Polishing method for surface of to-be-polished workpiece, glass member and application thereof and polishing fixture

A technology for glass parts and fixtures, which is applied to machine tools, grinding/polishing equipment, and manufacturing tools suitable for grinding workpiece planes, and can solve problems such as affecting the appearance of glass shells and the texture of glass surfaces is not fine enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

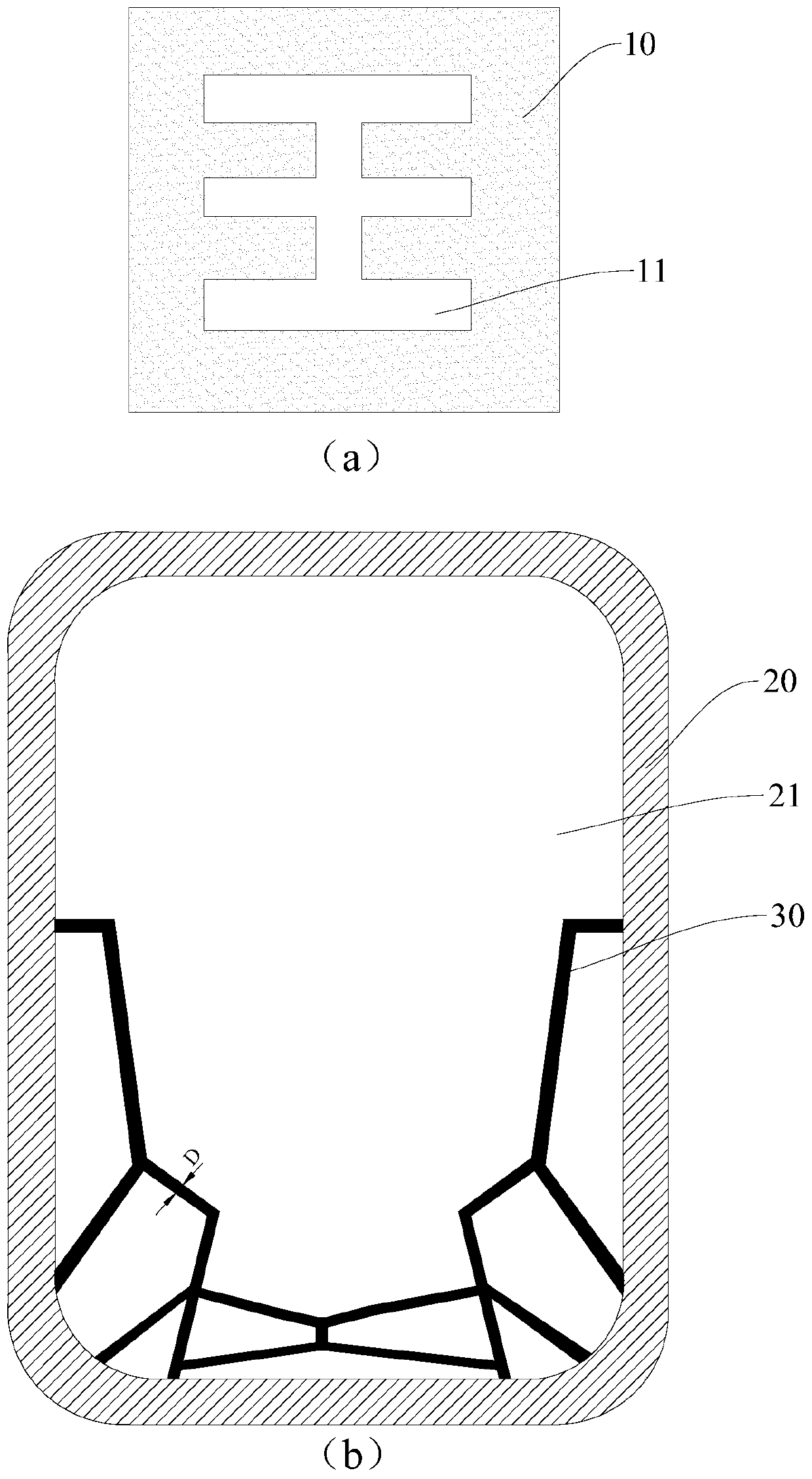

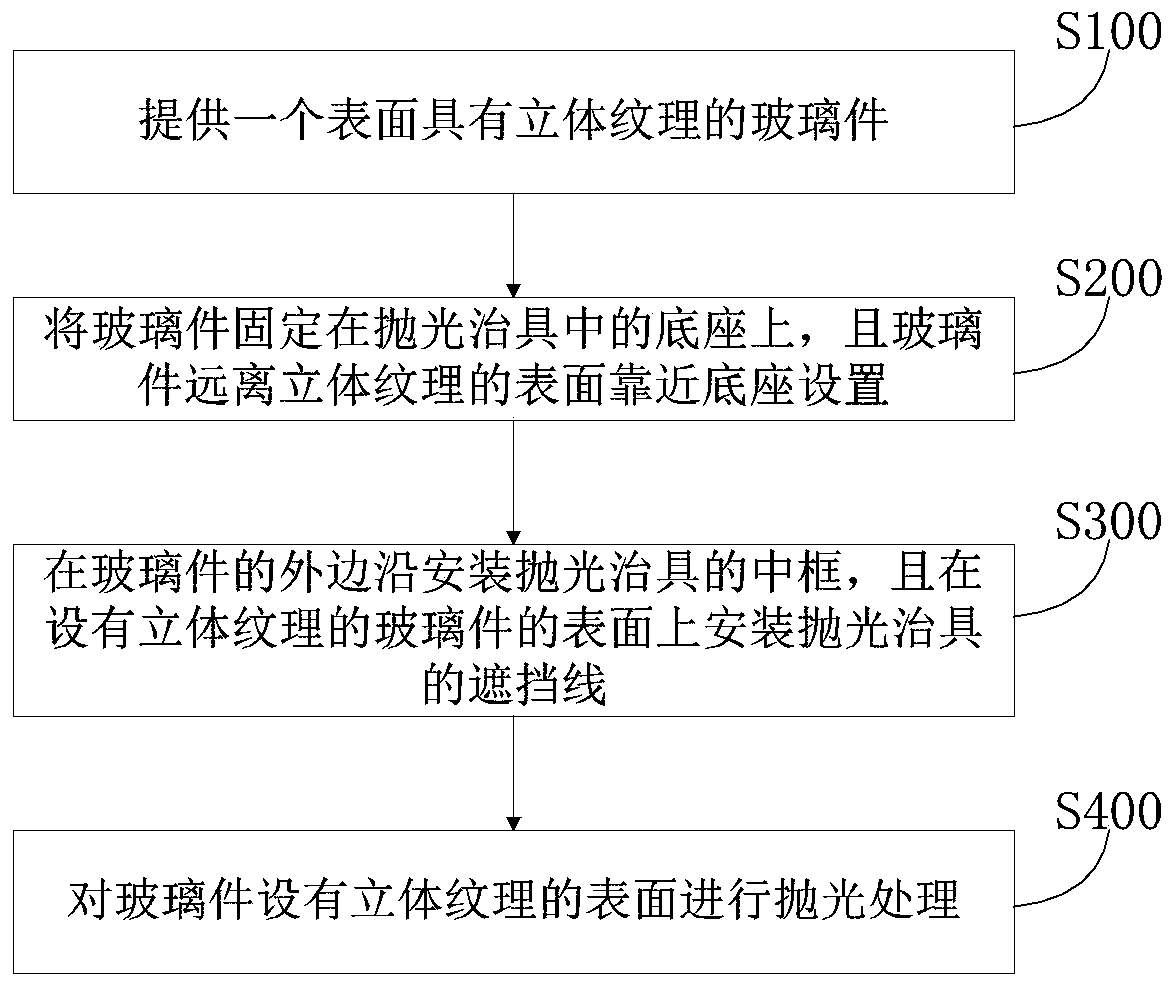

[0057] Through the CNC processing technology, the three-dimensional texture is processed on the surface of the original glass sheet;

