Circular annular underground culvert pipe construction method

A construction method, circular technology, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems that affect the stability and reliability of the work, the joints are prone to fall off, and the settlement is easy to occur, so as to achieve the guarantee Normal water supply, reduced probability of damage to culverts, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention are further described below, but the claimed scope is not limited to the description.

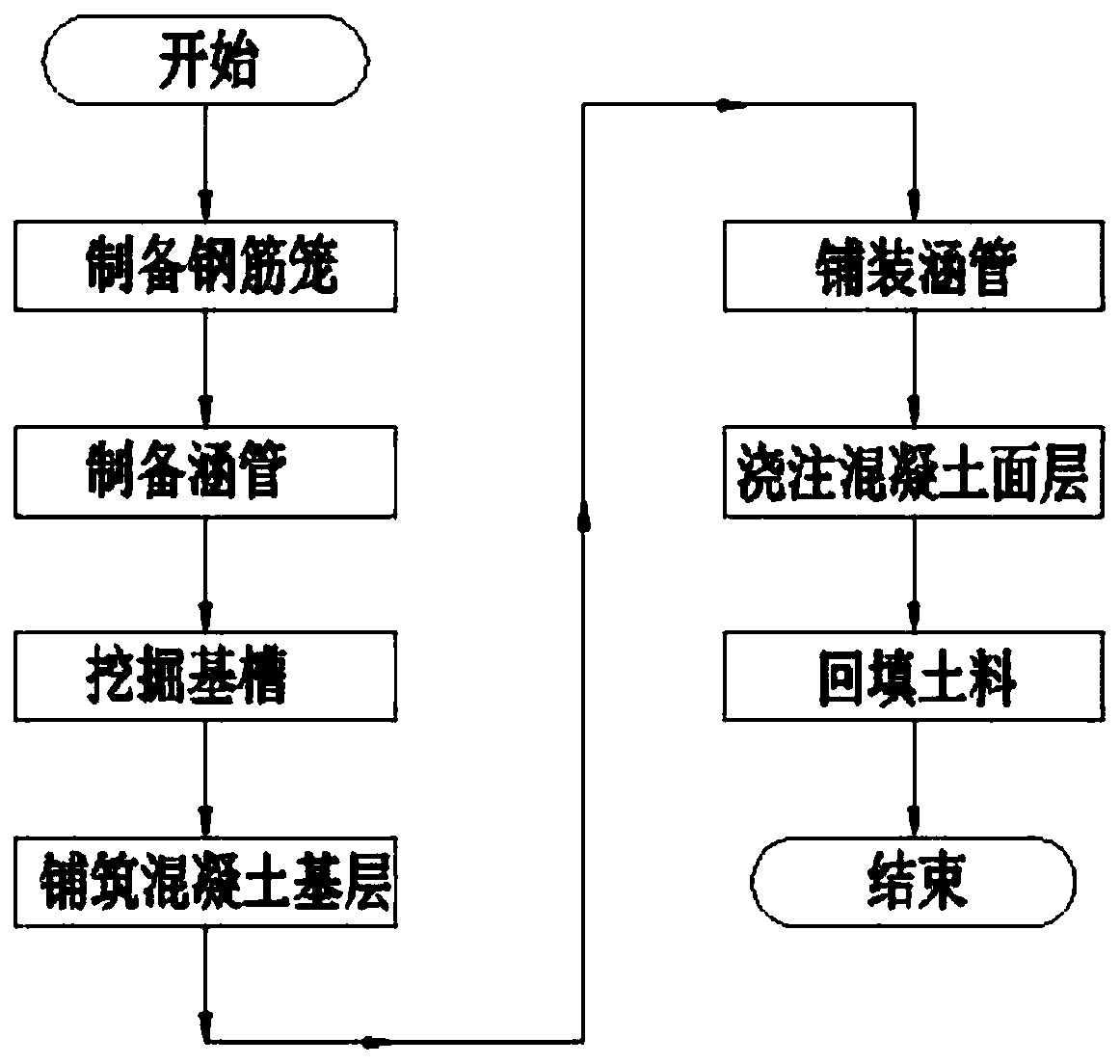

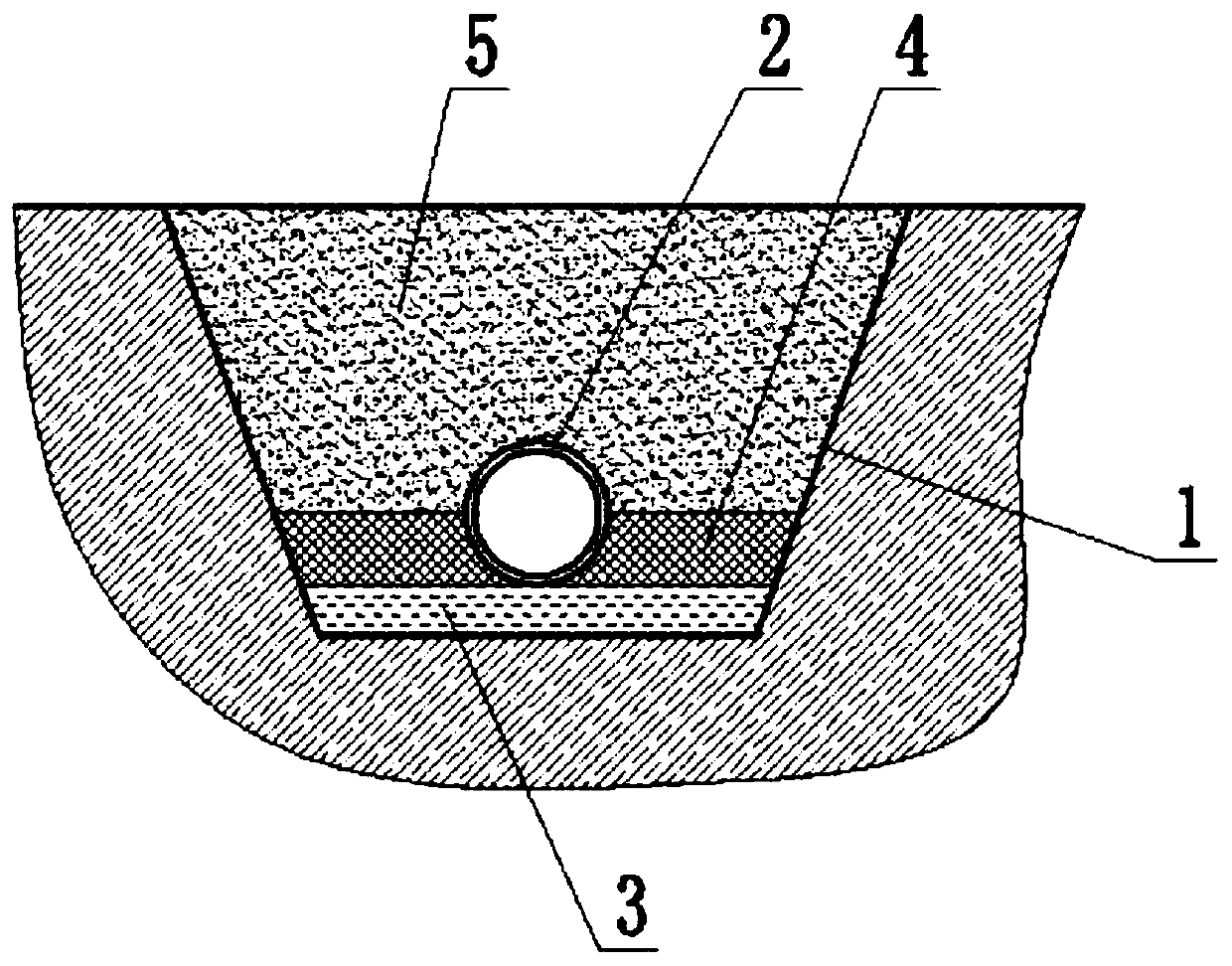

[0029] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention provides a construction method for an annular underground culvert 2, comprising the following steps:

