Detection tool for detecting die part

A technology of parts and molds, which is applied in the field of inspection tools for mold parts inspection, can solve problems such as errors and low efficiency in detecting mold parts, and achieve the effects of convenient use, reduced processing costs, and improved inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

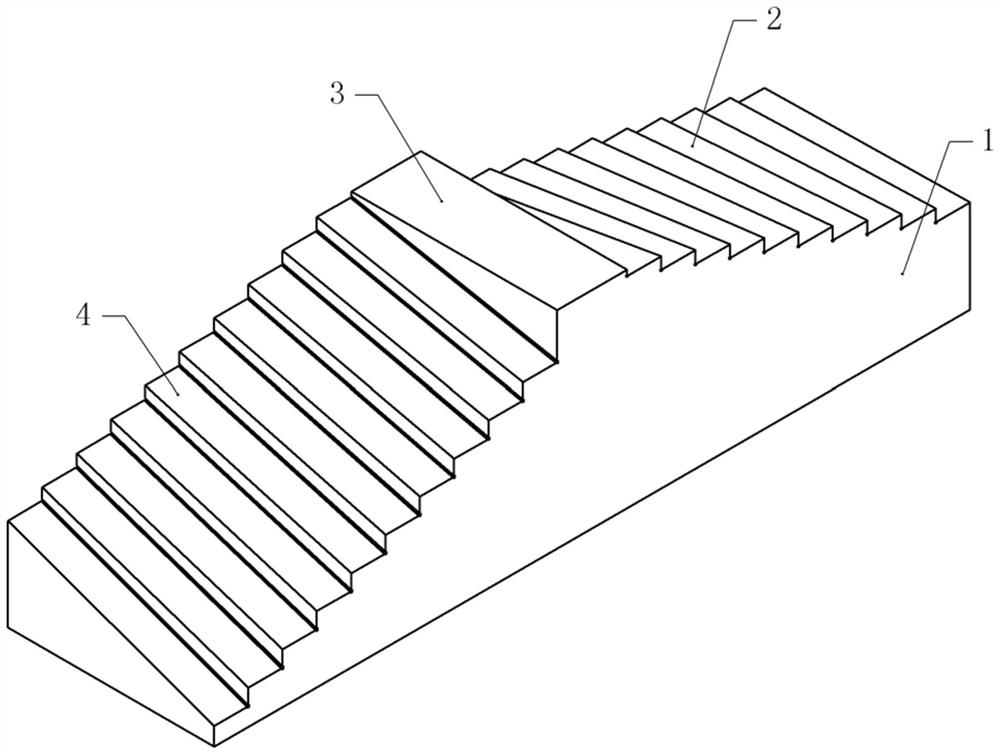

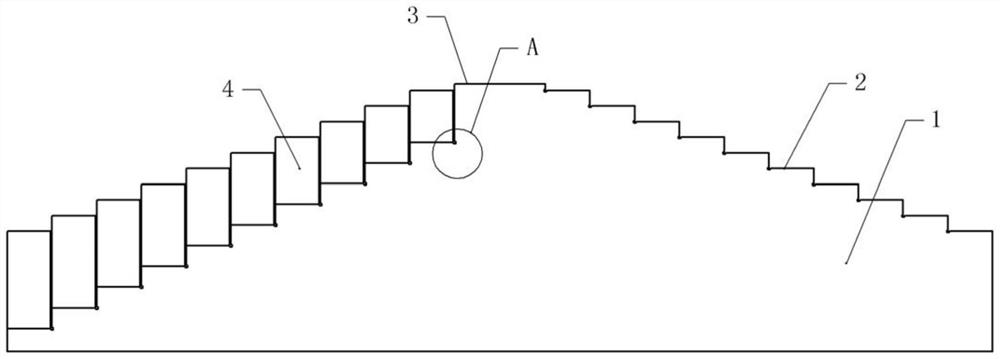

[0039] Basic as attached figure 1 , attached figure 2 And attached Figure 4 As shown, the inspection tool for mold parts inspection includes a boss 1. There are several inclined detection stations on both sides of the boss 1. The inspection station on the side of the boss 1 is inclined towards the front of the boss 1. The boss 1 1 The detection station on the other side is obliquely facing the back of the boss 1. The inclination angles of the detection stations gradually increase from top to bottom, and the inclination angles of two adjacent detection stations differ by 1°. In this embodiment, there are ten detection stations on each side of the boss 1, the inclination angle of the top detection station is 1°, and the inclination angle of the bottom detection station is 10°, that is, the inclination angle of the detection station is 1°. The tilt angle distribution is: 1°, 2°, 3°, 4°, 5°, 6°, 7°, 8°, 9°, 10°.

