Creasing plate for creasing sheet from paper, cardboard, carton, foil or similar material

An indentation board and indentation technology, which is applied in the manufacture of paper/cardboard containers, papermaking, rigid/semi-rigid containers, etc., can solve the problems of short service life and achieve the effect of long service life and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

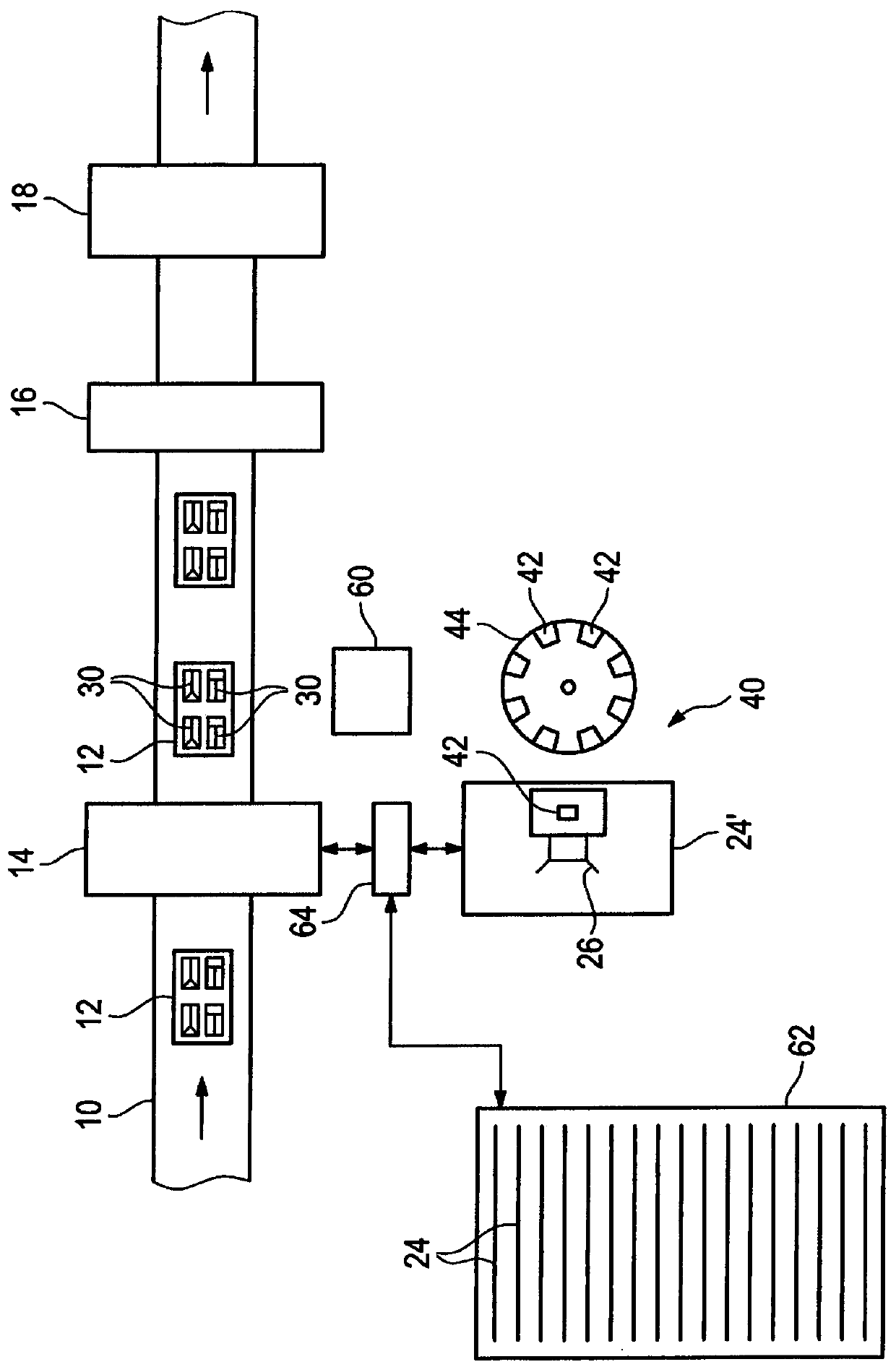

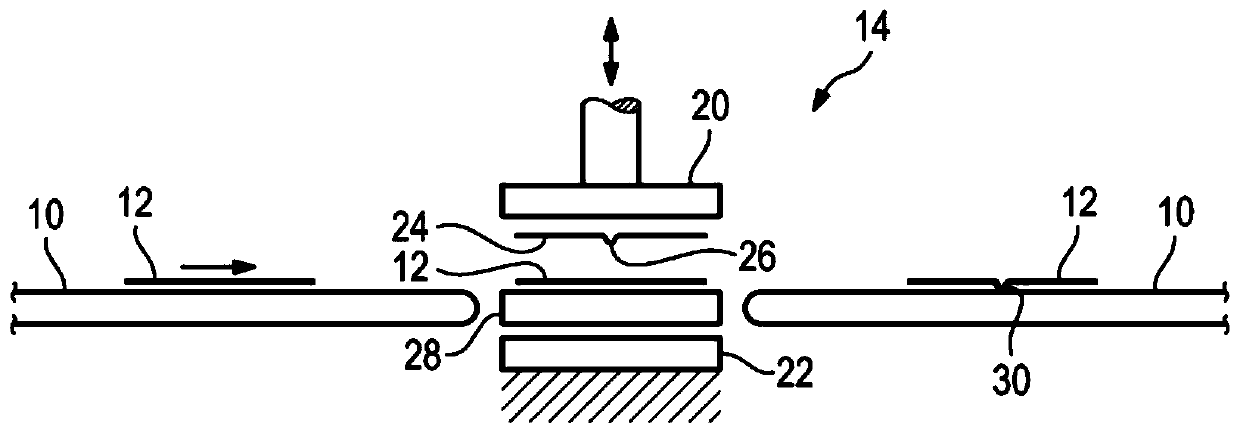

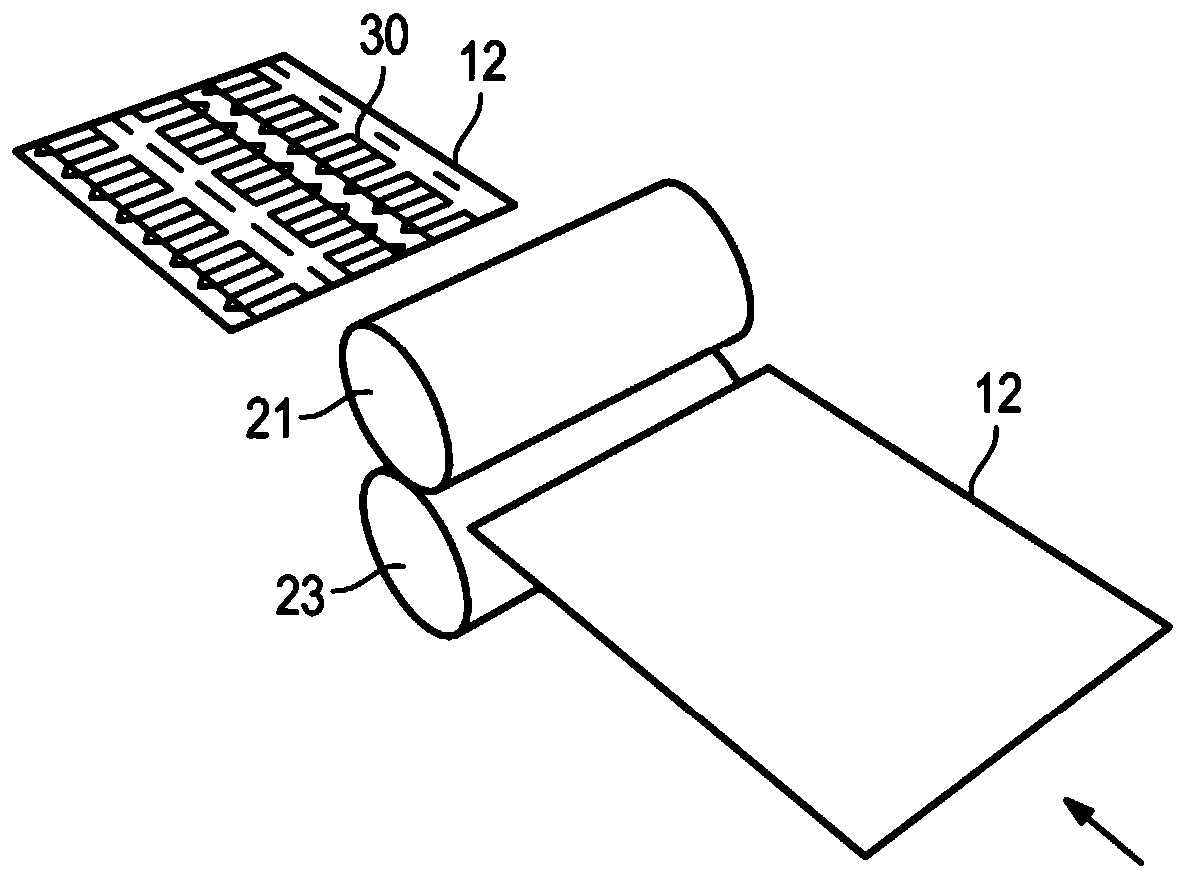

[0053] exist figure 1 , schematically shows the creasing machine. It comprises a conveyor system 10 for advancing a sheet material 12 through a creasing area 14 in which folding creases can be applied to the sheet material 12 .

[0054] Additional processing stations 16, 18 may be provided as part of or associated with the creasing machine. The processing stations 16, 18 may be used to cut, fold, glue, or otherwise process the sheet 12 or articles produced therefrom.

[0055] The sheet 12 may be made of cardboard, carton or foil, and may subsequently be processed to cut blanks from the sheet to form packages, boxes, bags, envelopes or similar products.

[0056] The sheet material 12 may be supplied to the creasing area 14 individually as shown in the figures or in the form of a continuous web guided through the creasing area 14 .

[0057] It is also possible to integrate a cutting system into the creasing area 14 which allows the individual blanks to be separated from the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap