Fine aggregate crushing value test equipment and test method thereof

A test equipment, technology of crushing value, applied in the direction of analyzing materials, using stable tension/pressure to test material strength, measuring devices, etc., can solve the problems of crush resistance of difficult sand materials and reduce the accuracy of test results, etc. To achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

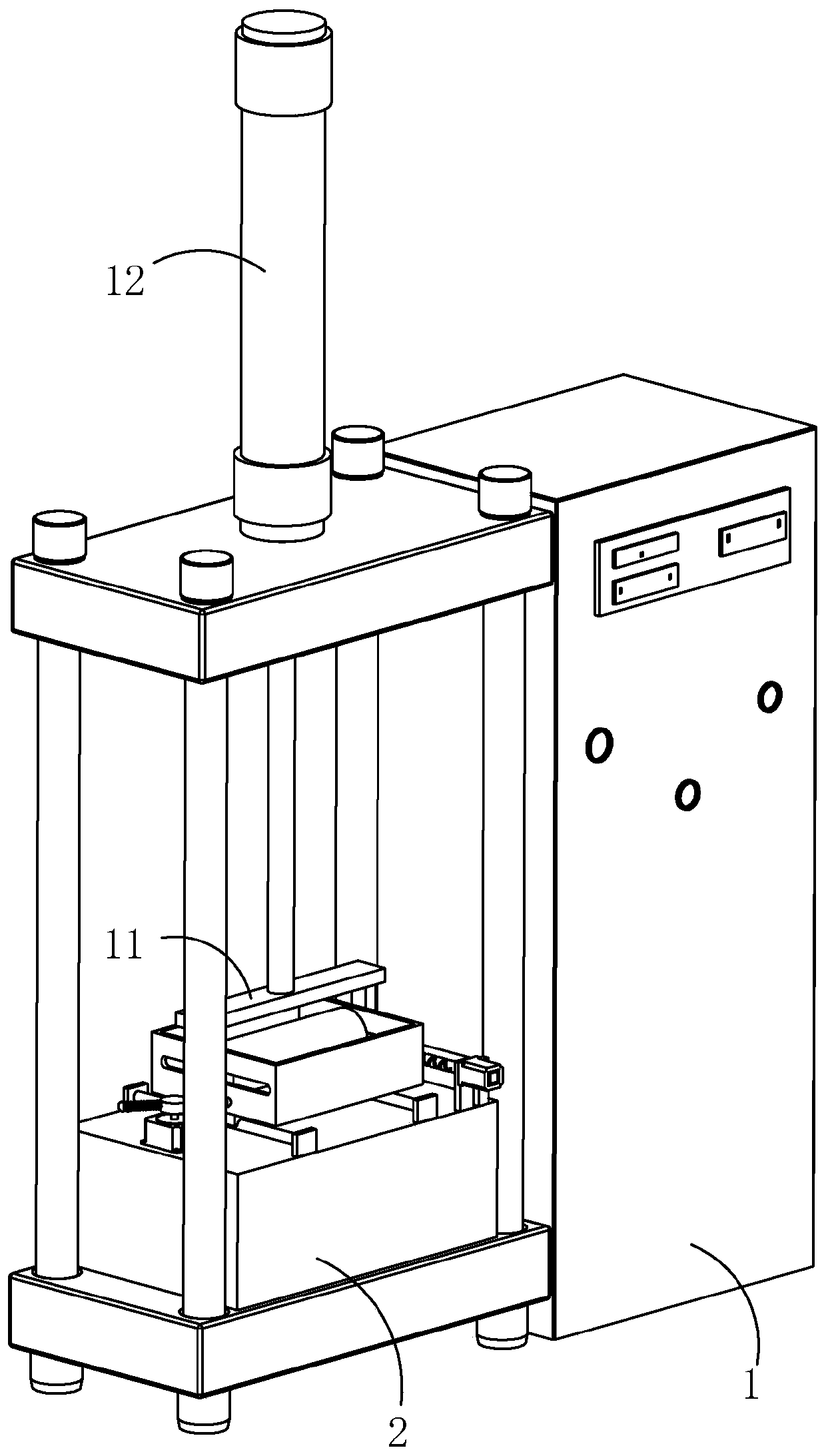

