A fan self-lubricating bearing seat and self-lubricating method

A self-lubricating bearing and bearing seat technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as damage to bearing seats, failure of lubricating oil to participate in time, and achieve the effect of full filling and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

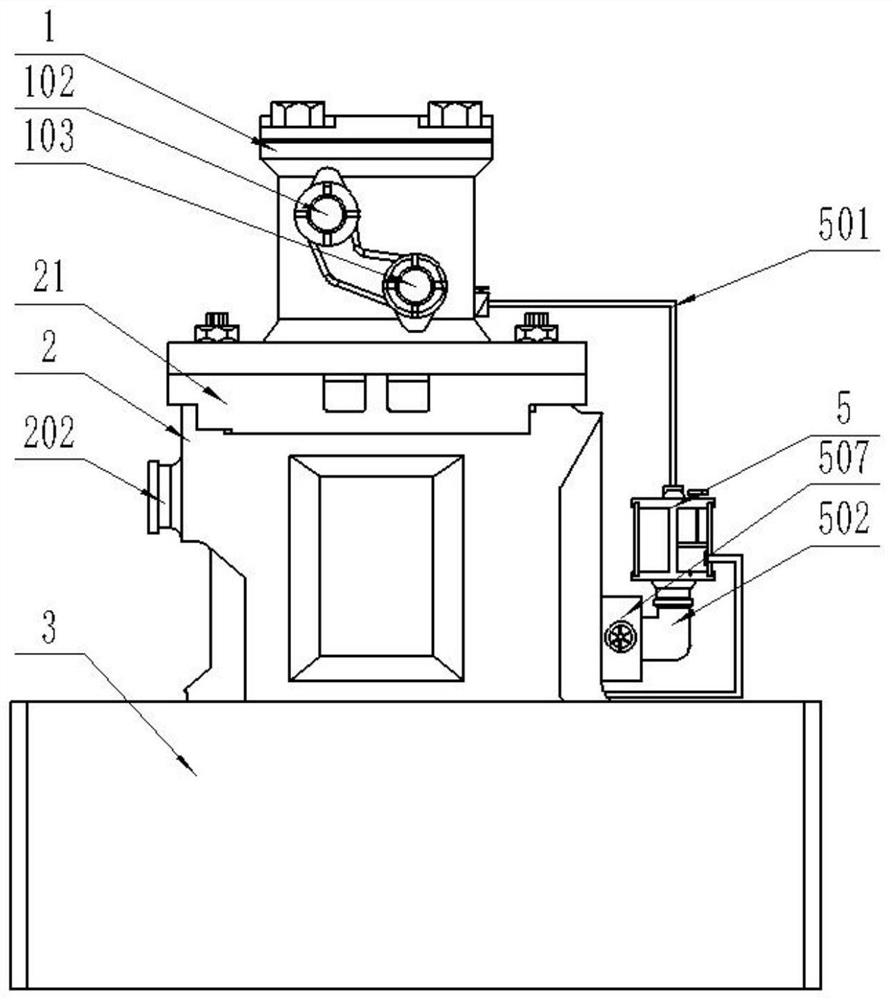

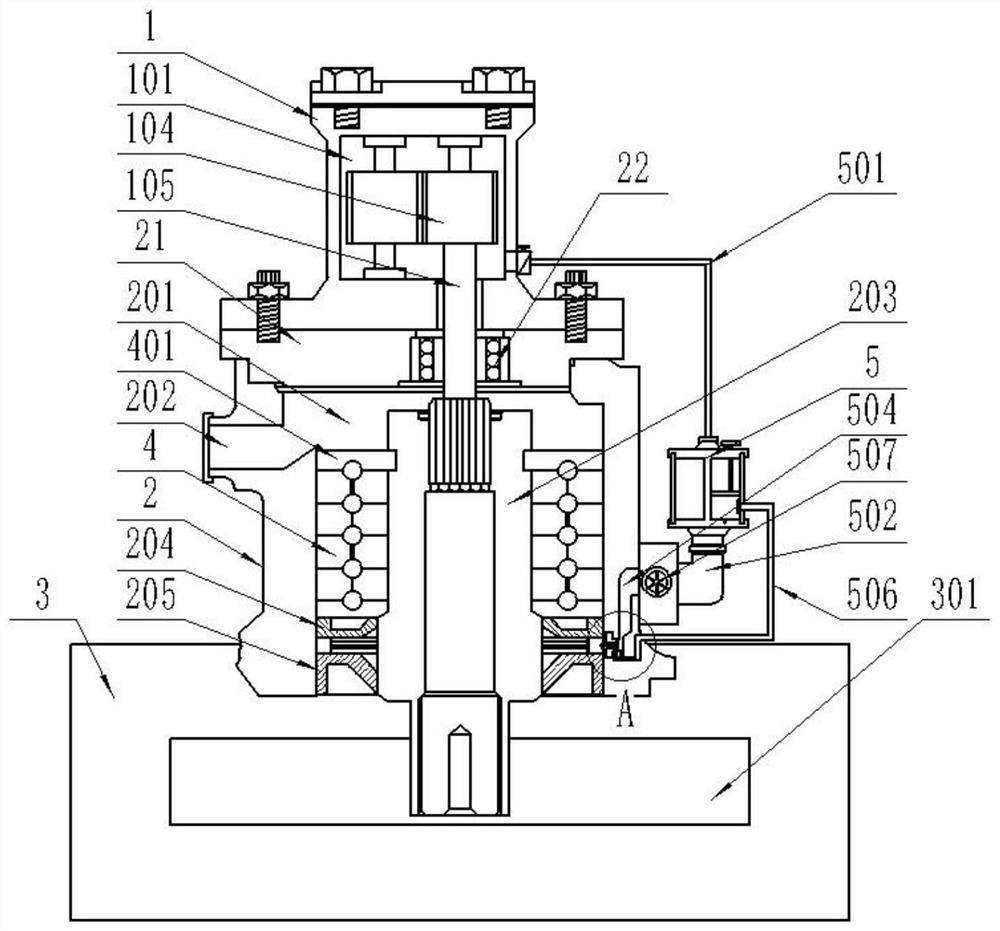

[0069] A fan self-lubricating bearing seat, wherein, such as figure 1 , 2 As shown, it includes: a hydraulic device 1 , a bearing seat 2 , a bearing assembly, a first oil seal 204 , a second oil seal 205 , a lubricating mechanism 5 , and a fan 3 .

