A cooling and sizing transmission device for medical packaging gluing paper after pressing and forming

A transmission device, cooling and shaping technology, applied to the surface coating liquid device, transportation and packaging, coating, etc., can solve the problems of inability to adjust the height of the transmission roller, inability to tighten the processing, and cumbersome cooling steps, etc., to achieve The cooling steps are cumbersome, the utilization rate is improved, and the cooling effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

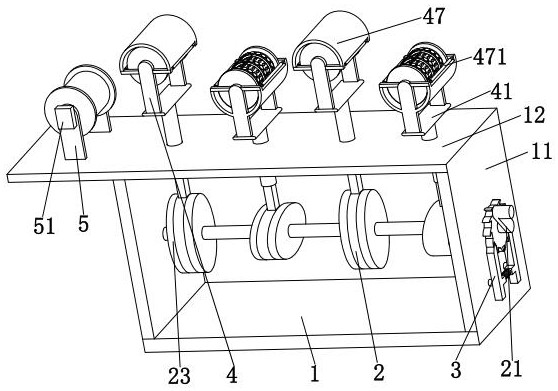

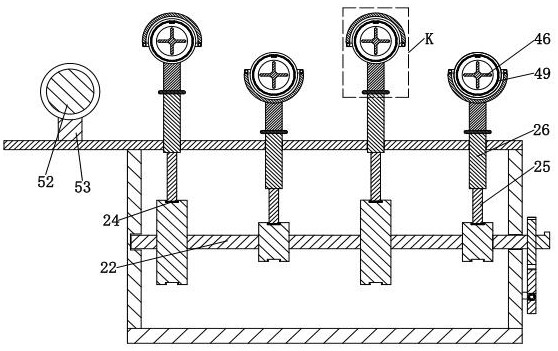

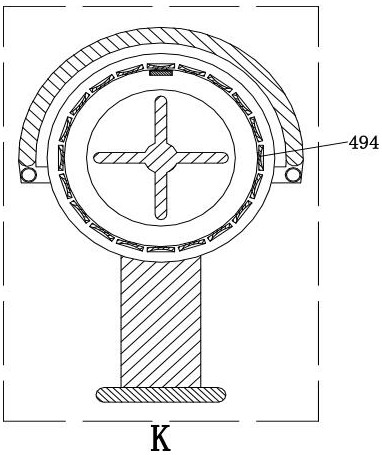

[0032]Such asFigure 1 to Figure 8As shown, a medical packaging glue-coated paper is compressed and formed into a cooling and shaping transmission device, which includes a bottom plate 1, a lifting device 2, a locking positioning device 3, a transmission device 4, and a winding device 5. The left and right ends of the bottom plate 1 A support plate 11 is installed symmetrically, a flat plate 12 is installed on the support plate 11, a winding device 5 is installed at the left end of the flat plate 12, a lifting device 2 is installed between the inner walls of the support plate 11, a transmission device 4 is installed on the lifting device 2, and the right end is supported A locking positioning device 3 is installed on the outer wall of the board 11.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com