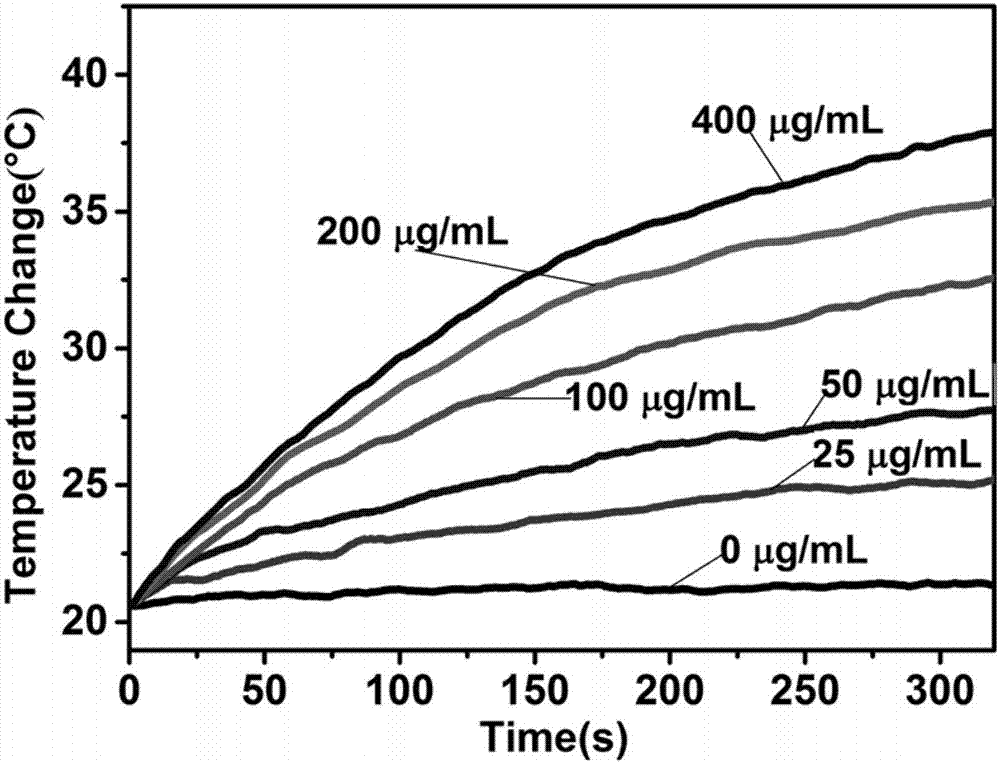

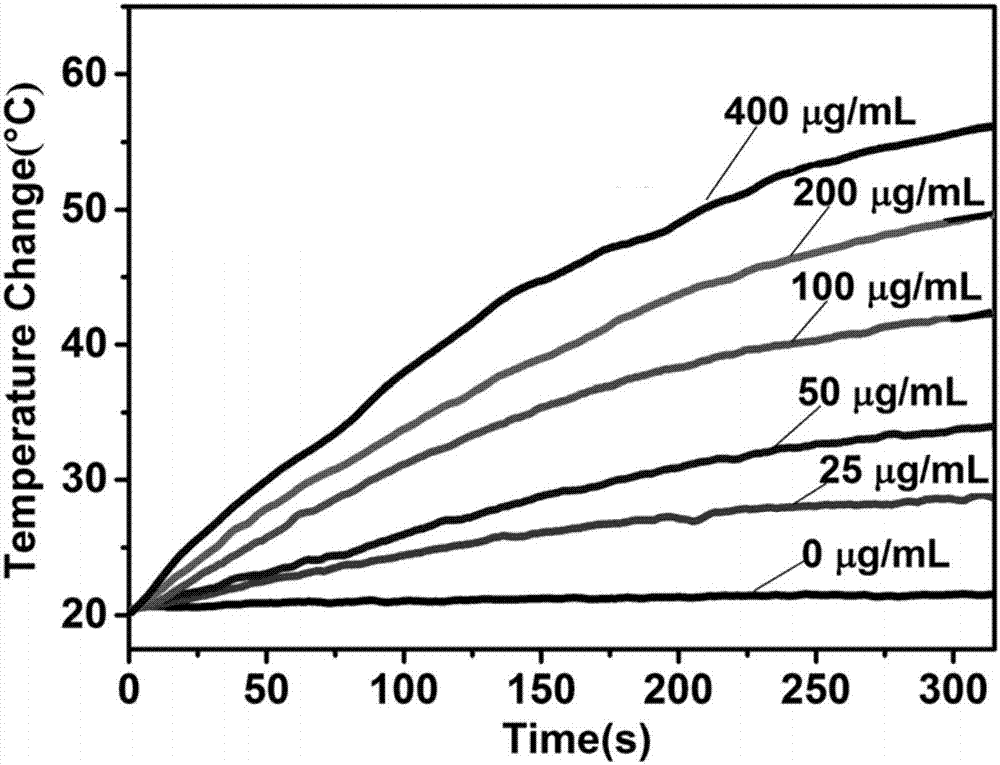

Selenium quantum dot/silicon dioxide/copper sulfide nanocomposite particle, preparation and application thereof

InactiveCN107469078AAccurate and efficient transmissionSmall toxicityOrganic active ingredientsEnergy modified materialsCancer cellSide effect

The invention relates to a selenium quantum dot / silicon dioxide / copper sulfide nanocomposite particle, preparation and application thereof. The nanocomposite particle has a chemical formula of Se@SiO2-FA-CuS, selenium quantum dot is adopted as the core, porous silicon dioxide is taken as the shell, amination modification is carried out on the shell surface, and a targeting reagent folic acid is grafted, and then copper sulfide nanoparticles are adsorbed on the shell surface through electrostatic effect. Compared with the prior art, the Se@SiO2-FA-CuS nanocomposite particle provided by the invention has a novel structure and good photothermal performance, has broad application prospects in terms of drug loading, photothermal therapy and targeted transportation, can achieve targeted transportation of anticancer drugs and photothermal reagents to cancer sites, effectively kills cancer cells while reducing the toxic and side effect on normal tissues and cells, further improves the therapeutic effect, and is of enormous potential in promotion of chemotherapy and photothermal therapy (PTT) combined application and enhancement of cancer treatment efficacy.

Owner:SHANGHAI UNIV OF ENG SCI

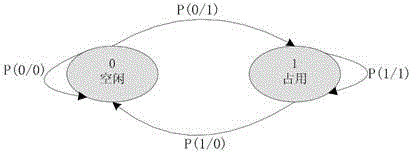

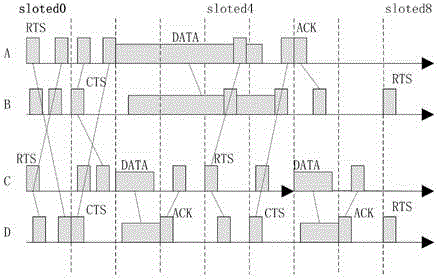

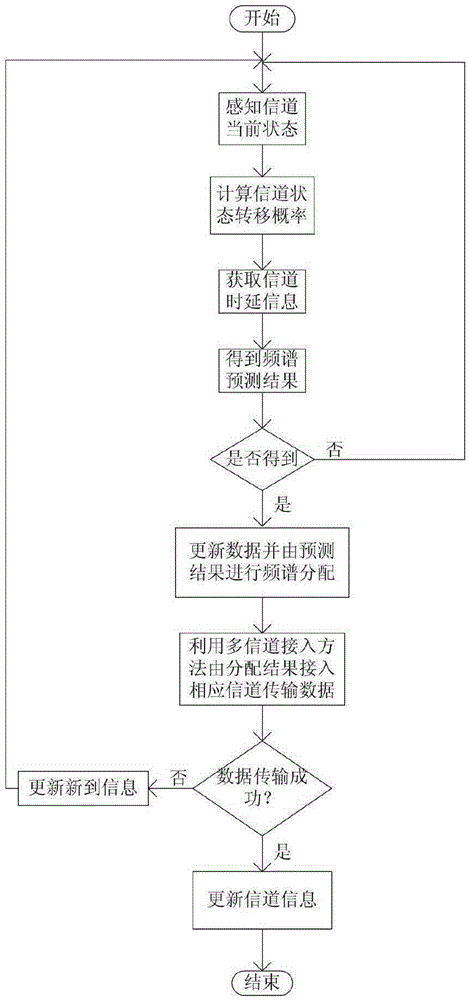

Method for node to access multiple channels exactly and efficiently in underwater cognitive network

InactiveCN105357158AAccurate and efficient underwater transmissionAccurate and efficient transmissionSpectral gaps assessmentTransmission monitoringNODALFrequency spectrum

The invention relates to a method for a node to access multiple channels exactly and efficiently in an underwater cognitive network. The method comprises the steps of performing spectrum prediction by utilizing a spectrum sensing result and obtaining state information of each channel after the spectrum sensing; performing optimized allocation based on the current state information of each channel and each channel bandwidth as the optimization goal of spectrum allocation is the maximum channel gain, and the spectrum allocation emphasizes on considering maximization of a channel capacity; dividing multiple time slots in order to avoid long propagation delay of a sound signal and save energy, wherein each control packet and each data packet only can be sent at the start moment of one time slot; and transmitting data by adopting a message string mode, wherein each data transmitting node is required to transmit the data at the start moment of the time slot with the serial number being integer multiples of 4 after the channel allocation is ended. According to the method for the node to access multiple channels exactly and efficiently in the underwater cognitive network, effective throughput of an underwater network system is increased, and efficient transmission of communication data is realized.

