Continuous crystal growth method of silicon carbide single crystal

A silicon carbide single crystal, high-purity silicon carbide technology, applied in single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem that silicon carbide single crystal stops growing, reduces the quality of silicon carbide single crystal, and cannot be grown during the growth process. Continuity and other problems, to achieve uniform and stable temperature field, reduce single crystal defects, uniform, stable and orderly temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1, continuous crystal growth method of silicon carbide single crystal

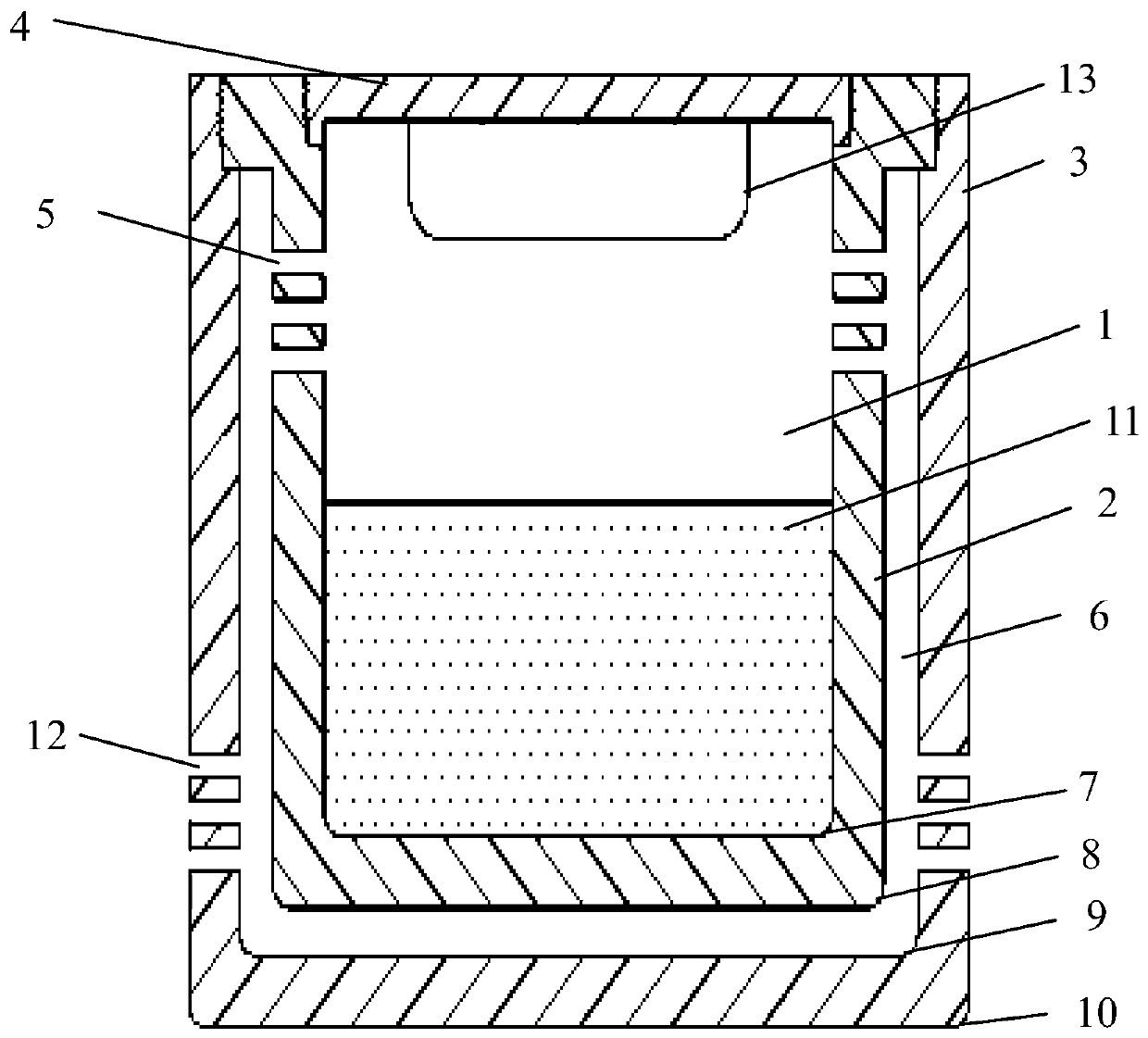

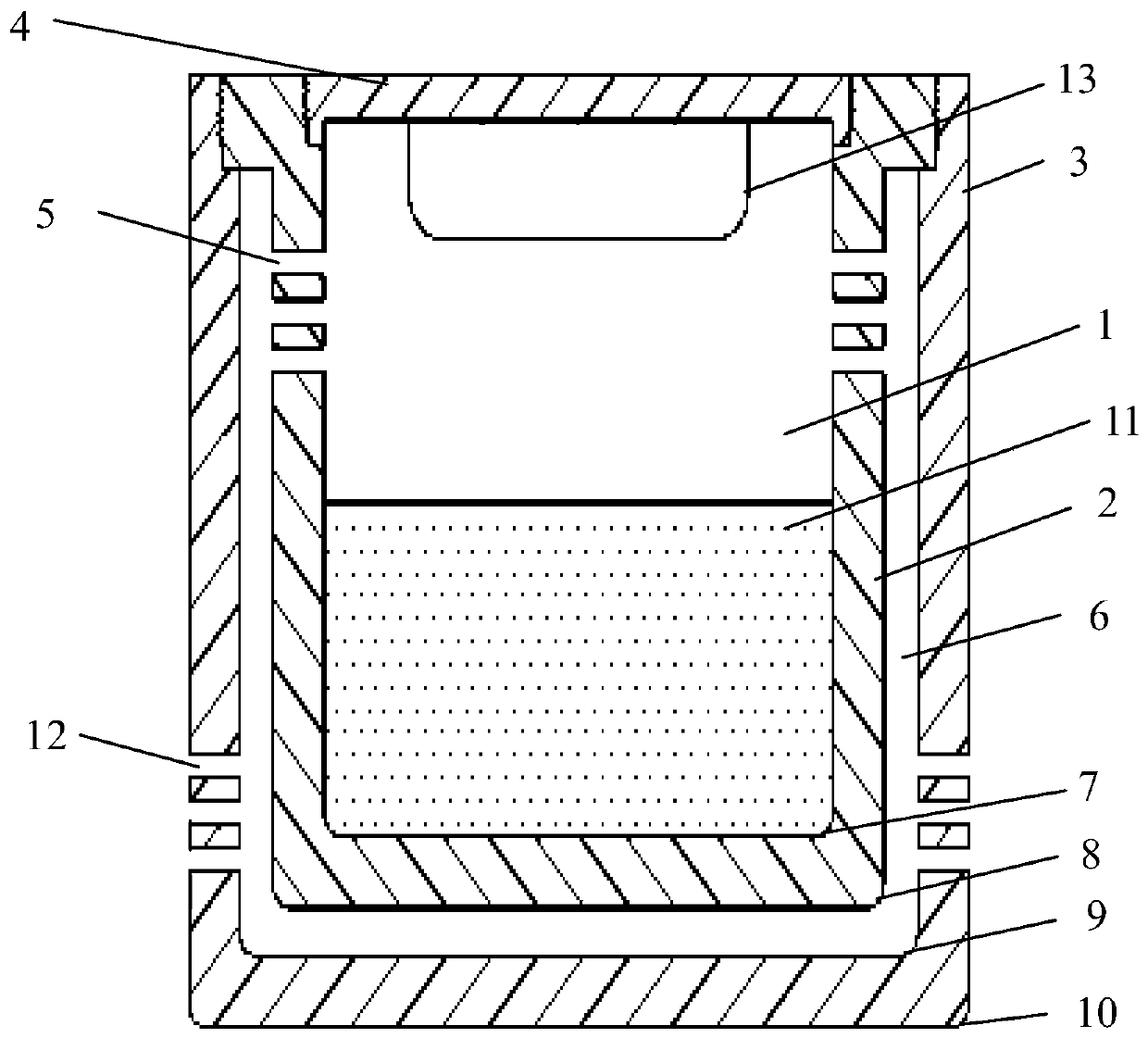

[0058] use as figure 1 The shown crucible produces silicon carbide single crystal according to the PVT method, and the specific steps are as follows:

[0059] 1. Place the high-purity silicon carbide powder in the chamber 1 of the crucible; put the seed crystal into the top of the lid 4 of the crucible, and seal the chamber 1;

[0060] 2. Vacuum chamber 1 to an air pressure of 10 -6 Below mbar, then pass high-purity inert gas to 400mbar, repeat this process 2-3 times, and finally pump the air pressure in chamber 1 to 10 -6 above mbar;

[0061] 3. Slowly raise the temperature in chamber 1 to 1000°C, and mix high-purity inert gas-argon and high-purity hydrogen at a volume ratio of 50:1 into the chamber to raise the air pressure to 700mbar and keep it for 8h;

[0062] 4. Reduce the pressure in chamber 1 to the single crystal growth pressure of 30mbar, and then pass the mixed gas (the vol...

Embodiment 2

[0066] Embodiment 2, continuous crystal growth method of silicon carbide single crystal

[0067] use as figure 1 The shown crucible produces silicon carbide single crystal according to the PVT method, and the specific steps are as follows:

