Building aggregate mine in-situ soil improvement and greening method

A construction aggregate and soil improvement technology, applied in the field of aggregate, can solve the problems of poor effect, long vegetation recovery time, slow speed, etc., and achieve the effect of reducing cost and excellent recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

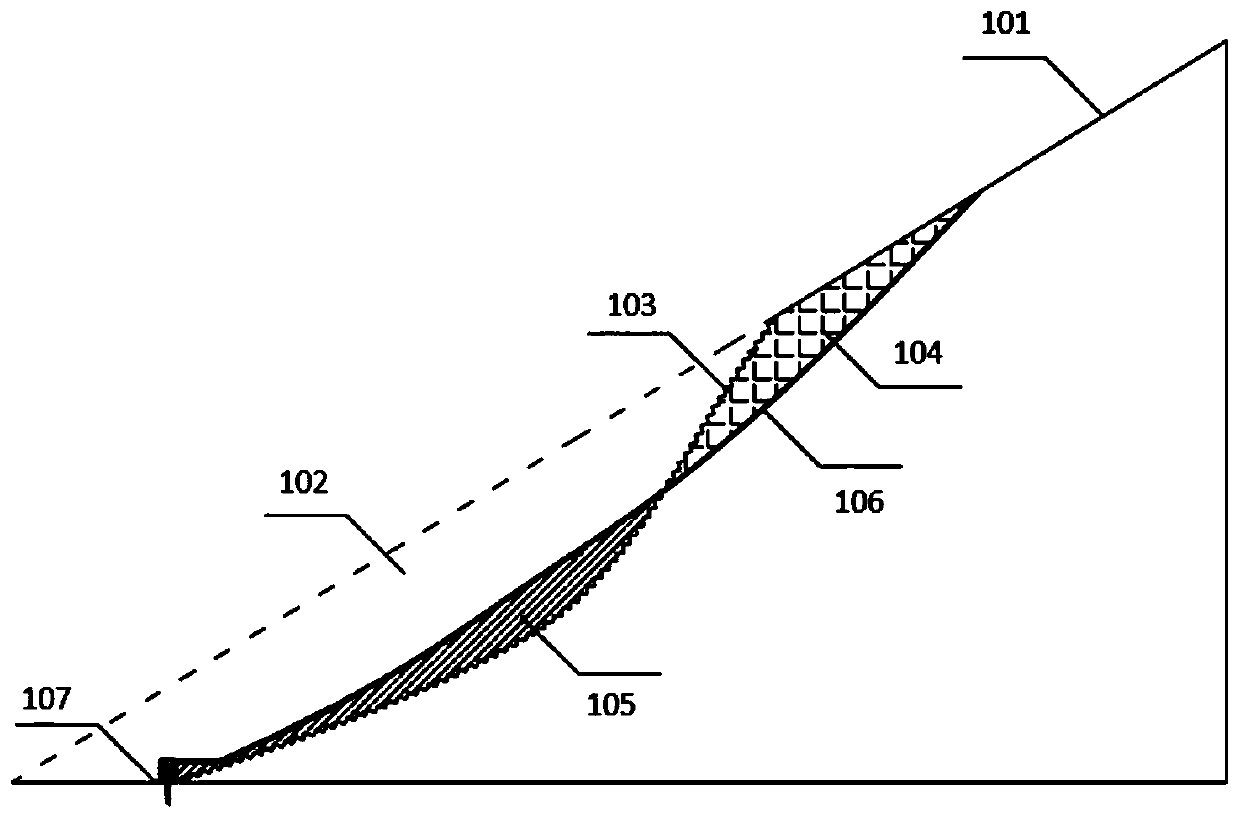

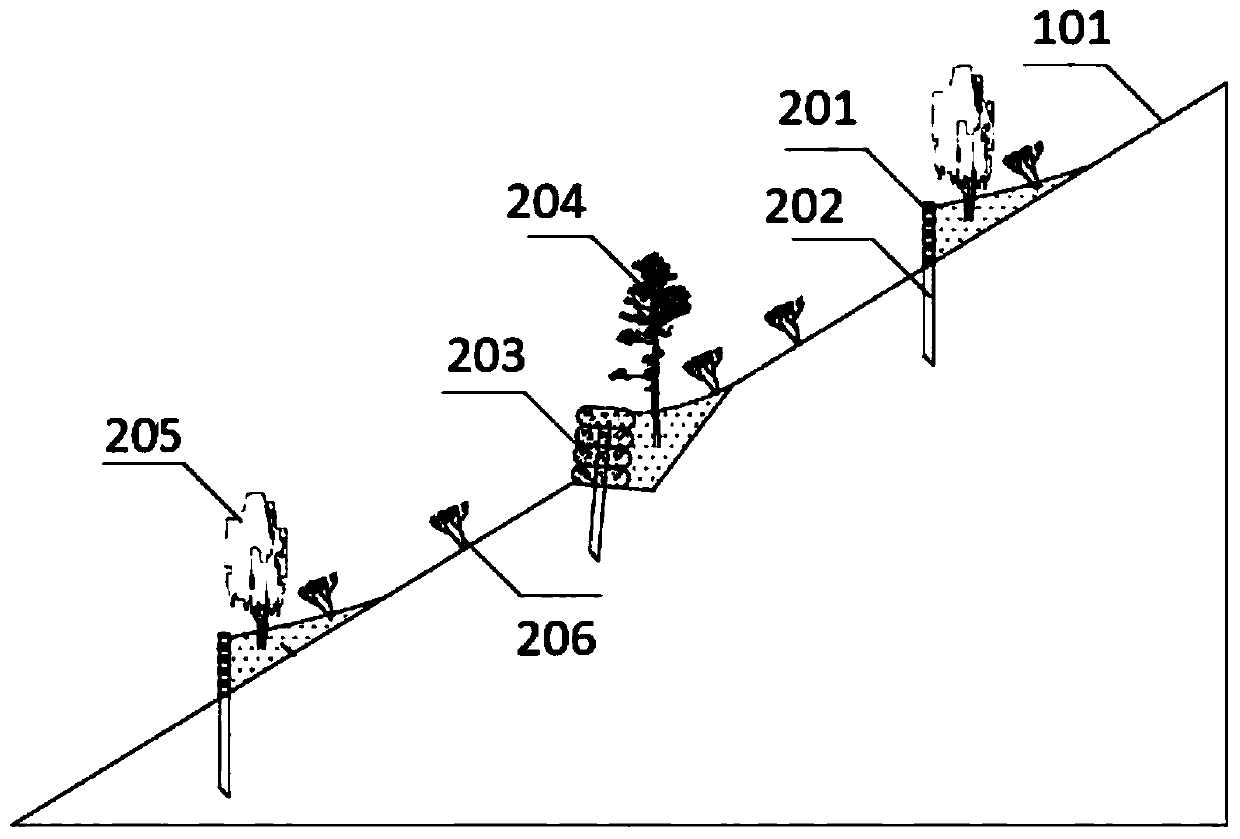

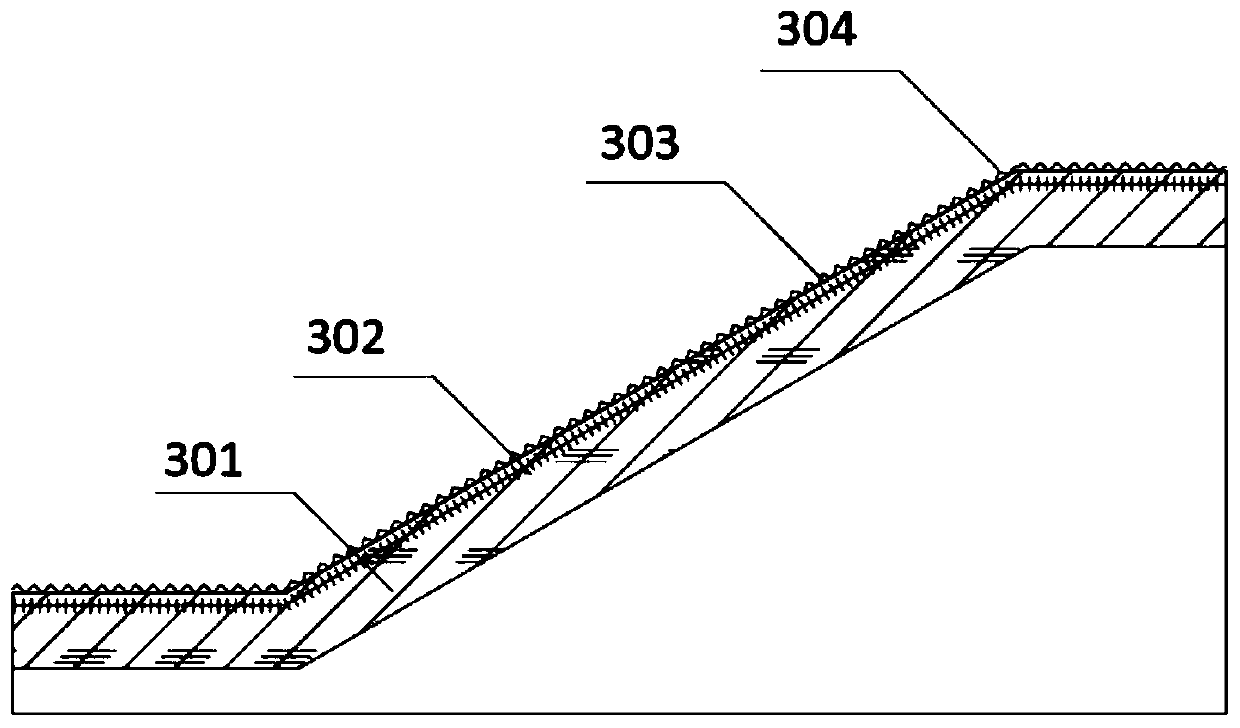

Method used

Image

Examples

specific Embodiment 1

[0050] Taking an aggregate mine in Fuyang, Zhejiang as an example, a 5,000-square-meter demonstration project has been completed in the dump site, with a slope of 36° and a slope length of 20m. 20cm, and the herbaceous coverage is about 25% after one year of natural enclosure. Due to the unsatisfactory natural recovery effect, the fine grooves on the slope are eroded violently, and a "V"-shaped erosion ditch is formed at the foot of the slope. The ditch is 7.4m long and 2.2m deep. m, the top width of the ditch mouth is 3.9m, and the bottom width is 1.7m, which tends to run through the top of the slope. The method proposed by the invention is used for in-situ improvement and greening.

[0051] (1) Artificially level and compact the foundation along the mouth of the "V" gully. The foundation is 0.8m wide and 8m long. On the compacted foundation, lay ecological bags along the mouth of the slope. The size of the ecological bags after filling is 12cm*30cm*70cm ;The long side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com