Owner:TIANJIN UNIV

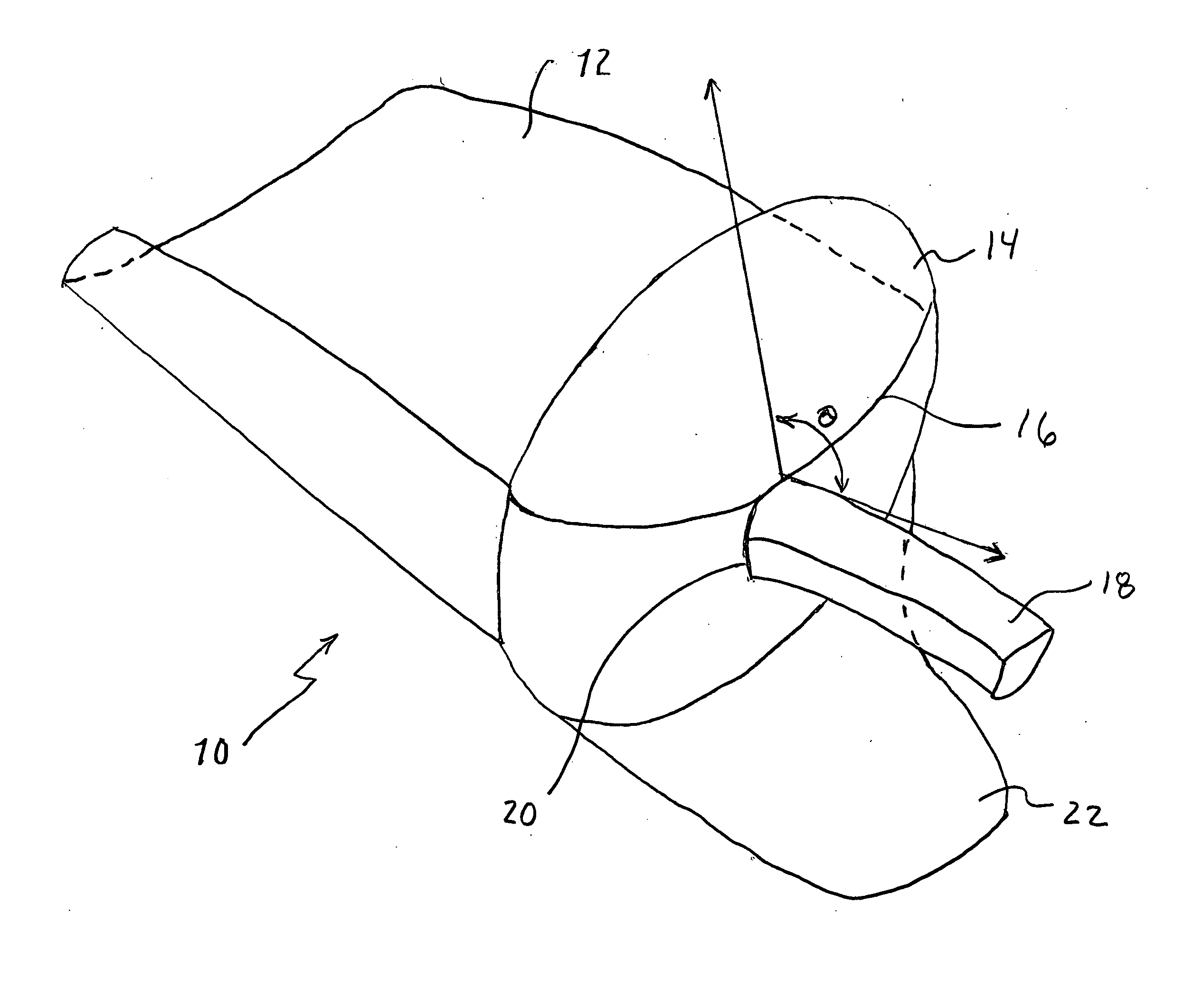

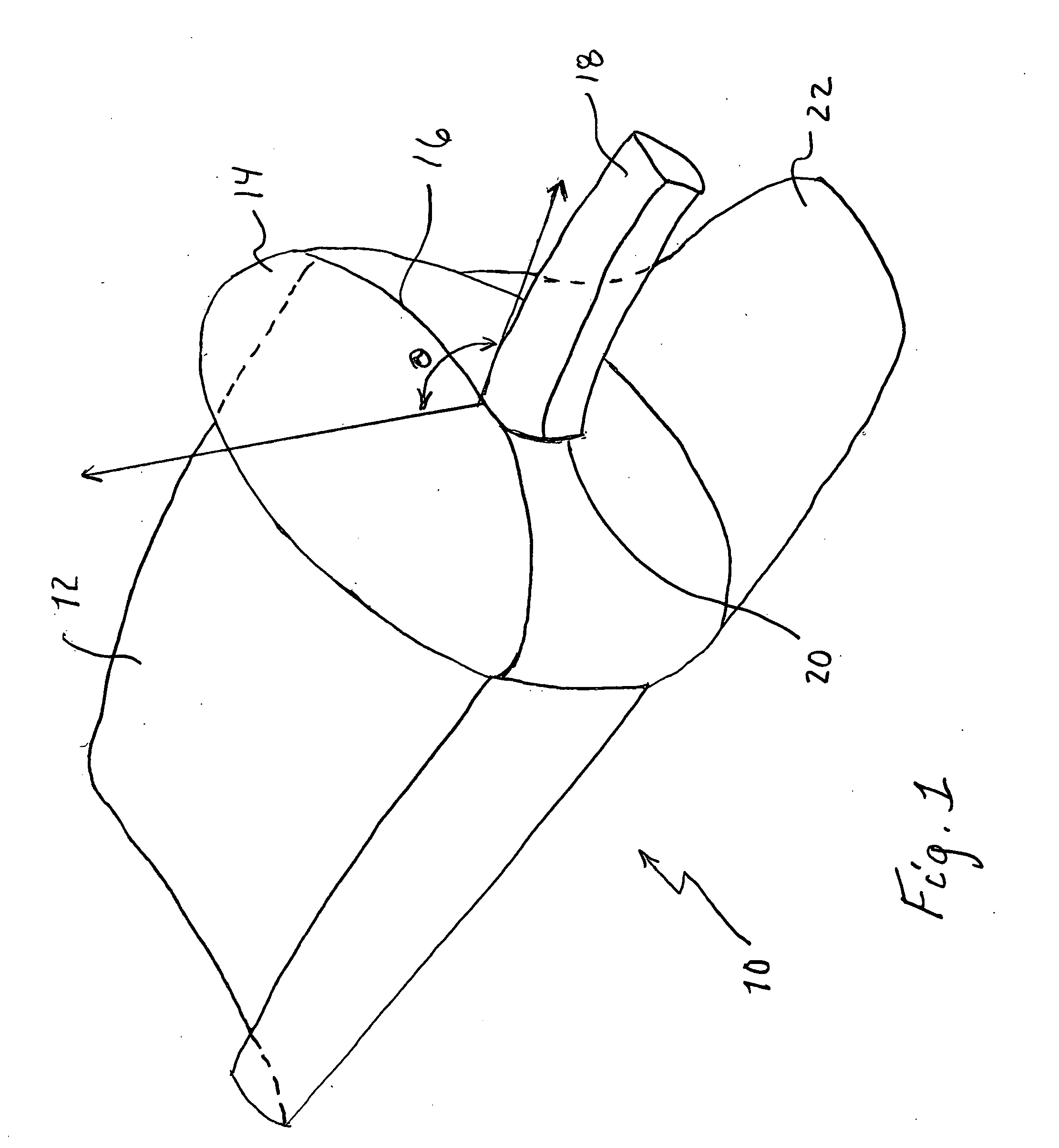

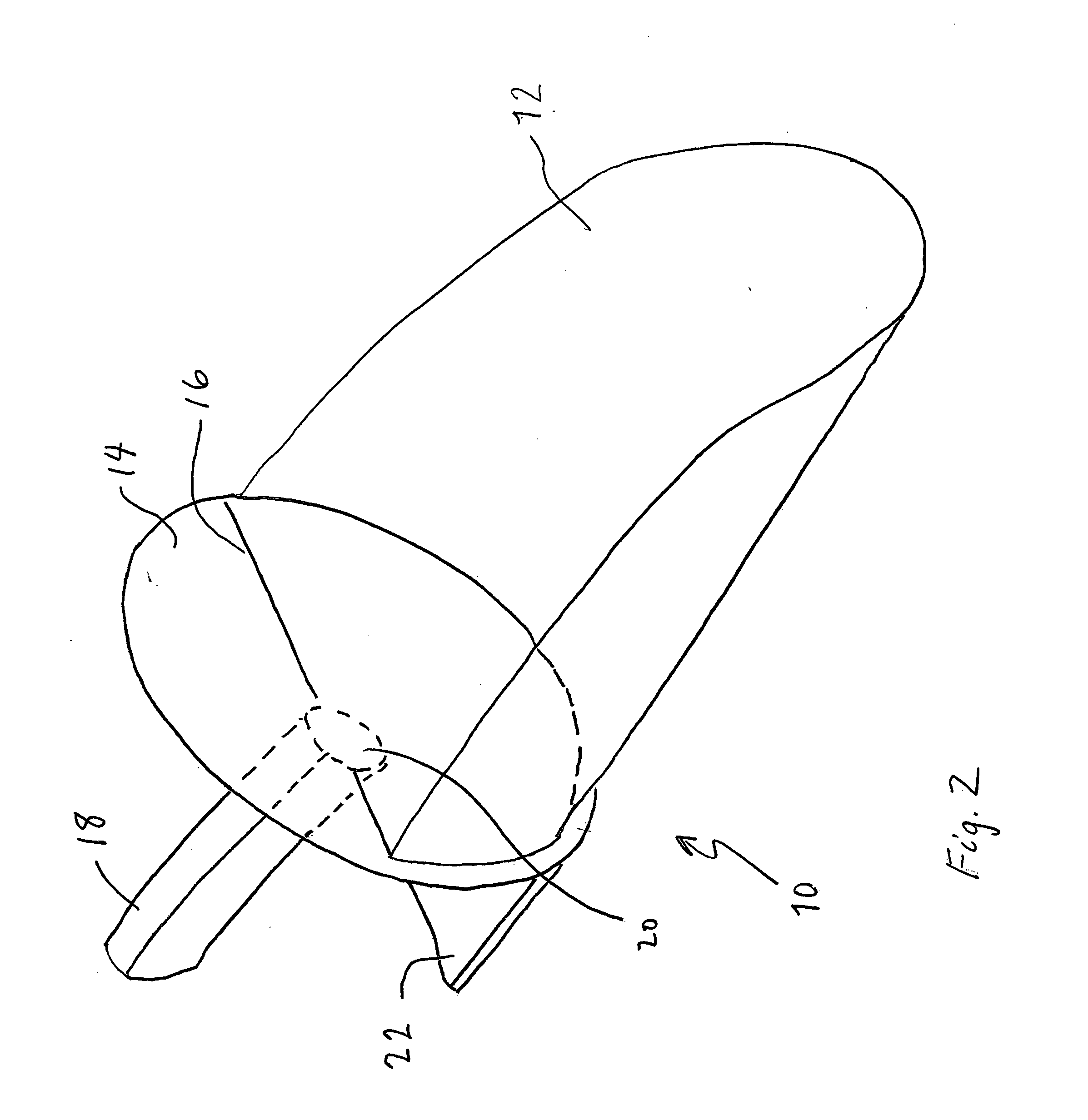

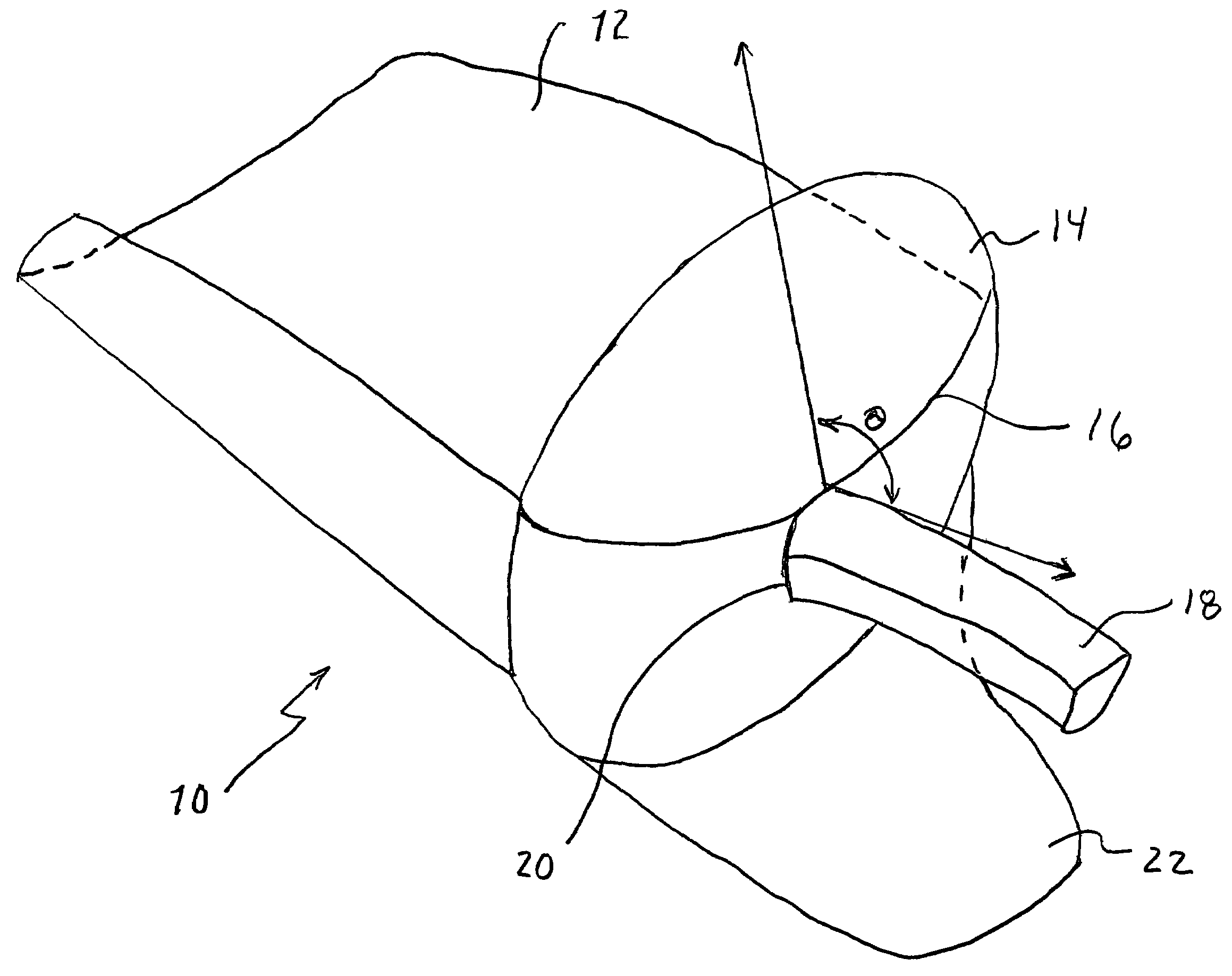

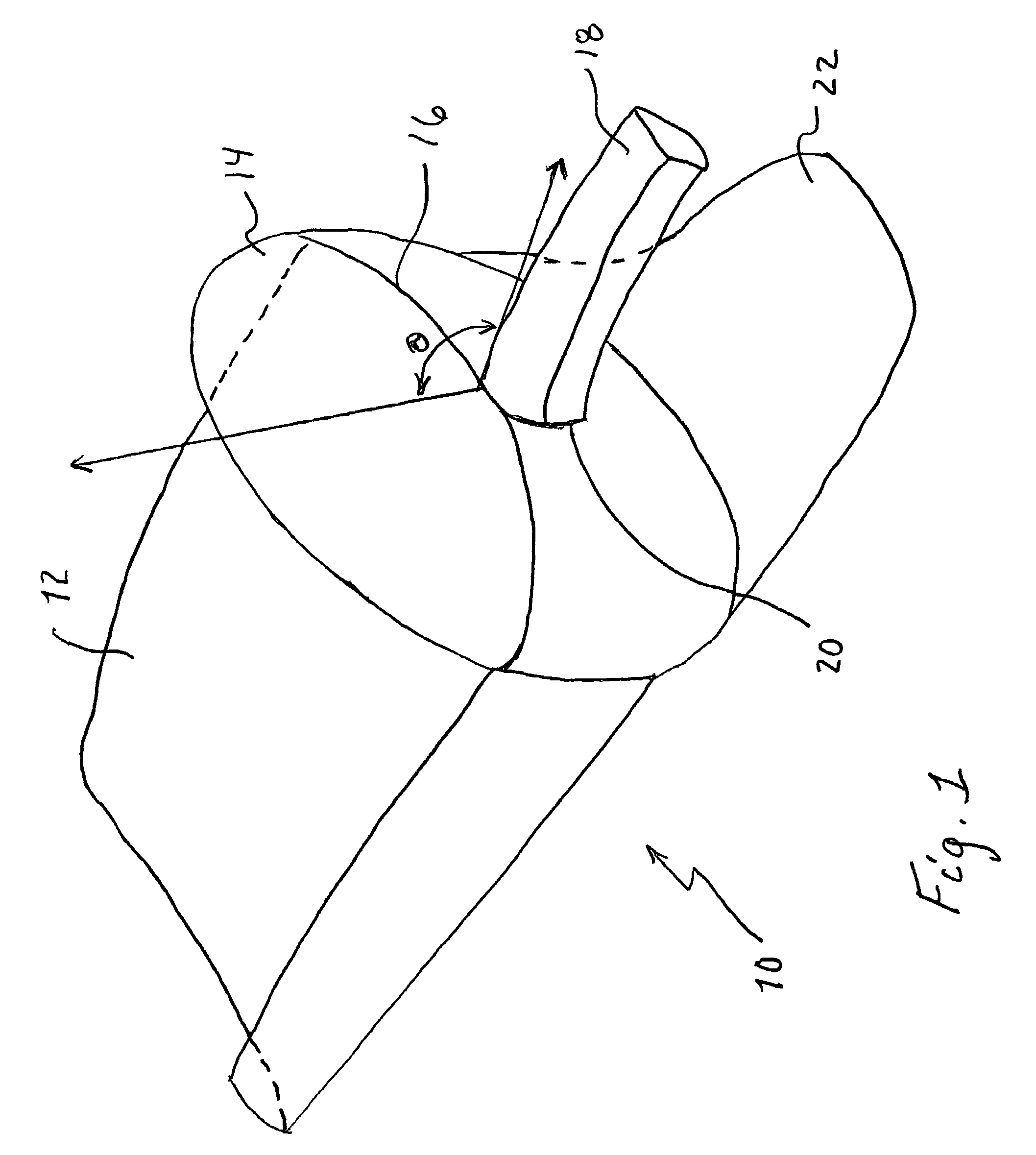

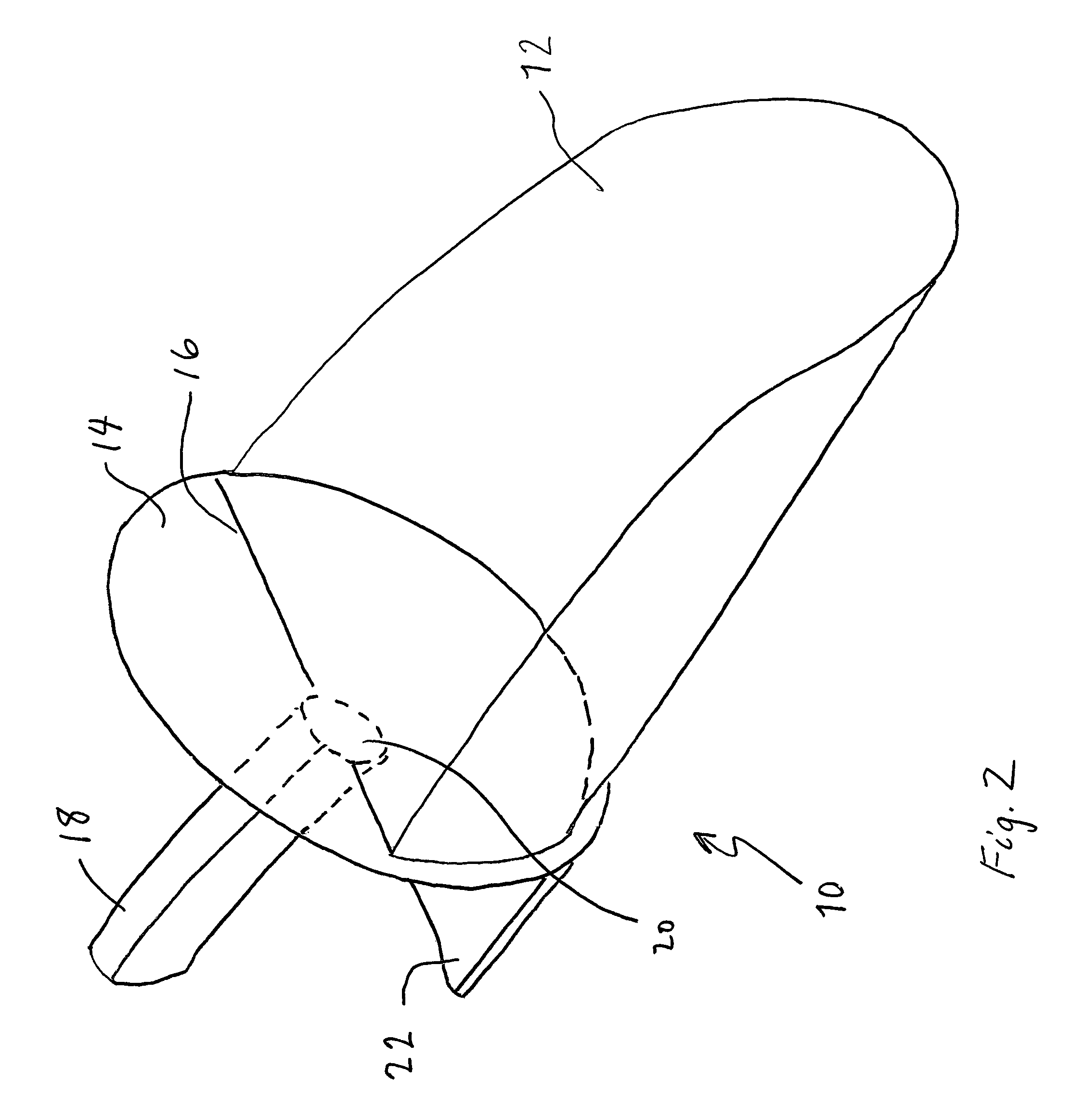

Scoop and sheath

ActiveUS20050151384A1Easily scoopedEfficient and precise product transferShop accessoriesBiomedical engineeringBack support

The present invention comprises a scoop having an angled or tapered front shovel portion, a shaped back support, an angled handle attached to the back support and a hand guard. A sheath to hold the scoop when not in use is also preferably provided.

