Rotary linear motor driving type remote control pressing plate

A linear motor, driving technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of unreliable rotation, cumbersome operation, power safety accidents, etc., to improve safety and reliability, broad application prospects, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

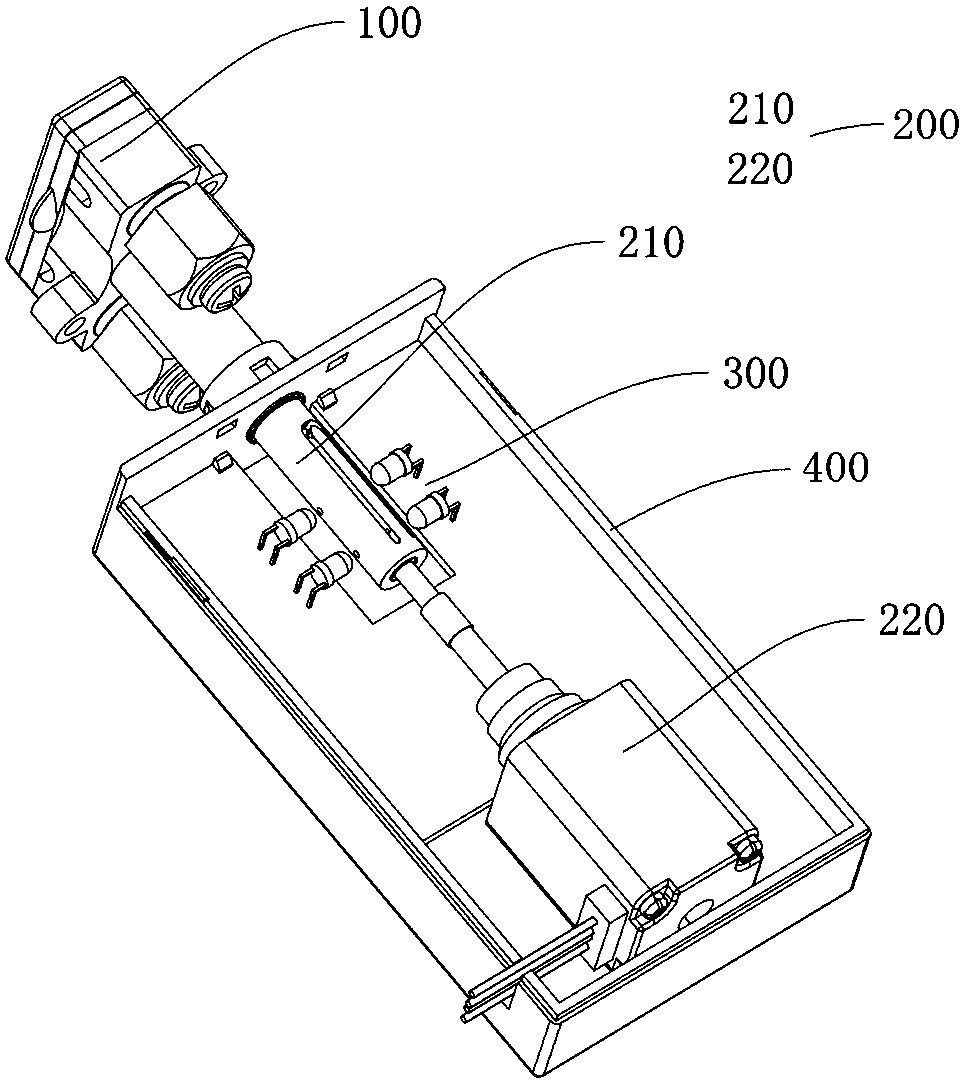

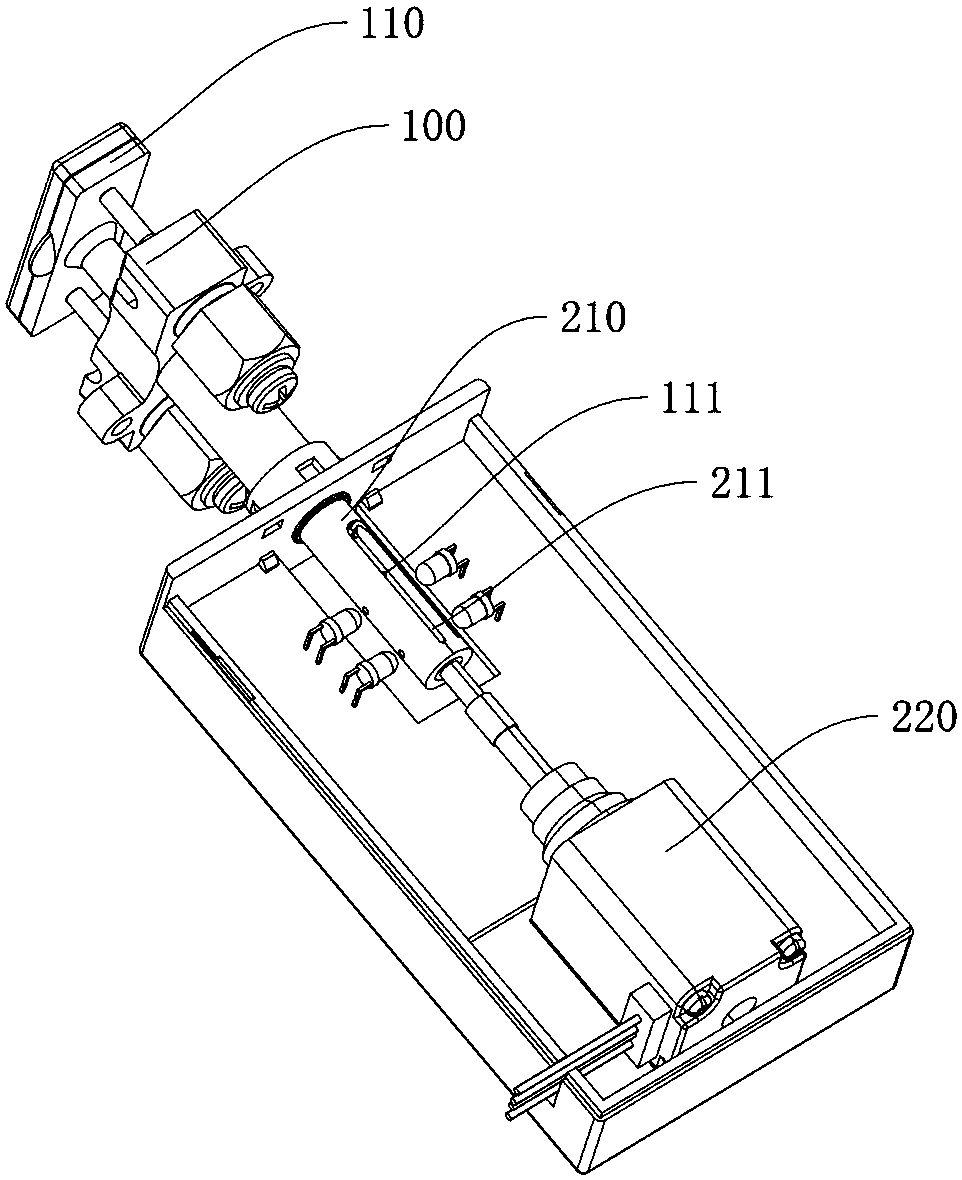

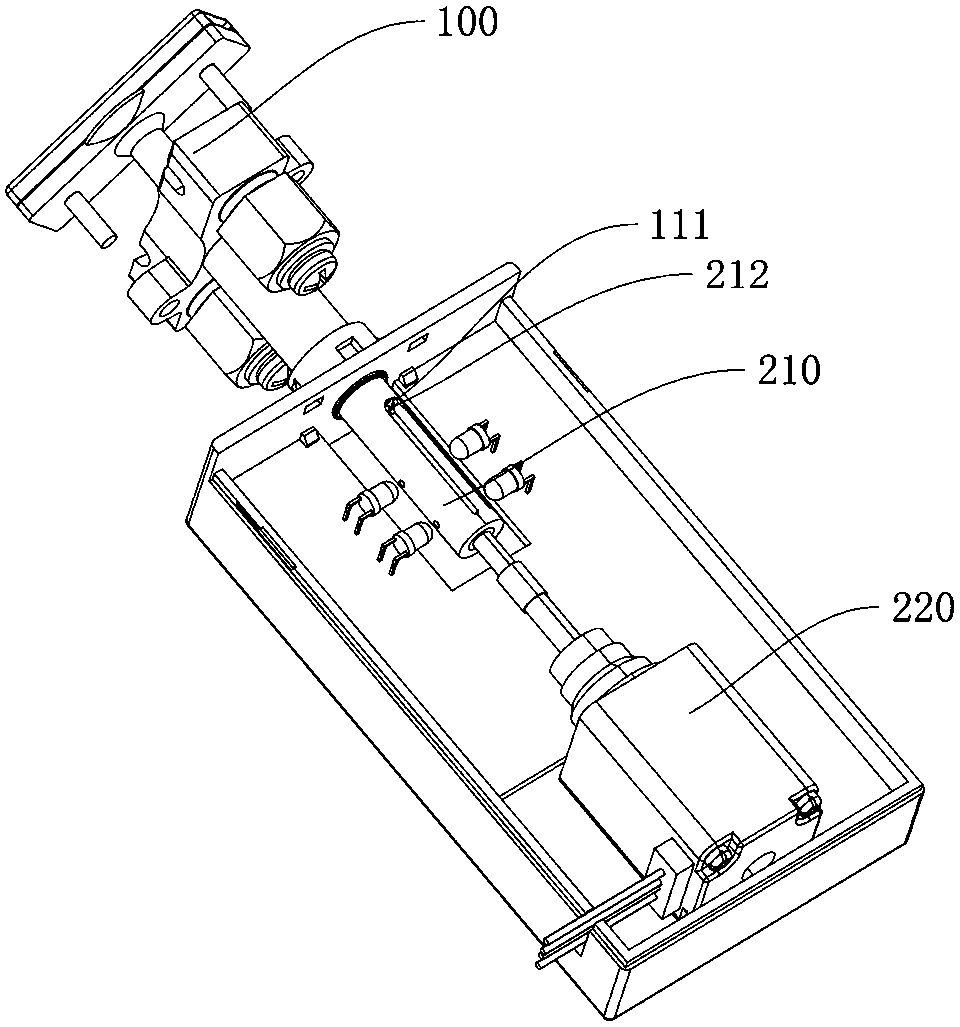

[0018] The invention provides a rotary linear motor-driven remote control press plate, which is used for remote control press plate throwing and withdrawing, and monitoring the real-time status of the press plate, such as Figure 1-4 As shown, it includes a platen assembly 100 in which the platen handle 110 can be pulled out and rotated 45° to return, and also includes a box-shaped casing 400 and a drive assembly 200 and a state detection device 300 disposed in the box-shaped casing 400 . The front rod body of the platen handle 110 protruding into the box-shaped housing 400 is provided with a limit post 111 and a detection part, and the drive assembly 200 includes a guide rail sleeve 210 and a rotary linear motor 220, and the guide rail sleeve 210 is fixed on In the box-shaped housing 400, guide rails and detection holes are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com