Novel advanced small pipe clamping device

An advanced small catheter and clamping device technology, applied in the direction of clamping device, positioning device, clamping, etc., can solve the problems of slow processing speed, many processes, high labor cost, etc., and achieve good quality, uniform shape and simple structure ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

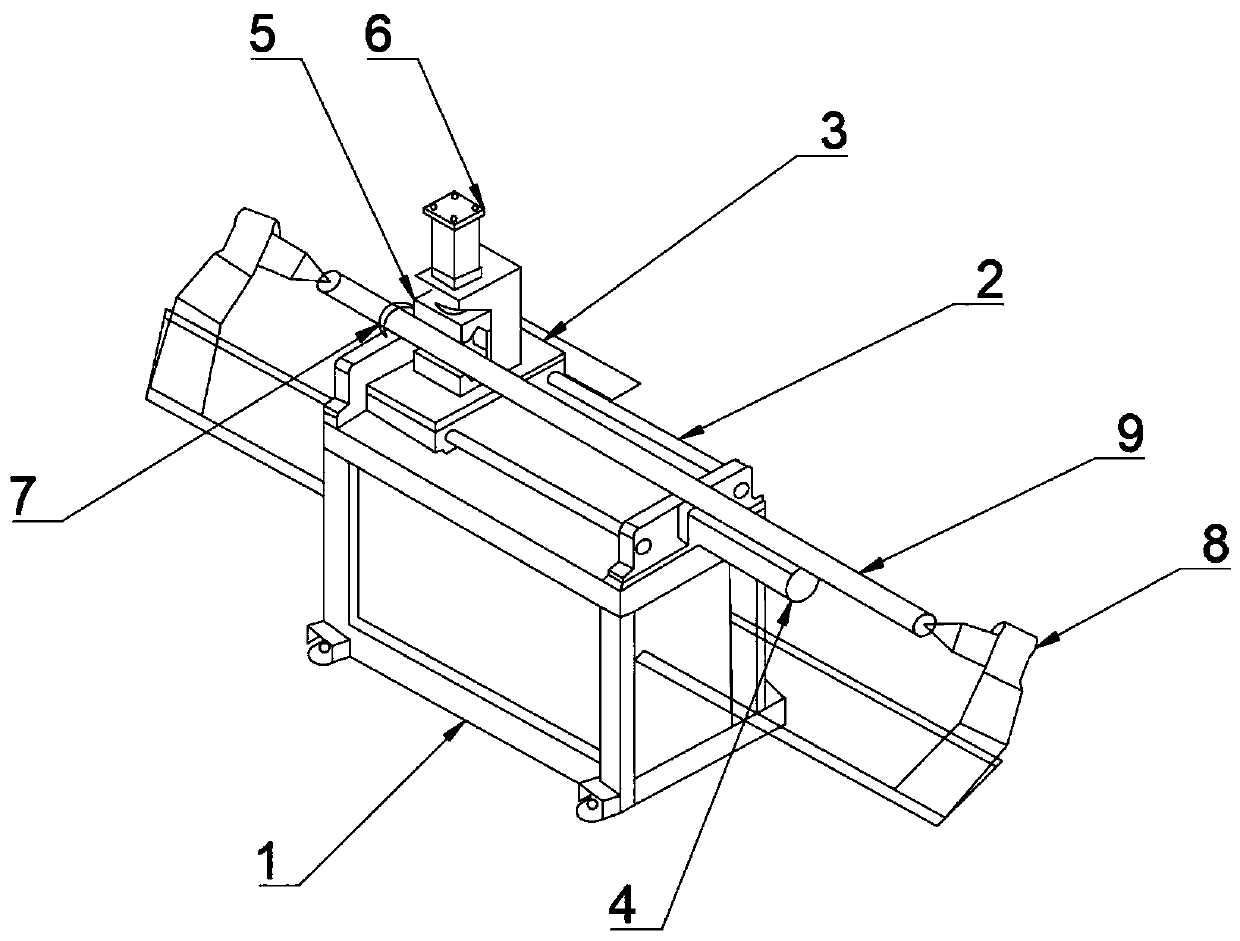

Image

Examples

Embodiment 1

[0019] Embodiment 1: When using the leading small catheter clamping device of the present invention, pass the leading small catheter through the auxiliary positioning retaining ring, and set it between the double positioning apex, move the distance of the double positioning apex to fix the leading small catheter, set The mobile screw pair on the support frame drives the mobile platform to position and move on the slide rail. The external CNC host computer specifically controls the mobile screw pair. When the mobile platform drives the hydraulic jaws to move to the coordinates that need to be drilled, the hydraulic cylinder will make The hydraulic claw moves, and a circular cutter is arranged between the upper claw and the lower claw of the hydraulic claw, and the overflow hole is opened at each position with the rotation of the small leading pipe.

Embodiment 2

[0021] Using the advanced small catheter clamping device of the present invention, the double positioning tip can be improved into a single positioning tip, and one end of the advanced small catheter is provided with an advanced small catheter tip shrinking machine. The drilling process is carried out on the clamping device, and the characteristics of the rotation and forward movement of the screw rod are used to complete the rotation of the hydraulic claws at various positions of the leading small conduit, and to make the forming effect of the cone head of the leading small conduit better than the traditional processing technology. .

[0022] In addition, the terms "first" and "second" are used for descriptive purposes only, and cannot be interpreted as indicating or implying relative importance or implicitly specifying the quantity of indicated technical features. Thus, the features defined as "first" and "second" may explicitly or implicitly include one or more of these fea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com