Owner:SAN JAMAR INC

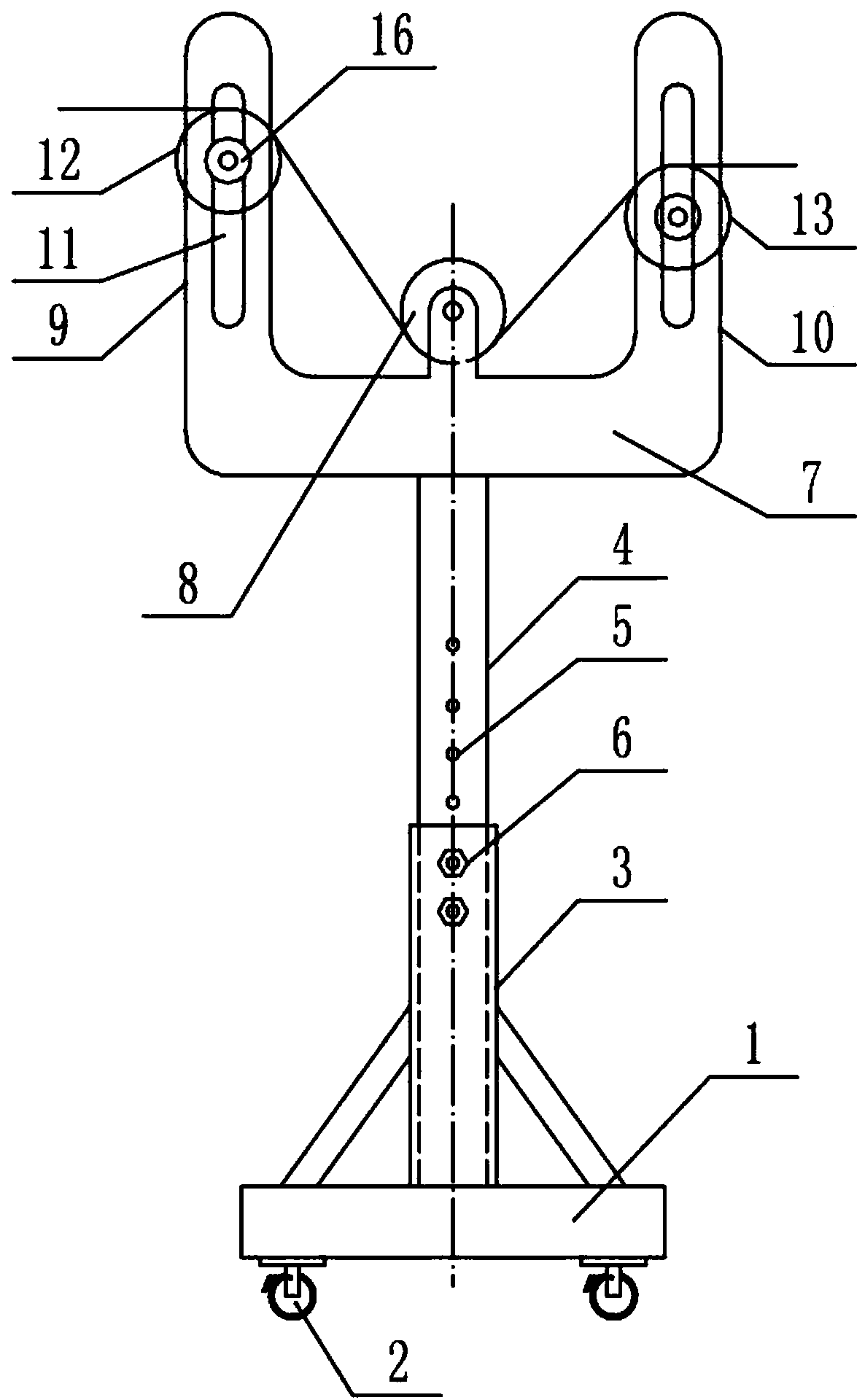

Yarn conveying and combing mechanism

InactiveCN105966980AQuick adjustment of conveying heightEfficient and accurate transmission and cardingFilament handlingHydraulic cylinderYarn

The invention discloses a yarn conveying and combing mechanism and belongs to the field of textile processing machinery. The yarn conveying and combing mechanism comprises a fixed support, a yarn pressing roller, a combing mechanism, a translation support and yarn guide rollers, wherein the translation support is vertically arranged at one side of the fixed support, a translation adjusting mechanism is horizontally arranged between the translation support and the fixed support, a plurality of translation wheels are rotatably connected to the lower side of the translation support, a yarn guide support is internally and horizontally connected with a plurality of yarn guiding rollers rotatably in sequence from top to bottom; the yarn pressing roller is horizontally arranged at the upper side of the fixed support, lifting hydraulic cylinders are separately vertically and symmetrically arranged on the fixed support at two ends of the yarn pressing roller, the combing mechanism is horizontally arranged on the fixed support at one side of the yarn pressing roller, and the combing mechanism comprises an adjusting plate, a rotating plate and a yarn combing plate. The yarn conveying and combing mechanism is reasonable in structure design, can quickly and efficiently convey and comb yarns, and can adjust the conveying width of the yarns according to requirements, thus meeting use requirements.

Owner:浙江正辉针织科技股份有限公司

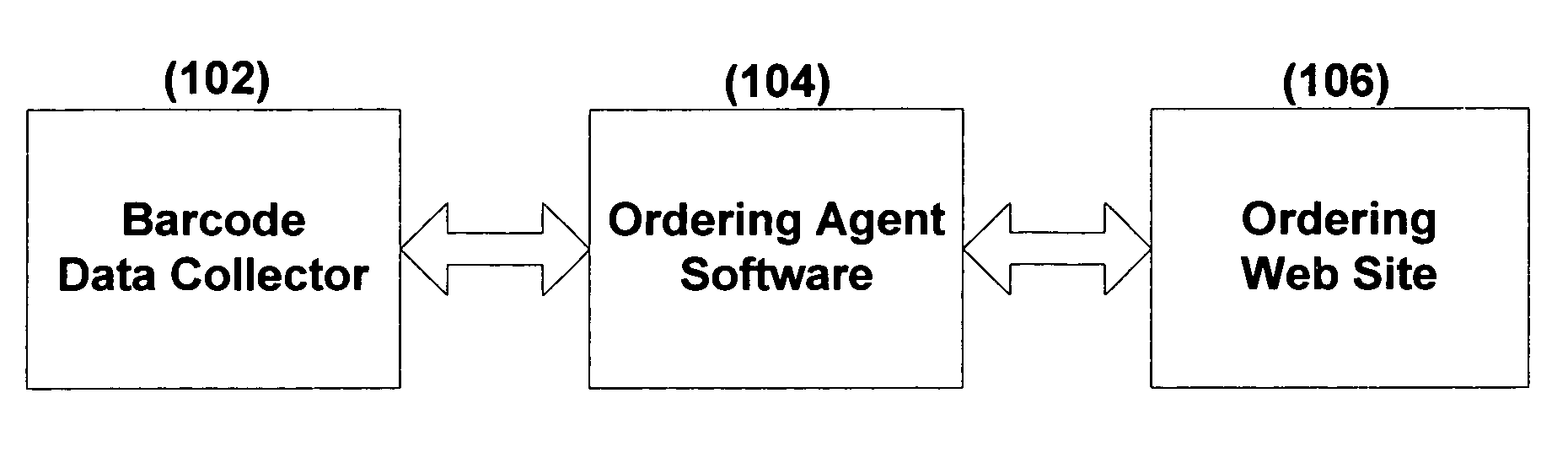

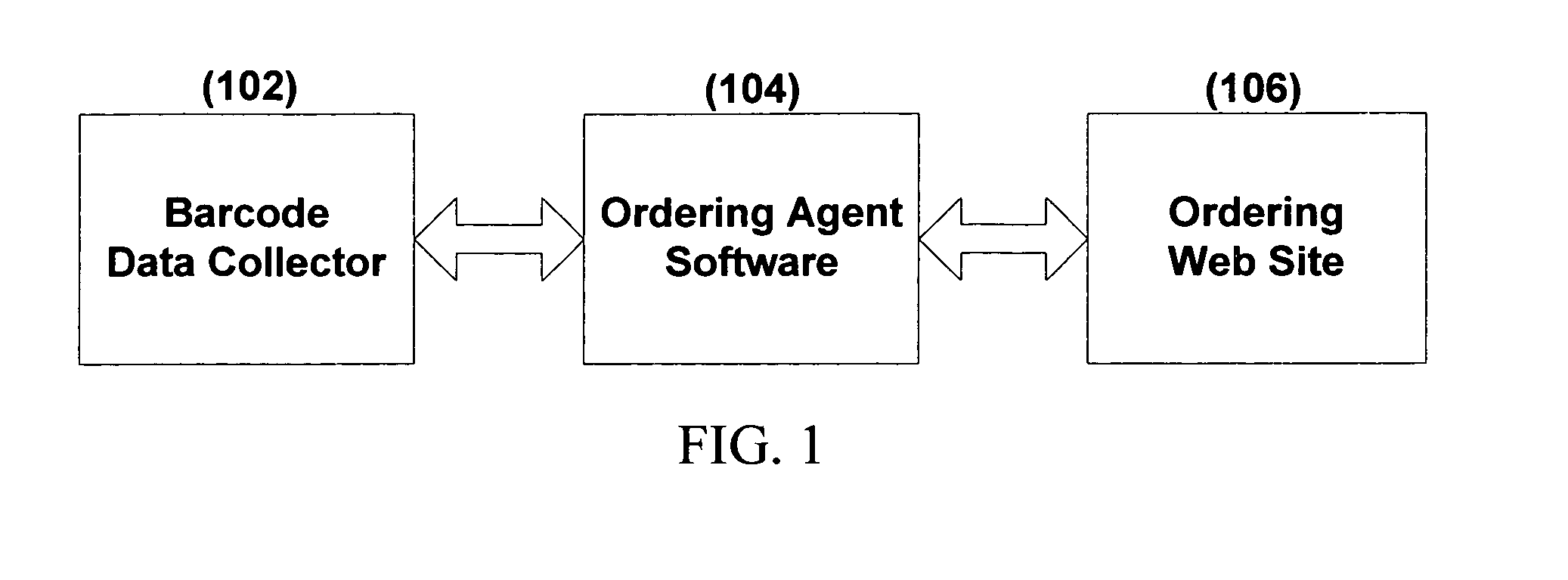

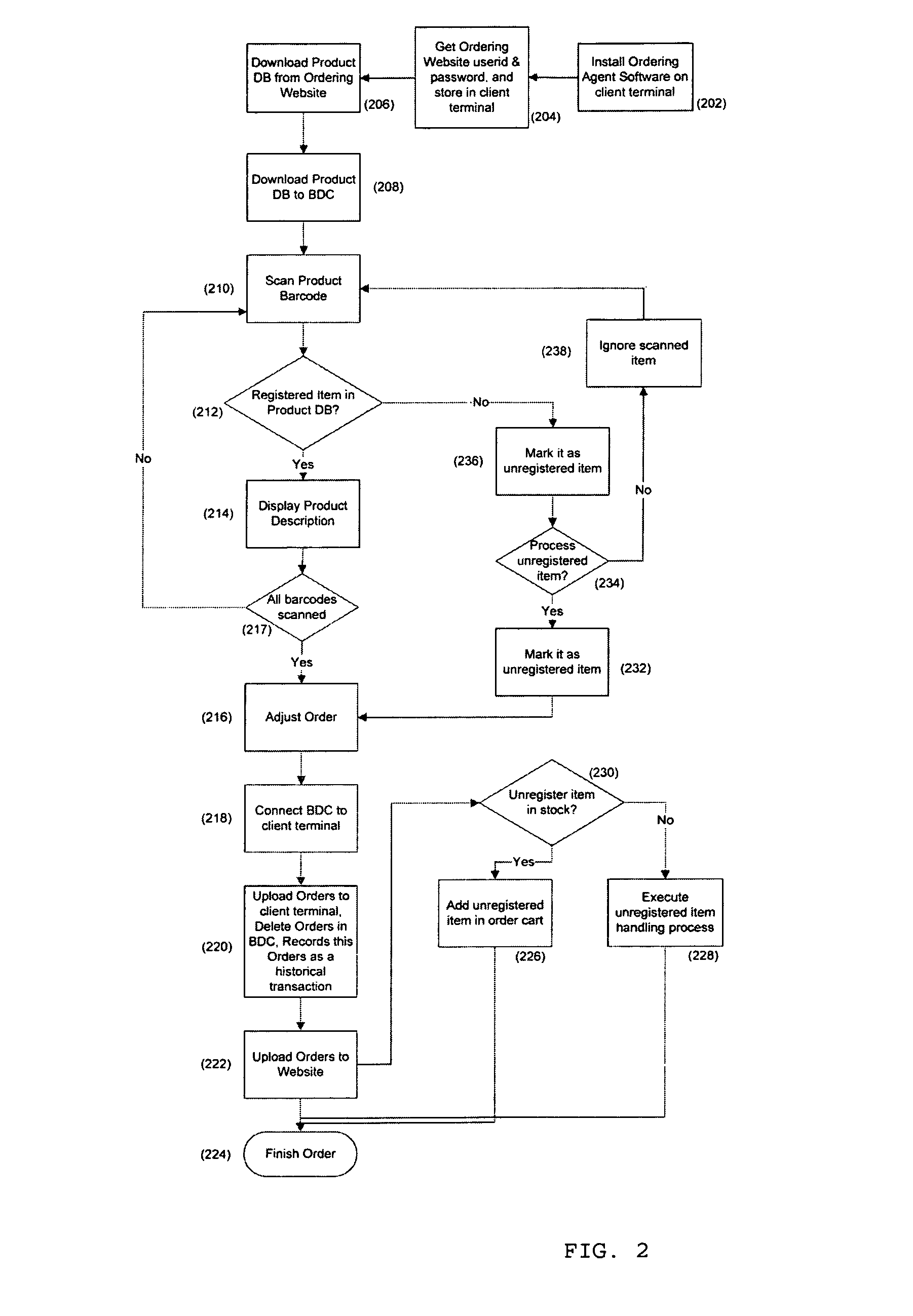

System and method for ordering using barcode data collector and online services

ActiveUS7954710B1Facilitate business transactionFacilitate information exchangeVisual presentationCommerceWeb siteBarcode

The present invention allows a user to place an order on an internal computer system or through a web site automatically by scanning UPC / EAN or product ID barcodes, without the need to modify supplier or other party websites. As such, a compact optical code reader with associated software is disclosed having multiple functions and is capable of performing various data processing functions involving scanned data. The system includes user and supplier identifiers which are employed to facilitate sales transactions.