[0070] The hydraulic device 1 is provided with a hydraulic chamber 101 and a transmission shaft 105 , and the transmission shaft 105 is arranged in the hydraulic chamber 101 .

[0071] The bearing seat 2 is arranged at the bottom of the hydraulic device 1 . The bearing seat 2 has a bearing chamber 201 and a connecting shaft 203 inside. The connecting shaft 203 is arranged in the bearing chamber 201 , and the transmission shaft 105 is connected to the connecting shaft 203 .

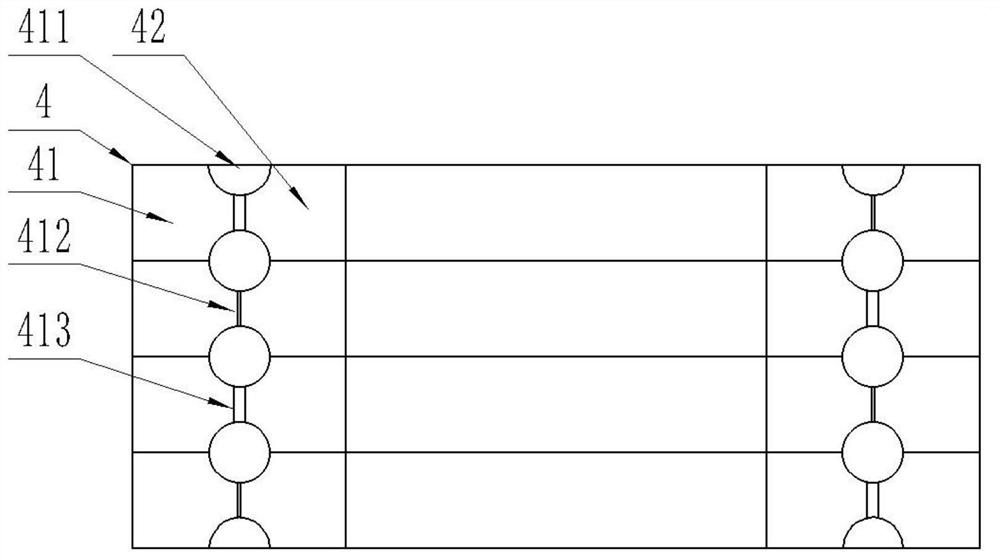

[0072] The bearing assembly is arranged in the bearing cavity 201 , the bearing assembly has a bearing unit 4 , and the bearing assembly is formed by stacking several bearing units 4 from bottom to top.

[0073] The first oil seal 204 is disposed at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com