Mixer for plastic machining

A mixing machine and plastic technology, which is applied in the field of plastic processing, can solve the problems of low quality of plastic products and difficulty in adequately mixing plastic particles, and achieve the effect of improving the quality of plastic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0030] see Figure 1-Figure 8 , the specific embodiments of the present invention are as follows:

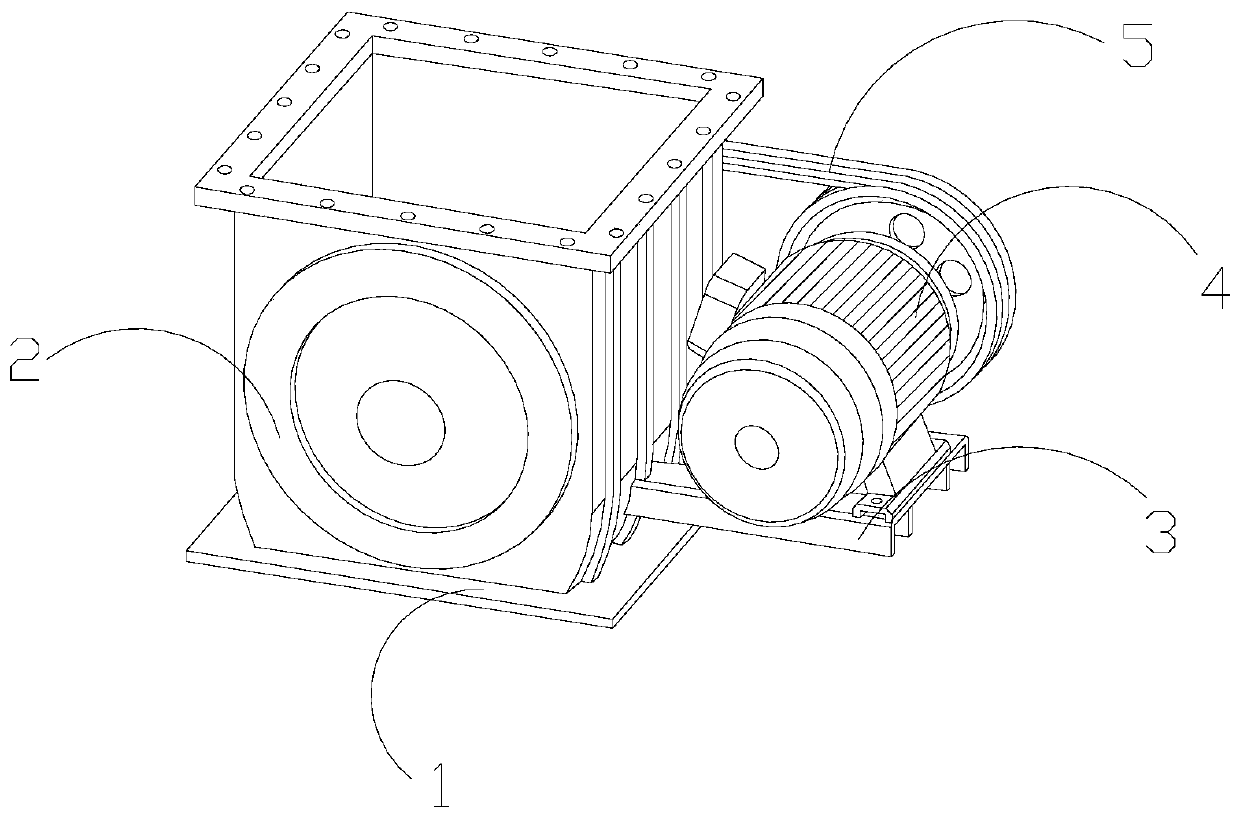

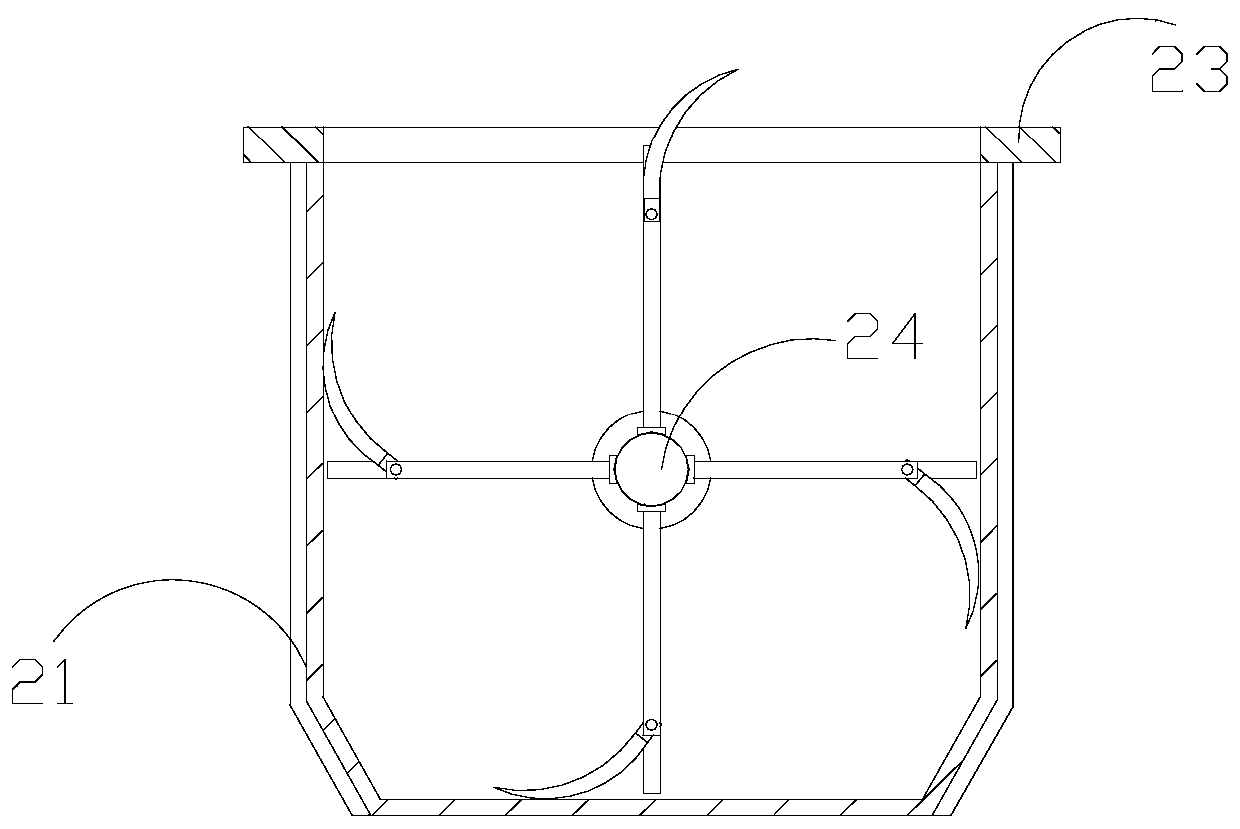

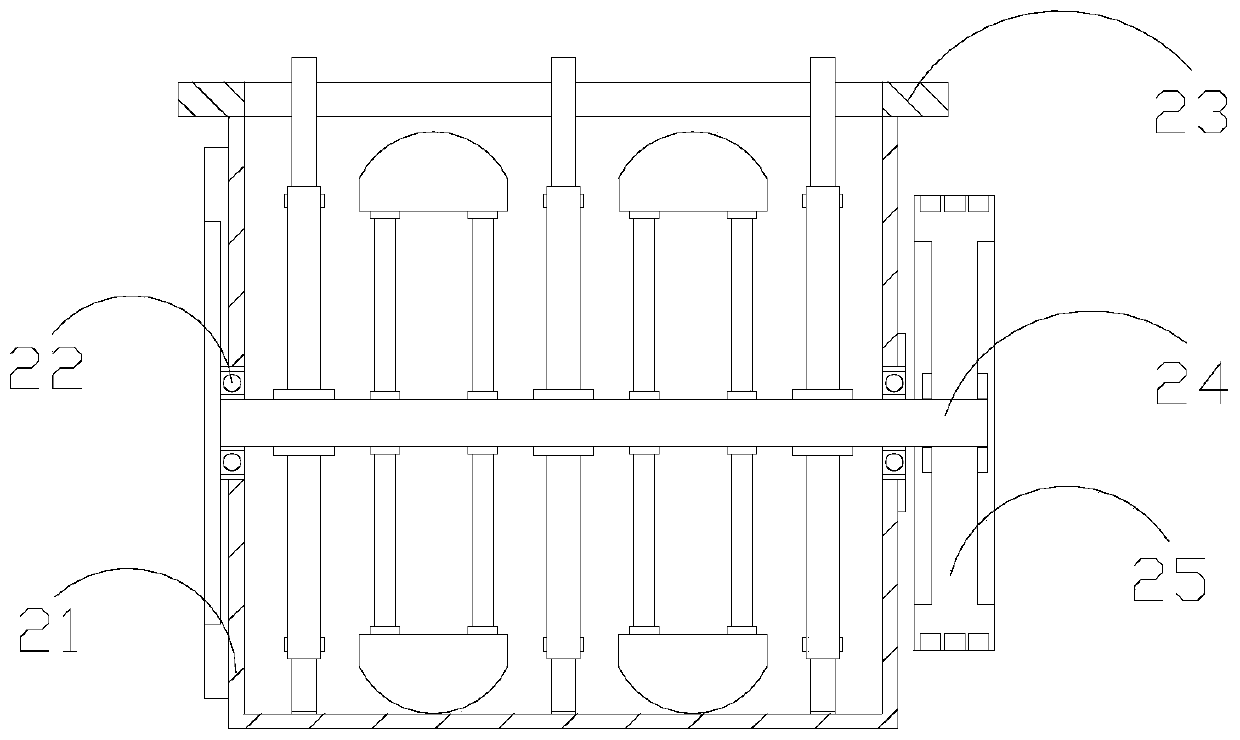

[0031] Its structure includes a base 1, a mixing structure 2, a support base 3, a motor 4, and a belt 5. The mixing structure 2 is installed on the upper end of the base 1 and welded to each other. The supporting base 3 is installed horizontally on the right side of the mixing structure 2. And phase welding, the motor 4 is installed on the upper end of the support base 3 and fixed by bolts, the mixing structure 2 and the motor 4 are connected by a belt 5; the mixing structure 2 includes a box body 21, a bearing 22, Along the plate 23, the agitating structure 24, and the pulley 25, the bearing 22 is embedded and installed on the inside of the box body 21 and is engaged with each other. The said edge plate 23 is horizontally installed on the upper end of the box body 21 and welded. The inner side and the right end of the box body 21 are clamped with the pulley 25 , and the pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com