Owner:KOAMTAC

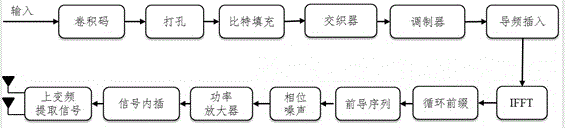

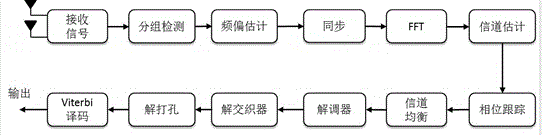

Multi-antenna vehicle network communication method based on IEEE802.11p standard

InactiveCN105490715AIncrease capacityImprove information rateSpatial transmit diversityTraffic signalSystem capacity

The present invention provides a multi-antenna vehicle network communication method based on an IEEE802.11p standard. The method comprises the following steps: step one, a plurality of antennas are respectively mounted on a vehicle node / a roadside node as a transmitting terminal and a receiving terminal, to form a multi-antenna vehicle network; step two, the transmitting terminal codes signals; step three, an MIMO doubly-selective channel is used for the wireless transmission of the signals; step four, the receiving terminal combines the signals received from each antenna to perform joint detection on the signals; and step five, the receiving terminal decodes the signals. According to the present invention, the multi-antenna vehicle network communication method combines the MIMO technology in an existing IEEE802.11p standard system, effectively increases the system capacity and spectrum efficiency without increasing the system bandwidth, enables the system to perform rapid information acquisition and information transmission on a vehicle driving at a high speed, realizes the reliable high-speed transmission of traffic signals in an intelligent transportation communication network, improves the transportation efficiency, alleviates the traffic congestion, and improves the road network capacity.

Owner:QINGDAO ACADEMY OF INTELLIGENT IND

Pipe fitting turning and conveying device

ActiveCN110540040ATurn over smoothly and accuratelySmooth and accurate verticalConveyorsConveyor partsPipe fittingEngineering

The invention discloses a pipe fitting turning and conveying device, and belongs to the field of workpiece machining and conveying mechanical devices. A turning mechanism is arranged on a conveying support on the upper side of a front conveying mechanism. A pipe moving mechanism is horizontally arranged on a conveying support on the upper side of a rear conveying mechanism. A front pipe conveyingbelt is horizontally arranged on the upper side of a front pipe conveying support. A turning connecting plate is fixedly arranged on one side of a turning gear in the radial direction of the turning gear. A pipe clamping mechanism is fixedly arranged on one side of the turning connecting plate. A rear pipe conveying belt is horizontally arranged on the upper side of a rear pipe conveying support.A pipe sucking connecting plate is vertically arranged on one side of a horizontal moving support. A horizontal moving guide plate on one side of the horizontal moving support is slidingly arranged ona pipe moving support in the horizontal direction. The pipe fitting turning and conveying device is reasonable in structural design, a pipe fitting can be conveniently and efficiently grabbed and turned, can be turned from a vertical station to a perpendicular station and can be adsorbed and conveyed and accurately placed on the rear pipe conveying belt to be conveyed, the pipe fitting conveyingautomatic degree is improved, and the machining use requirement is met.

Owner:皮休车轮科技(台州)有限公司

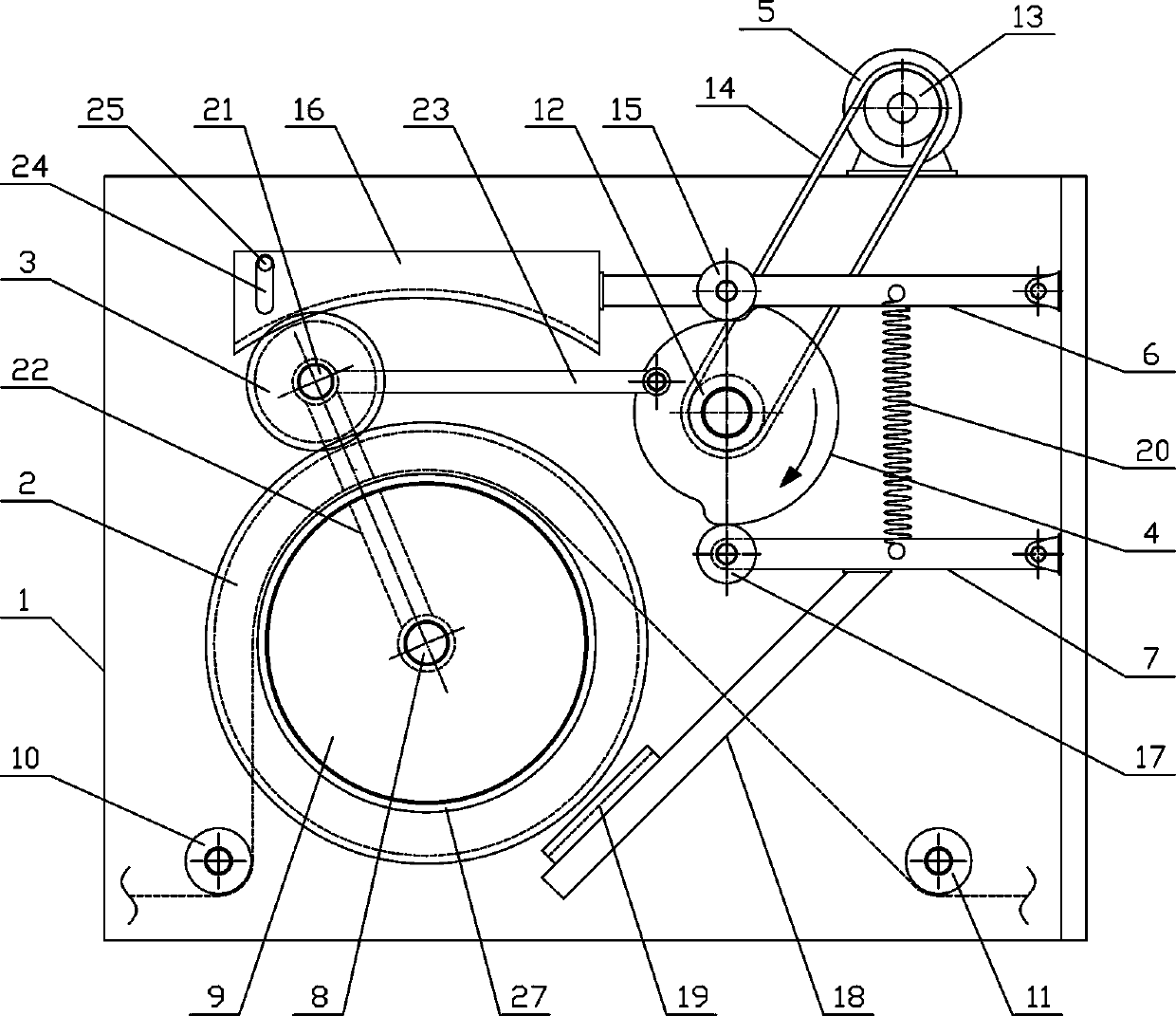

Intermittent material guiding and processing mechanism

PendingCN107745992AReasonable structural designImprove processing efficiencyWebs handlingGear wheelElectric machinery

The invention discloses an intermittent material guiding and processing mechanism and belongs to the field of processing and transferring mechanical devices. The intermittent material guiding and processing mechanism comprises a fixing support, a material guiding gear, a reciprocating gear, a rotary cam, a material guiding motor, an upper driven swing rod and a lower driven swing rod; one side ofthe material guiding gear is horizontally and coaxially provided with a material guiding roll, and one end of the upper driven swing rod is provided with an arc-shaped gear plate; a limiting clampingplate is arranged on the lower side of the middle of the lower driven swing rod in a downward inclining mode, and a tension spring is arranged between the upper driven swing rod and the lower driven swing rod; the reciprocating gear is vertically arranged between the material guiding gear and the arc-shaped gear plate, and a material guiding swing rod is arranged between a reciprocating swing shaft and a material guiding rotary shaft; and a reciprocating connecting rod is arranged between the reciprocating gear and the rotary cam. According to the intermittent material guiding and processing mechanism, the structural design is reasonable, the material guiding roll can be driven to intermittently rotate according to the needs of processing so that belts can be driven by the material guidingroll to be intermittently and stably transferred, the belt processing efficiency and quality are improved, and the demands of production and use are met.

Owner:TONGXIANG YUESHUN WRAP KNITTING

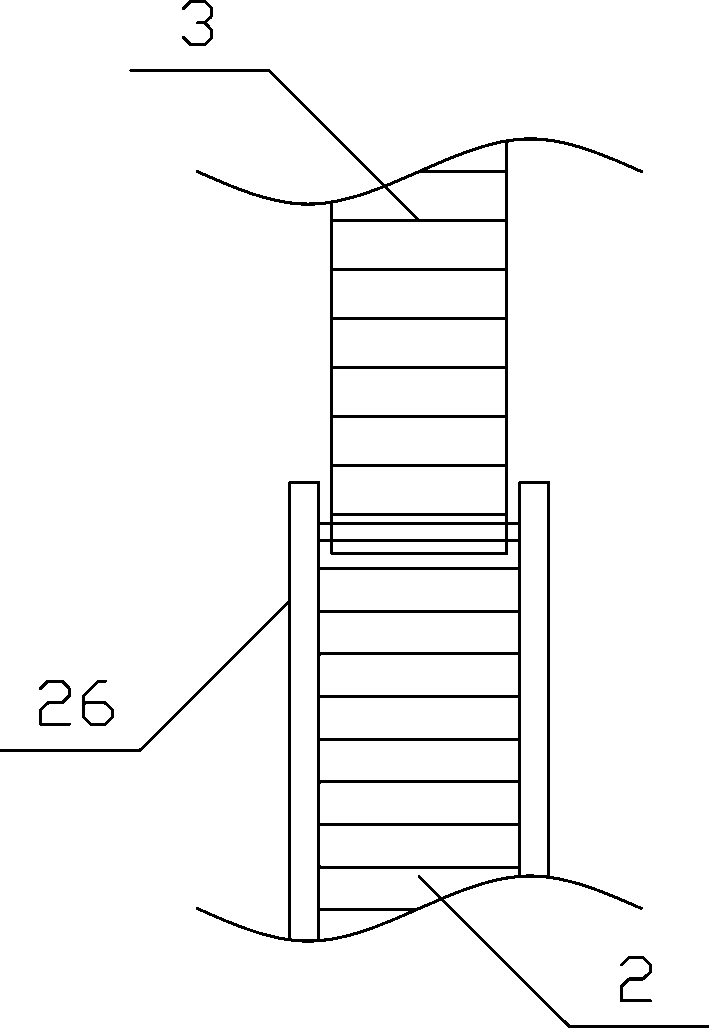

Conveying transition device of chemical fiber yarn

The invention relates to a conveying transition device of chemical fiber yarn. The device comprises a base, wherein universal wheels are arranged at the lower part of the base, a stand column is arranged on the base, a transition frame is arranged on the stand column, and a fixed roller is arranged in the middle of the transition frame; a plurality of fixed wheels are arranged on the fixed roller,and a left support frame is arranged on the left side of the transition frame; a right support is arranged on the right side of the transition frame, and the left support and the right support are identical in structure; vertical long kidney-shaped holes are formed in the left support and in the right support respectively, and a left movable roller is arranged in the long kidney-shaped hole of the left support; a right movable roller is arranged in the long kidney-shaped hole of the right support, and movable wheels are arranged on the left movable roller and the right movable roller. The device is simple in structure and convenient to use. The device can be moved freely according to needs of chemical fiber yarn conveying and can be adjusted according to different heights of the chemicalfiber yarn so as to guarantee efficient and accurate conveying of the chemical fiber yarn and meet the requirements of production and application.

Owner:ZHANGJIAGANG JINYI CHEM FIBER

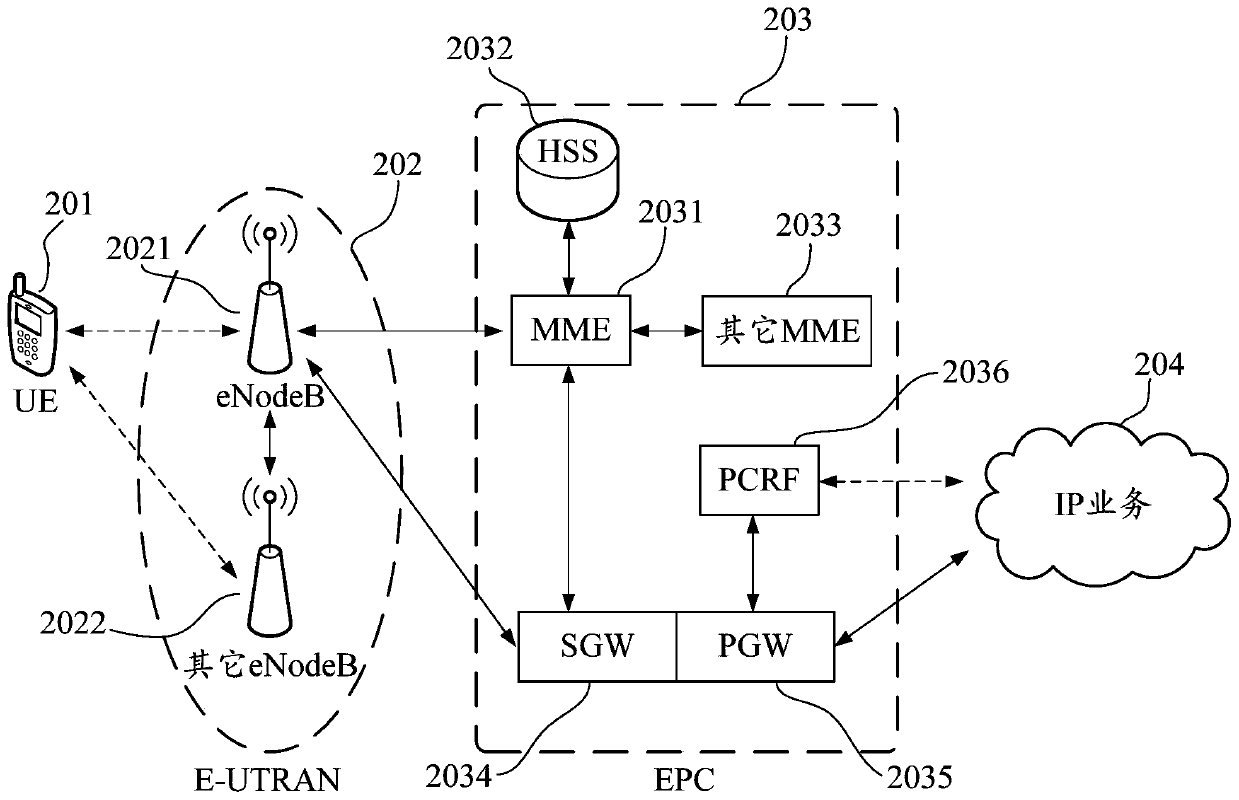

Data transmission method, server and computer readable storage medium

PendingCN110049516AIncrease occupancyAvoid wasteful situationsNetwork traffic/resource managementOccupancy rateCell network

The invention discloses a data transmission method, a server and a computer readable storage medium, and the method comprises the steps: obtaining a load and a transmission bit error rate of a cell network where a terminal is located when a data transmission request is received; determining a first transmission rate of the terminal in a first preset network and a second transmission rate of the terminal in a second preset network according to the load and the transmission error rate, the cell network comprising the first preset network and the second preset network; and transmitting to-be-transmitted data corresponding to the data transmission request according to the first transmission rate and the second transmission rate. According to the scheme, the first preset network and the secondpreset network are combined to transmit the to-be-transmitted data, so that the situation that the resource occupancy rate of one party in the preset network is high and the resource of the other party is wasted is avoided, the transmission is more accurate and effective, and full utilization of network resources is realized.