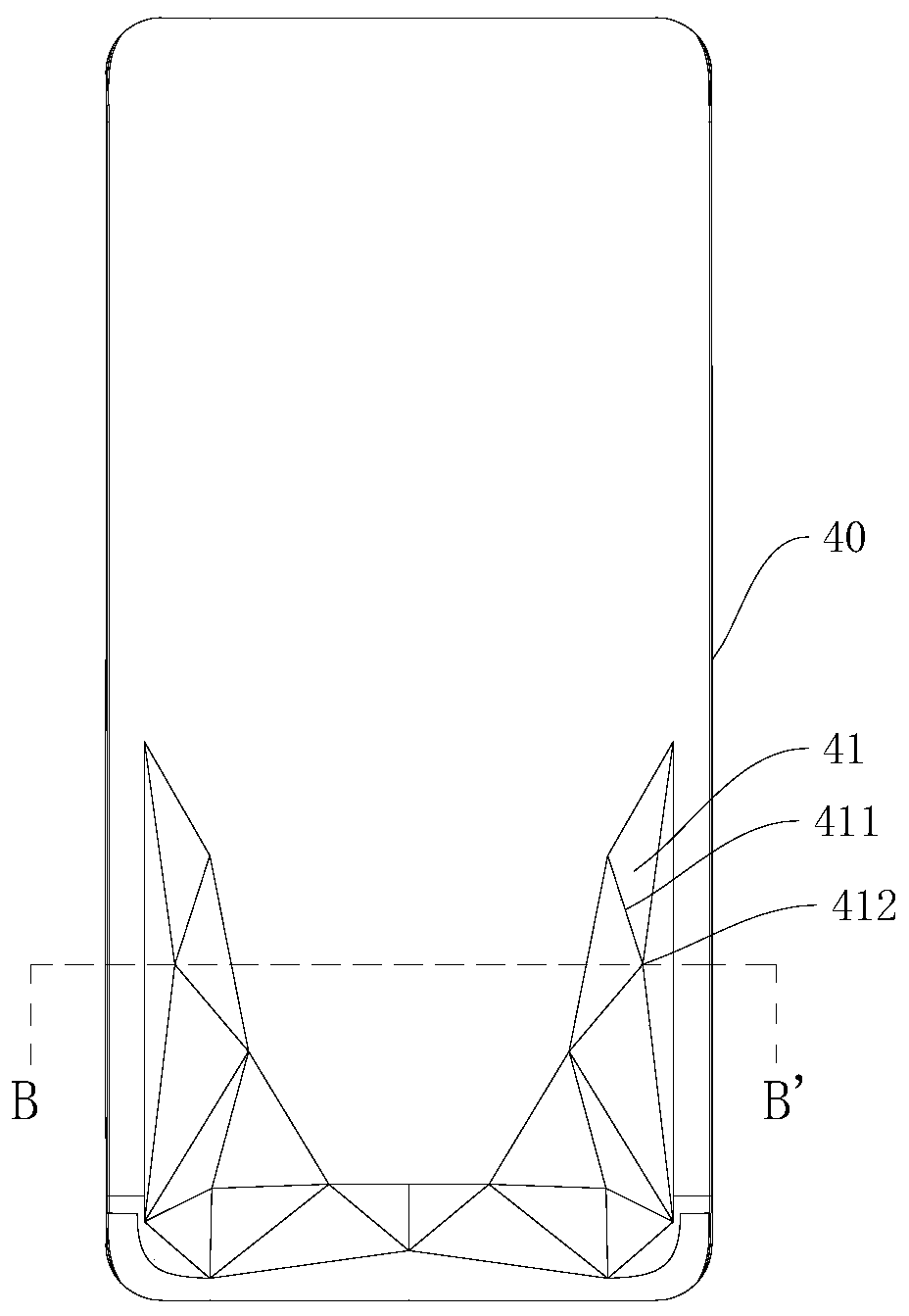

[0058] The above-mentioned glass parts with three-dimensional texture are installed and fixed on the polishing fixture (refer to figure 1 ), wherein the shading line of the polishing jig blocks the ridges covering the three-dimensional texture, wherein the width of the shading line is 22 microns, and the thickness of the shading line is 35 microns;

[0059] The surface provided with the three-dimensional texture is polished, wherein the process conditions of the polishing process meet: the polishing pressure is 1kg / cm 2 The rotation speed of the carrier is 92rpm; the rotation speed of the platen is 110rpm, and when the polishing treatment is completed, the ink layer has not completely fallen off, and the polishing treatment step on the surface of the glass piece is ended.

[0060] The radius of the R angle at the ridgeline of the three-dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap