Primary air stepped wavy air distribution deslagging device of circulating fluidized bed boiler

A circulating fluidized bed and step-type technology, which is applied in the field of step-type wave air distribution and slag discharge device for circulating fluidized bed boiler primary air, can solve the problems of lowering, easy blockage of slag discharge pipe, uneven air distribution, etc., and achieve wind cap The structure is simple, the uniformity of air distribution is improved, and the effect of not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

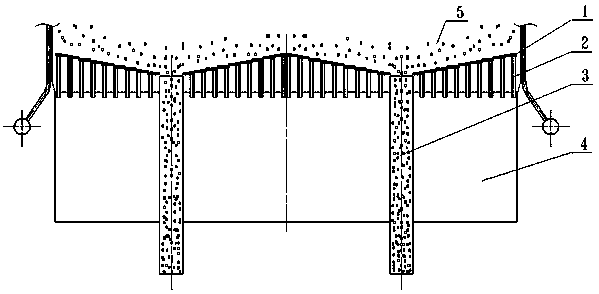

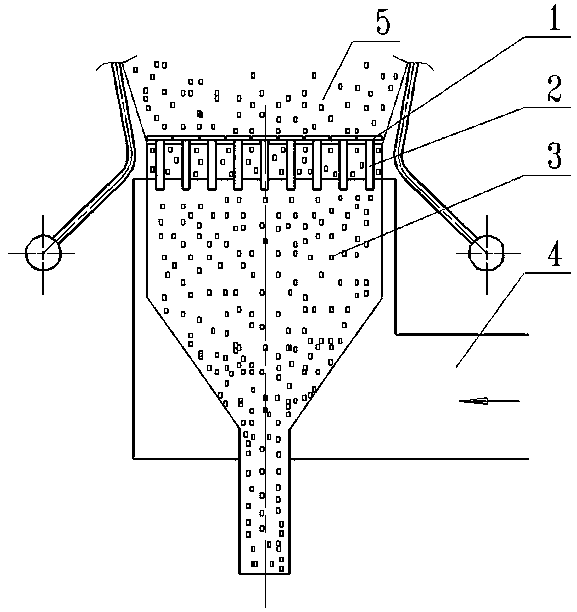

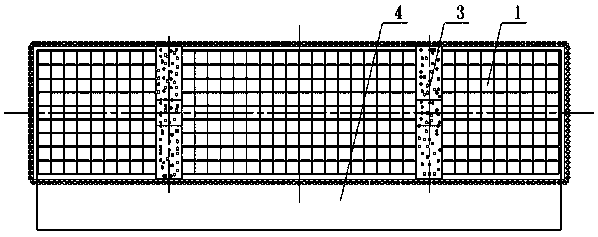

[0025] Example: as attached Figure 1-5 As shown, a circulating fluidized bed boiler primary air step-type wave air distribution and slag removal device is located at the lower part of the boiler furnace 5. The air cap head 1 and the air pipe 2 form a "crutch-shaped" air cap, and the air pipe 2 is connected to the bellows 3. In the width direction of the boiler, by setting air pipes 2 of different lengths, the "crutch-shaped" hoods are connected end to end in a stepped and wavy arrangement, and the upper surface of the "crutch-shaped" hoods is inclined. In this example, there are 36 "crutch-shaped" hoods in each group, and 9 groups of hoods are arranged in parallel in the direction of boiler depth, and a total of 324 hoods are installed on the air distribution plate, forming 2 groups of wave-shaped arrangements. At the bottom of each group of "waves", there is an ash hopper 3, a total of 2 ash hoppers 3, the ash hopper 3 passes through the bellows 4, and its lower outlet is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com