Owner:NUBIA TECHNOLOGY CO LTD

Scoop and sheath

The present invention comprises a scoop having an angled or tapered front shovel portion, a shaped back support, an angled handle attached to the back support and a hand guard. A sheath to hold the scoop when not in use is also preferably provided.

Owner:SAN JAMAR INC

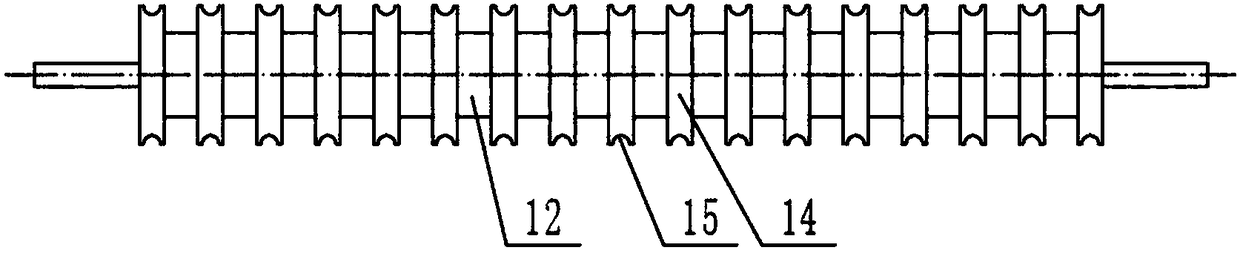

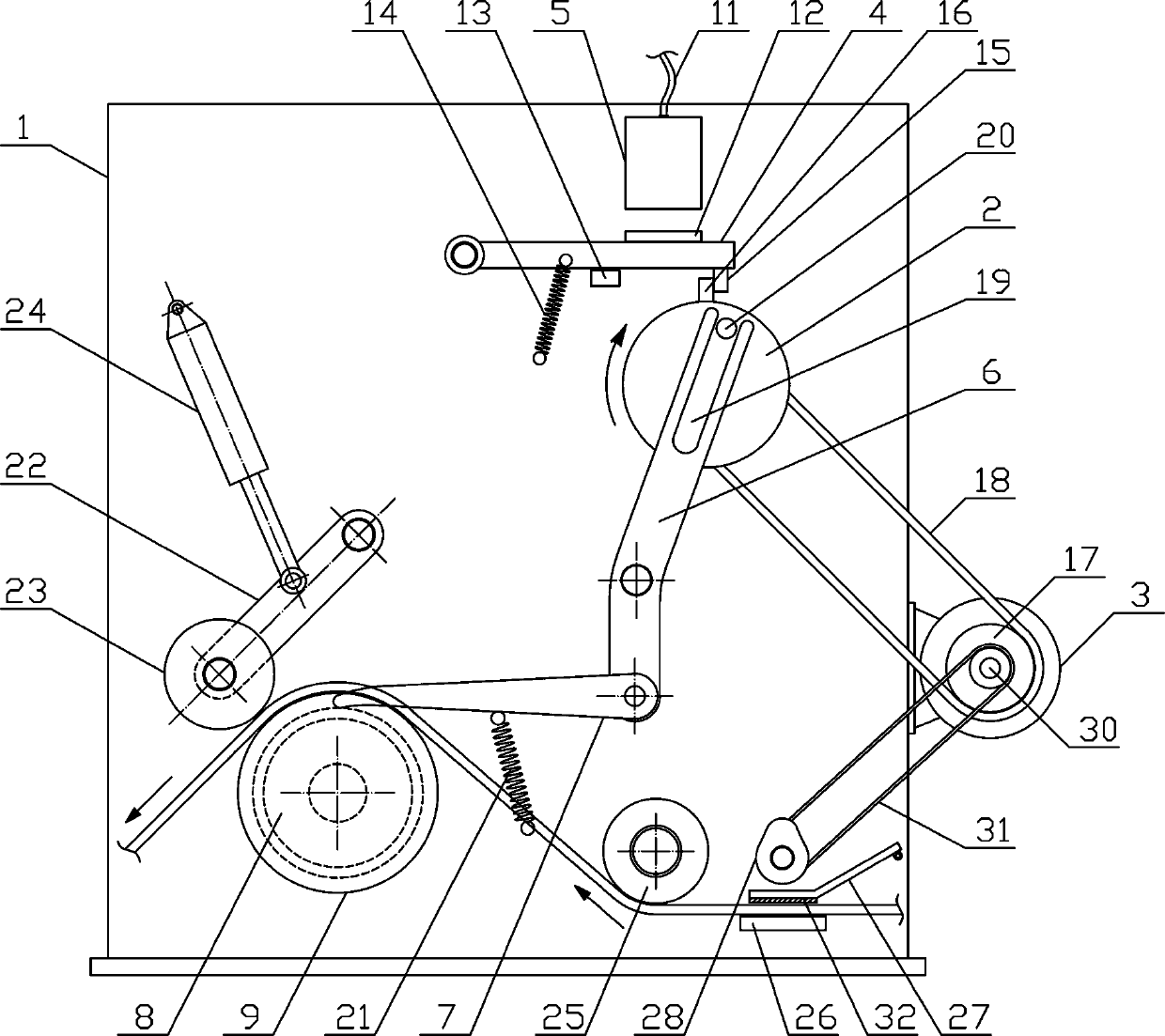

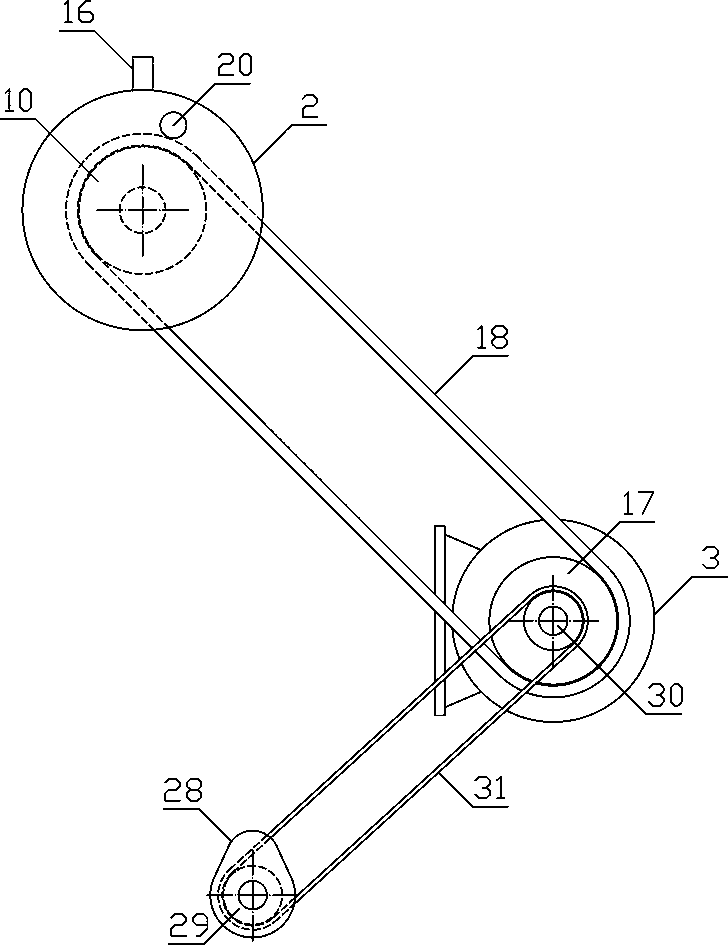

Strip delivery mechanism

The invention discloses a strip delivery mechanism and belongs to the field of delivery processing mechanical equipment. The strip delivery mechanism comprises a fixing bracket, a rotating disc, a delivery belt motor, a control rod, an electromagnet, a driving connecting rod, a delivery belt pawl, a delivery belt ratchet wheel, a delivery belt roller and a belt pressing mechanism, wherein the control rod is arranged at the upper side of the rotating disc; the driving connecting rod is arranged at the lower side of the rotating disc; the outer end of one side of the rotating disc is horizontally provided with a rotating pin rod which is matched with a rotating clamping slot; one side of the delivery belt ratchet wheel is coaxially and horizontally provided with the delivery belt roller; thedelivery belt pawl is arranged at the lower side of the driving connecting rod; one end of the delivery belt pawl is meshed with the delivery belt ratchet wheel; a belt pressing bracket is arranged at one side of the upper portion of the delivery belt roller; the lower end of the belt pressing bracket is horizontally and rotationally connected with a belt pressing roller; and the belt pressing mechanism is horizontally arranged on the fixing bracket positioned at one side of a belt guide roller. The strip delivery mechanism disclosed by the invention is reasonable in structural design, stableand controllable in a strip delivery process and capable of efficiently, accurately and intermittently delivering strips so as to meet the production and application requirements.

Owner:TONGXIANG YUESHUN WRAP KNITTING

Novel automatic rotating piece device

ActiveCN103231295AAccurate and efficient transmissionIncrease transfer efficiencyEdge grinding machinesAutomatic controlAutomated control system

The invention provides a novel automatic rotating piece device. The novel automatic rotating piece device is located between two edge grinding machines and comprises an automatic rotating piece mechanism, a glass conveying table and an automatic control system. The automatic rotating piece mechanism is connected with a first side edge of the glass conveying table and is electrically connected with the automatic control system. The automatic rotating piece mechanism comprises a rotatable press wheel, a support frame, a cylinder and a location leaning grille. The rotatable press wheel is vertically placed above the glass conveying table and comprises an upper press wheel and a lower press wheel, the support frame is connected with the first side edge, the cylinder is vertically arranged below the glass conveying table, the cylinder is connected with the automatic control system through an air pipe, and the location leaning grille is connected with the upper portion of the first side edge. The novel automatic rotating piece device has the advantages that automatic and rapid rotation of glass in the glass edge grinding process can be achieved, and scratch to the glass surface is also avoided simultaneously.

Owner:天津南玻节能玻璃有限公司 +1

Flax strip winding mechanism

PendingCN108505155AReasonable structural designGuaranteed stabilityContinuous wound-up machinesSprocketTextile processing

The invention discloses a flax strip winding mechanism, and belongs to the field of textile processing mechanical equipment. The lifting bearing plate of the flax strip winding mechanism is slidably arranged on the lifting guide rod in a vertical direction, the chain wheel bracket at the output end of the lifting cylinder is vertically connected with a lifting chain wheel, the middle part of the lifting bearing plate is vertically connected with a winding sleeve, the pressure cylinder connecting plate and the winding turntable are integrally formed and arranged, a plurality of telescopic pressing rods are symmetrically arranged on the upper side of the pressing cylinder connecting plate along the radial direction of the winding turntable, the winding sleeve is slidably arranged on the winding guide rod in a vertical direction, the output end of the pulling motor is horizontally and fixedly provided with a pulling gear matched with the rotating gear, the upper end of the winding guide rod is vertically provided with a guide bar bracket. The flax strip winding mechanism has the advantages that the structural design is reasonable, the flax strips can be continuously and uniformly wound, the degree of compactness of the flax strips during the winding process can be ensured, the automation degree of the winding of the flax strips is improved, and the requirements of production and use are met.

Owner:嘉兴市华益股份有限公司

Proximate matter transversely-moving conveying device

The invention discloses a proximate matter transversely-moving conveying device, and belongs to the field of conveying mechanical equipment. The proximate matter transversely-moving conveying device comprises a conveying support, a fixing support, a lifting support, a bearing support and a transversely-moving motor; a plurality of main conveying rollers are horizontally, evenly and rotationally connected to the middle portion of the upper side of the conveying support, a plurality of auxiliary conveying rollers are horizontally, evenly and rotationally connected to the two sides of the conveying support, the bearing support is horizontally arranged on the lower side of the lifting support, and the transversely-moving motor drives a transversely-moving lead screw; a transversely-moving block can horizontally move along a transversely-moving guide rod; and a bearing roller is horizontally arranged on the lower side of the bearing support, limiting air cylinders are horizontally arranged on the two sides of the bearing support, and limiting rollers are horizontally and rotationally connected to one side of the transversely-moving plate. The proximate matter transversely-moving conveying device is reasonable in structural design, and proximate matter can be horizontally and accurately conveyed rapidly and efficiently; and the proximate matter can be stably lifted and transversely moved according to needs, the proximate matter machining efficiency and quality are improved, and the production and using requirements are met.

Owner:曹林仙

Flax carding feeding mechanism

InactiveCN108861350AImprove efficiencyQuality improvementConveyorsConveyor partsMechanical equipmentLeather belt

The invention discloses a flax carding feeding mechanism and belongs to the field of textile processing mechanical equipment. A driving mechanism and a horizontal-moving mechanism of the flax cardingfeeding mechanism are sequentially arranged on one side of a fixed bracket from top to bottom. The two sides of a driving belt are connected to a main rotating roller and an auxiliary rotating rolleron the two sides of a driving bracket correspondingly in a wound mode. A plate sucking bracket is horizontally arranged on the outer side of the driving belt. A horizontal-moving guiding plate is slidably arranged on a horizontal-moving guiding rod in the horizontal direction. A plate pulling air cylinder and a plate pushing air cylinder are horizontally and fixedly arranged on the two sides of ahorizontal-moving bracket correspondingly. A lifting bracket is vertically and fixedly arranged on the lower side of the horizontal-moving guiding plate. A material pressing mechanism is vertically arranged at the output end of a lifting air cylinder. The flax carding feeding mechanism is reasonable in structural design, flax can be compressed and fixed conveniently, rapidly and firmly to be conveyed in a horizontal-moving mode, the flax can be pulled to conduct reciprocating lifting movement continuously and stably in the flax horizontal-moving conveying process, the flax carding efficiency and quality are improved, and the needs of production, processing and using are met.

