Pouring and sealing type high-temperature-resistant LED explosion-proof lamp

A technology for LED explosion-proof lamps and LED lamp caps, which can be used in gas/waterproof devices, cooling/heating devices for lighting devices, lighting and heating equipment, etc., which can solve the problems of reduced lamp life, cross-influence of heat transfer, lack of sealing function, etc. , to achieve the effect of improving waterproof sealing performance, improving heat dissipation effect and good irradiation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

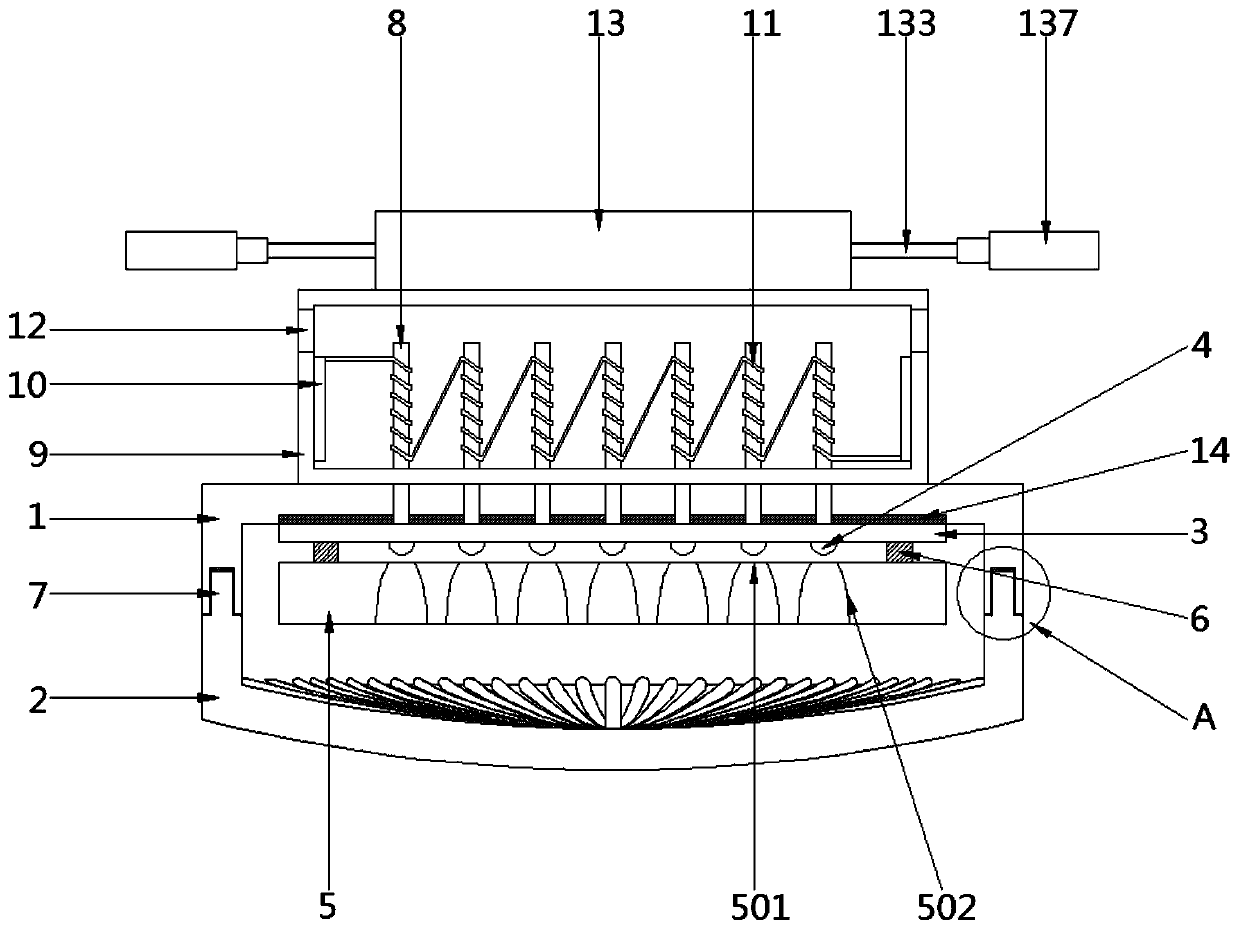

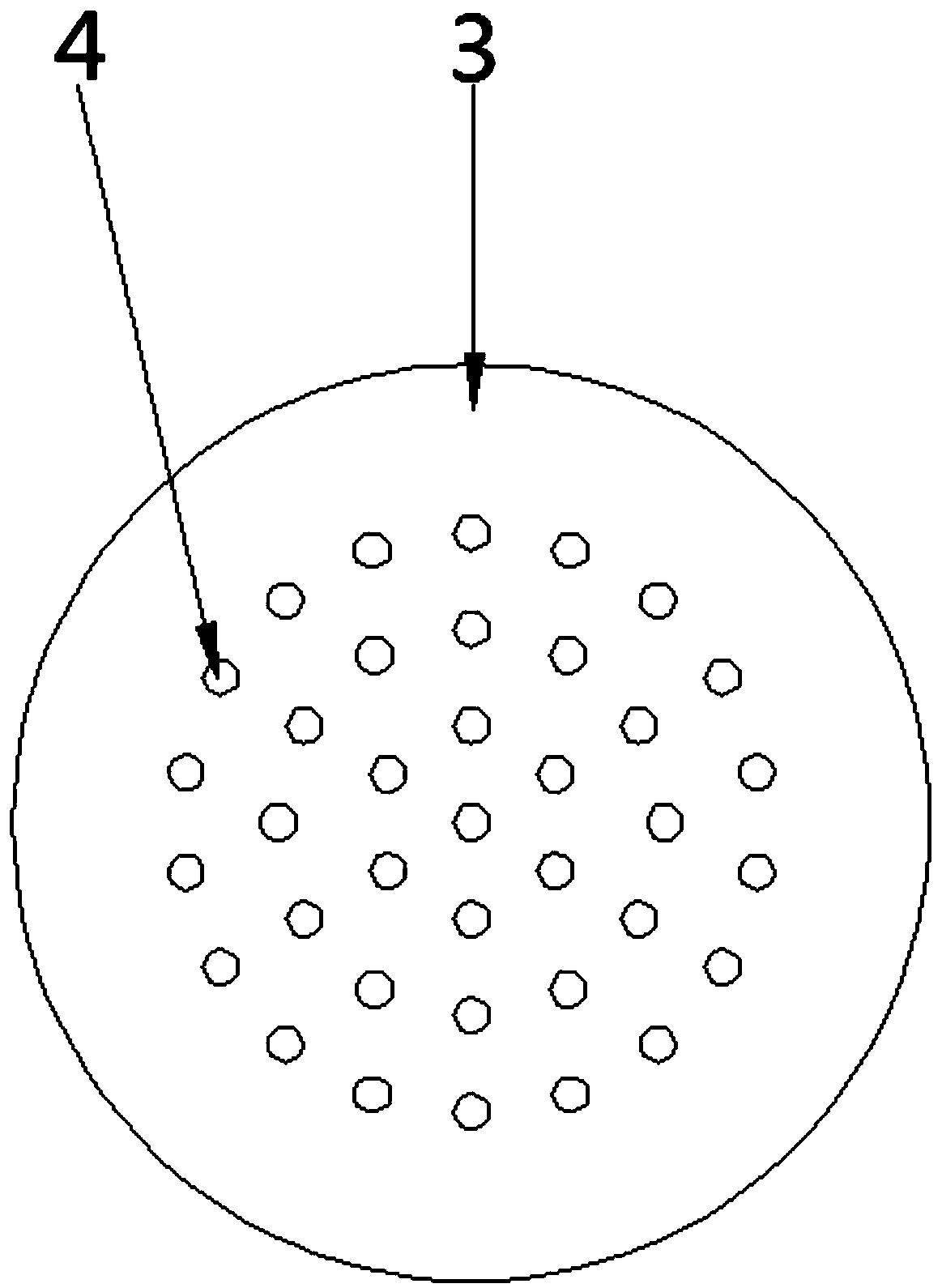

[0042] see figure 1 , Figure 3-6 ,一种浇封型耐高温LED防爆灯,包括灯体1,灯体1的下侧设有透镜2,灯体1上固定有基板3,基板3上均匀设有多个 LED灯头4,基板3的下侧设有反光板5,反光板5通过固定柱6固定在基板3的下表面上。

[0043] 反光板5包括开设在反光板5上的多个反光通孔反光通孔501,多个反光通孔501与多个 LED灯头4一一对应设置,反光通孔501的口径由上至下逐渐增大,反光通孔501的内壁形成反光面502,反光面502为弧形面,且反光面502的横截面为圆形。

