Suspension bridge beam prefabricating and assembling construction process

A construction technology, prefabrication and assembly technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of high construction cost, high risk of formwork high-altitude construction, long construction period, etc. The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

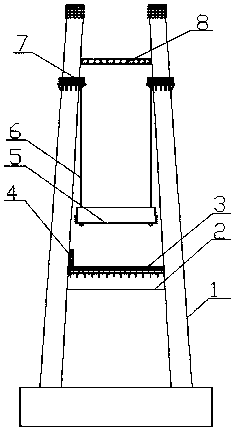

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0035] Embodiments of the invention

[0036] Practical example of the process of the invention:

[0037] Implementation project: Guizhou Fenglin Bridge

[0038] The specific implementation process, the steps are as follows:

[0039] 1) Installation of overhanging operation platform: Weld corbels on the embedded parts on the outside of the lower beam, and erect a distribution beam every 500mm on the corbels, and lay bamboo plywood on the distribution beams to form an overhanging operation platform;

[0040] 2) Installation of guardrail: install a 1.6m-high guardrail on the periphery of the overhanging operation platform, a channel is reserved at the connection between the guardrail and the tower column, and a protective net is installed around the guardrail;

[0041] 3) Reciprocating ladder installation: install a reciprocati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com