Owner:徐阳

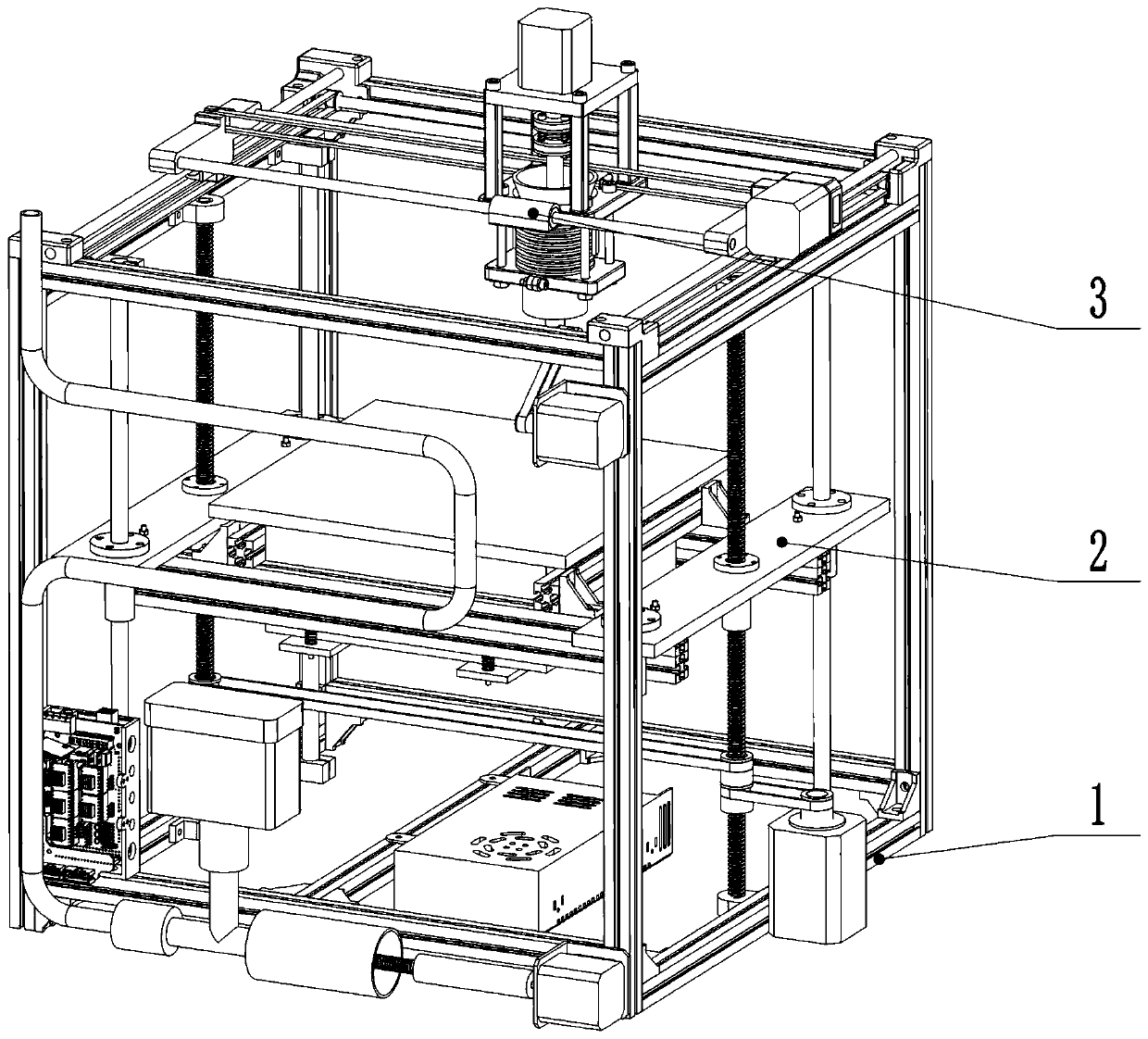

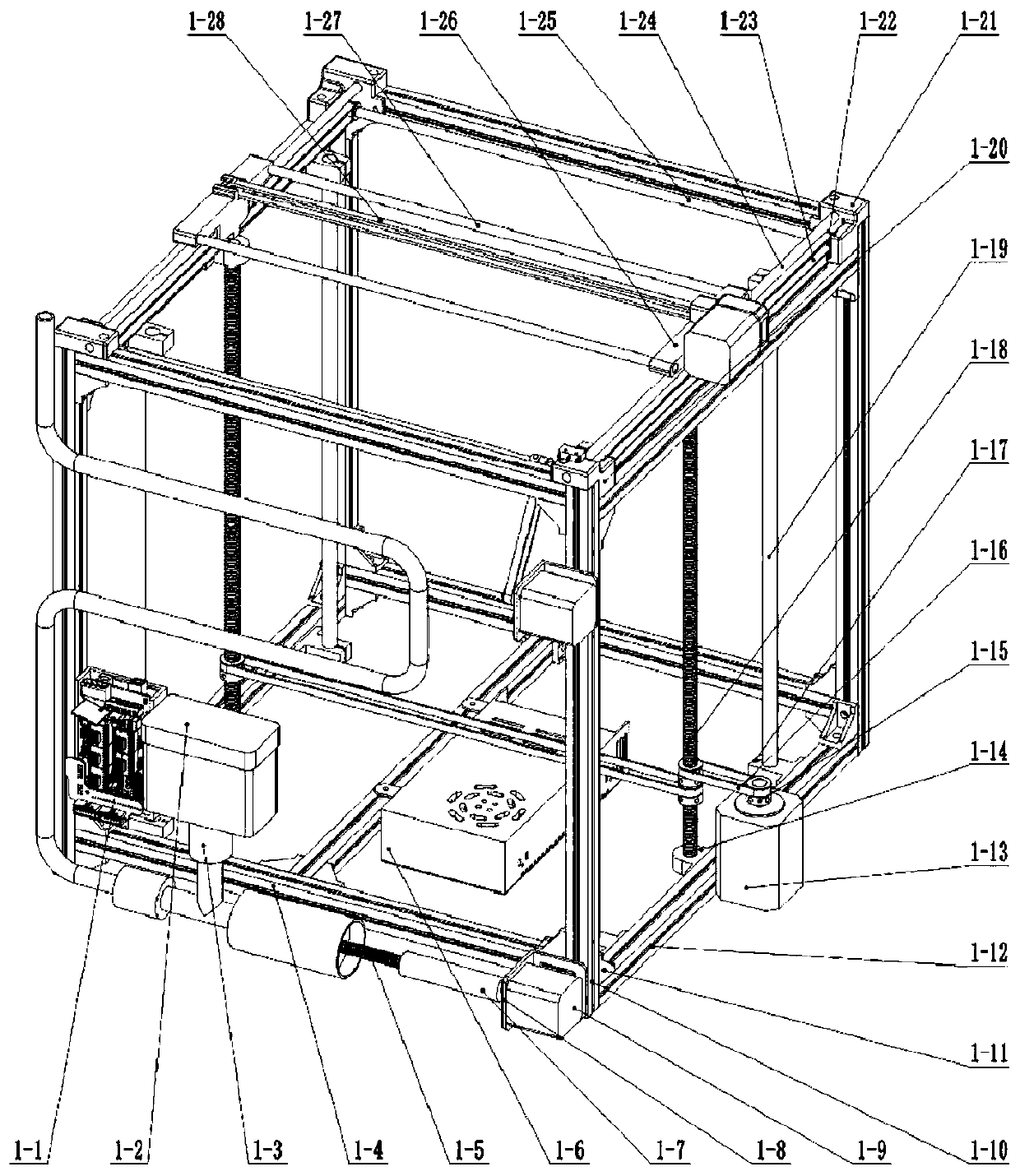

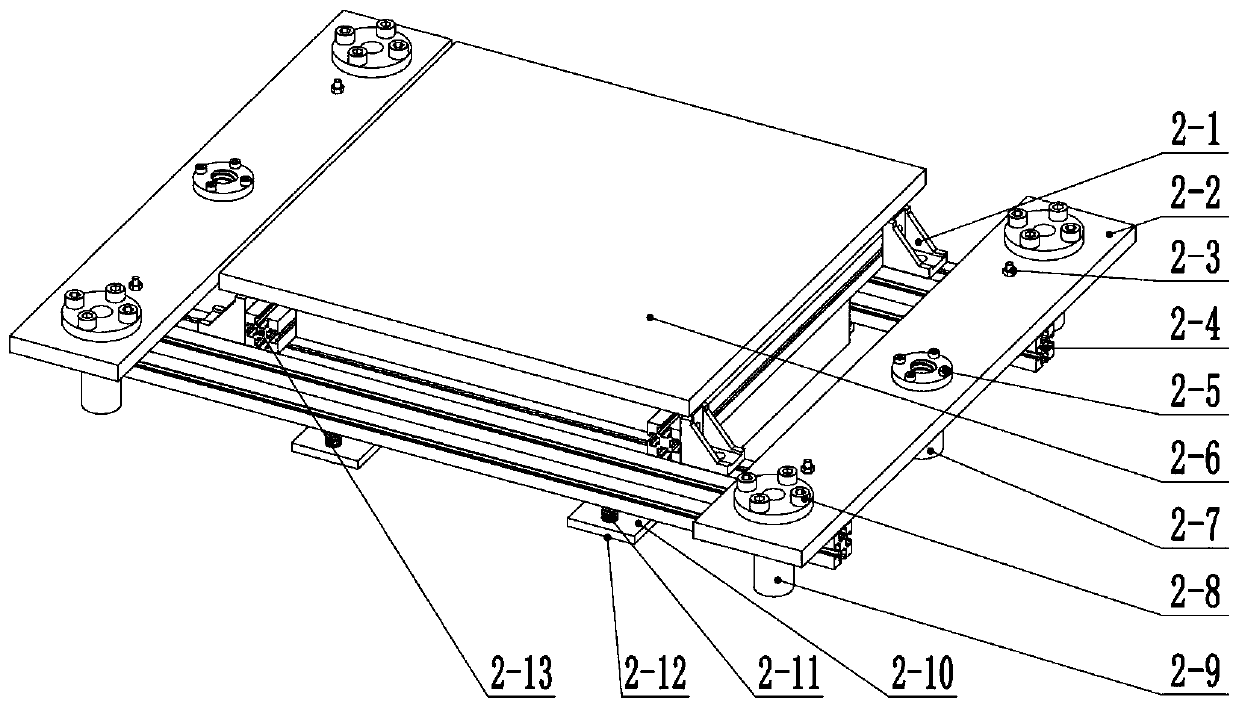

Multifunctional food 3D printer

ActiveCN109924529AAccurate and efficient transmissionStable structureAdditive manufacturing apparatusFood coatingStructure and functionSpray nozzle

The invention discloses a multifunctional food 3D printer and belongs to the technical field of machining. The outer frame is provided with a Z-axis guiding movement mechanism, an X-axis guiding movement mechanism and a Y-axis guiding movement mechanism; a hot bed structure is mounted on the Z-axis guiding movement mechanism; an X-axis guiding movement mechanism is arranged on the Y-axis guiding movement mechanism; a spiral stirrer type spray head mechanism is arranged on the X-axis guiding movement mechanism; and the output end of the storage conveying mechanism is connected to the spiral stirrer type spray head mechanism through a hose. The multifunctional food 3D printer adopts a hydraulic storage conveying mechanism to convey required food raw materials to a stirring tank for stirring;a stirrer extrudes out the food raw materials with fluidity such as dough, egg liquid, chocolate, syrup, ice cream and the like through a nozzle; the hot bed is comprehensive in structure and function, and can realize processing under multiple environments of cold, hot and normal temperature. The function is greatly expanded, and the demands of consumers on multiple mouthfeel are met.

Owner:XUZHOU UNIV OF TECH

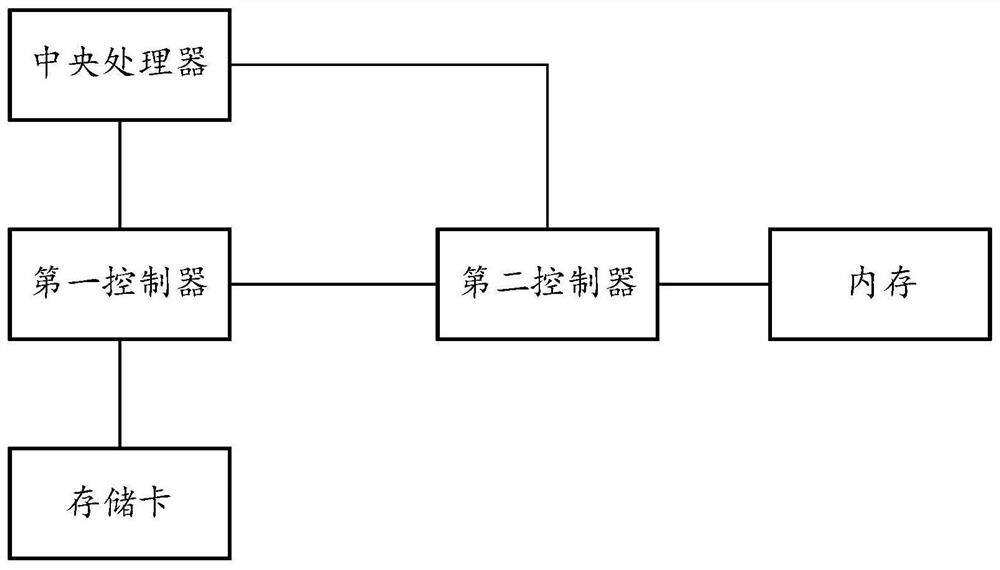

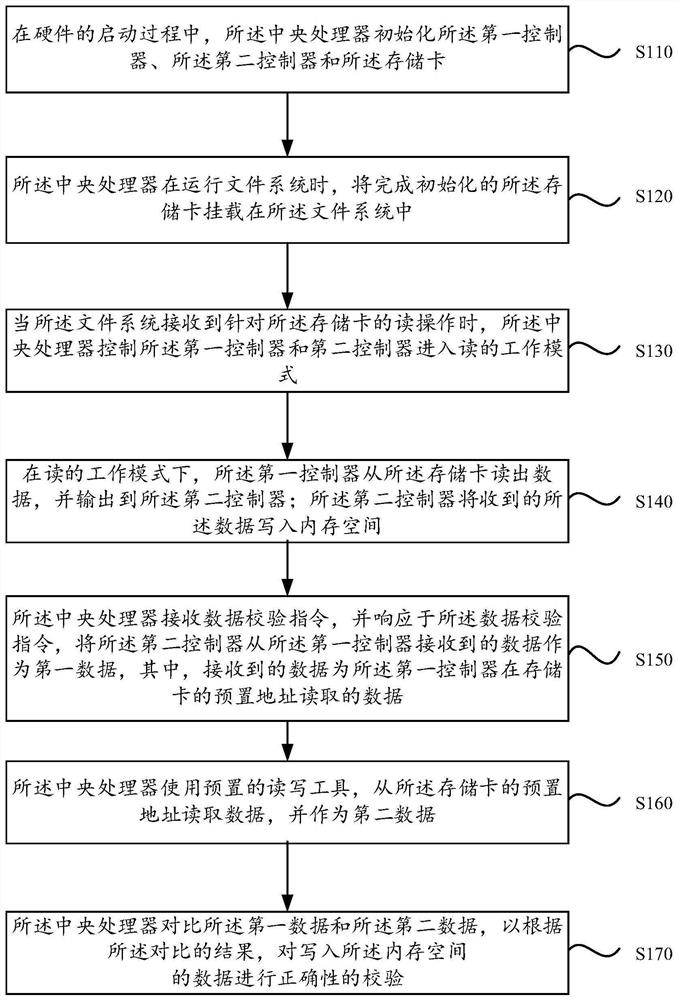

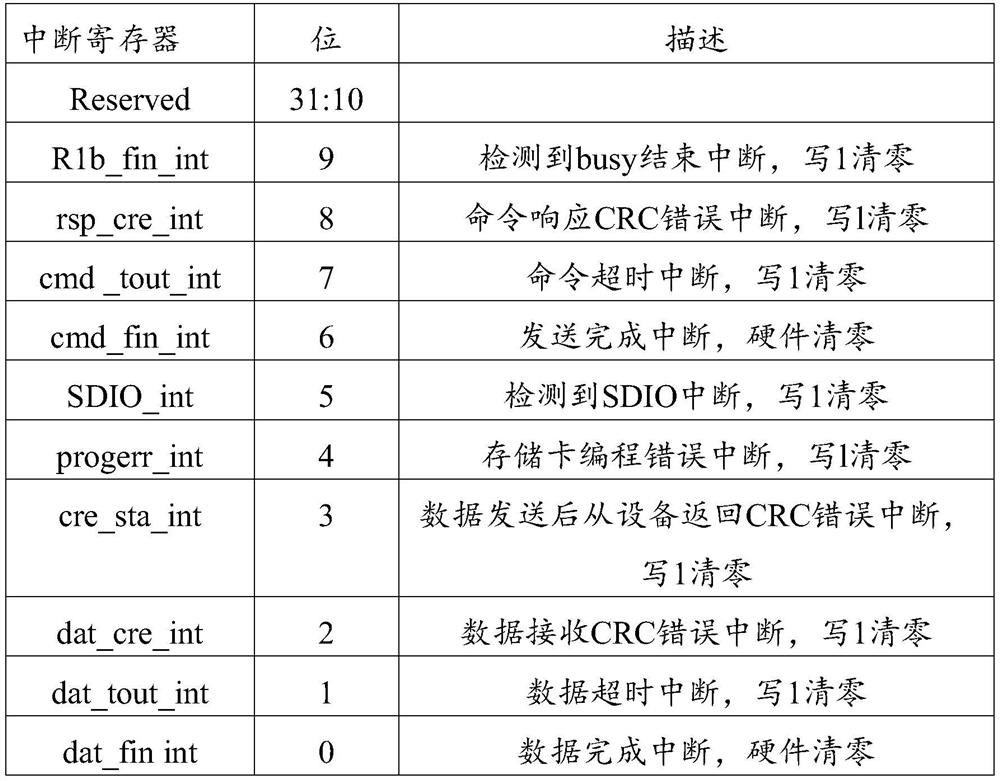

Memory card control method and system

ActiveCN112799974AIncrease success rateGuaranteed transmission efficiencyRegister arrangementsMemory adressing/allocation/relocationFile systemSource Data Verification