[0044] 透镜2包括入射面201和出射面202,出射面202为向下凸出的球面形状,入射面201上设有多个凸起设置的入射棱筋203,入射棱筋203在入射面201上沿其周向呈环形阵列排布,且入射棱筋203沿入射面201的径向延伸设置,相邻的两个入射棱筋203之间的距离在远离入射面201的圆心的方向上逐渐变大,相邻的两个入射棱筋203之间形成入射凹槽204。

[0045] LED灯工作时,基板3通电,反光面502用于将LED灯发出的光源反射至透镜2上,从而增加亮度,节约能耗,由于反光面502为弧形面,且反光面502的横截面为圆形,可防止光源发射时集中至一处,使得反射的光源更加分散,透镜2上设置入射面201,且在入射面201上设置入射棱筋203和入射凹槽204,可使入射的光往不同的方向入射和反射,光源入射时同时发生散射,使得光源通过透镜2后往不同方向出射,使得出射光更加均匀,有效的防眩光,从而达到良好的照射效果。

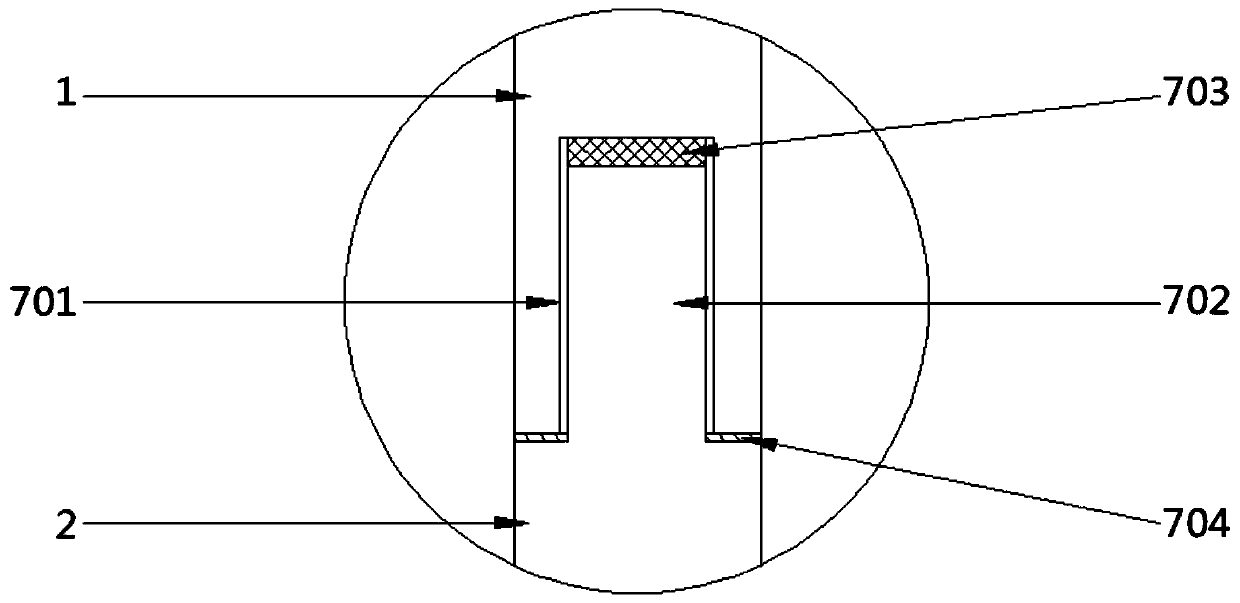

[0046] see Figure 1-2 ,灯体1和透镜2接触处设有密封结构7,密封结构7包括开设在灯体1上的环形螺纹槽701和与透镜2上侧壁一体成型的环形螺纹凸起702,环形螺纹凸起702与环形螺纹槽701相配合,环形螺纹凸起702的顶部设有密封垫703,灯体1和透镜2的接触面上涂抹有防水胶层704。

[0047] 通过设置密封结构7,环形螺纹凸起702与环形螺纹槽701相配合,并在环形螺纹凸起702的顶部设有密封垫703,能够对灯体1和透镜2的接口处进行密封,密封效果,有效的提高了LED灯的防水性能。

[0048] 防水胶层704由甲基含氢硅油和含有金属盐类催化剂的甲基乙烯硅油组成,甲基含氢...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com