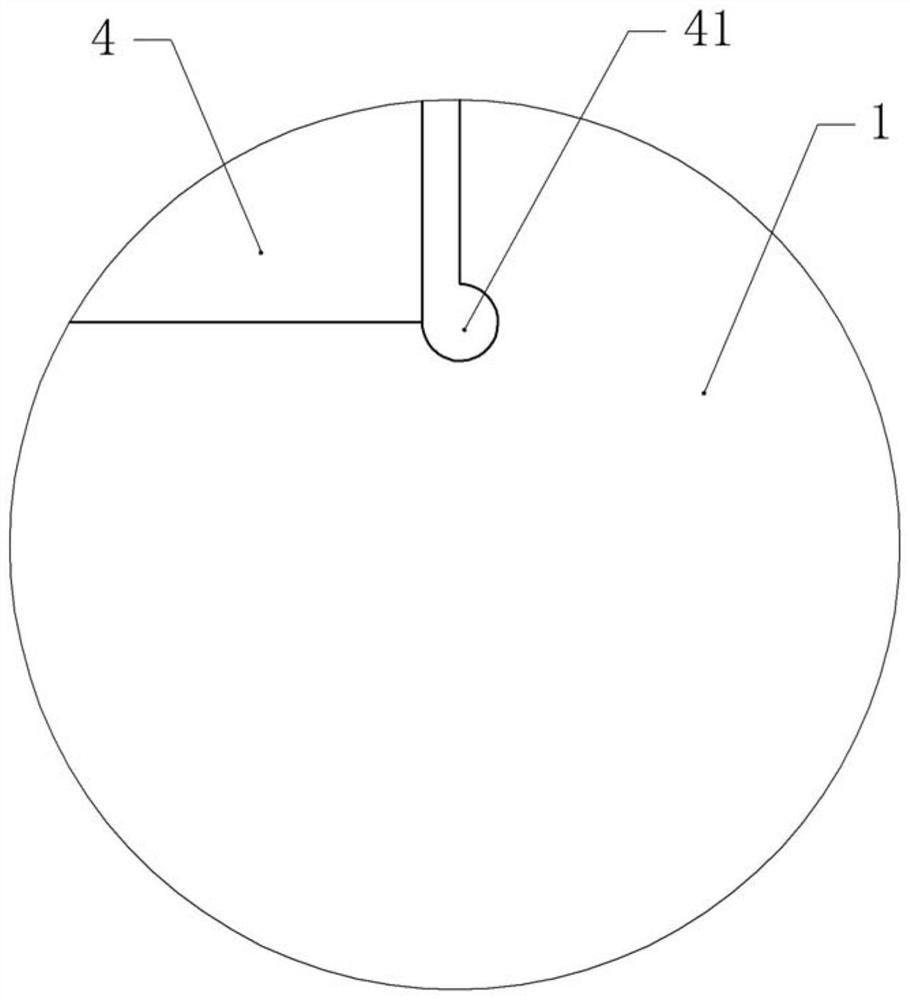

[0040] combined with image 3 As shown, there is an escape g...

Embodiment 2

[0045] The difference between embodiment two and embodiment one is that, as attached Image 6 As shown, the main piece 411 and the secondary piece 412 are horizontally slidably connected in the avoidance groove 41, and the cross-sections of the main piece 411 and the secondary piece 412 are arc-shaped, and when the main piece 411 and the secondary piece 412 are fitted together, they can also form a Arc-shaped, the main sheet 411 and the secondary sheet 412 are bonded with elastic gaskets, and the elastic gaskets are made of rubber.

[0046] In this embodiment, when the thickness of the edges and corners of the mold part is B / C / D (B>C>D), when D is encountered, the elastic gasket can be deformed to a certain extent to adapt to the D thickness.

[0047] When the situation C is encountered, the main piece 411 or the secondary piece 412 can be taken out from the escape groove 41 to adapt to the C thickness.

[0048] When encountering condition B, the main piece 411 and the secondar...

Embodiment 3

[0051] The difference between embodiment three and embodiment one is that, as attached Figure 7 And attached Figure 8 As shown, some baffles 5 are arranged on both sides of the boss 1, and the baffles 5 are located at the low end side of the detection station (due to the inclination of the detection station, there are high and low ends), and the height of the baffles 5 varies with the detection position. The height of the workstation increases gradually, combined with the attached Figure 9 As shown, the baffle plate 5 includes an outer plate 51 and an inner plate 55, the inner plate 55 is located in the outer plate 51, the inner plate 55 is welded with a protrusion, the outer plate 51 is provided with a chute vertically slidingly connected with the protrusion, and the outer plate 51 A channel 53 is opened on the plate 51 , and an air hole 54 facing the escape groove 41 is communicated with the channel 53 , and a pressure relief valve 52 is fixed in the channel 53 by screws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com