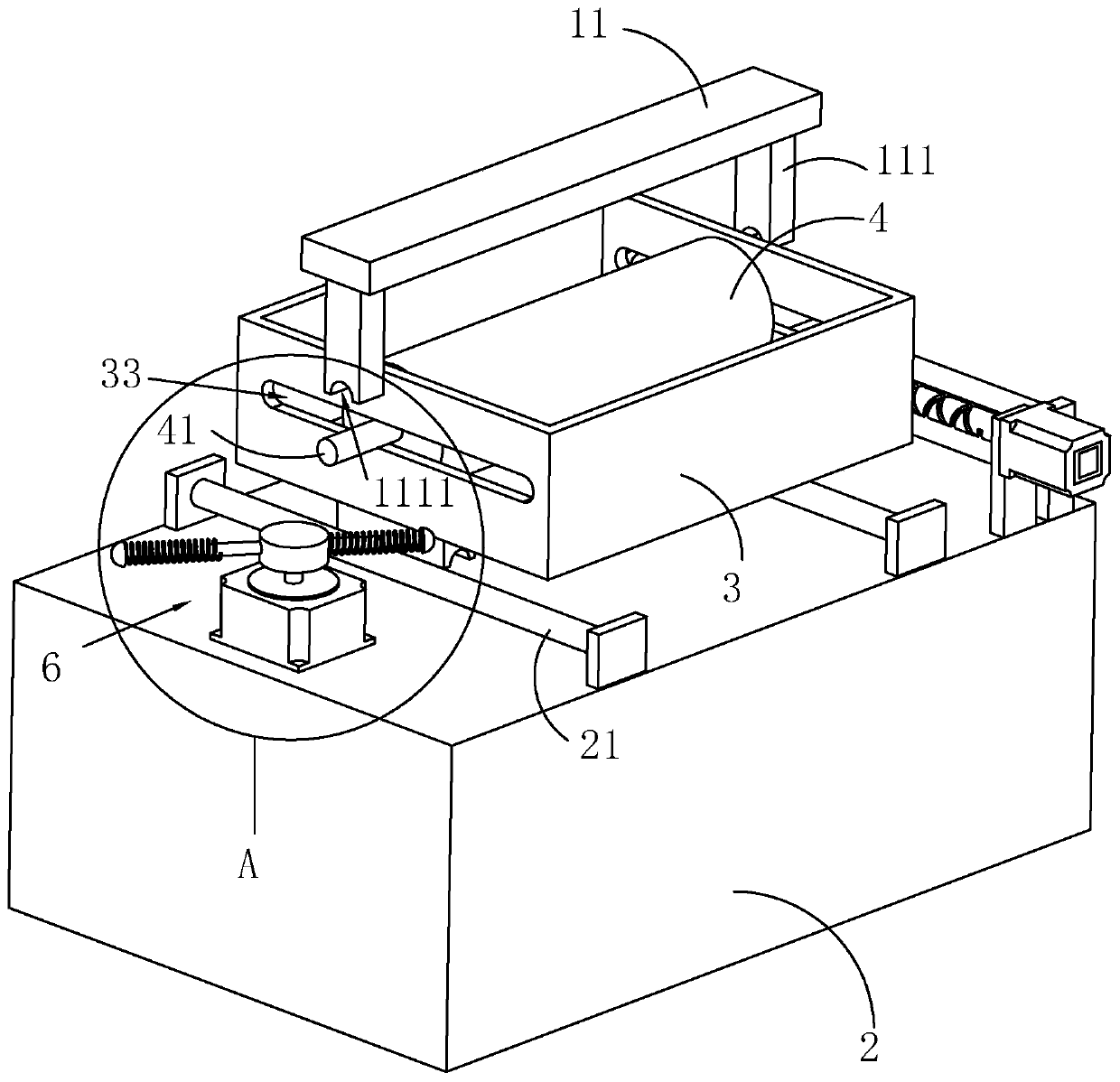

[0043] like figure 1 , 2 As shown, a fine aggregate crushing value test equipment includes a body 1, a base 2 and an upper pressing seat 11. The body 1 is provided with a driving source 12 for driving the upper pressing seat 11 to move up and down, and the driving source 12 is an oil cylinder. A trial box 3 is arranged on the base 2 , and a pressing roller 4 is rotatably arranged on the upper pressing base 11 .

