Device for continuously producing isooctyl nitrate

A technology of isooctyl nitrate and mixed acid, which is applied in the field of devices for continuous production of isooctyl nitrate, can solve the problems of high difficulty in process control, side reactions and overreactions, low production efficiency and the like, achieves waste of cost, improved structure, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A detailed description will be given below in conjunction with embodiments:

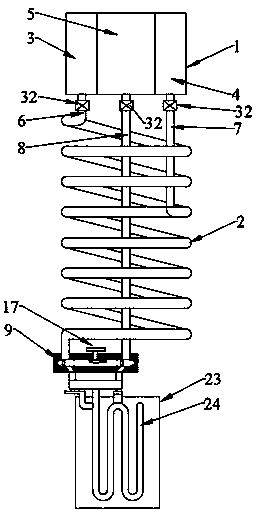

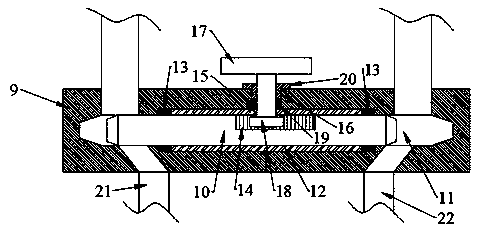

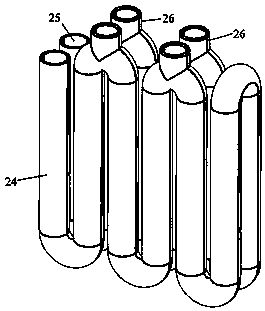

[0017] A device for continuously producing isooctyl nitrate includes a mixed acid component, a flow regulating component and a reactor component. The mixed acid component includes a raw material storage tank 1 and a mixed acid spiral tube 2. The raw material storage tank 1 includes a sulfuric acid storage chamber 3, a nitric acid storage chamber 4 and a deionized water storage chamber 5. A first outlet pipe 6 is installed at the bottom of the sulfuric acid storage chamber 3, and the first outlet pipe 6 and the mixed acid spiral pipe 2 are installed in a sealed butt connection, and the mixed acid spiral pipe 2 is also provided with a second outlet pipe 7; One end of the second outlet pipe 7 and the mixed acid spiral tube 2 are integrally formed to communicate, and the other end is connected to the nitric acid storage chamber 4; the bottom of the mixed acid spiral tube 2 is installed on the flow ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com