Honeycomb sandwich composite material acoustic lining wall plate hole penetrating rate control method

A composite material and control method technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of hole blockage, the through-hole ratio cannot meet the requirements, and the noise reduction function cannot be realized, so as to ensure the noise reduction and noise reduction. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

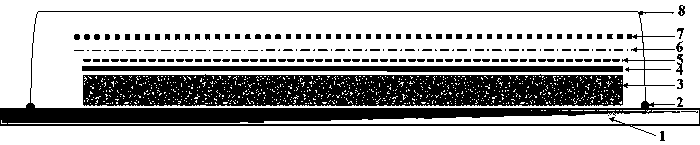

[0033] The adhesive film is a high-temperature epoxy adhesive film cured at 180±5°C. The present invention provides a method for controlling the through-porosity of a honeycomb sandwich composite acoustic lining wall panel. The steps are as follows:

[0034] a. Composite lower skin molding: Fabric or unidirectional tape prepregs are used to lay up laminates on tooling 1 according to the predetermined layup angle and number of layups. After sealing the bag, use an autoclave to cure, demould, and cut .

[0035] b. Lay a layer of adhesive film 4 and peelable layer 5 on the lower skin 3 of the composite material in sequence, after laying isolation film 6 and air felt 7 in sequence, and lay putty strips 2 on the edge, and assemble with 8 vacuum bags Seal the bag and pre-cure at 100±10°C for 20-30min.

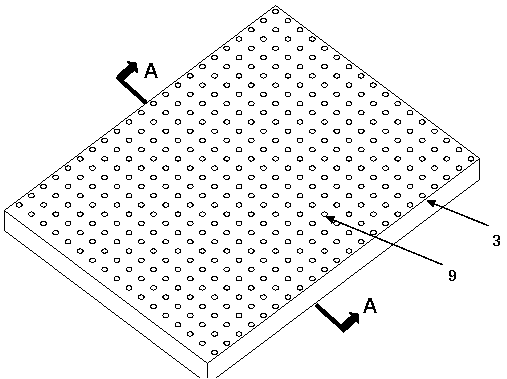

[0036] c. Drill the array holes of the composite board prepared in b.

[0037] d. Tear off the strippable layer on the drilled combination board with the array holes completed in...

Embodiment 2

[0040] In the present invention, the adhesive film bonded between the lower skin 3 of the composite material and the honeycomb core 10 is pre-cured for a short time on the lower skin 3 of the composite material, and then the acoustic lining array holes are drilled together with the peelable layer 5 . The specific operation process is as follows:

[0041] a. Use fabric or unidirectional tape prepreg to complete the manufacture of the composite material lower skin 3, and the composite material lower skin 3 is in the state of a cured laminate;

[0042] b. Before the acoustic lining hole 9 is drilled in the lower skin 3 of the composite material, a layer of adhesive film 4 and a peelable layer 5 are successively laid on its surface. The function of the peelable layer is to protect the adhesive film 4, prevent pollution and facilitate subsequent Adhesive bonding, short-term pre-curing at a temperature lower than the final curing temperature of the adhesive film.

[0043] c. Drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com