Semi-automatic steel ball mounting equipment and using method thereof

An installation equipment, semi-automatic technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of many operation steps, low work efficiency, interruption of transportation, etc., achieve stable and orderly transportation, improve production efficiency, and install fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

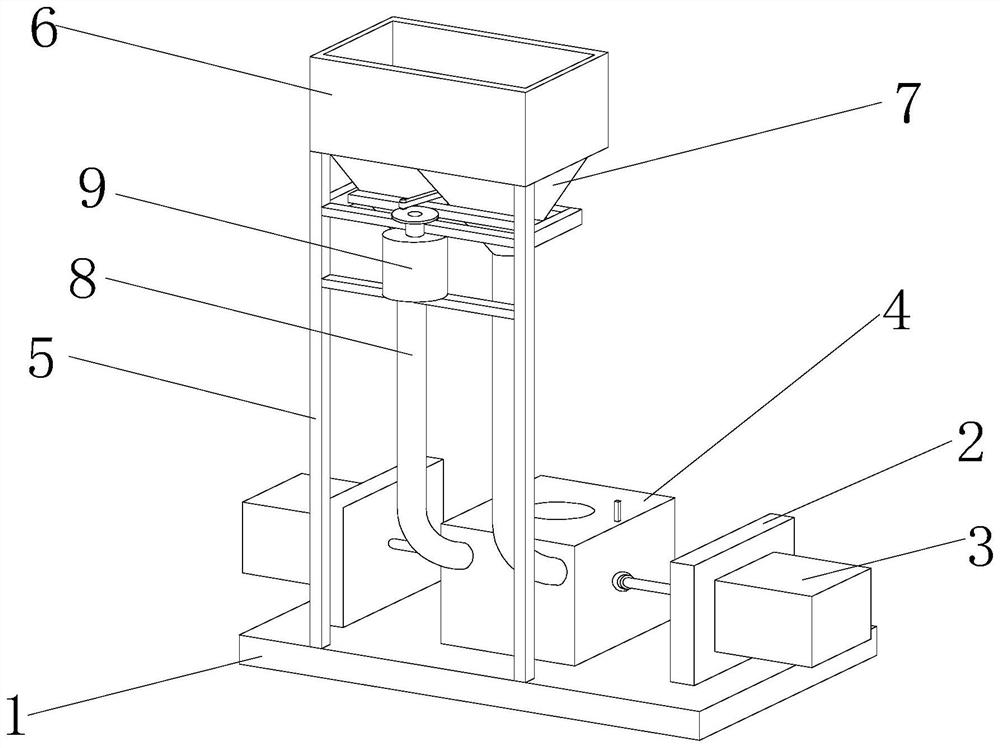

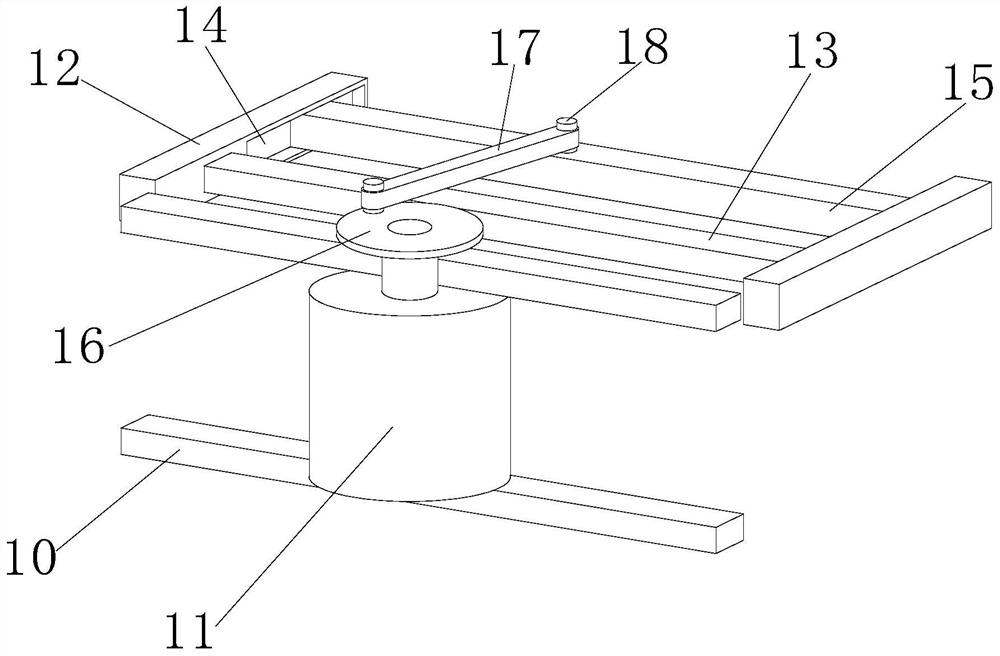

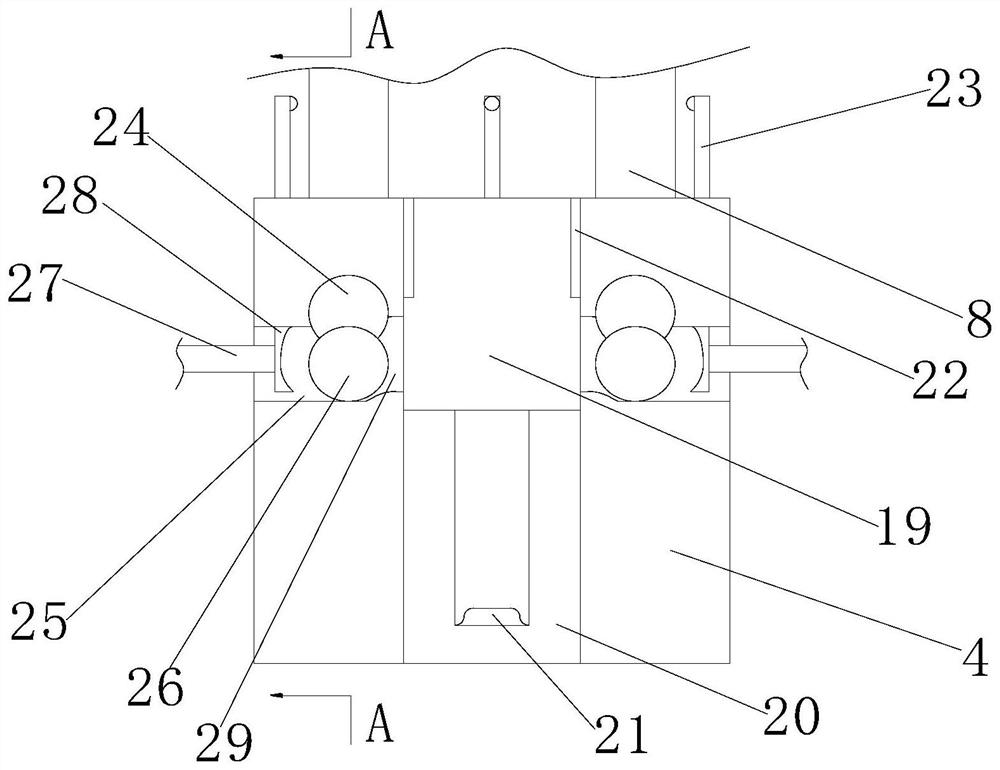

[0035] see Figure 1-5 Shown: semi-automatic steel ball installation equipment, including a working platform 1, a support frame 2 is installed on both sides of the upper surface of the working platform 1, and a cylinder 3 is installed on the two support frames 2, and the two cylinders 3 is symmetrically arranged, the output end of the cylinder 3 is fixedly connected with a push rod 27, the push rod 27 runs through the support frame 2 and is slidably connected with the support frame 2, and a push rod 27 is arranged between the two push rods Mounting block 4, the middle part of the mounting block 4 is provided with a clamping groove 19, and both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com