A heat-conducting flame-retardant polyester composite material and a heat dissipation device for LED lamps

A technology of flame-retardant polyester and composite materials, which is applied in the field of thermally conductive flame-retardant polyester composite materials and heat-dissipating components for LED lamps, can solve the problem that flame-retardant butylene terephthalate does not have thermal conductivity, and plastics do not have thermal conductivity. Improvement, poor thermal conductivity and other problems, to achieve the effect of low cost of material formula, reduced dosage, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0053] Embodiment 1~12 and comparative example 1~7

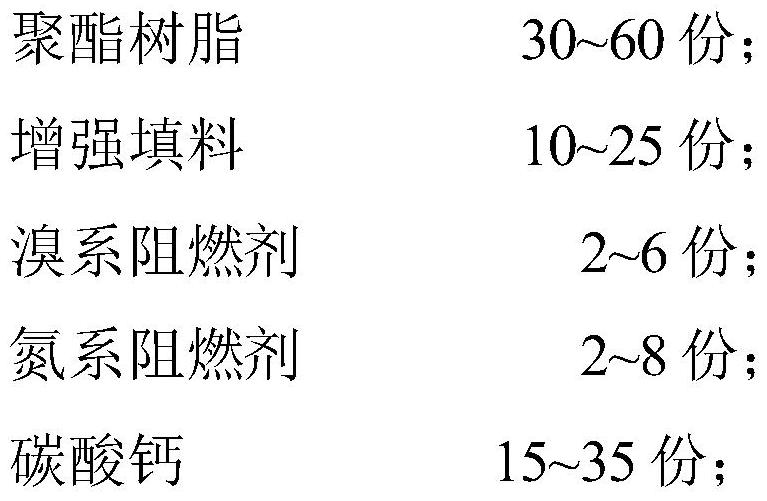

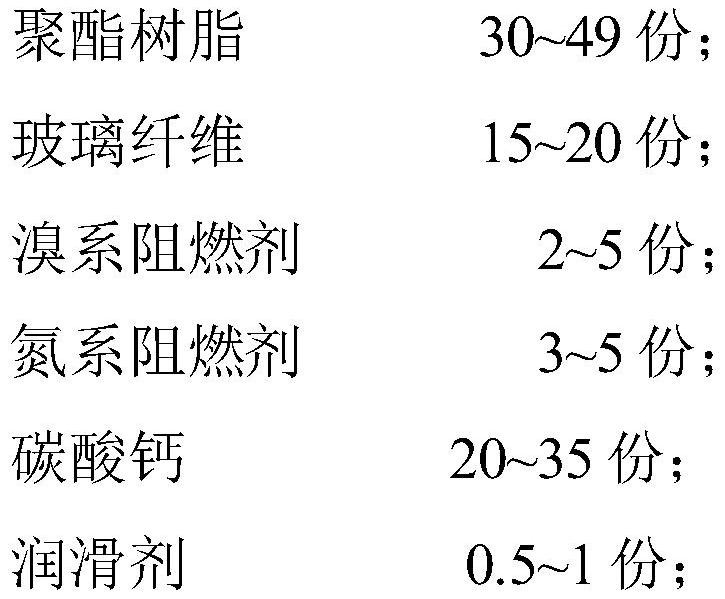

[0054] For each raw material in each embodiment and comparative example, refer to the proportions in Table 2 and Table 3 below. Unless otherwise specified, each raw material is calculated by weight percentage.

[0055] The preparation process of composite materials, specifically:

[0056] The polyester resin is pre-dried in an oven at 110-120°C for 2-3 hours to ensure that its moisture content is ≤0.05;

[0057] Produced by melt blending extrusion process, the raw material components except glass fiber are mixed in a high-speed mixing pot at room temperature and high speed for 10-15 minutes, and the obtained mixture is fed into the twin-screw extruder through the main feeding port, and the glass fiber is fed from the side The feed is fed into a twin-screw extruder, melted and blended, cooled, air-dried and granulated to obtain the product. The polyester resin modified extrusion processing temperature parameters are shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com