Automatic spring coiling equipment of measuring tape

A coil spring and tape measure technology, applied in metal processing equipment, forming tools, feeding devices, etc., can solve the problems of high product scrap rate, machine wear, and coil spring motor load, etc., and achieve the control interface that is easy to learn and the heating area. Uniform and uniform finished product shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

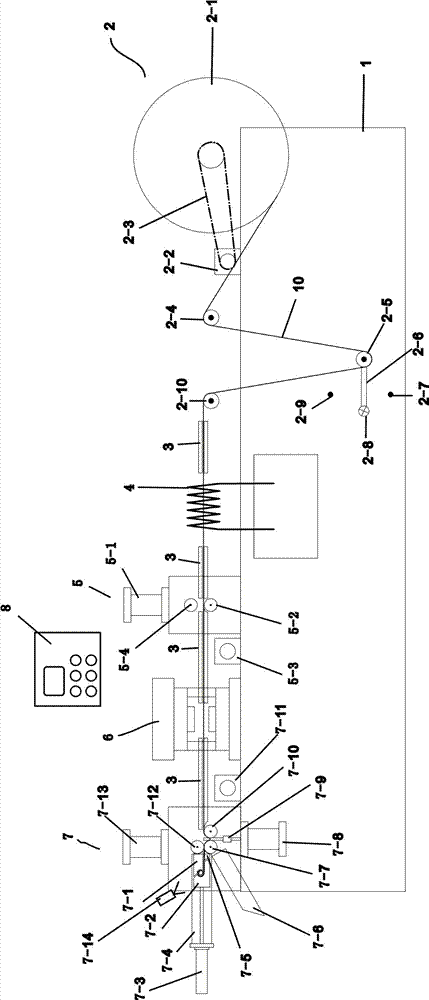

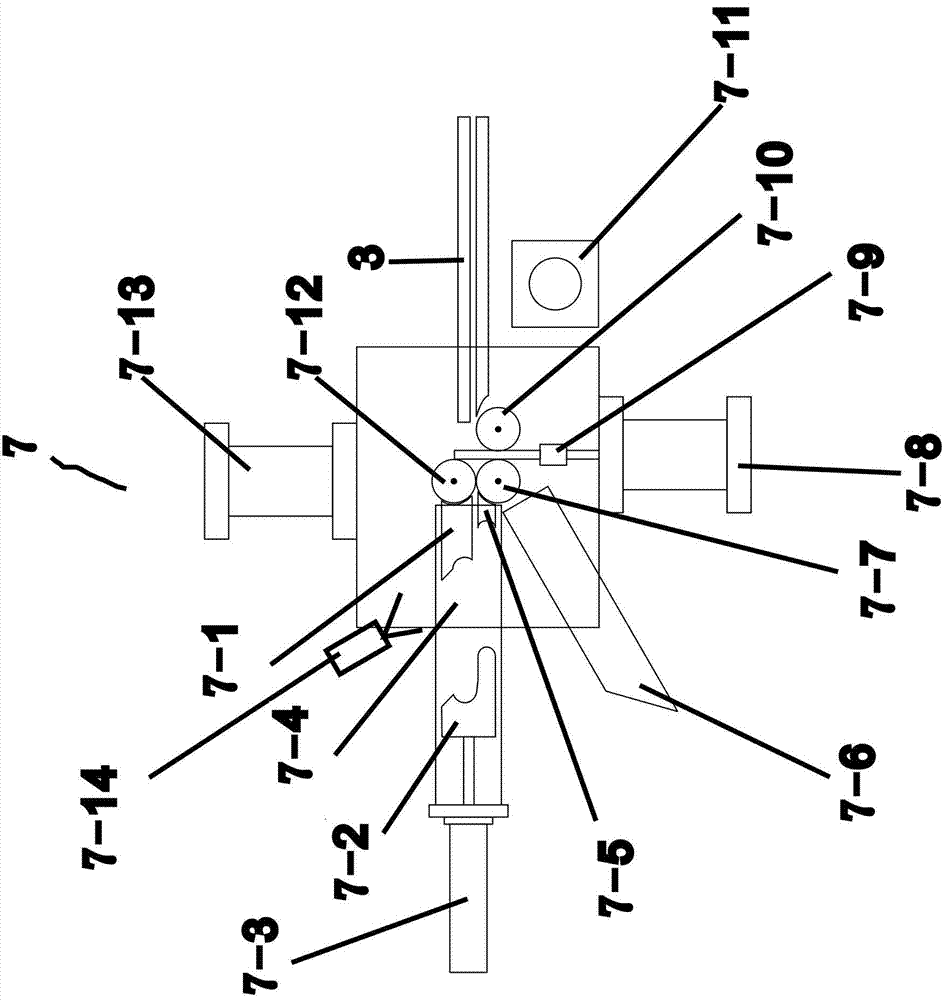

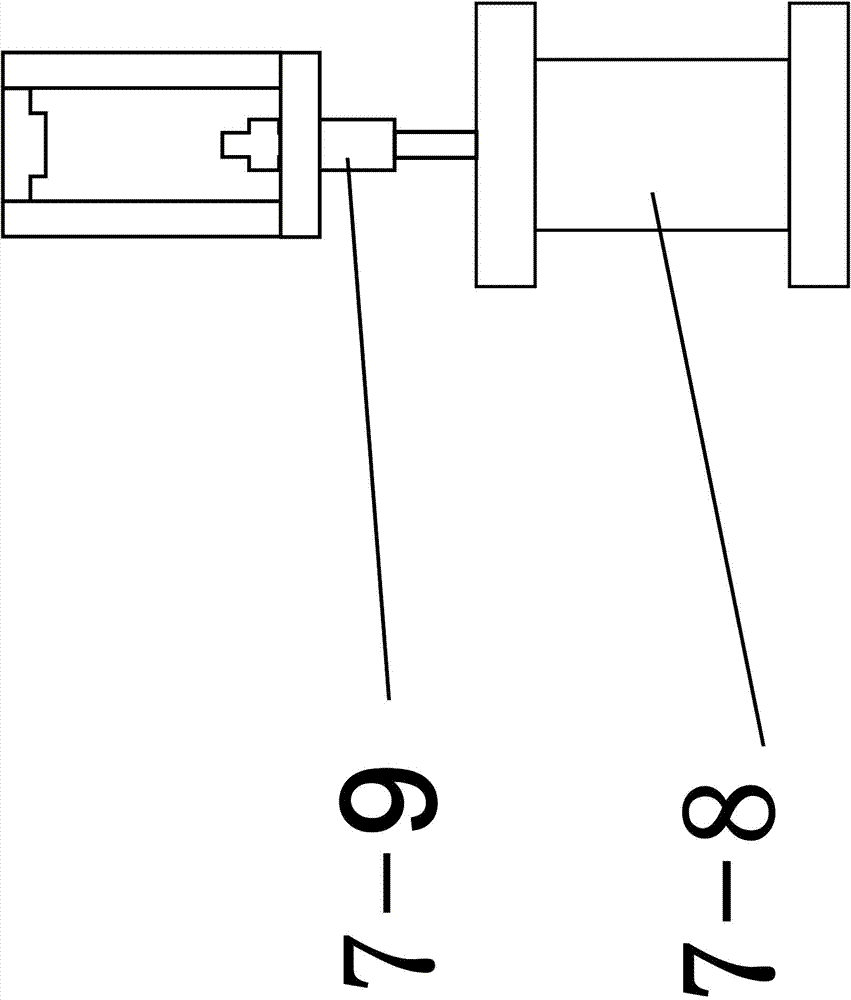

[0019] Such as figure 1 , 2 , shown in 3, a kind of tape measure automatic coiling spring equipment, comprises controller 8, frame 1, and unwinding mechanism 2, feeding mechanism 5, punching mechanism 6, coiling spring mechanism 7 that are arranged on frame 1 successively, The anti-roll mechanism 2 is wound with a spring belt 10, and the frame 1 between the unwind mechanism 2 and the feeding mechanism 5 is also provided with an electromagnetic heating induction coil 4 as an annealing mechanism. Between the machine 2 and the electromagnetic heating induction coil 4, between the electromagnetic heating induction coil 4 and the feeding mechanism 5, between the feeding mechanism 5 and the punching mechanism 6, between the punching mechanism 6 and the coil spring mechanism 7 are provided with The horizontal groove 3 that the spring tape passes horizontally, the groove 3 plays a certain positioning effect.

[0020] The unwinding mechanism 2 includes a material reel 2-1 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com