Device loaded on mechanical arm for ultrasonically detecting surface topography of additive component

A technology of surface topography and ultrasonic detection, applied in measurement devices, re-radiation of sound waves, radio wave measurement systems, etc. High efficiency, easy to analyze the effect of the surface topography of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

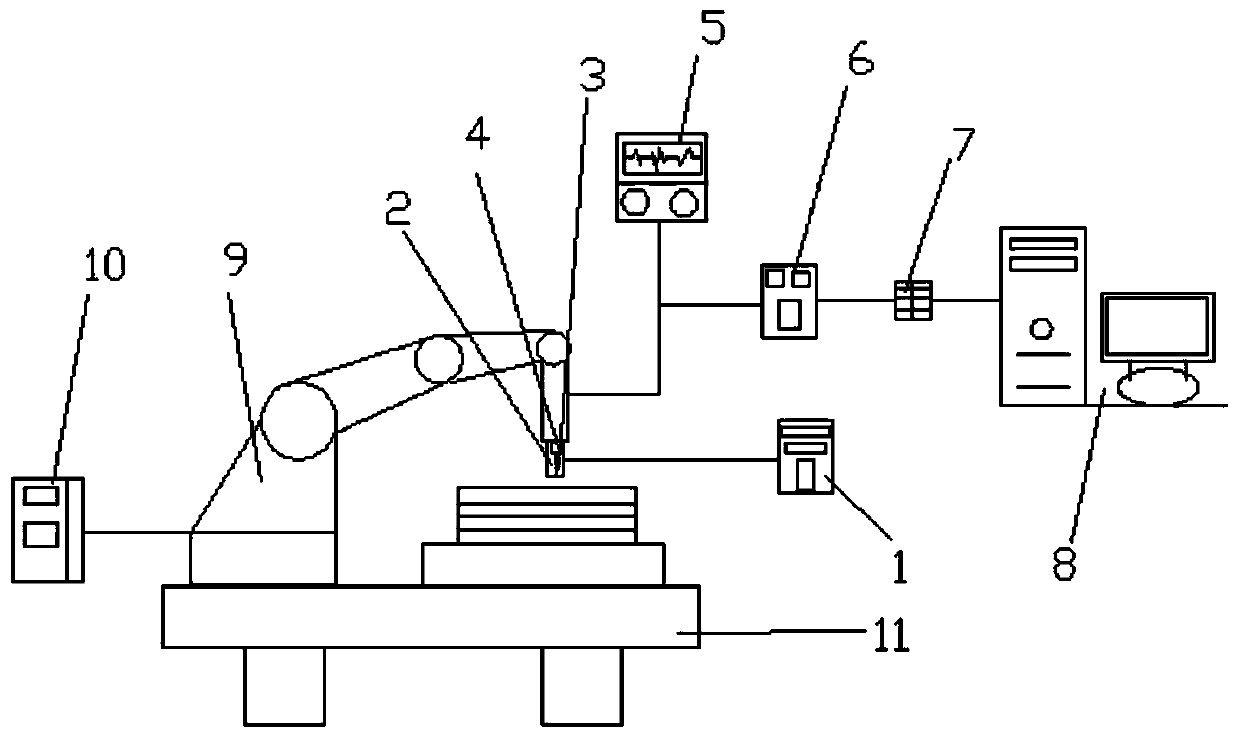

[0028] A device for ultrasonically detecting the surface morphology of high-nitrogen steel mounted on a mechanical arm. The surface size of the high-nitrogen steel used is 100mm×350mm. The detection steps are as follows:

