Vertical-open caisson-combined whirling well construction method suitable for complex geological conditions

A technology with complex geological conditions and construction methods, applied in the field of swirl well construction, can solve problems such as inability to meet on-site construction requirements, many construction safety hazards, and large construction excavation volume, so as to reduce impact, reduce workload, and ensure safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Geological conditions for the construction of a geovortex well: 1.1 layers of miscellaneous soil between 0 and 3.48m, 4.1 layers of argillaceous siltstone between 3.8-5.1m, 4.2 layers of argillaceous siltstone between 5.1m and 8.5m, 8.5m to 27.5m There are 4.3 layers of argillaceous siltstone between m and 4.4 layers of argillaceous siltstone below 27.5m. At the same time, because it is located in the coastal area, the groundwater is relatively abundant; the construction period is short, and the surrounding rolling line foundation, water treatment foundation and equipment installation need to be carried out at the same time Construction: Both the forward construction method (vertical excavation) and the reverse construction method (caisson construction) cannot meet the site construction requirements.

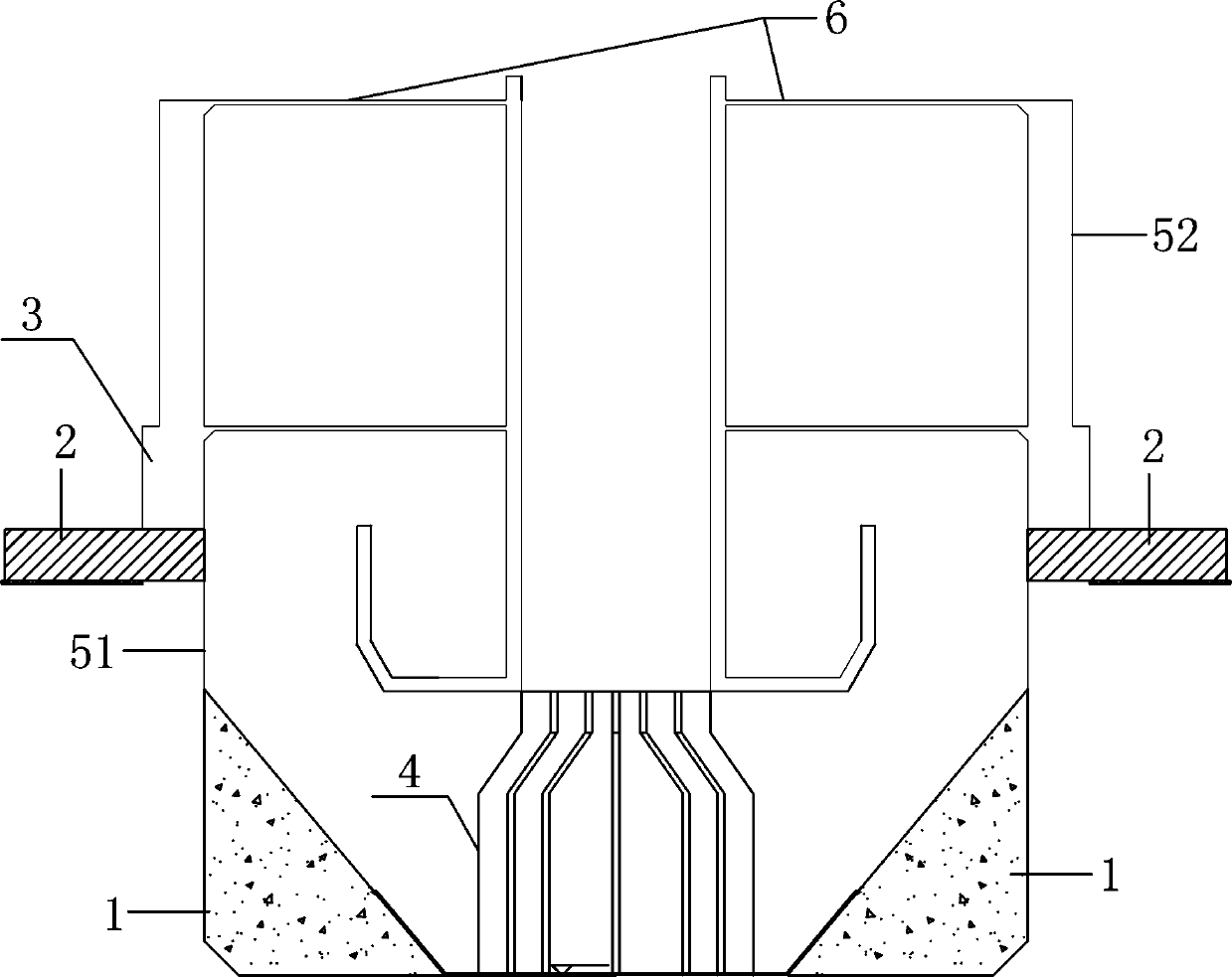

[0020] Swirl well such as figure 1 shown.

[0021] Adopt the construction method of swirl well with the combination of forward and reverse adapting to complex geological...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com