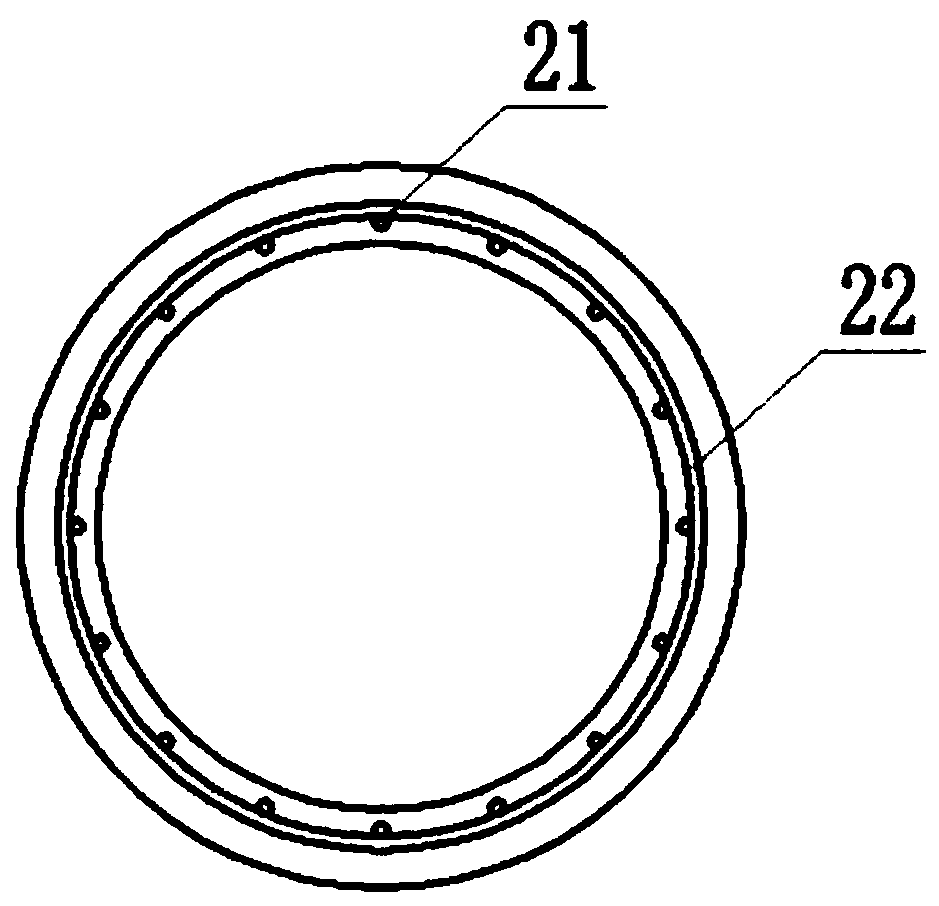

[0030] Step 1: Preparing the reinforcement cage: take the steel bars processed into a circular shape through the bending process as the circumferential stirrups 22, use several straight steel bars as the axial steel bars 21, and first press the circumferential stirrups 22 according to the appropriate The spacing is coaxial and juxtaposed, and the axial steel bars 21 are welded one by one on the inner surface of each circumferential stirrup 22, and the central axis of the axial steel bar 21 is parallel to the central axis of all circumferential stirrups 22. A reinforcing bar cage is prepared; further, in the reinforcing bar cage, the distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com