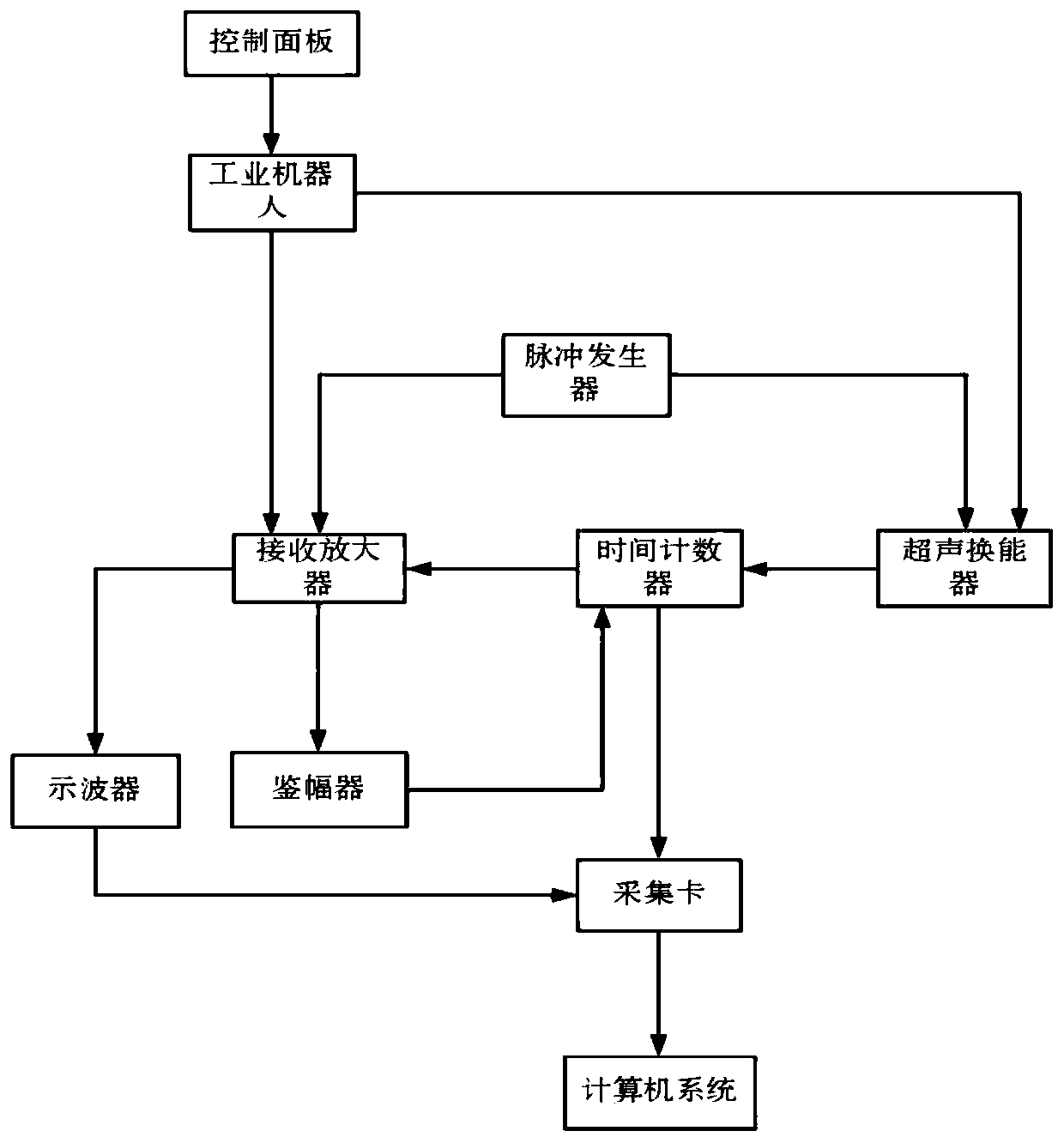

[0029] The ultrasonic transceiver device is fixed on the robot arm 9 with a flexible clamp, and the walking path planning of the robot arm 9 is performed on the robot control panel 10 .

[0030] The surface size of the tested component is 100mm×350mm, so the pulse generator 1 is used to set the pulse repetition frequency to 500HZ, the ultrasonic transducer 2 is excited to emit ultrasonic waves vertically to the tested sample, and the timer 4 is triggered to start timing.

[0031]Place the high-nitrogen steel components on the same horizontal platform as the robot. The planning path takes the x direction as the scanning direction, and the y direction as the offset direction. At the same time, check whether the ultrasonic transceiver device is perpendicular to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com