Hairpin flat wire motor stator and hairpin flat wire motor

A technology for motor stators and hairpins, applied in electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc., can solve the problem of difficulty in meeting motor performance design requirements, reducing the height and size of the outlet end, and complicated wiring of transition connecting lines. It can meet the requirements of motor performance design and manufacturing process design, the winding structure is simple and compact, and the effect of reducing high-speed skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

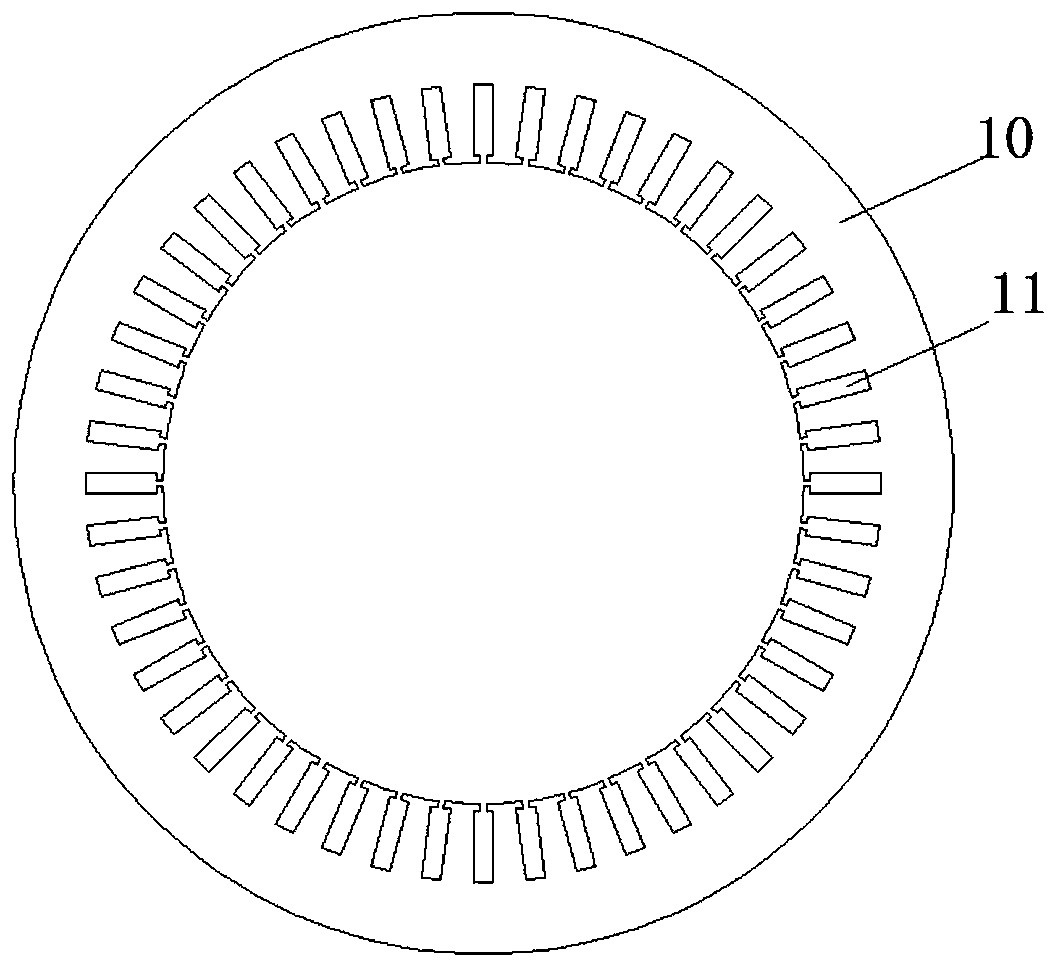

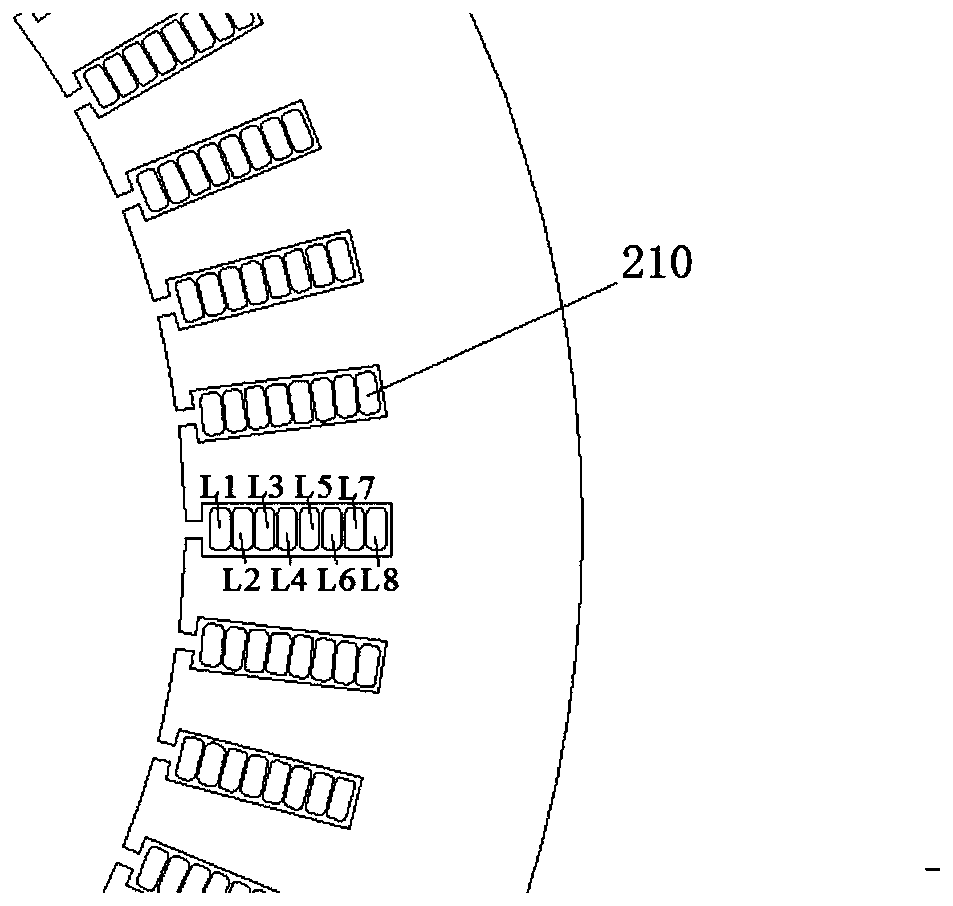

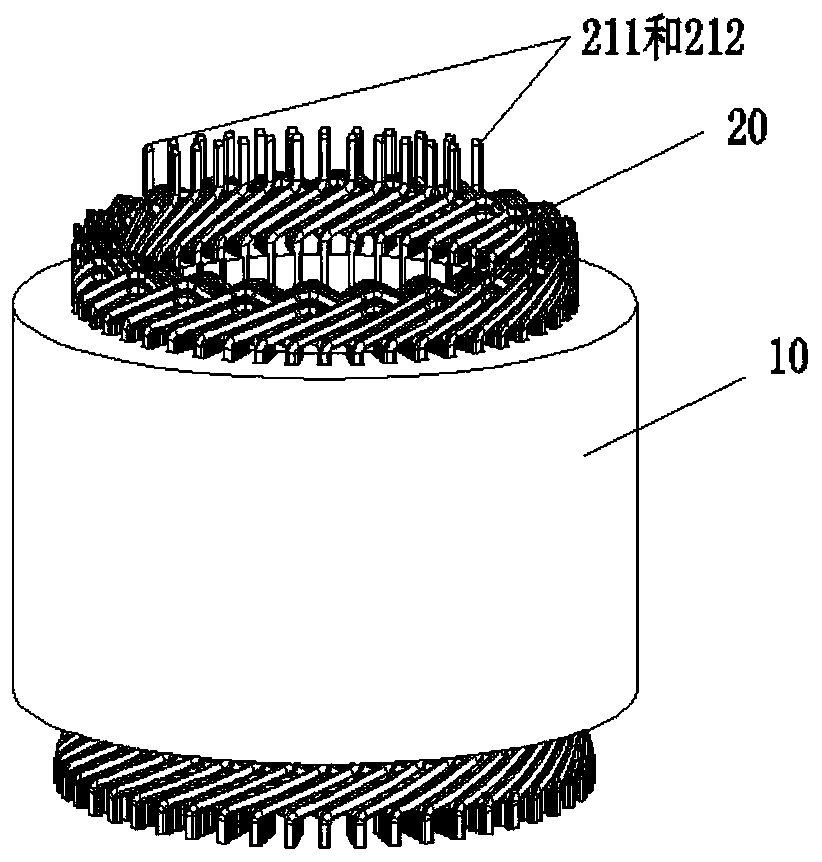

[0030] Also refer to Figure 1-Figure 3 , figure 1 It is a top structural schematic diagram of a stator core of a hairpin flat wire motor in some embodiments of the present invention. figure 2 It is a schematic diagram of the distribution of conductors in the slots of the stator core of the hairpin flat wire motor in some embodiments of the present invention. image 3 It is a three-dimensional structural view of the stator of the hairpin flat wire motor in some embodiments of the present invention. The stator of the hairpin flat wire motor includes: a stator core structure 10 and a stator winding 20 . Wherein, the inside of the stator core structure 10 is evenly spaced with a plurality of winding slots 11 extending along its axial direction, and the winding slots 11 are distributed with conductors 210 . One side of the two ends of the stator core 10 is the hairpin end of the winding, and the other side is the welding end of the winding. The stator winding 20 is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com