A kind of preparation method of high-strength tissue paper product

A tissue paper, high-strength technology, applied in chemical instruments and methods, paper making, paper making machines, etc., can solve the problems of inability to completely pulverize, reduce the utilization rate, and large loss of raw materials, achieve simple grinding and reduce the difficulty of work. , the effect of rapid shattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] As a preferred embodiment of the present invention, a method for preparing a high-strength tissue paper product specifically includes the following steps:

[0029] Step 1: Prepare the corresponding ingredients in advance: 100-200 parts of waste paper scraps, 20-40 parts of flour, 20-40 parts of starch, 100-120 parts of water, 2.0-3.0 parts of sodium hydroxide solution, 0.15-0.20 parts of hydrogen peroxide, Bleach 2.0-3.0 parts;

[0030] Step 2: Use a shredder to crush waste paper scraps, then mix 0.03 parts of hydrogen peroxide with 20 parts of water, then soak the crushed waste paper scraps in diluted hydrogen peroxide for 30-40 minutes, The rotating speed of stirring is 60 rev / s, and the hydrogen peroxide and waste paper scraps are boiled at high temperature at the same time, and the high-temperature boiling temperature is 90-100 degrees Celsius until the waste paper scraps are boiled. At the same time, stirring is used during the soaking process When the soaking is ...

Embodiment 2

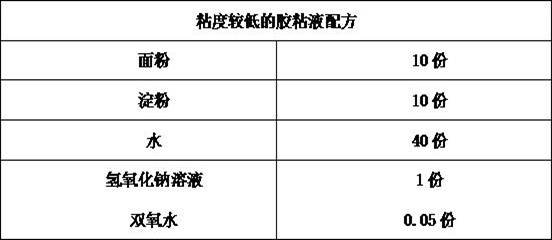

[0037] As a preferred embodiment of the present invention, according to step 5 and step 6, the glue with higher viscosity and the glue with lower viscosity all include flour, starch, water, sodium hydroxide solution and hydrogen peroxide, and the glue with lower viscosity Mucus preparation specifically includes the following steps:

[0038] Step 1: first add 10 parts of starch, 10 parts of flour and 20 parts of water into the reaction tank and stir evenly;

[0039] Step 2: Add 1 part of sodium hydroxide solution into the reaction kettle and alkalize the reaction for 15-25 minutes at room temperature;

[0040] Step 3: Add 0.05 parts of hydrogen peroxide to the reaction kettle, and the oxidation time is 20-30 minutes, and then add 20 parts of water.

[0041] Form 1 as follows:

[0042]

[0043] In Table 1 of this embodiment, by adding 10 parts each of flour and starch, 40 parts of water, 1 part of sodium hydroxide solution and 0.05 part of hydrogen peroxide, the starch cont...

Embodiment 3

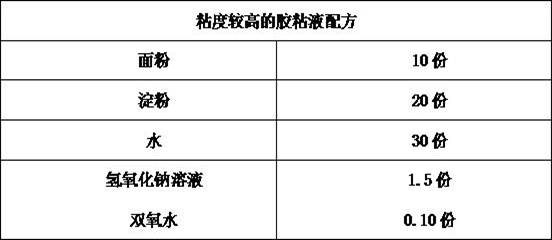

[0045] As a preferred embodiment of the present invention, the preparation of the higher viscous viscous solution specifically includes the following steps:

[0046] Step 1: first add 20 parts of starch, 10 parts of flour and 20 parts of water into the reaction tank and stir evenly;

[0047] Step 2: Add 1.5 parts of sodium hydroxide solution to the reaction kettle and perform alkalization reaction at room temperature for 15-25 minutes;

[0048] Step 3: Add 0.10 parts of hydrogen peroxide to the reaction kettle, and the oxidation time is 20-30 minutes, and then add 10 parts of water.

[0049] Form 2 as follows:

[0050]

[0051] In Table 2 of this embodiment, by adding 10 parts of flour, 20 parts of starch, 30 parts of water, 1.5 parts of sodium hydroxide solution and 0.10 parts of hydrogen peroxide, the starch content in the mixture is more, and the viscosity of starch is used. Thereby, the viscosity on the finished adhesive liquid is higher, and the viscosity of the adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com