The invention relates to a memory card control method and system. The method is applied to a central processing unit and comprises the following steps: when the central processing unit runs a file system, mounting an initialized memory card in the file system; when the file system receives a read operation for the memory card, the central processing unit controls the first controller to read data from the memory card and outputs the data to the second controller; the second controller writes the received data into a memory space; the central processing unit responds to the data verification instruction and takes data received by the second controller from the first controller as first data; the data is read from a preset address of the memory card by using a preset read-write tool, and serves as second data; and the first data is compared with the second data to check the correctness of the data written into the memory space according to a comparison result, thereby realizing the technical effect of improving the security and accuracy in the memory card starting and data transmission processes.

Owner:INTEWELL (GUANGZHOU) SOFEWARE TECH CO LTD

Working method of continuous seed guiding and packaging mechanism

ActiveCN111907795ASmooth and smooth pouringReasonable structural designSolid materialAgricultural engineeringStructural engineering

The invention discloses a working method of a continuous seed guiding and packaging mechanism, and belongs to the field of seed conveying and packaging mechanical equipment. A seed conveying mechanismand a metering and transferring mechanism are sequentially and fixedly arranged on one side of a material guiding support from top to bottom; a material pouring and packaging mechanism is horizontally and fixedly arranged on the material guiding support on one side of the metering and transferring mechanism; a seed storage hopper is vertically and fixedly arranged on the material guiding supporton the upper side of a conveyor belt; a material blocking mechanism is fixedly arranged on the material guiding support on the lower side of a material collecting pipe; the end part of one side of a transferring connecting plate is fixedly connected with the end part of a reciprocating rotating shaft; a metering hopper is arranged on a hopper connecting plate on the outer side of a metering and weighing scale on the transferring connecting plate; the output end of a lifting air cylinder is vertically and rotatably connected with a hopper push wheel; and a tank conveying belt is horizontally arranged on the upper side of a tank conveying support. According to the working method of the continuous seed guiding and packaging mechanism provided by the invention, the structural design is reasonable, seeds can be accurately and high-efficiently metered and transferred, automatic packaging and conveying of the seeds can be achieved, and the seed packaging use demand is met.

Owner:戴志刚

Continuous conveying mechanism for Pipe fittings

ActiveCN112027600ATurn over smoothly and accuratelySmooth and accurate verticalConveyorsConveyor partsPipe fittingGear wheel

The invention discloses a continuous conveying mechanism for pipe fittings, and belongs to the field of mechanical equipment for machining and conveying workpieces. A turnover mechanism of the continuous conveying mechanism disclosed by the invention is arranged on a conveying bracket arranged at the upper side of a front conveying mechanism; a straw moving mechanism is horizontally arranged on aconveying bracket arranged at the upper side of a rear conveying mechanism; a front straw conveying belt is horizontally arranged at the upper side of a front straw conveying bracket; a turnover connecting plate is fixedly arranged at one side of a turnover gear and in the radial direction of the turnover gear; a straw clamping mechanism is fixedly arranged at one side of the turnover connecting plate; a rear straw conveying belt is horizontally arranged at the upper side of a rear straw conveying bracket; a straw connecting plate is vertically arranged at one side of a translation bracket; atranslation guide plate at one side of the translation bracket is slidably arranged at a straw moving bracket and in the horizontal direction. The continuous conveying mechanism disclosed by the invention is reasonable in structural design, can be used for grabbing and turning over pipe fittings conveniently and efficiently, so that the pipe fittings are turned over from a vertical station to a horizontal station, and the pipe fittings can be adsorbed, transferred and accurately placed on the rear straw conveying belt to be conveyed, thus the automation degree of conveying of the pipe fittingsis improved, and the requirements of machining and use are met.

Owner:玉环优智科技有限公司

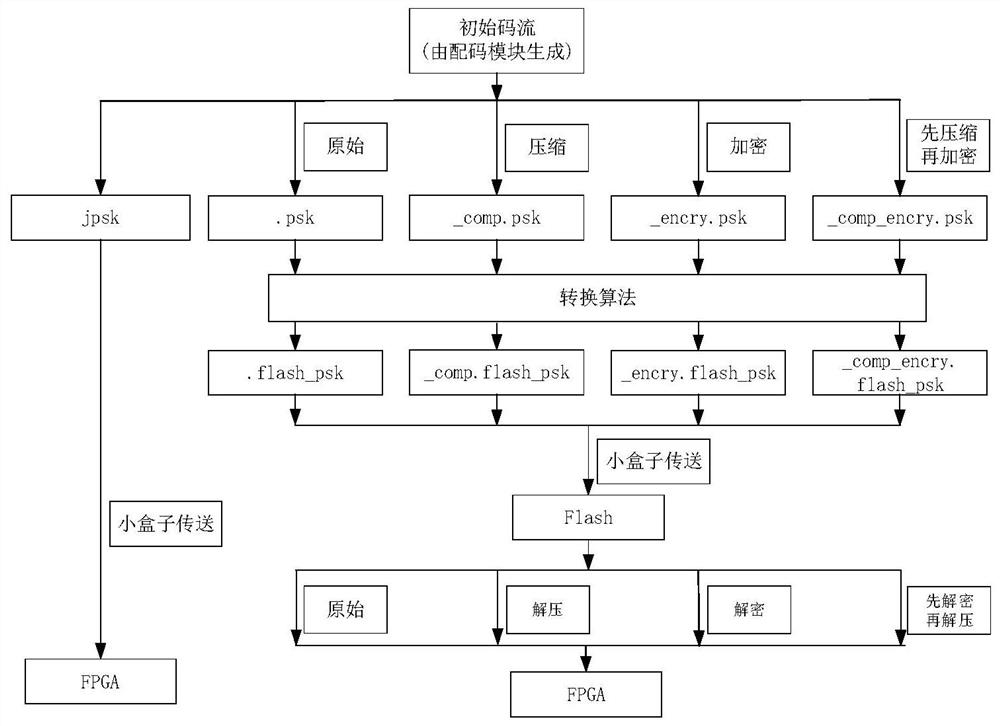

Method and system for downloading code streams of different formats to FPGA

PendingCN113542377ASimplify the download processAccurate and efficient transmissionDigital video signal modificationTransmissionTransmission protocolTransformation algorithm

The invention discloses a method and a system for downloading code streams in different formats to an FPGA, which greatly simplify the code stream downloading process, can accurately and efficiently transmit the code streams in different formats to the FPGA and improve the flexibility and the efficiency. The method for downloading the code streams in different formats to the FPGA comprises the following steps of: (1) defining different formats of the code streams, and correspondingly processing the initial code streams, so that the number of bits contained in a code stream file meets a specific requirement to obtain the code streams in the corresponding formats; (2) carrying out a uniform conversion algorithm to convert the psk format into a corresponding flash psk format; and (3) defining a transmission protocol of the small box, and transmitting the flash psk format file to the Flash device by adopting a uniform transmission mode.

Owner:EHIWAY MICROELECTRONIC SCI & TECH SUZHOU CO LTD

Power utilization information collection method and system based on technology of Beidou satellite navigation system

ActiveCN102810243BAvoid managementAccurate and efficient transmissionTransmission systemsRadio transmissionTelecommunications linkPrimary station

The invention provides a power utilization information collection method and a system based on a technology of a Beidou satellite navigation system. The technical scheme comprises the following steps of: obtaining a meter reading data message of collected power utilization information, also generating a Beidou communication message by the data conversion of the meter reading data message and transmitting the Beidou communication message to a prepositive end by a Beidou communication link; and reducing the Beidou communication message to the original format of the meter reading data message by the prepositive end and also transmitting to an application server of a central master station for carrying out united managing and monitoring. By adopting the method and the system which are provided by the invention, the power utilization information of residents in a site can be connected to a master station of a power utilization information management system in a seamless way by utilizing the two-way communication function of a Beidou satellite navigation system under the condition that traditional operation equipment is not reconstructed so as to realize the process from the collection of data in the site to the connection of a Beidou communication channel. The power utilization information of regions with undeveloped communication can be effectively and reliably obtained at real time.

Owner:GZH BEIDOU TECH GRP

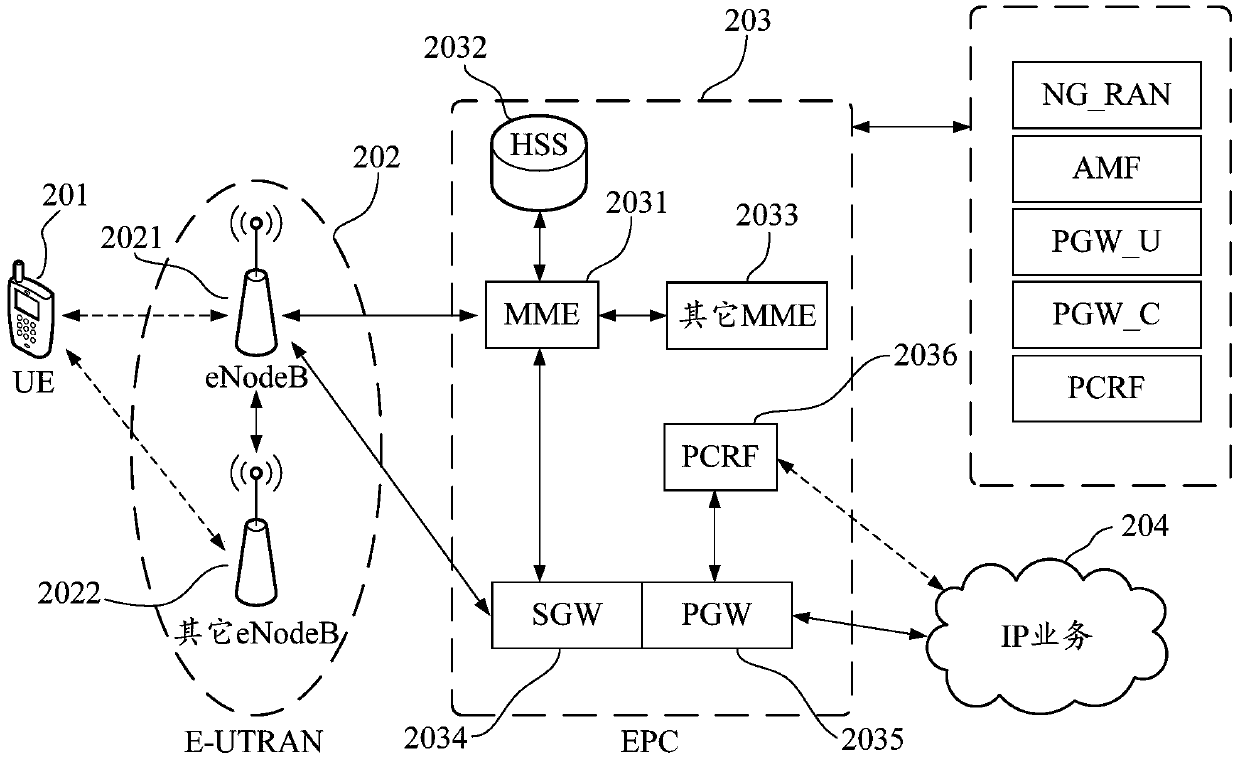

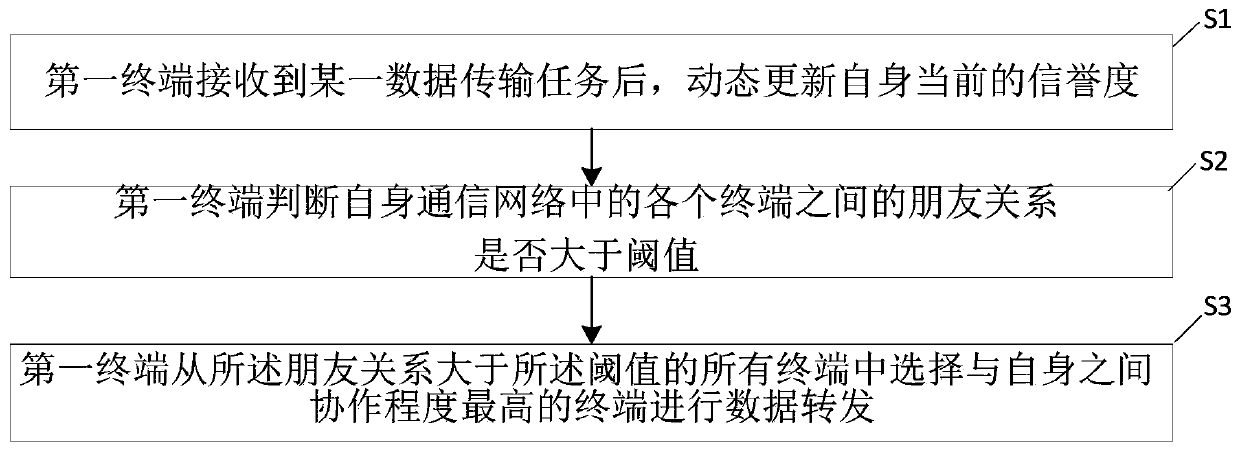

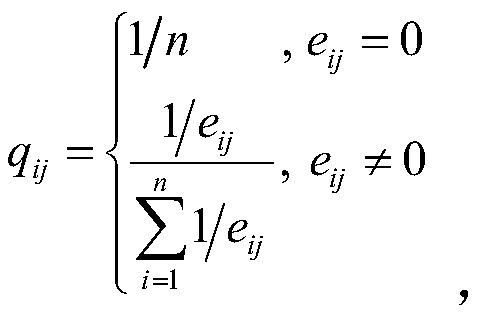

Credibility perception-based data transmission control method suitable for 5G network

ActiveCN110636525AReduce latencyReduce load rateNetwork traffic/resource managementG-networkData transmission

The invention discloses a credibility perception-based data transmission control method suitable for a 5G network, which comprises the following steps that: after receiving a certain data transmissiontask, a first terminal dynamically updates the current credibility of the first terminal, wherein the credibility is related to the quality of data acquired by the first terminal; the first terminaljudges whether the friend relationship among the terminals in the communication network of the first terminal is larger than a threshold value or not, wherein the friend relationship is determined through a Gong Bernoulli function; and the first terminal selects the terminal with the highest cooperation degree with the first terminal from all the terminals with the friend relationship greater thanthe threshold value to perform data forwarding, and the cooperation degree is determined according to the credibility and the friend relationship. According to the credibility perception-based data transmission control method suitable for the 5G network, the data transmission efficiency can be improved.

