Movable side window of automatic lifting driver's cab

An automatic lifting and moving side technology, applied in window devices, railway car body parts, transportation and packaging, etc., can solve the problems of cumbersome and inconvenient operation, and achieve the effect of simple and compact structure, high reliability and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

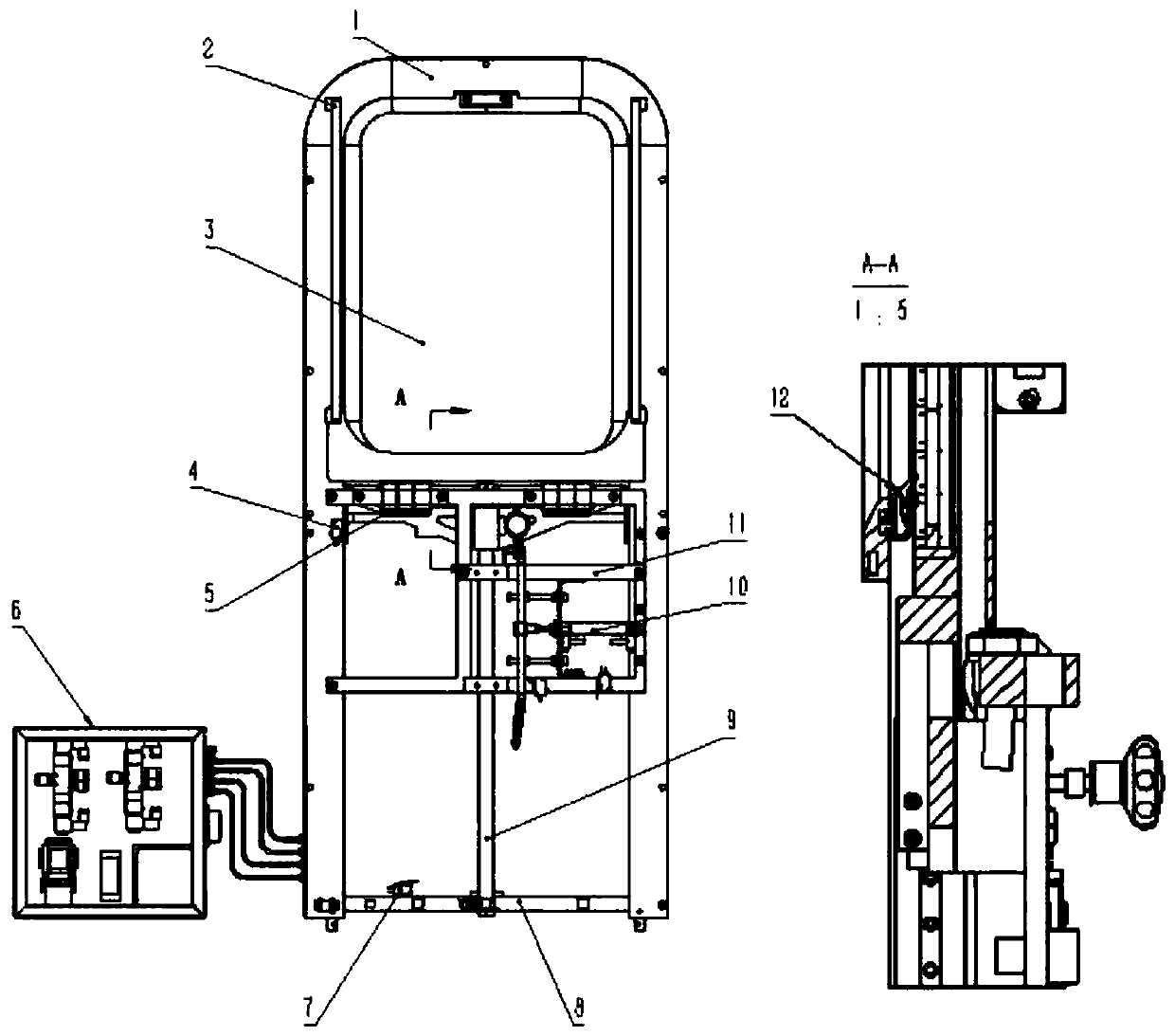

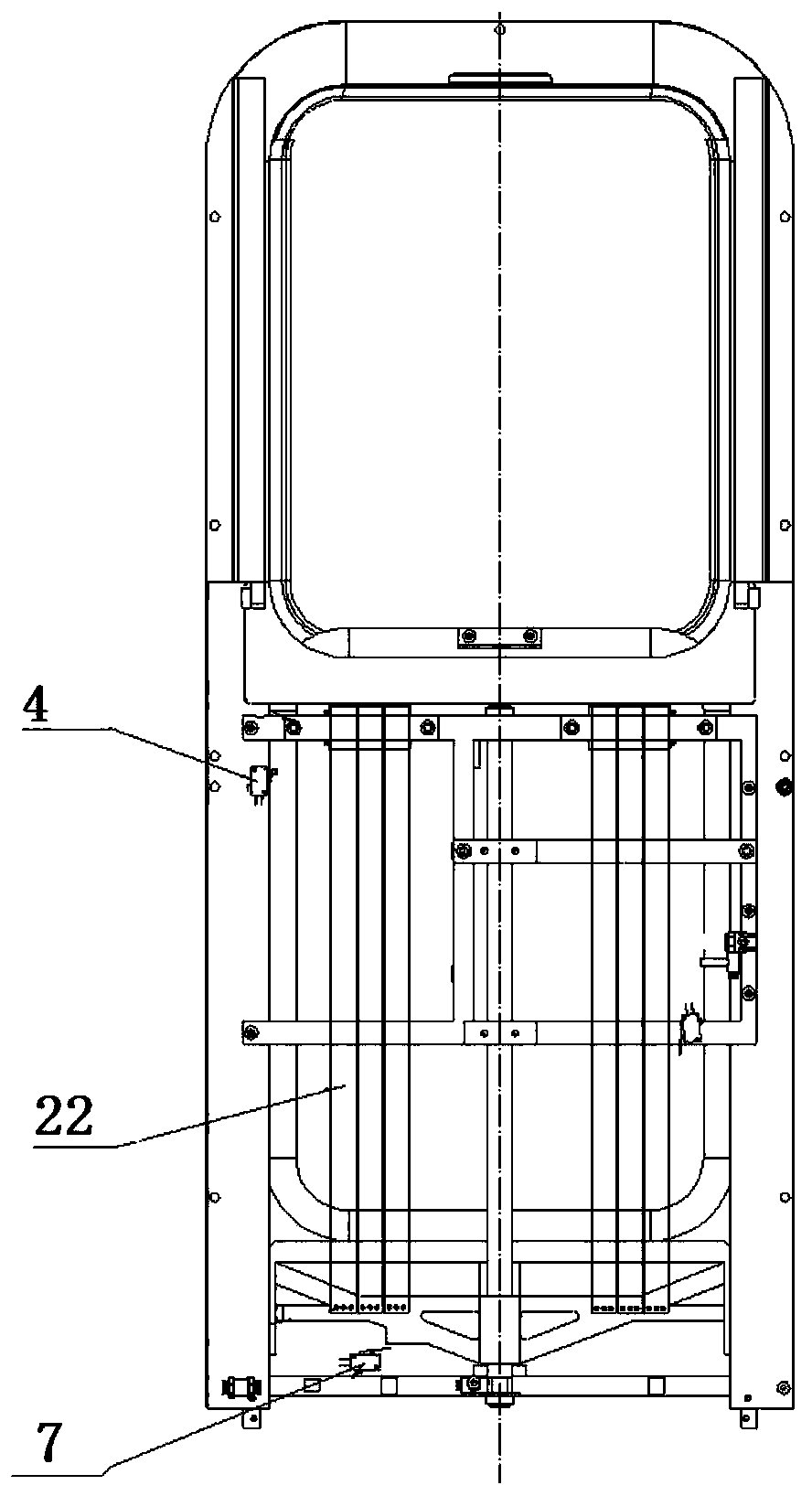

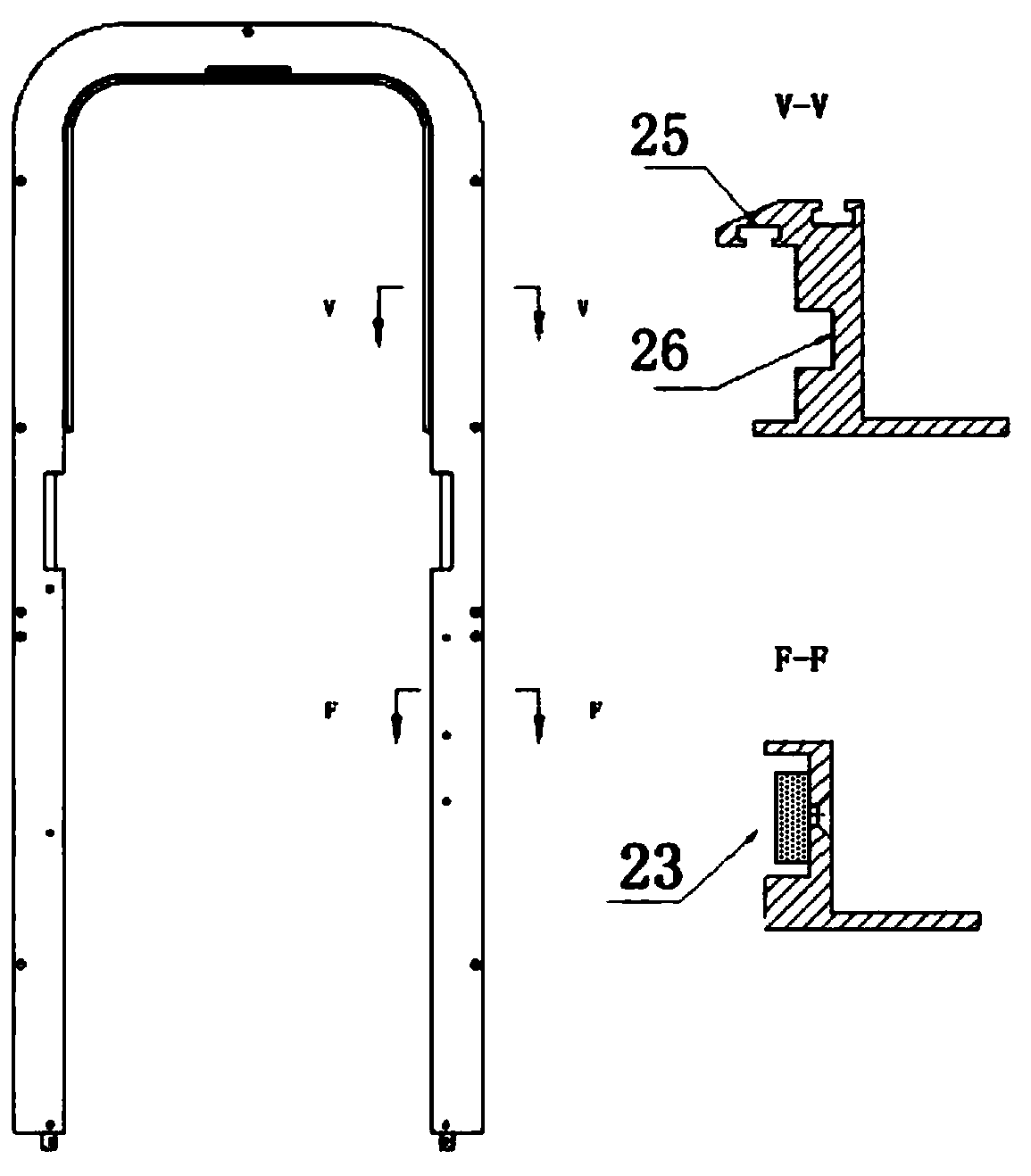

[0034] like figure 1 , image 3 , Figure 4 , Figure 10 and Figure 11 As shown, a fixed window frame 1 of the movable side window of an automatic lifting cab is molded by aluminum alloy profiles, the fixed window frame 1 is fixed with the cylinder frame 11 by screws, and the light curtain sensor 2 is fixed by screws, and it is fixed with the bottom beam 8 Fastened with screws. The fixed window frame 1 is designed with a sealing groove 25 for installing the glass sealing strip 12. The glass sealing strip 12 is compressed and deformed by flocking treatment on the surface. When the movable window is closed, the glass sealing strip 12 rides on the movable window glass 3 to form a closed ring. , to achieve waterproof sealing function. Guide grooves 26 are arranged at an angle of 90° to the sealing grooves 25 on the left and right sides, and guide rails 23 are arranged on the left and right sides of the lower half of the fixed window frame 1 .

[0035] like figure 1 , Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com