[0068] 1. Place the high-purity silicon carbide powder in the chamber 1 of the crucible; put the seed crystal into the top of the lid 4 of the crucible, and seal the chamber 1;

[0069] 2. Vacuum chamber 1 to an air pressure of 10 -6 Below mbar, then pass high-purity inert gas to 300mbar, repeat this process 2-3 times, and finally pump the air pressure in chamber 1 to 10 -6 above mbar;

[0070] 3. Slowly raise the temperature in chamber 1 to 800°C, and mix high-purity inert gas-helium and high-purity hydrogen at a volume ratio of 100:1 into the chamber to raise the air pressure to 600mbar and keep it for 10h;

[0071] 4. Reduce the pressure in the chamber 1 to the single crystal growth pressure of 10mbar, and then pass the mixed gas (t...

Embodiment 3

[0075] Embodiment 3, continuous crystal growth method of silicon carbide single crystal

[0076] use as figure 1 The shown crucible produces silicon carbide single crystal according to the PVT method, and the specific steps are as follows:

[0077] 1. Place the high-purity silicon carbide powder in the chamber 1 of the crucible; put the seed crystal into the top of the lid 4 of the crucible, and seal the chamber 1;

[0078] 2. Vacuum chamber 1 to an air pressure of 10- 6 Below mbar, then pass high-purity inert gas to 500mbar, repeat this process 2-3 times, and finally pump the air pressure in chamber 1 to 10- 6 above mbar;

[0079] 3. Slowly raise the temperature in chamber 1 to 1200°C, and mix high-purity inert gas-argon and helium gas with high-purity hydrogen at a volume ratio of 120:1 into the chamber to make the air pressure Rise to 800mbar and keep for 5h;

[0080] 4. Reduce the air pressure in the chamber 1 to the single crystal growth pressure of 50mbar, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com