Owner:BEIJING SMARTCHIP MICROELECTRONICS TECH COMPANY +2

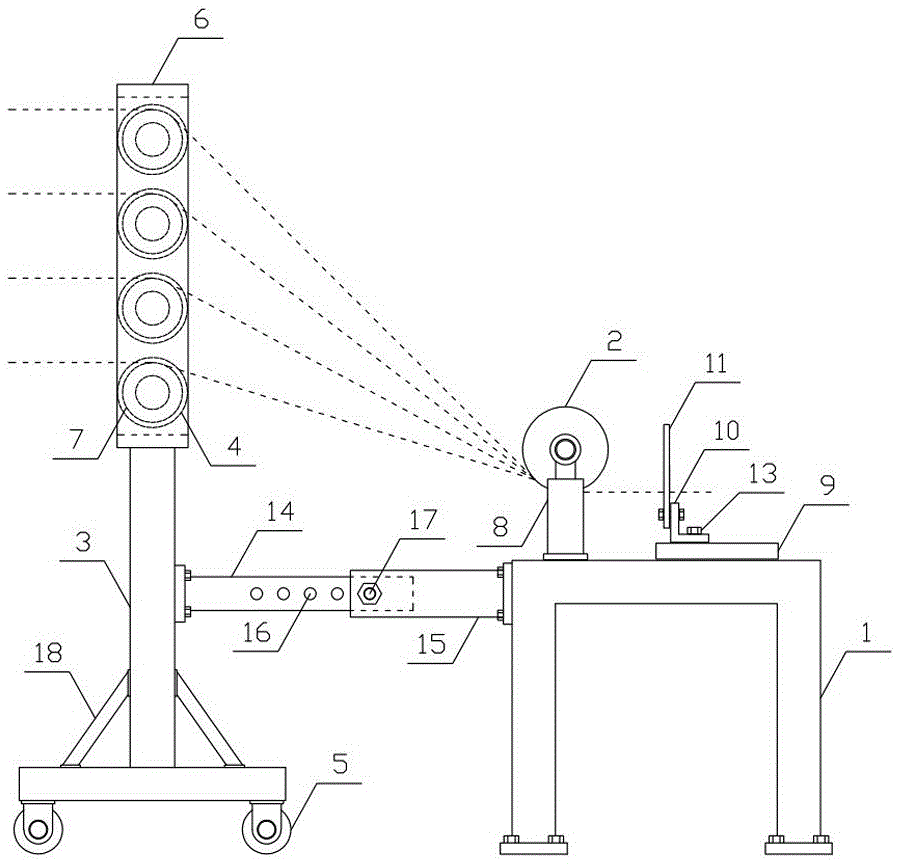

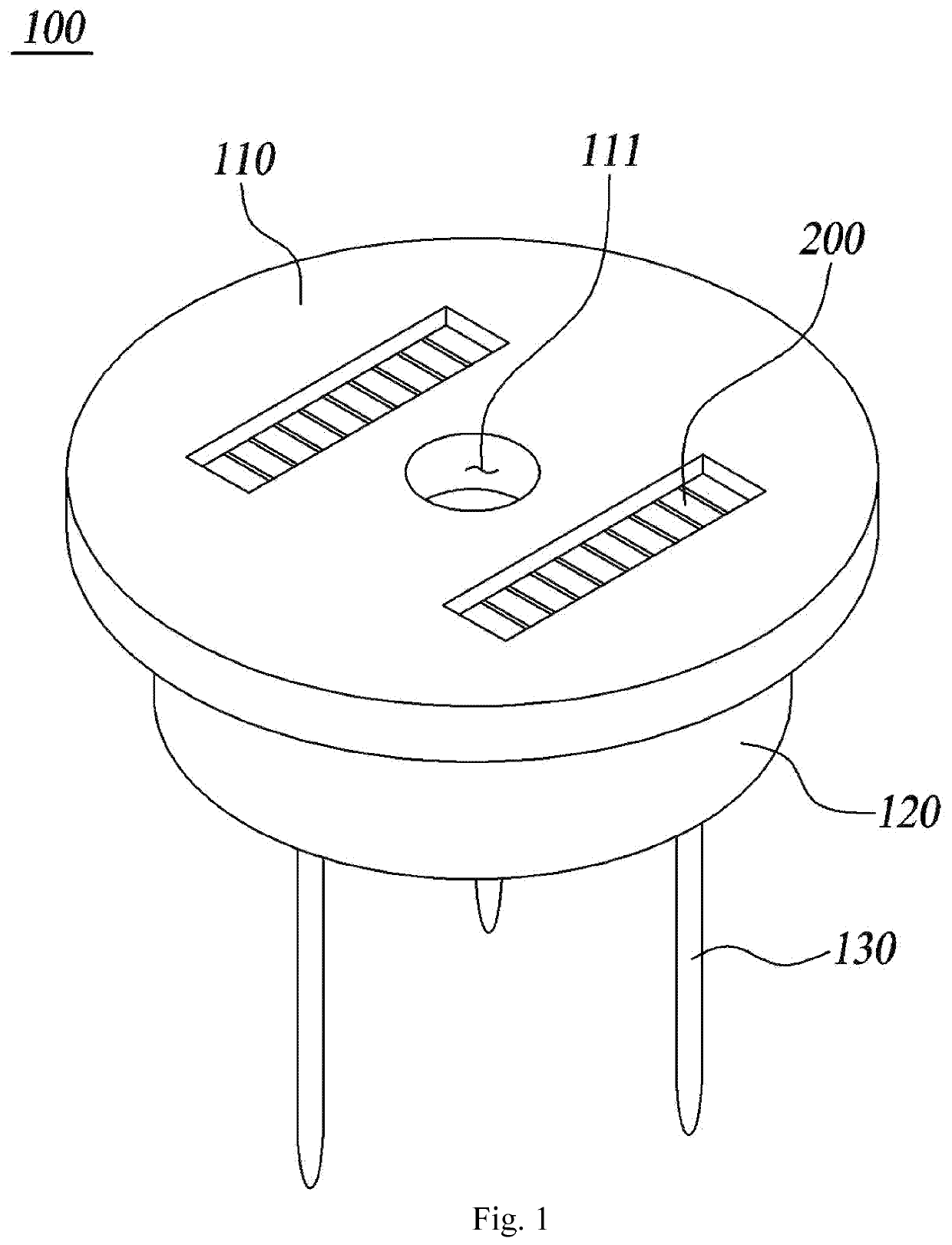

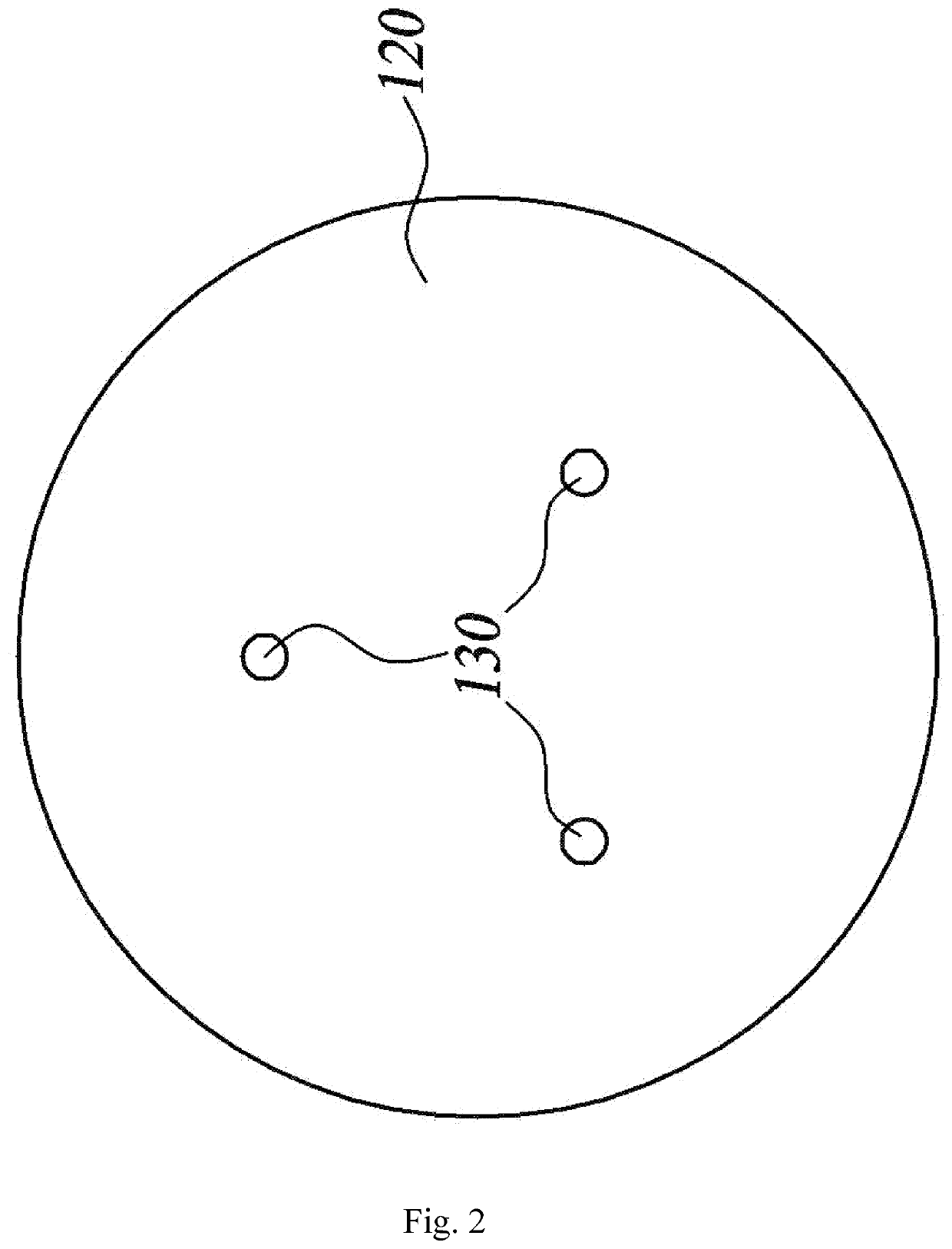

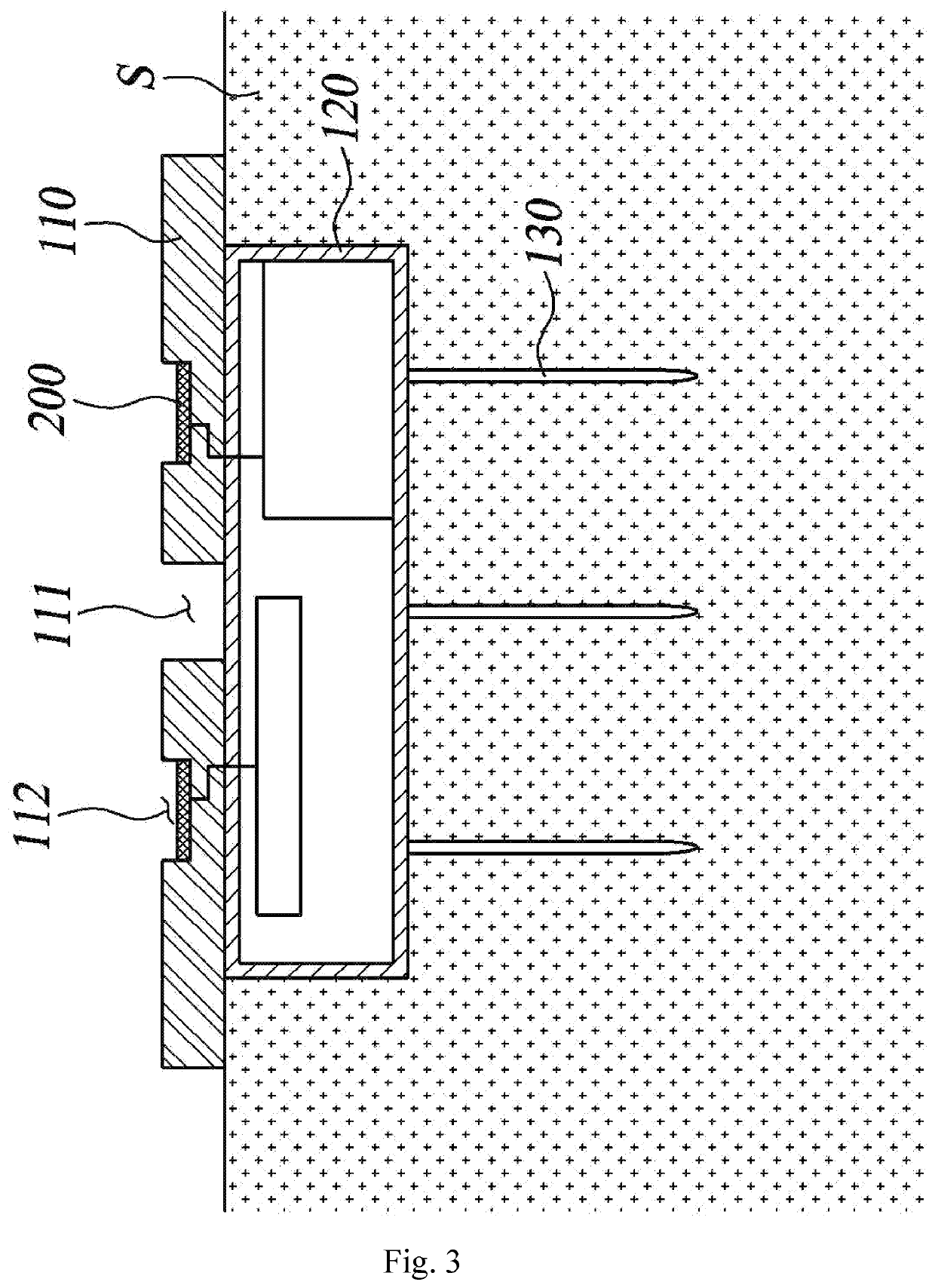

Lawn monitoring system

PendingUS20220217930A1Accurate and efficient transmissionImprove versatilityPhotovoltaic supportsEntertainmentSimulationAgricultural engineering

One aspect of the present invention relates to a lawn monitoring system, and more specifically, to a lawn monitoring system installed at various locations where lawn is created, such as a golf course, a soccer field, a baseball field, etc., to receive lawn status information, thereby enabling a lawn manager to manage the lawn based on the information received from the system. The lawn monitoring system according to an embodiment of the present invention has effects of accurately and efficiently transmitting the status information of the lawn in places where the lawn is created, such as a golf course, a soccer field, a baseball field, to a lawn manager.

Owner:KIM DOO SOO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com