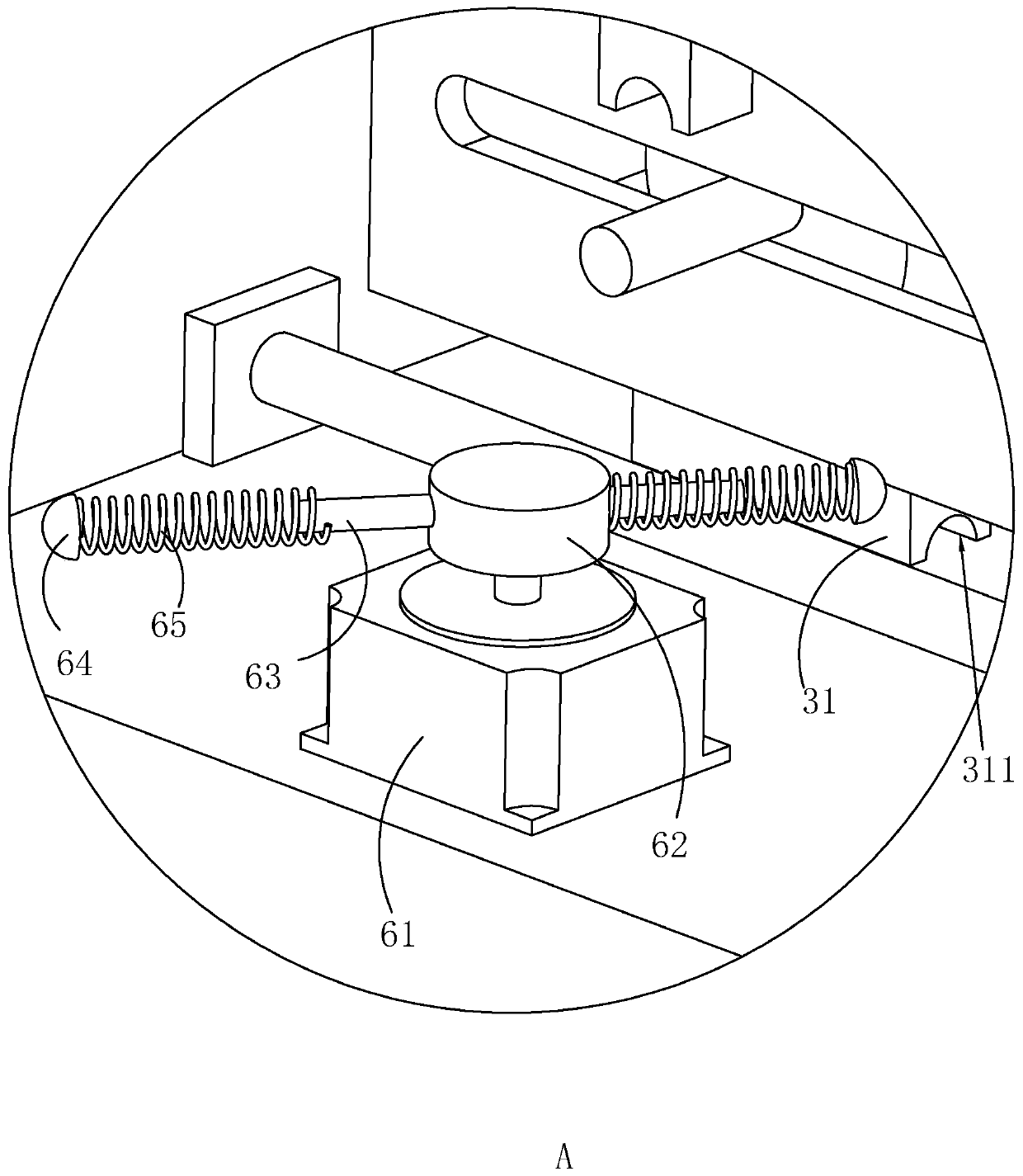

[0044] like figure 2 , 3 As shown, slide bars 21 are fixedly arranged on the base 2 along the axial direction perpendicular to the pressing roller 4, and at least two slide bars 21 are arranged in parallel. A chute 311 slidably connected to the slide bar 21 is provided, and the chute 311 is a C-shaped slot.

[0045] Among them, such as Figure 4As shown, the base 2 is provided with a drive assembly for sliding the trial box 3 , and the drive assembly includes a screw rod 51 , a drive block 52 and a drive motor 53 . The screw rod 51 is rotated and arranged on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com